0 ratings0% found this document useful (0 votes)

79 viewsM/S S. S. Builders, Road Works Division, Ludhiana, Punjab

M/S S. S. Builders, Road Works Division, Ludhiana, Punjab

Uploaded by

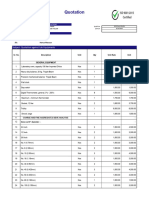

Tanveer IqbalM/s S. S. Builders has proposed a peak time quality control laboratory resource deployment plan for a road project in Assam. The plan details 31 types of equipment needed for soil, field density, and concrete testing, including ovens, proctor moulds, CBR machines, compressive strength testing machines, cube moulds, and more. The quantities planned and currently available are listed. While most equipment types have adequate available units, some key items like ovens, proctor rammers, and cube moulds have shortages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

M/S S. S. Builders, Road Works Division, Ludhiana, Punjab

M/S S. S. Builders, Road Works Division, Ludhiana, Punjab

Uploaded by

Tanveer Iqbal0 ratings0% found this document useful (0 votes)

79 views3 pagesM/s S. S. Builders has proposed a peak time quality control laboratory resource deployment plan for a road project in Assam. The plan details 31 types of equipment needed for soil, field density, and concrete testing, including ovens, proctor moulds, CBR machines, compressive strength testing machines, cube moulds, and more. The quantities planned and currently available are listed. While most equipment types have adequate available units, some key items like ovens, proctor rammers, and cube moulds have shortages.

Original Title

QC

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

M/s S. S. Builders has proposed a peak time quality control laboratory resource deployment plan for a road project in Assam. The plan details 31 types of equipment needed for soil, field density, and concrete testing, including ovens, proctor moulds, CBR machines, compressive strength testing machines, cube moulds, and more. The quantities planned and currently available are listed. While most equipment types have adequate available units, some key items like ovens, proctor rammers, and cube moulds have shortages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

79 views3 pagesM/S S. S. Builders, Road Works Division, Ludhiana, Punjab

M/S S. S. Builders, Road Works Division, Ludhiana, Punjab

Uploaded by

Tanveer IqbalM/s S. S. Builders has proposed a peak time quality control laboratory resource deployment plan for a road project in Assam. The plan details 31 types of equipment needed for soil, field density, and concrete testing, including ovens, proctor moulds, CBR machines, compressive strength testing machines, cube moulds, and more. The quantities planned and currently available are listed. While most equipment types have adequate available units, some key items like ovens, proctor rammers, and cube moulds have shortages.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

M/s S. S.

BUILDERS, ROAD WORKS DIVISION, LUDHIANA, PUNJAB

Proposed Peak Time "Q/C Laboratory Resources" Deployment Plan for the Project "BADARPUR BYPASS, 4 Lane Configuration

Road From Km.27.300 To Km.38.400"BASE CAMP Located at NETAJI ROAD, Mohanpur Pt-II, CACHAR, ASSAM - 788804"

Q/C Laboratory Resources Planned to be deployed as per Scope of Work

PLATE-VI

Quantity

Availability

Sr. No. Description Of Equipment/Apparatus (Nos)

(Probable)

Net Planned Net Available

A Soil Testing Apparatus:

