My Resume PDF

My Resume PDF

Uploaded by

Abdullah SheikhCopyright:

Available Formats

My Resume PDF

My Resume PDF

Uploaded by

Abdullah SheikhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

My Resume PDF

My Resume PDF

Uploaded by

Abdullah SheikhCopyright:

Available Formats

MUHAMMAD AZIZULLAH

Email : engr.mazizullah@gmail.com Mob. : +92-324-9757024.

Gulzar-e-Ibrahim St., DC Rd., Gujranwala – 52250, Pakistan.

www.linkedin.com/in/muhammad-azizullah-46b793187/

P ROFE SSIONAL S UMMARY

Reliable young ‘Mechanical Engineer’, seeking a challenging position in multifaceted engineering industries (Cement, Chemical, Fertilizer,

Refining, etc.). Demonstrated effective performance in highly reputed organizations, with unwavering commitment towards profession.

Worked as an integral part with all levels of employees in cross-functional teams. Possessing excellent problem-solving and team work

approach.

A R E A S OF E X P E R T I S E

Solid Know-how of Mechanical Technology (Machining, CNC, Hydraulics, Rotating Machinery, Metal Work, Welding, etc.).

Effective Technical Knowledge (Matlab, SolidWorks, Tooling, etc.) Excellent Safety skills for the work

Grasp on designing equipment using AutoCAD Engineering Analysis, Job Planning, Problem Solving.

Strong aptitude for Math and IT (Microsoft Office, Visio Professional) Interpersonal and Communication Competency.

Time Management and Closely Working with the Team. Abilities to create ideas and execute

correctly.

ACADEMIC CREDENTIALS

B.Sc. (Mechanical Engg.) University of Engineering & Technology, Lahore, (NFC-IEFR Campus, Faisalabad). 3.27/4.00 2015–2019

Intermediate KIPS College Gujranwala. A Grade 2013–2015

High School Quaid-e-Azam divisional public school Gujranwala. A+ Grade 2011–2013

AND ACHIEVEMENTS

Engineering Job Dec 2022 - present

Master Tiles & Ceramics Pvt Ltd, Gujranwala Plant.

Working as an Assistant Manager Reliability and Workshop dealing with following Tasks:

Responsible for ensuring that the facilities, layout and machinery used to produce new and existing materials and goods run to their maximum

efficiency and output. This includes Total Preventative Maintenance, Managing breakdowns of Mechanical, Hydraulics & Instrumentation

equipment.

Contribute to the creation and implementation of best practice maintenance vision, strategy, policies, processes and procedures to aid and

improve operational performance.

Contribute to new business initiatives and projects and review and communicate the impact on Maintenance activities

Manage the process of the introduction of new machinery, plant and equipment from drawing up the specification, to managing suppliers

through to full installation in collaboration with all relevant parties.

Develop, implement and manage key performance indicators (KPIs) for each area of responsibility.

Ensure that the function operates in accordance with company health, safety and environmental policies

Manage, coach and develop a high performing Maintenance team that meets agreed objectives and which delivers best practice results, added

value and continuous improvements

Work collaboratively, negotiate and engage with key stakeholders to facilitate delivery and compliance with the maintenance strategy.

Engineering Job July 2021 – Dec 2022

Mughal Iron And Steel Mill Plant Lahore.

Working as a Senior Planner Workshop and Reliability Engineer and dealing with following Tasks:

Ensure that recommended maintenance activities on facilities are execute in a coordinated and cost effective way through the creation of facilities

integrated maintenance plan.

Creates and update the maintenance plan for all shutdown activities to under taken during facilities turnaround outages. Coordinate with other

stake holder in execution of major activities and other technical operating activities.

Plan all activities using CMMS and in collaboration with subject matter expert and assist in development of work packs, monitoring, execution,

schedule and close out of work order, conduct post work closure review and analyses to capture process improvement.

Ensure proper documentation and close out of maintenance work orders and any change made to maintenance procedure.

