Din 1.0619

Din 1.0619

Uploaded by

aniketCopyright:

Available Formats

Din 1.0619

Din 1.0619

Uploaded by

aniketOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Din 1.0619

Din 1.0619

Uploaded by

aniketCopyright:

Available Formats

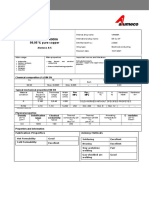

Material - DIN 1.

0619

Standard Specification for Steel Castings for Pressure Purposes; Steel Grades for Use at

Room Temperature and Elevated Temperatures

Group - Ferrous Mild Steel Alloys

Sub Group - DIN 1.0619 Steel Castings for Pressure Purposes; Steel Grades for Use at Room Temperature and

Elevated Temperatures

Application - Intended for Valve, Pump, General Engineering, Automotive and Other Industries

Grade Belongs to the Industry - Casting

Chemical Composition Heat Treatment

Carbon C% 0.180 - 0.230

Silicon Si % 0.600 max.

Manganese Mn % 0.500 -1.200

Phosphorus P% 0.030 max. Normalising or Annealing or Hardening + Tempering

Sulphur S% 0.020 max.

Chromium Cr % 0.300 max.

Nickel Ni % 0.400 max.

Molybdenum Mo % 0.120 max.

Copper Cu % 0.300 max. Mechanical Properties

Iron Fe % Balance Tensile Strength in Mpa 420 - 600

- - - Yield Strength in Mpa 240 min.

- - - Elongation in % 22 min.

- - - Reduction of Area in % -

- - - Hardness in BHN -

- - - Impact in Joule 27 J @ RT

Cross Reference Table

Material Standard Country Grade Belong to the Industry

A757 A 1 Q ASTM USA Casting

J03002 UNS USA Casting

SA 216 WCB ASME USA Casting

1.0619 EN European Union Casting

A 660 WCB ASTM USA Fusion Welding, Bending and Forming

SA-660 WCB ASME USA Centrifugal Casting

A216 WCB ASTM USA Casting

Further any inquiry to discuss with Gravity Cast Pvt. Ltd. – Gravity Group of Companies team member Call

on +918469160029, or email marketing@gravitycastindia.com

All information in our data sheets and website is indicative only and is not intended to be a substitute for the full specification from which it is extracted. It is intended to

provide typical values to allow comparison between metal alloy option rather than a definitive statement of mechanical performance or suitability for a particular

application as these will vary with temperature, product type and product application. It is presented apart from contractual obligations and does not constitute any

guarantee of properties or of processing or application possibilities in individual cases. Our warranties and liabilities are stated exclusively in our terms of business.

ONE STOP SOLUTION FOR METAL PARTS

You might also like

- Cálculo de Torque Válvulas de Mariposa PDFDocument2 pagesCálculo de Torque Válvulas de Mariposa PDFJuan Manuel Lara100% (1)

- MAST CalculationDocument4 pagesMAST Calculationaniket100% (3)

- Astm A216 WCBDocument1 pageAstm A216 WCBAkshay ValaNo ratings yet

- Material ASTM A352 LCCDocument1 pageMaterial ASTM A352 LCCHarryNo ratings yet

- Sae 1022Document1 pageSae 1022talebimahdi924No ratings yet

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDocument1 pageMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05No ratings yet

- Aisi 1045Document1 pageAisi 1045Achmad MiftahNo ratings yet

- Aisi 4330Document1 pageAisi 4330ahmedNo ratings yet

- Asme Sa-29 1018Document1 pageAsme Sa-29 1018Nelson RangelNo ratings yet

- Sae 1080Document1 pageSae 1080bharathi_pmNo ratings yet

- Technical Specifications - ASTM A27 Grade 70-40Document1 pageTechnical Specifications - ASTM A27 Grade 70-40S.Mohsin AliNo ratings yet

- DIN G S 17 CrMo 5-5Document1 pageDIN G S 17 CrMo 5-5kaushal sagarNo ratings yet

- AISI 1070 FichaDocument1 pageAISI 1070 FichaNestor SortoNo ratings yet

- Uns S44800Document1 pageUns S44800Mohammad TaherNo ratings yet

- Astm B62 C83600Document1 pageAstm B62 C83600hemant skNo ratings yet

- Astm B 575 N06455Document1 pageAstm B 575 N06455titan.iran68No ratings yet

- Asme SB-283 C70620Document1 pageAsme SB-283 C70620Don AskmeNo ratings yet

- ASTM A297 Grade HHDocument1 pageASTM A297 Grade HHinfo.nulyproNo ratings yet

- Astm A108Document1 pageAstm A108vvnmechNo ratings yet

- Astm B 622 N06455Document1 pageAstm B 622 N06455titan.iran68No ratings yet

- Astm A487 4 (A)Document1 pageAstm A487 4 (A)baladiroyaNo ratings yet

- Astm B 491 6063Document1 pageAstm B 491 6063جبر البرحNo ratings yet

- ASTM A 108 Grade 1020Document1 pageASTM A 108 Grade 1020juan ormacheaNo ratings yet