0 0

1 Oven - Thermostatically controlled (range- 50 to 250 Size- 450 x600 x450 mm) 1 0

0 0

2 Oven - Thermostatically controlled (range- 50 to 300 Size- 600 x 900 x 600 mm) 1 0

3 Proctor Mould 100mm diameter & 1000 cc Volume 2 1

4 Proctor Mould 150mm diameter & 2250 cc Volume 2 1

5 Proctor Rammer (Light) 1 1

6 Proctor Rammer (Heavy wt. 4.89 kg) 3 1

7 A steel straightedge about 30 cm in length and having one bevelled edge. 2 0

8 CBR Machine capacity of 5 000 kg, deformation rate of 1.25 mm/min- 1 1

9 CBR Mould 150 mm dia 36 3

10 Surcharge Weight Round (2.5 Kg) 36 3

11 Surcharge Weight Slotted (2.5 Kg) 36 3

12 Perforated Dish 150 mm dia 36 3

13 Spacer Disk 150mm Diameter & 50mm Thickness 2 1

14 Penetration Plunger 50mm diameter 1 1

15 LL& PL Apparatus (Casagrande ) 1 0

16 LL& PL Apparatus (Penetrometer) 2 1

17 Porcelain Evaporating Dish - about 12 to 15 cm in diameter. 2 0

18 Spatula - flexible, with the blade about 8 cm long and 2 cm wide 2 0

19 Spatula - flexible, with the blade about 15 cm long and 3 cm wide 6 0

20 Containers - air-tight and non-corrodible (dia. 75mm , deep 50mm) 100 0

21 Containers - air-tight and non-corrodible (dia. 50mm , deep 50mm) 100 0

22 Flat Glass Plate - 10 mm thick and about 45 cm square 1 0

23 Shear testing Machine 1 Set 0

24 Shear box grid plates, porous stones, base plates, and loading pad and water jacket 1 Set 0

25 Loading Frame & Weights 1 Set 0

26 Proving Ring (25 KN ) 2 2

27 Proving Ring ( 50 KN) 2 2

28 Proving Ring (2 KN) 2 2

29 Micrometre Dial-Gauges accurate to 0.01 mm 3 6

30 Steel spoon, trowel 2 0

31 Water Dropper 2 0

32 10% Fine Value Testing 1 1

B Field Density Testing Apparatus:

Sand Pouring Cylinder Dia. (100 mm) with Cutting Tray (300 mm square and 40 mm

1 deep with a 100 mm hole in the centre) & Cylindrical Calibrating Container (Internal Dia. 2 set 1 set

100 mm & Internal Depth 150 mm)

Sand Pouring Cylinder Dia (200 mm) with Cutting Tray (450 mm square and 50 mm

2 deep with a 200 mm hole in the centre) & Cylindrical Calibrating Container (Internal 2 set 1 set

Dia. 200 mm &Internal Depth 250 mm)

3 Chisel (35 cm long), Steel Scale (30 cm long) 2 0

4 Hammer wt. - 500 gm 2 0

5 Rapid Moisture Meter Box 2 0

6 Measuring Tape (30 mtr) 1 0

7 Calcium Carbide 4 box 0

C Concrete Testing Apparatus:

1 Compressive Strength Testing Machin (Capacity 2000 KN) 1 1

2 Concrete Mixture (200 Liter Capacity) 1 1

3 Cube Mould (150mm x 150mm x150mm) 150 22

4 Cube Mould (100mm x 100mm x100mm) 6 0

5 Beam Mould (700mm x 150mm x 150mm) 15 30

6 Slump Cone 6 1

7 S.P Gravity Test Apparatus Set (wire basket type) 1 1

8 Thickness Gauge (Flakiness) 2 0

9 Length Gauge (Elongation) 2 0

10 Vicat's Apparatus (Set) 1 0

11 Motor Cube Vibration Machine 1 1

12 Motoe Cube Mould (7.06 cmX7.06 cmX7.06 cm) 9 36

13 Gauging Trowel 2 0

14 Pure bristle brush for cleaning the sieve 1 0

15 Pycnometer Bottle 1000 ml (for Sp.Gravity) 2 0

16 Thermostatically controlled Water Bath (20 Liter) 1 0

17 Aggregate Impact Value Test Machine (with apparatus) 1 1

18 Los Angeles Abrasion Testing Machine 1 1

19 Abrasive Charge steel spheres 48 mm dia and each weight between 390 to 445 g. 12 12

20 LeChatelier Mould (with glass plate & weight) for cement Soundness test 4 0

21 LeChatelier Flask (for Cement Sp.Gravity) 1 1

QC. Resources - SS BUILDERS 1 BADARPUR BYPASS-IV LANE

Quantity

Availability

Sr. No. Description Of Equipment/Apparatus (Nos)

(Probable)

Net Planned Net Available

22 Concrete Vibrating Tabel 1 1

23 Standard Sand (G-1, G-2, G-3) 2 bag each 0

D For Self Compacting Concrete:

