WHS 2016 Scaffolding SWMS

WHS 2016 Scaffolding SWMS

Uploaded by

alstonlopez96Copyright:

Available Formats

WHS 2016 Scaffolding SWMS

WHS 2016 Scaffolding SWMS

Uploaded by

alstonlopez96Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

WHS 2016 Scaffolding SWMS

WHS 2016 Scaffolding SWMS

Uploaded by

alstonlopez96Copyright:

Available Formats

ABN: 35145102432

Address:18 hunter place, castle hill, NSW 2154 PH:0412641287 E:peter@fieldsglassandglazing.net.au Web: www.fieldsglassandglazing.net.au

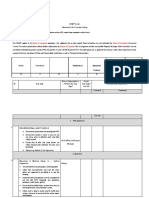

SAFE WORK METHOD STATEMENT (SWMS)

PROJECT DETAILS:

Project: Area:

Job Address:

Job Description:

WORK ACTIVITY: Scaffolding

Page 1 of 12-

Consult relevant workers during development, approval and communication of this SWMS SWMS Approved by:

1

Name: (Include names of workers Signature: Job Title: Date: Name:

who were consulted in relation to

this SWMS) Signature:

Date:

Overall Risk Rating After 4 Acute 3 High

Personnel responsible for monitoring and managing activity:

Controls 2 Moderate 1 Low

COMMUNICATE THIS SWMS TO ALL PERSONS INVOLVED IN TASK PRIOR TO WORK COMMENCING

____________will conduct regular inspections and observations to ensure SWMS is being complied with.

Hold Daily Tool Box Talks to identify, control and communicate additional site hazards.

Cease work immediately if incident or near miss occurs. Amend the SWMS in consultation with relevant persons.

______________ will approve and communicate amendment to all affected workers before work resumes.

As required by WHS legislation, make the SWMS available for inspection or review.

As required by WHS legislation, keep record of SWMS (until job is complete or for 2 years if involved in a notifiable incident).

IMPORTANT NOTES:

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 1

Signature: Date:

Check local government standards, codes of practice, regulations and legislation for any training requirements before use.

Apprentices and Trainee Personnel are usually permitted to operate certain machinery and equipment provided they are guided and supervised by an experienced

and qualified person, while also recording the hours of use in an approved logbook.

WorkCover National Certificates of Competency are nationally recognised and these specific certificates do not have to be changed over to work interstate.

1. Only a person holding a Certificate of Competency as a Scaffolder is allowed to erect all scaffolding from which a person or an object could fall 4 m or more.

2. Only a scaffolder must erect all scaffolding other than prefabricated types.

3. Implement appropriate controls to prevent unauthorised access to unattended scaffolds.

4. Unless a person authorised by the electricity supply authority has fitted tiger tails and insulated matting, do not work closer than 4 m to the electrical service

lines.

5. Never exceed the safe working load of any component of the scaffold. All scaffolds must have the SWL marked on them.

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 2

Signature: Date:

Potential Hazards/Risks Control Measures - Steps To Follow Responsible

Task Steps RB RA

of Each Step Safety Checks & PPE Officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

1. General precautions Space restrictions In general, component scaffolds have a minimum width of

1.2 m, and a maximum width of 3.0 m.

Working height

No freestanding scaffold must exceed a height of 3 times

Assembly the minimum base dimension. Above this height, use ties

or outriggers.

When erecting a scaffold, always follow the assembly

instructions from the manufacturer.

Allow only competent persons to erect the scaffolding.

Only components designed for and provided for must be

used for the type of scaffolds.

Prevent unauthorised access to unattended scaffolds by

using appropriate warning signs.

Before any person can climb on to or work from the

scaffold, always check the stability of the completed

scaffold.

Make sure all the components are properly fitted

together.

Make sure that all the mating surfaces are undamaged

and clean.

Never mix the components.

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 3

Signature: Date:

Potential Hazards/Risks Control Measures - Steps To Follow Responsible

Task Steps RB RA

of Each Step Safety Checks & PPE Officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

To prevent unauthorised access, use barrier tapes, etc.

Never climb on to or work from an unstable scaffold.

2. Erection - Fixed Foundation Make sure all footings are firm and compacted, stable

and well drained.

Footings

If the surface is soft, use timber sole boards and

Bracing baseplates under the feet.

Make sure that all uprights are vertical by using levelling

screws. All feet must be in firm contact with the surface

on which it is erected.

For ensuring stability, fit plan and vertical bracing on the

scaffold.

For level footing, dig into slopes.

Never use metal plates under the feet.

Make sure that the collar-locking device is properly

engaged on the base frame.

3. Erection - Mobile Foundation Use mobile scaffolds only on stable, level and firm

surfaces.

Castors

Make sure that all wheels can turn smoothly and all the

Bracing locks are operable.

Make sure that all uprights are vertical by using levelling

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 4

Signature: Date:

Potential Hazards/Risks Control Measures - Steps To Follow Responsible

Task Steps RB RA

of Each Step Safety Checks & PPE Officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

screws. All wheels must have full contact with the surface

on which it is erected.