Responsible for controlling all projects, initiation, scoping, cost estimation, schedule, alignment, monitoring and control & closure,

The ability to achieve a range of goals on an ongoing basis by coordinating labor, equipment and other resources whilst maintaining high standard

of safety and housekeeping.

Projects:

Designed, Planned, Executed and smooth closure of following additional projects

Crusher and conveyor system for Slang Crusher

Batching System along with Conveyor system for Tuff tile Plant

Over Head Crane (EOT) capacity 80/35 ton

Vibratory System for Kiln(CCM) Vibrofeeder

Coil Making Machine for DC motor strip Winding

Batching mixture capacity 2 ton

Bottle Cleaning system for R/O plant.

Engineering Job MAY 2019 - July 2021

Master Tiles & Ceramics Pvt Ltd, Gujranwala Plant.

Working as a Workshop and Reliability Engineer and dealing with following Tasks:

Oversee various workshop activities

(Machining, Welding, Fabrication of different machinery parts and equipment’s. Moreover, try to modify the current machinery).

Utilize knowledge and experience to devise strategies of reliability check and prevention with respect to maintenance Operations to ensure

health and safety environment.

Spearhead HR activities to manage staff members in order to attain maximum output from production units.

Having proper command on operating System Application and Product (SAP).

Key Accomplishment:

Appraised by top management for delivering exceptional services during probation period.

Deduced the cost for maintenance by 20% by analyzing the working principle, operations and utilizing proper material for fabrication of different

parts within time frame.

Led the staff with the learning program named “HAR DUM TAYAR” and guided them with different operations essential fabrication and repairing

process & In addition guided the technical staff for the best implementation of jobs.

Enhanced the modification in design of different workpieces for the smooth running of industrial process by new innovations and ideas

Completed the jobs within given time frame more efficiently by utilizing adequate knowledge about fabrication and repairing process.

Engineering Internship March 2019 - April 2019

Master Tiles & Ceramics Pvt Ltd, Gujranwala Plant.

Working as internship engineer and learning about the maintenance of following:

Coal Plant : Heat Exchanger, Cooler, Evaporator.

Body Department : Automatic Weight and Balancing, H Belt Maintenance.

Mixing Chamber : Maintenance of Rollers and Blades.

Tile Press Machine : Hydraulic Press, Automatic Rollers and Gears.

Kiln : Automatic Ceramic Roller, Motors and Gears.

Squaring Line : Sizing Belts, Motor and Gear.

Polishing : Laser Polishing, Machine and Maintaining Equilibrium in Process.

Sorting : Laser Sorting.

Packing sector : Automatic Packing Machine.

LGV : Maintenance of Laser Guided Vehicle.

Machine Shop : Learning to operate CNC Wire Cut machine, CNC Lathe, Milling, Manual wire cut Machine, Casting and Drilling.

Trainee Engineer – Part Time Engineering Internship Sep 2018 – Feb 2019

UNITED TEXTILE Ltd., (short-term engagement on maintenance):

Worked as Maintenance Engineer at United Textile and practiced for Predictive Inspection, Maintenance and Scheduling of following :

Blow Room : Fan Impellers, Tooth Segments, Gear Motors of Reciprocating Rollers, Drive Belts, Dust Extraction Sheets and Gear

Boxes.

Cardig Section : Carding Elements, Flat to Cylinder Setting, Suction Points and Cylinder Gas Kits

Unilap Section : Wastes Suction Pipes and Pumps, top and bottom Rollers, Safety Switches, Pneumatic Switches, Lubrication of Gear

Box.

Comber Section : Feed tables, Combs, Belt and Drives, Turning Table Chain’s Tension, Bearing and Bushes.

Simplex Section : Drafting Zones and Neck Bearings of Bottom Rollers.

Auto-Coner : Waxing Shafts, Pressure Forks, Cradle Sensors, Filters, Suction Arms and Cradles Vibration

Engineering Internship Jul – August 2018

OIL & GAS DEVELOPMENT COMPANY Ltd. (OGDCL), Islamabad, Capital Territory:

No. OGTI/up-097-APP#458 ( www.ogdcl.com )

Internship was divided into two segments:

Rig Maintenance Department OGTI Islamabad : Spent 3 weeks in rig maintenance department where repairs of rig parts is carried out.