1 Concrete flow table test apparatus 1 0

2 V- Funnel flow time test apparatus 1 0

3 L box test apparatus 1 0

4 Sieve Segregation Resistance test apparatus 1 0

E Bitumen Testing Apparatus:

1 Marshal Stability Testing Machine 1 0

2 Marshal Mould 100 mm Dia 18 0

3 Refill Box (20 mm & 40 mm) 2 0

4 Bitumen Penetrometer (with needle) 1 0

5 Softening Point Apparatus(Ring & Ball type) 1 0

6 Furol Viscometer 1 0

7 Flash & fire point Test Apparatus 1 0

8 Ductility Test Apparatus 1 0

9 Bitumen Extractor, electrically-operated 2 0

10 Compaction Pedestal (Electrically operated ) 1 0

11 Compaction Pedestal 100mm Dia (Manually) 1 0

12 Core Cutting machine with 10/15 cm dia diamond cutting edge (Diesel operated) 1 0

13 Vacuum pump for Max. Theoretical Sp. Gravity. 1 0

14 2000 ml Theoretical Sp. Gravity Bottle 3 0

15 5000 ml Theoretical Sp. Gravity Bottle 1 0

16 Bitumen Viscosity Apparatus (with viscometer) 1 0

17 Sp Gravity Bottle 50 ml 1 0

18 Hand Gloves (Leather & Rubber) 20 0

19 Benzene 200 lit 0

F Electronic Balance & Measuring Instruments:

1 100 ml Cylinder Borosil (Glass) 12 1

2 250ml Cylinder Borosil (Glass) 2 7

3 500 ml Cylinder Borosil (Glass) 2 3

4 250 ml glass jar 4 19

5 500 ml glass jar 6 35

6 100 ml Cylinder (Plastic) 6 0

7 500 ml Cylinder (Plastic) 4 0

8 500 ml Plastic Jug 2 0

9 1000 ml Plastic Jug 1 0

10 100 kg Electronic Balance (10 gm Accuracy) 1 0

11 50 kg Electronic Balance (1 gm Accuracy) 1 0

12 30 kg Electronic Balance (1 gm Accuracy) 3 1

13 15 kg Electronic Balance (0.5 gm Accuracy) 1 1

14 5 kg Electronic Balance (0.1 gm Accuracy) 1 0

15 600 gm Electronic Balance (0.01 gm Accuracy) 2 3

G Miscellaneous Apparatus:

0

1 Hot Plate (Size 18'' x 12'') 200 1 0

2 Rain Gauge 1 0

0 0

3 Digital Thermometer (0 to 250 ) 4 0

0

4 Glass Thermometer (0 to 100 ) 4 0

0

5 Glass Thermometer (0 to 300 ) 3 0

6 HTC-1 Thermometer Hygrometer 2 0

7 Hydrometer (0.5 to 1.0 & 1.0 to 1.5 ) 2 each 0

8 Digital Vernier Caliper 1 0

9 Mini Laser Temperature Meter 1 0

10 Dry soft absorbent cloths each not less than 75 x 45 cm. 2 0

11 straightedge 3.5 Meter long 1 0

12 Camber checking Gauge 3.0 meter long 1 0

13 Bulk Density container 30000 ml volume 1 0

14 Bulk Density container 15000 ml volume 1 0

15 Bulk Density container 3000 ml volume 1 0

16 Enamel Tray 30 X45 cm 6 5

17 Enamel Tray 60 X52 cm 6 6

18 Enamel Tray 27 X27 cm 6 6

19 Enamel Tray 90 X 50 cm 4 0

20 Enamel Tray 300mm Dia 8 4

21 Prime Coat Tray 4 0

H 450 mm. Dia. IS Sieve

1 100 mm IS Sieve 1

2 80 mm IS Sieve 1 1

3 75 mm IS Sieve 1 0

4 63mm IS Sieve 1 2

5 60 mm IS Sieve 1 0

6 53 mm IS Sieve 2 1

7 50 mm IS Sieve 1 1

8 45 mm IS Sieve 2 1

9 40 mm IS Sieve 2 1

10 37.5 mm IS Sieve 1 1

QC. Resources - SS BUILDERS 2 BADARPUR BYPASS-IV LANE

Quantity

Availability

Sr. No. Description Of Equipment/Apparatus (Nos)