- Astm A743 Cf8mDocument1 pageAstm A743 Cf8makdrnlNo ratings yet

- Astm B 163 N06690Document1 pageAstm B 163 N06690Cassio Lopes BrazNo ratings yet

- Astm b176 Uns c86500Document1 pageAstm b176 Uns c86500Kashif MohiuddinNo ratings yet

- Astm A29 4130Document1 pageAstm A29 4130comprasacsa1208No ratings yet

- BS 3100 Grade A4Document1 pageBS 3100 Grade A4vvnmechNo ratings yet

- AISI 1060 FichaDocument1 pageAISI 1060 FichaNestor SortoNo ratings yet

- Astm A351 Cf8Document1 pageAstm A351 Cf8akdrnlNo ratings yet

- BS 970 En8dDocument1 pageBS 970 En8djobseekerarulkumarNo ratings yet

- Astm A 108 Grade 1215Document1 pageAstm A 108 Grade 1215sagj0330No ratings yet

- Astm A351 CF8MDocument1 pageAstm A351 CF8MnadeemNo ratings yet

- Sae 1010Document1 pageSae 1010Sonu MauryaNo ratings yet

- Jis H 5302 Adc12Document1 pageJis H 5302 Adc12Hazem MahmoudNo ratings yet

- Astm A 510 1040Document1 pageAstm A 510 1040ashishshukla.kecNo ratings yet

- ISO 3522 Al Si8Cu3Document1 pageISO 3522 Al Si8Cu3contactemoi155No ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- ASTM A 494 CU5MCuCDocument1 pageASTM A 494 CU5MCuCdss1234No ratings yet

- BS CW617NDocument1 pageBS CW617NVikrant PawarNo ratings yet

- Sae D550Document1 pageSae D550eduardoNo ratings yet

- ASTM B148 Nickle Aluminum Bronze UNS C95500Document1 pageASTM B148 Nickle Aluminum Bronze UNS C95500Aneesh AwasthiNo ratings yet

- Asme SB-283 C37700Document1 pageAsme SB-283 C37700Don AskmeNo ratings yet

- Sae J403 Uns G10050Document1 pageSae J403 Uns G10050Shrikar KuradeNo ratings yet

- Ref TC - ANSI - AA B390Document1 pageRef TC - ANSI - AA B390Abhilash BaranwalNo ratings yet

- Ams 5358Document1 pageAms 5358D.I.GNo ratings yet

- Din en 1706 Ac - 71100Document1 pageDin en 1706 Ac - 71100Anudeep NittalaNo ratings yet

- ASTM B148 Aluminum Bronze UNS C95300Document1 pageASTM B148 Aluminum Bronze UNS C95300andrelorandiNo ratings yet

- ASTM A128 Grade B-3 PDFDocument1 pageASTM A128 Grade B-3 PDFEko PrasetyoNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument3 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979No ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- (Discontinued ) : ASTM A202 Low Alloy Steel, Grade BDocument1 page(Discontinued ) : ASTM A202 Low Alloy Steel, Grade BDhanyajaNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- Ficha Tecnica - BS EN 1982 CuSn7Zn4Pb7-C (CC493K)Document1 pageFicha Tecnica - BS EN 1982 CuSn7Zn4Pb7-C (CC493K)freddy benavidesNo ratings yet

- ASTM A284 Steel, Grade CDocument1 pageASTM A284 Steel, Grade CBalaNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNo ratings yet

- 20 MN Ni MoDocument2 pages20 MN Ni MocomprasNo ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338minhyen88No ratings yet

- Aalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Document3 pagesAalco Metals LTD Aluminium Alloy 6082 T6 Extrusions 338Karan NanwaniNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Stillon Sanitary Valves CatalogueDocument12 pagesStillon Sanitary Valves CatalogueaniketNo ratings yet

- Ss Corrugated Hoses CatalogueDocument6 pagesSs Corrugated Hoses CatalogueaniketNo ratings yet

- Frequency Response AnalysisDocument94 pagesFrequency Response AnalysisaniketNo ratings yet

- Mast Calculation: Maximum Allowable Stem Torque Is Calculated From Roark FormulaDocument2 pagesMast Calculation: Maximum Allowable Stem Torque Is Calculated From Roark FormulaaniketNo ratings yet

- Pneumatic Linear Actuators Cylinder - PLSDocument8 pagesPneumatic Linear Actuators Cylinder - PLSaniketNo ratings yet