Rig N-1 at Soghri#3 : I spent one week at rig N-1, which is located at soghri#3 and Rig was in working position at that time. It was drilling up

to 1500 meters down into Earth.

Engineering Internship June – Sept 2017

UNITED MOTORS (Pvt.) LTD.

4 months internship which was divided into eight parts, as follows:

Quality Control Department : Learnt about ISO Standards applied for Quality of their manufactured products and the Vendors supplies.

Engine Assembly Line : Gained knowledge about the Construction of Engine including Process of Punching, Engine Assembly,

Leakage Test and Computerized Bench Testing.

Paint Shop : I learnt the painting process for Petrol Tanks.

Shock Assembly Line: In this line I learnt about the Shock Absorbing process of Bikes followed by the assembly of Spring Shocks.

CNC Machine Shop : In CNC Machine Shop (CMS) I studied about manual Lathes and CNC Machine operations, used to produce parts

like Crankcase of Engine, Front Hub and Back Hub. In this shop the testing of these parts was also carried out.

Main Assembly Line : I understood about the whole assembly and final inspection process of motor bike before sending to the market.

Final Inspection Test Bench : Explored different tests carried out for acceleration, speedometer, breaking system and wheel alignment.

Senior Vice President ASME NFC IEFR – Local Chapter Sep 2018 – April 2019

American Society of Mechanical Engineers, New York City, U.S.:

Planning and implementing local section programs and services.

Working with Convener to help set goals for the following year.

Leading and managing the affairs of the local section.

Sharing of documents, resources and knowledge for others.

Being the main point of contact for ASME Headquarters.

Calling and conducting local section meetings.

Motivating and encouraging other officers to support and organize activities.

Maintaining frequent communication between the Local Section and Industrial Liaison.

Submitting a Local Section Annual Report to ASME.

Reviewing the section’s financial condition with the treasurer.

C ERTIFICATIONS

Certification Diploma (online) in Project Management, revised course 2017. ( www.alison.com )

One day CPD Certification on Safe Working, by PEC.

FI NAL Y EAR P ROJECT Sept 2018 – May 2019

NFC-IEFR, Faisalabad:

Thesis: Fabrication and Analysis of Solar Refrigerator with DC compressor.

Mini Projects:

Fabrication of Small Impulse Turbine

Review paper Solar Parabolic Trough collector and solar Linear Fresnel collector Technologies.

HONORS

Achievement to become joint secretary at local chapter Blood Donor Society at NFC Faisalabad.

Attained a position of Event organizer at local Iefrian Debating Society, organized the debating competition at country level.

Assigned as project leader in final year project.

Appointed as class representative in University.

Member of International Association of Engineers (IAENG)

International member of an ISA (International Society of Automation).

Received merit based Laptop Award from Chief Minister Punjab (2014).

EXTRA -CURRICULAR

Volunteer work.

(Coach Undergraduate Students about ASME and the benefits of membership as Student for this great platform)

Gardening

Trekking

Pet care

R EFERENCES

Can be provided on Request.

You might also like

- Resume Himanshu MishraDocument3 pagesResume Himanshu MishraAnkush SehgalNo ratings yet

- Maintenance Engineer Sample ResumeDocument4 pagesMaintenance Engineer Sample ResumeÄbdur Ráhmán100% (1)

- UMER QASIM Master CVDocument4 pagesUMER QASIM Master CVTahaNo ratings yet

- Saravanan M - Resume NewDocument3 pagesSaravanan M - Resume NewjillNo ratings yet

- Kirankumar Rohit: ManagerDocument3 pagesKirankumar Rohit: ManagerMuhammad IqbalNo ratings yet

- Vijay Pal: GB ProjectDocument4 pagesVijay Pal: GB ProjectpalvjNo ratings yet

- Sandeep Varma Resume Jan 2021Document4 pagesSandeep Varma Resume Jan 2021Kaiwlya BhoyarNo ratings yet