(Probable)

Net Planned Net Available

11 31.5 mm IS Sieve 1 1

12 26.5 mm IS Sieve 2 1

13 25 mm IS Sieve 1 1

14 22.4 mm IS Sieve 2 1

15 20 mm IS Sieve 2 1

16 19 mm IS Sieve 2 1

17 16 mm IS Sieve 1 1

18 14 mm IS Sieve 1 0

19 13.2 mm IS Sieve 2 1

20 12.5 mm IS Sieve 2 1

21 11.2 mm IS Sieve 2 1

22 10 mm IS Sieve 2 1

23 9.5 mm IS Sieve 2 1

24 8 mm IS Sieve 1 1

25 6.7 mm IS Sieve 2 1

26 6.3 mm IS Sieve 2 1

27 5.6 mm IS Sieve 1 0

28 4.75 mm IS Sieve 2 2

29 2.8 mm IS Sieve 1 0

30 2.36 mm IS Sieve 2 1

31 1.7 mm IS Sieve 2 1

32 1.18 mm IS Sieve 2 1

33 Pan (Dia 450 mm) 2 1

I 200 mm. Dia. IS Sieve

1 4.75 mm IS Sieve 1 1

2 2.8 mm IS Sieve 1 0

3 2.36 mm IS Sieve 1 1

4 2.0 mm IS Sieve 2 1

5 1.7 mm IS Sieve 1 0

6 1.4 mm IS Sieve 1 0

7 1.18 mm IS Sieve 1 1

8 1.0 mm IS Sieve 2 0

9 0.850 mm IS Sieve 1 0

10 0.710 mm IS Sieve 1 0

11 0.600 mm IS Sieve 3 1

12 0.425mm IS Sieve 2 1

13 0.355 mm IS Sieve 1 0

14 0.300 mm IS Sieve 2 1

15 0.212 mm IS Sieve 1 0

16 0.180 mm IS Sieve 1 0

17 0.150 mm IS Sieve 2 1

18 0.090 mm IS Sieve 2 0

19 0.075 mm IS Sieve 3 1

20 Pan (dia 200mm)

PROPOSED BY REVIEWED & APPROVED BY

Project Manager

S.S. BUILDERS

QC. Resources - SS BUILDERS 3 BADARPUR BYPASS-IV LANE

You might also like

- 18M Span Superstructure Drawings - MCW - 07.05.2019Document7 pages18M Span Superstructure Drawings - MCW - 07.05.2019Tanveer IqbalNo ratings yet

- Gantry Drawing - ApprovedDocument1 pageGantry Drawing - ApprovedTanveer IqbalNo ratings yet

- Electrical Team Consumable ItemsDocument4 pagesElectrical Team Consumable ItemsHamid Khan100% (1)

- LaboratoryDocument4 pagesLaboratorysohaib ahmedNo ratings yet

- RASAMRUT-BIO Quotation - IIAMC NashikDocument3 pagesRASAMRUT-BIO Quotation - IIAMC NashikVaibhav BhadageNo ratings yet

- Lab Equipment ListDocument17 pagesLab Equipment ListPalla Bhaskara RaoNo ratings yet

- ERA STSMethodM 2013 Laboratory Equipments TO REDocument7 pagesERA STSMethodM 2013 Laboratory Equipments TO REYeabsra YonasNo ratings yet

- KONEG-DYNAMIC-CONE-PENETROMETER_JKR-MACKINTOSH-1Document1 pageKONEG-DYNAMIC-CONE-PENETROMETER_JKR-MACKINTOSH-1amirul izaniNo ratings yet

- Lab Equipment ListDocument2 pagesLab Equipment Listnh37.planningNo ratings yet

- List of Lab Equipments - JSRDocument2 pagesList of Lab Equipments - JSRdivithNo ratings yet

- Scaffold FundamentalDocument28 pagesScaffold Fundamentaljay b100% (1)

- Recommended List of Equipments For FQA Civil LabDocument3 pagesRecommended List of Equipments For FQA Civil LabPRASAD THOMBARENo ratings yet