- PRCA S2 T - DatasheetDocument4 pagesPRCA S2 T - DatasheetaniketNo ratings yet

- Deep GrooveDocument3 pagesDeep GrooveaniketNo ratings yet

- Drafting SOPDocument7 pagesDrafting SOPaniketNo ratings yet

- Electro Pneumatic Positioner MP-600 SeriesDocument8 pagesElectro Pneumatic Positioner MP-600 SeriesaniketNo ratings yet

- Electric Linear Actuators New ITL (20180105-1)Document9 pagesElectric Linear Actuators New ITL (20180105-1)aniketNo ratings yet

- A12 A13 Cylinder PDFDocument7 pagesA12 A13 Cylinder PDFaniketNo ratings yet

- A 571Document5 pagesA 571aniketNo ratings yet

- Book 1Document1,501 pagesBook 1delwarNo ratings yet

- ASME P Material Numbers: P No. EN288 Base MetalDocument6 pagesASME P Material Numbers: P No. EN288 Base Metalsagar1503100% (1)

- Logam Dan PaduanDocument34 pagesLogam Dan PaduanEga NugrahaNo ratings yet

- Carbide ToolingDocument90 pagesCarbide ToolingHuron Industrial SupplyNo ratings yet

- Astm A694 F65Document1 pageAstm A694 F65Anonymous oVRvsdWzfB100% (2)

- Comparison of Steel Grades by ChemistryDocument5 pagesComparison of Steel Grades by ChemistryMehman NasibovNo ratings yet

- ASTM Comparison PDFDocument1 pageASTM Comparison PDFRaja HoneNo ratings yet

- 22 The Weldability of Steels 09-09-05Document16 pages22 The Weldability of Steels 09-09-05vijaykumarnNo ratings yet

- Appendix EDocument6 pagesAppendix Ekaisertrevino56No ratings yet

- ASTM A213 T11 Alloy Steel, Chromium Molybdenum, F11-1: Metal Ferrous Metal Tool Steel Cold Work SteelDocument1 pageASTM A213 T11 Alloy Steel, Chromium Molybdenum, F11-1: Metal Ferrous Metal Tool Steel Cold Work SteelsemetayNo ratings yet

- Victorinox Swiss Army I.N.O.X. Quick GuideDocument12 pagesVictorinox Swiss Army I.N.O.X. Quick Guidemeor3705No ratings yet

- JIS Steel Wires StandardDocument7 pagesJIS Steel Wires StandardPS NguyễnNo ratings yet

- WeldingDocument1 pageWeldingNNo ratings yet

- Properteis Ofrefractory Metals and Metals PDFDocument48 pagesProperteis Ofrefractory Metals and Metals PDFBasavaraj N.CNo ratings yet

- UTP Steel+brochure EN 2017 WEBDocument28 pagesUTP Steel+brochure EN 2017 WEBCarlos Anibal OrtizNo ratings yet

- Weight CalculationDocument14 pagesWeight CalculationAkshay KadiaNo ratings yet

- InsertosDocument48 pagesInsertosDuvan VillaNo ratings yet

- Saw Blades: Amada Machine Tools EuropeDocument66 pagesSaw Blades: Amada Machine Tools Europebuva034No ratings yet

- Approved List of Manufacturers: Pipe FittingsDocument8 pagesApproved List of Manufacturers: Pipe FittingsSourav Kumar GuptaNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- Assumptions For VER EstimationDocument17 pagesAssumptions For VER EstimationPukhraj SethiyaNo ratings yet

- Oferta INGRASAMINTE PRUTUL - 02.02Document2 pagesOferta INGRASAMINTE PRUTUL - 02.02Murgoci IonelaNo ratings yet

- Exothermic Welconnection Copper Strip To Ground RodDocument8 pagesExothermic Welconnection Copper Strip To Ground RodBenny HillNo ratings yet

- Is 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsDocument9 pagesIs 4759 - 2006 - Hot-Dip Zinc Coatings On Structural Steel and Other Allied ProductsabhibmaneNo ratings yet

- SAWDocument4 pagesSAWLuis LugoNo ratings yet

- 24 D F Block Elements Formula Sheets QuizrrDocument17 pages24 D F Block Elements Formula Sheets QuizrrShubhanshu ChandraNo ratings yet

- Alloy & Special SteelsDocument33 pagesAlloy & Special Steelstanishka narayan100% (1)

- SGS 249 Geometallurgical Experience PDFDocument6 pagesSGS 249 Geometallurgical Experience PDFEmil AzhibayevNo ratings yet

- Lista de Materiales LHMATDocument5 pagesLista de Materiales LHMATfduarteNo ratings yet

- Pulls Plates Escutcheons Catalogue SectionDocument22 pagesPulls Plates Escutcheons Catalogue SectionOwenNo ratings yet