For ensuring stability, fit plan and vertical bracing on the

scaffold.

Never use mobile scaffolds on a slope greater than 7

degrees.

Make sure all the wheels have locks fitted.

Make sure all the wheels are locked when erecting the

scaffold.

4. Access Position of ladders To access the working platform, fit access ladders inside

the scaffold assembly.

Security of ladders

Hook the ladder over the end frame, brace it to a lower

end frame and let it extend at least 0.9 m above the

working platform.

Avoid climbing on the scaffold frame.

Do not attempt to climb up the outside of the scaffold.

5. Working platforms Construction of platform Use a working platform of a “captive” type that locks on to

the frame.

Guardrails and edge

protection The surface of a working platform must always be of non-

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 5

Signature: Date:

Potential Hazards/Risks Control Measures - Steps To Follow Responsible

Task Steps RB RA

of Each Step Safety Checks & PPE Officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

slip finish.

Do not load the platform more that the marked SWL.

Provide full edge protection comprising handrail, midrail

and toeboard or infil panel and a handrail for each

working platform and access platform.

To calculate the load on the platform, include the weight

of all persons, tools, materials and equipment.

Keep the top rail between 0.9 m and 1.1 m above the

working surface.

6. Working on scaffolds Risk of falling Face the ladder when climbing, keep both hands on stiles

and climb slowly.

Falling objects

Use a rope to raise equipment, material and tools to the

Electrical hazards working platform.

Always keep the entire body within the confines of the

guardrails. Never reach out beyond arm’s length from the

scaffold.

When working of the platform of a scaffold, never use any

type of ladder.

Never attach hoisting equipment to a scaffold unless the

manufacturer or supplier has explicitly indicated that it is

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 6

Signature: Date:

Potential Hazards/Risks Control Measures - Steps To Follow Responsible

Task Steps RB RA

of Each Step Safety Checks & PPE Officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

safe to do so.

Wearing protective footwear is advised if the handled

material or equipment is likely to cause foot injury should

it fall.

If practicable, and if there is a risk of falling objects,

provide an exclusion zone around the scaffold.

If there is a risk of being struck by falling objects, all

persons working near the scaffold must wear head

protection.

Be careful when handling metal objects near electric

wiring.

Be careful when climbing and descending ladders.

While climbing or descending ladders, never carry

objects in hand.

Work only from a working platform.

Be careful when raising tools, materials and equipment to

the working platform.

Wearing foot protection is necessary.

In case exclusion zone cannot be provided, erect a

containment screen around the scaffold.

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 7

Signature: Date:

Potential Hazards/Risks Control Measures - Steps To Follow Responsible

Task Steps RB RA

of Each Step Safety Checks & PPE Officer

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented.

Wearing head protection is necessary.

Keep away from electrical hazards.

7. Relocation of mobile Stability – mobile scaffolds Before any person can climb on to the scaffold or works

scaffolds from it, make sure that scaffold wheels are locked.

Do not move a scaffold when any person is still on it.

Before moving the mobile scaffold, check the path of

travel for any obstructions, holds, electric wires and

leans, etc.

Check for stability before the scaffold is re-used after

relocating. Relock all the wheels and adjust the levelling

screws if necessary.

Before moving, remove all loose items.

Avoid tipping over the scaffolding while moving it; move it

carefully.

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 8

Signature: Date:

PERSONAL PROTECTIVE EQUIPMENT

Personal Protective Equipment Requirements

Hearing Protective Head Eye Hand Sun Safety Harness

Foot Protection Clothing Protection Protection Protection Protection

Protection

PPE Notes:

The above PPE Requirements are the minimum requirements for all personnel involved in this task. Be sure to conduct a Risk Assessment for other

factors that may influence the work environment such as Temperatures – Hot/Cold, Working in the Sun, Night Work etc. Be sure that all PPE used is

approved by Australian Standards.

References:

AS/NZS 1891 Industrial Fall Arrest Systems and Devices

AS/NZS 4576:1995 Guidelines for Scaffolding

AS/NZS 1576 Scaffolding

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 9

Signature: Date:

SIGN OFF

Workers and relevant Persons Conducting Business or Undertaking (PCBU) were consulted for developing this SWMS. I have read the above SWMS and I

understand its contents. I confirm that I have the necessary training and skills, including any relevant certifications to undertake the related tasks contained in this

SWMS. I agree to comply with any safety guidelines, requirements and recommendations as set forth by the responsible officer within this SWMS including safety

instructions and use of recommended Personal Protective Equipment.

Name Qualifications Signature Date Time Employer

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 10

Signature: Date:

RISK ASSESSMENT

References: Risk Management Code of Practice 2007, AS/NZS 31000 -2009 Risk Management Principles and guidelines

Step 1 Determine Likelihood – What is the possibility that the effect will occur?

Step 2 Determine Consequence – Expected Consequences Level of Consequence Examples

Likelihood Definition

Insignificant/Acceptable No consequence – so minor that the

Almost Expected to happen in A common and very possible result consequence is manageable

certain most circumstances.