- Lab. EquipmentDocument12 pagesLab. EquipmentSk Sabir HossainNo ratings yet

- Required Laboratory Appratus For 01 PKG: JAGDAMBA Construction SURAJPURDocument2 pagesRequired Laboratory Appratus For 01 PKG: JAGDAMBA Construction SURAJPURchitranjan4kumar-8No ratings yet

- Forney OnlineDocument12 pagesForney OnlineHumberto MorenoNo ratings yet

- Concrete: CementDocument10 pagesConcrete: CementHumberto MorenoNo ratings yet

- Daftar Tabel Equipment Cost Dari Total PeralatanDocument6 pagesDaftar Tabel Equipment Cost Dari Total PeralatanMuhammad SyaifullahNo ratings yet

- Lab Equipment List FinalDocument10 pagesLab Equipment List FinalYasir Ali DharejoNo ratings yet

- Metropolitan AscendDocument3 pagesMetropolitan AscendKakulu Paul MutatiinaNo ratings yet

- Taper Gurmala PlatesDocument144 pagesTaper Gurmala PlatesGurdeepNo ratings yet

- Quality Items Po-1Document7 pagesQuality Items Po-1Kaushal raiNo ratings yet

- Material Requirement CL-9&12Document9 pagesMaterial Requirement CL-9&12tanish mahamunkarNo ratings yet

- Material Price Database (Lakewood)Document10 pagesMaterial Price Database (Lakewood)Wing BasconNo ratings yet

- Common Testing List MKRM CompactDocument4 pagesCommon Testing List MKRM CompactM Ry ZealNo ratings yet

- Hondo Boq Civil WorksDocument92 pagesHondo Boq Civil WorksRhine EsperanzateNo ratings yet

- Kibish Construction: List of Laboratory Equipment Mobilized To ProjectDocument2 pagesKibish Construction: List of Laboratory Equipment Mobilized To ProjectSolomon MehariNo ratings yet

- Master Cut CatalogDocument125 pagesMaster Cut Cataloggabriel_127971761No ratings yet

- MastercutCatalog PDFDocument125 pagesMastercutCatalog PDFOscar Huberto Salazar HerreraNo ratings yet

- Quote To JAMES JIM TIMAKADocument5 pagesQuote To JAMES JIM TIMAKAGerald ObalimNo ratings yet

- Bill of MaterialsDocument4 pagesBill of MaterialsMark Gerald Prades RegalaNo ratings yet

- Quality Lab Equipment ListDocument2 pagesQuality Lab Equipment ListRajAn SharWanNo ratings yet

- XM1016T-0.1 0.3Document8 pagesXM1016T-0.1 0.3carlosNo ratings yet

- Boq-08 11 2022Document3 pagesBoq-08 11 2022Angshuman Roy ChoudhuryNo ratings yet

- Lab Equipments ListDocument3 pagesLab Equipments ListconstructiontiplNo ratings yet

- LKP WALINI SjahrialDocument46 pagesLKP WALINI SjahrialAfdhol ChoirNo ratings yet

- RFQ 2020-002 Medical DevicesThoracicGI Staplers TackersDocument9 pagesRFQ 2020-002 Medical DevicesThoracicGI Staplers Tackersthegasman003No ratings yet

- Hailiang CatalogueDocument1 pageHailiang CatalogueNelson_1492No ratings yet

- Lab Equipment - Bitiminous Work: S.NO. Description Quantity RemarksDocument1 pageLab Equipment - Bitiminous Work: S.NO. Description Quantity Remarksjay krishnaNo ratings yet

- General Properties: Element Tekan Komponen Struktur Menahan LenturDocument5 pagesGeneral Properties: Element Tekan Komponen Struktur Menahan LenturOecoep IteemNo ratings yet

- Koneg Instruction Manual - Mackintosh - JKR Probe Set (Colour)Document10 pagesKoneg Instruction Manual - Mackintosh - JKR Probe Set (Colour)Bumi BinadayaNo ratings yet

- Noida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadDocument116 pagesNoida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadLOHITH N100% (1)

- Belt Aligment Tool TKBA 10 & 20Document2 pagesBelt Aligment Tool TKBA 10 & 20Zia UddinNo ratings yet