- Resume: Sunil Kumar Morwal Oct. Mechanical Engineer Project & CommissioningDocument4 pagesResume: Sunil Kumar Morwal Oct. Mechanical Engineer Project & CommissioningSunil kumar MorwalNo ratings yet

- Naukri RajKumarArora (27y 0m)Document5 pagesNaukri RajKumarArora (27y 0m)Amit SinhaNo ratings yet

- Vasanth Kumar K.T Exp SAP MM 14 LPADocument5 pagesVasanth Kumar K.T Exp SAP MM 14 LPAIT Jobs IndiaNo ratings yet

- Durga Prasad CVDocument4 pagesDurga Prasad CVSathi MechNo ratings yet

- Updated Resume Sachin Kumar TiwariDocument3 pagesUpdated Resume Sachin Kumar TiwariRitesh Kumar TiwariNo ratings yet

- Mahesh Joshi Updated CV 24Document4 pagesMahesh Joshi Updated CV 24mbjoshi1968No ratings yet

- RMG Industry Expert - K. M. MUNIR HUSSAINDocument4 pagesRMG Industry Expert - K. M. MUNIR HUSSAINAshish J. GeorgeNo ratings yet

- Deep ResumeDocument4 pagesDeep ResumeMOHANNo ratings yet

- ResumeDocument5 pagesResumeVaibhav Vithoba NaikNo ratings yet

- CV For Nurul Amin 2021 PDFDocument9 pagesCV For Nurul Amin 2021 PDFPiplu DasNo ratings yet

- Elect Engr ResumeDocument4 pagesElect Engr ResumeKhalid MehmudNo ratings yet

- XXXXXXXXXX: Corrective Actions. Effective Communicator & Negotiator With Strong Analytical, ProblemDocument2 pagesXXXXXXXXXX: Corrective Actions. Effective Communicator & Negotiator With Strong Analytical, ProblemashaNo ratings yet

- Area of Expertise:: Project Planning & ExecutionDocument3 pagesArea of Expertise:: Project Planning & ExecutionSam SonNo ratings yet

- Amit Tiwari TPM 21.7.22Document6 pagesAmit Tiwari TPM 21.7.22vaishaliNo ratings yet

- Sahil Batra: Residential DetailsDocument5 pagesSahil Batra: Residential DetailsSPECTRUM DRIILING TOOLS INTERNATIONALNo ratings yet

- Fletcher Theophilus Ato CVDocument7 pagesFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNo ratings yet

- Resume of R. Naveen KumarDocument5 pagesResume of R. Naveen Kumarajin ekkishowNo ratings yet

- Sudhir NewDocument2 pagesSudhir NewMayank SinghNo ratings yet

- 01 VKT - 2012 JanDocument6 pages01 VKT - 2012 JanVinod Kumar TurkiNo ratings yet

- SIMBA Power & Infra Company ProfileDocument29 pagesSIMBA Power & Infra Company ProfileBala SubramanianNo ratings yet

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- Aalok MishraDocument4 pagesAalok MishraAlok MishraNo ratings yet

- Shailendra Agrawal: DGM - InstrumentationDocument4 pagesShailendra Agrawal: DGM - InstrumentationShailendra AgrawalNo ratings yet

- Farrukh CVDocument23 pagesFarrukh CVFarrukh AhmedNo ratings yet

- Resume Ropit 1 Aug 19Document4 pagesResume Ropit 1 Aug 19Ropit SharmaNo ratings yet

- Asad AliDocument5 pagesAsad AliMisbhasaeedaNo ratings yet

- Senior Mechanical Engineer Cement Industry .: Ashokkumar.CDocument2 pagesSenior Mechanical Engineer Cement Industry .: Ashokkumar.CShankker KumarNo ratings yet

- Naukri RishiRawat (14y 0m)Document5 pagesNaukri RishiRawat (14y 0m)Amit SinhaNo ratings yet

- Curriculum Vitae: Pramod - Junior CAM EngineerDocument4 pagesCurriculum Vitae: Pramod - Junior CAM EngineerpramodNo ratings yet