- Isolated Footing DesignDocument11 pagesIsolated Footing DesignPadmanabh Shridhar DesaiNo ratings yet

- 20200406_145337_Shakers - orbital SHLDDocument3 pages20200406_145337_Shakers - orbital SHLDAhmed MeddyNo ratings yet

- Lab EquipmentDocument1 pageLab EquipmentMOHD SUHAILNo ratings yet

- Soil Testing TejasDocument6 pagesSoil Testing TejasEdufirst EnterprisesNo ratings yet

- CorrectionSlip 1 of AOR EandMDocument66 pagesCorrectionSlip 1 of AOR EandMthumula.rameshNo ratings yet

- Internship Report of ISHAN EQUIPMENTS LTDDocument38 pagesInternship Report of ISHAN EQUIPMENTS LTDTapanNo ratings yet

- Hamza ManzoorDocument3 pagesHamza Manzoortahir royalNo ratings yet

- Schedule Dan Progress Kitchen Messhall RealDocument15 pagesSchedule Dan Progress Kitchen Messhall RealPrima 02No ratings yet

- Apco Infratech PVT - Ltd. Lab Equipment Required For MMP-2Document1 pageApco Infratech PVT - Ltd. Lab Equipment Required For MMP-2Amit MaityNo ratings yet

- Babar Bhi Karchi 03052036089Document2 pagesBabar Bhi Karchi 03052036089Ahmed SaeedNo ratings yet

- Uni Delay LPDocument1 pageUni Delay LPAlexander OpazoNo ratings yet

- Book 1Document4 pagesBook 1Monique LopezNo ratings yet

- SBU URB PlatformDocument6 pagesSBU URB PlatformMusaab MohamedNo ratings yet

- 01-Shubham-Coep-Cent Design-R0Document16 pages01-Shubham-Coep-Cent Design-R0vishal bhiseNo ratings yet

- MATERIAL SHEET Raigad-Dsr-2015-16-PwdDocument30 pagesMATERIAL SHEET Raigad-Dsr-2015-16-PwdVikasNo ratings yet

- Cement TestingDocument15 pagesCement Testingbayo adefemiNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Lvup Approved.Document6 pagesLvup Approved.Tanveer IqbalNo ratings yet

- W-Met - Crash Barrier-ApprDocument1 pageW-Met - Crash Barrier-ApprTanveer IqbalNo ratings yet

- Pavement Design Report-Comment-Rohit-4-2-19Document1 pagePavement Design Report-Comment-Rohit-4-2-19Tanveer IqbalNo ratings yet

- GADDocument1 pageGADTanveer IqbalNo ratings yet

- Pier and Foundation - Fo-37+655-DrawingsDocument5 pagesPier and Foundation - Fo-37+655-DrawingsTanveer IqbalNo ratings yet

- Key Plan: Section A-ADocument2 pagesKey Plan: Section A-ATanveer IqbalNo ratings yet

- ProspectusDocument17 pagesProspectusTanveer IqbalNo ratings yet

- Inspection Request Form No. - : P P N - C C N - A DDocument1 pageInspection Request Form No. - : P P N - C C N - A DTanveer IqbalNo ratings yet

- Red Wine Varieties and Origin of Grapes UsedDocument22 pagesRed Wine Varieties and Origin of Grapes UsedAifa LeiNo ratings yet

- CBSE Class 10 Chemistry Worksheet - Carbon and Its CompoundsDocument5 pagesCBSE Class 10 Chemistry Worksheet - Carbon and Its Compoundsanubhavupadhyay1221No ratings yet

- E-Waste (Management and Handling) Rules, 2011Document18 pagesE-Waste (Management and Handling) Rules, 2011Roshni Thammaiah0% (1)

- World's First Water Treatment Techniques Using Apple and Tomato Peels - ScienceDailyDocument4 pagesWorld's First Water Treatment Techniques Using Apple and Tomato Peels - ScienceDailyorionNo ratings yet

- Reading Skills QP 11 PDFDocument6 pagesReading Skills QP 11 PDFsatheeshsep24No ratings yet

- 4224 PDFDocument4 pages4224 PDFDrDikshita BhowmikNo ratings yet

- 7 Engineering MaterialsDocument58 pages7 Engineering MaterialsSOURABH GANGWARNo ratings yet

- MF009 6B Human Reproduction System James LDocument26 pagesMF009 6B Human Reproduction System James LPikuNo ratings yet

- Service Manual: 19N-M100, CN19M10 19N-M100SDocument30 pagesService Manual: 19N-M100, CN19M10 19N-M100SEfren HidalgoNo ratings yet

- OB Unit-3Document16 pagesOB Unit-3animesh_anushNo ratings yet

- Dams and Its Types: Different Parts & Terminologies of DamsDocument7 pagesDams and Its Types: Different Parts & Terminologies of DamsPaul Ivan Asencio CasumpangNo ratings yet

- Analog VlsiDocument28 pagesAnalog VlsihegdehegdeNo ratings yet

- The Four Idols of Francis BaconDocument6 pagesThe Four Idols of Francis BaconZaeznushan AdrizanNo ratings yet

- Ahmed Hussein AliDocument182 pagesAhmed Hussein AliLaura Sofia Chinchilla MoralesNo ratings yet

- Latihan Soal Bahasa Inggris (Tes Bintara) TAHAP 3.Document6 pagesLatihan Soal Bahasa Inggris (Tes Bintara) TAHAP 3.Luh SiantariNo ratings yet

- 2022-Cu (II) Complexes of Flavonoids in Solution Impact of The Cu (II) Ion On The Antioxidant and DNA-intercalating PropertiesDocument12 pages2022-Cu (II) Complexes of Flavonoids in Solution Impact of The Cu (II) Ion On The Antioxidant and DNA-intercalating Propertieslas.chemicalNo ratings yet

- Well Testing: Lecture #8: Well Test Analysis of Gas Reservoirs-Module BDocument21 pagesWell Testing: Lecture #8: Well Test Analysis of Gas Reservoirs-Module BHadi Bapir SlemanNo ratings yet

- Griffin 1976Document21 pagesGriffin 1976Manu K VasudevanNo ratings yet

- Summary Purchases AdditionalDocument24 pagesSummary Purchases Additionalkrissialibres21thcdcNo ratings yet

- Elbphilharmonie EssayDocument2 pagesElbphilharmonie EssayViberlie PonterasNo ratings yet

- 4PW16741-1 B EKBT - Bufftertank - Installation Manuals - EnglishDocument6 pages4PW16741-1 B EKBT - Bufftertank - Installation Manuals - EnglishBernard GaterNo ratings yet

- 20 J 9557 PDFDocument16 pages20 J 9557 PDFأنوار الحقNo ratings yet

- The Earth: 5,940,000,000,000,000,000,000 Metric TonsDocument15 pagesThe Earth: 5,940,000,000,000,000,000,000 Metric TonsAreeb AkhtarNo ratings yet

- 2010 Confinement of Deep Beam Nodal RegionsDocument9 pages2010 Confinement of Deep Beam Nodal RegionsKhNo ratings yet

- WeatheringDocument6 pagesWeatheringamit kumar guptaNo ratings yet

- 03 - Qa - 116 - 15 (1) (4 Files Merged) PDFDocument20 pages03 - Qa - 116 - 15 (1) (4 Files Merged) PDFsubeesh upNo ratings yet

- File T NG ToeicDocument72 pagesFile T NG ToeicTrọng Nghĩa DươngNo ratings yet

- Gate Valve Series 371/W371 Open Stem & Yoke (OS&Y) Gate Valves Series 372/W372 Non Rising Stem (NRS) Gate ValvesDocument6 pagesGate Valve Series 371/W371 Open Stem & Yoke (OS&Y) Gate Valves Series 372/W372 Non Rising Stem (NRS) Gate ValvesCinthya Yesenia Cruz MedinaNo ratings yet

- b1 Reading Travel PDFDocument3 pagesb1 Reading Travel PDFMaria Perez CrespoNo ratings yet

- Training Programme: Central Soil and Materials Research StationDocument15 pagesTraining Programme: Central Soil and Materials Research StationRaviKumarNo ratings yet