- MD Al AminDocument4 pagesMD Al AminElango SundaramNo ratings yet

- Short Description of 09years Professional Journey: Covering LetterDocument7 pagesShort Description of 09years Professional Journey: Covering Lettersuria qaqcNo ratings yet

- Abdul Aziz Khan: ObjectiveDocument6 pagesAbdul Aziz Khan: ObjectiveAbdul Aziz KhanNo ratings yet

- Eng Muhammad Own Raza - Menasco JAFDocument18 pagesEng Muhammad Own Raza - Menasco JAFWaqar KhanNo ratings yet

- Resume-B N RautDocument6 pagesResume-B N RautBalaji RautNo ratings yet

- Fletcher Theophilus Ato CVDocument7 pagesFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNo ratings yet

- Ijaz Ahmed (Mechanical-Engr)Document4 pagesIjaz Ahmed (Mechanical-Engr)AnsarNo ratings yet

- Resume 2Document6 pagesResume 2Mansingrao BhosaleNo ratings yet

- Y. Vikas Singla: Project Management MaintenanceDocument3 pagesY. Vikas Singla: Project Management Maintenanceyv singlaNo ratings yet

- Resume Aamir KhanDocument2 pagesResume Aamir Khanmumtazqadri46No ratings yet

- Vikram Singh Bhati (Electrical Lead Engineer)Document3 pagesVikram Singh Bhati (Electrical Lead Engineer)Vikram Singh BhatiNo ratings yet

- Muhammad Shafique : CONTACT #: +92-308-4593005 +92-321-6934750 Email AddressDocument3 pagesMuhammad Shafique : CONTACT #: +92-308-4593005 +92-321-6934750 Email AddressSunny MeharNo ratings yet

- Muhammad Ashir: Work ExperienceDocument4 pagesMuhammad Ashir: Work ExperienceMuhammad AshirNo ratings yet

- Nuqman Zulkifli Mechanical Design Engineer ResumeDocument2 pagesNuqman Zulkifli Mechanical Design Engineer ResumeLeon KowNo ratings yet

- Mazhar 1Document4 pagesMazhar 1Mohammed SultanNo ratings yet

- Dinesh Pratap Singh - Dios KennetDocument4 pagesDinesh Pratap Singh - Dios KennetdharmendrNo ratings yet

- K.S.Venkatraman: Core Competencies Brief OverviewDocument3 pagesK.S.Venkatraman: Core Competencies Brief OverviewHariNo ratings yet

- Total Experience:-6 Years (5 Years in Die Casting.) : Deepak A Jagzap Diploma IN Mechanical EnggDocument3 pagesTotal Experience:-6 Years (5 Years in Die Casting.) : Deepak A Jagzap Diploma IN Mechanical EnggSmart TradingNo ratings yet

- CV - SamBen Jose 2023Document4 pagesCV - SamBen Jose 2023MECH SAMNo ratings yet

- Masood Ahmed: Contact: +91-9177220515Document4 pagesMasood Ahmed: Contact: +91-9177220515Raj AryanNo ratings yet

- HSE Supervisor Opening19Document7 pagesHSE Supervisor Opening19Narashya PermanaNo ratings yet

- Baboolal VishwakarmaDocument2 pagesBaboolal VishwakarmababoolalvishwakarmaNo ratings yet

- Ibrahim AhmedDocument3 pagesIbrahim Ahmedanuragkumar.engineerNo ratings yet

- Design Project1Document19 pagesDesign Project1Syed Munawar Ali100% (1)

- EX15646 UL COC Foam SprinklerDocument1 pageEX15646 UL COC Foam SprinklerPeter Keith Vela RuizNo ratings yet

- Daihatsu Feroza ECU PinoutDocument3 pagesDaihatsu Feroza ECU Pinoutamau.km14No ratings yet

- PDF Kta19m PDFDocument2 pagesPDF Kta19m PDFFelipe Antonio Aurolo Moraga100% (2)

- Brought To You by Pro Gear & Transmission. For Parts or Service CallDocument3 pagesBrought To You by Pro Gear & Transmission. For Parts or Service CallOscar GonzálezNo ratings yet

- Gauge Theory Physics Economics PDFDocument37 pagesGauge Theory Physics Economics PDFEMMANUEL MARTINEZ ARIASNo ratings yet

- Netcall ManualDocument7 pagesNetcall Manualnimisha rajuNo ratings yet

- E CatalogueDocument331 pagesE CatalogueAlivelu MangaNo ratings yet

- Category Specifications Requirement Owgels Godcare E3-5-01Pw0 Owgels Godcare Oz-5-01Pw0 Chaban Group Oxytec-10Document1 pageCategory Specifications Requirement Owgels Godcare E3-5-01Pw0 Owgels Godcare Oz-5-01Pw0 Chaban Group Oxytec-10amit261287No ratings yet

- Game of Thrones Fan 3D Prints His Very Own Replica of Oberyn Martell's Blade PDFDocument5 pagesGame of Thrones Fan 3D Prints His Very Own Replica of Oberyn Martell's Blade PDFBruna CastanheiraNo ratings yet

- Setup Guide For MPC-HC + MadVRDocument10 pagesSetup Guide For MPC-HC + MadVRxen1251No ratings yet

- 2-78 Peak SIM LockDocument49 pages2-78 Peak SIM LockTiwakorn DarajitNo ratings yet

- Resume09 2011Document29 pagesResume09 2011downloader1983No ratings yet

- Galva PulseDocument4 pagesGalva PulseAlex CrispimNo ratings yet

- Finite Impulse Response (FIR) FiltersDocument39 pagesFinite Impulse Response (FIR) Filtersvinodkumbhar2012No ratings yet

- 400 KV Switchyard - IDocument70 pages400 KV Switchyard - IRajeshwar Raj100% (7)

- Bom of CCM 1 Structure: Item Name Size Qnty Weight (MT) SL NO Required MaterialsDocument2 pagesBom of CCM 1 Structure: Item Name Size Qnty Weight (MT) SL NO Required MaterialsSanjeev SharmaNo ratings yet

- SurpriseDocument3 pagesSurpriseErika RuizNo ratings yet

- Aurbus X From Could and Dark To Ready For TaxiingDocument14 pagesAurbus X From Could and Dark To Ready For TaxiingJaimilton Gomes da SilvaNo ratings yet

- High Classroom Temperatures 1Document5 pagesHigh Classroom Temperatures 1alexNo ratings yet

- Aircraft ConfigDocument30 pagesAircraft ConfigRaphael Francisco PuttiniNo ratings yet

- Design Considerations For Curtain Wall Parapets in Cold ClimatesDocument8 pagesDesign Considerations For Curtain Wall Parapets in Cold ClimatesGino TironiNo ratings yet

- Group 11Document33 pagesGroup 11api-666595981No ratings yet

- TB 03 Calculations Normalisations ConversionsDocument17 pagesTB 03 Calculations Normalisations ConversionsRaul BxinNo ratings yet

- Atlas MilitaryDocument12 pagesAtlas MilitaryRasoolKhadibiNo ratings yet

- Motor Operating Device UEMC 40 A - , B - , D - : Installation, Operating and Recycling GuideDocument38 pagesMotor Operating Device UEMC 40 A - , B - , D - : Installation, Operating and Recycling GuidecepchileNo ratings yet

- MS For Core Walls Dowels Location Repair (Towers)Document5 pagesMS For Core Walls Dowels Location Repair (Towers)rayNo ratings yet

- T210 Electrical Part List PDFDocument6 pagesT210 Electrical Part List PDFDaniel Cekul100% (1)

- 121 Files 215 MB API RP 2A-LRFD-2019 NFPA 451-2020 PD CEN TR 17320:2019Document1 page121 Files 215 MB API RP 2A-LRFD-2019 NFPA 451-2020 PD CEN TR 17320:2019Mohamad ShafeyNo ratings yet

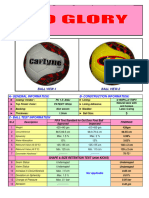

- 4 C10 GloryDocument1 page4 C10 GloryAmer ZeeshanNo ratings yet