Minor First aid treatment only; manageable and

Likely Will probably occur in Known to have occurred and has contained.

most circumstances. happened before

Moderate Medical treatment; manageable with 3rd party

Possible Might occur at some Could occur and is likely it has assistance.

time happened before

Unlikely Could occur at some Not likely to occur Major Serious injuries; Down time and loss of

time productivity

Rare May occur only in Very unlikely Catastrophic Death; Very serious consequences

exceptional

circumstances

Step 3 Determine the risk score Step 4 Record risk score (Note – Risk scores are only estimated and should not be

Solely relied upon)

CONSEQUENCE

Score Action

LIKELIHOOD Insignificant Minor Moderate Major Catastrophic 4 URGENT – Act on and lower the risks immediately.

A: Acute Demands immediate attention.

Almost 3 High 3 High 4 Acute 4 Acute 4 Acute 3

certain H: High Decisions required urgently by Management.

Likely 2 Medium 3 High 3 High 4 Acute 4 Acute 2

M: Moderate Follow instructions given by management.

Possible 1 Low 2 Medium 3 High 4 Acute 4 Acute

1 Manageable. Review regularly, and if any conditions of

Unlikely 1 Low 1 Low 2 Medium 3 High 4 Acute L: Low work change.

Rare 1 Low 1 Low 2 Medium 3 High 3 High

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 11

Signature: Date:

DISCLAIMER

BlueSafe Australia Pty Ltd supplies a generic template system of word documents that helps the employer to get a head start by providing them with a foundation to

build a Work Health & Safety system for their business. BlueSafe Australia Pty Ltd templates are generic in nature and are not designed to be relied solely upon

without the customisation of specific tasks.

Acquiring or creating & implementing an WHS System can greatly reduce the risks which are associated with your business, however having a complete WHS

System does not 100% insulate a business from accidents or injuries in a workplace, and it does not guarantee that a Compensation Claim won’t be filed, however it

significantly reduces the probability or likelihood by creating, adjusting and refining your systems as much as possible and ensuring that staff follow them.

The documents provided by BlueSafe Australia Pty Ltd are designed to help the employers’ awareness to safety in the workplace, and helping them with the first step

to meeting their legislative obligations as an employer. Not only this, but it also creates an awareness for the employee in helping them be aware of their legislative

obligations in the workplace, by taking responsibility for their actions, be ‘Safety Minded’ and helping the employer to create and maintain a safe workplace which also

significantly reduces the possibilities and risks of an injury while at work.

The obligation rests with the employer to ensure that all systems in the workplace are applicable, practical and safe for their employees while ate work.

BlueSafe Australia Pty Ltd or any of our strategic alliances including associates or any third parties will not and cannot be held responsible for any claims, legal

responsibility and litigation resulting from a workplace incident. It is the employers’ responsibility to provide a safe work environment for all staff, contractors and

visitors in which BlueSafe Australia Pty Ltd does not in any way offer any service that carries or negates that responsibility. BlueSafe Australia Pty Ltd offers a number

of products that gives employers a foundation to begin building a comprehensive system in order to meet their legislative requirements and obligations. BlueSafe

Australia Pty Ltd will not and does not in any way offer any protection or indemnity from any form of litigation or claims, or any liabilities incurred or sustained. The

absolute responsibility to create, implement and maintain a safe system of work and a safe working environment ultimately rests with the employer.

DOCUMENT NO: ACTIVITY: REVIEW NO: DATE:

Authorised by: © BlueSafe Australia 2013 All rights reserved Page 12

Signature: Date:

You might also like

- Jha Swing Stage Scaffold PDFDocument2 pagesJha Swing Stage Scaffold PDFkaruna60% (5)

- Risk Assessment For External Façade & Canopies CleaningDocument6 pagesRisk Assessment For External Façade & Canopies Cleaningjulius50% (2)

- Working at Heights SwmsDocument11 pagesWorking at Heights Swmssyed khaja misbhuddinNo ratings yet

- Job Hazard Analysis of Site SURVEYINGDocument1 pageJob Hazard Analysis of Site SURVEYINGYogesh Gowda100% (1)

- Assignment 3 - Lien ProceduresDocument12 pagesAssignment 3 - Lien Proceduresrajnishatpec100% (2)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- Risk Assessment For External Façade & Canopies CleaningDocument8 pagesRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (2)

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- SWMS ScaffoldingDocument9 pagesSWMS Scaffoldingvictor100% (2)

- Drilling Piling Swms 10 15763 SAMPLEDocument7 pagesDrilling Piling Swms 10 15763 SAMPLEAlok JagannathNo ratings yet

- Tales of Dunk and EggDocument4 pagesTales of Dunk and EggRajneeshBhardwaj0% (1)

- Safe Work Method Statement (SWMS) : ScaffoldingDocument13 pagesSafe Work Method Statement (SWMS) : ScaffoldingemmyNo ratings yet

- Safe Work Method Statement (SWMS) : ScaffoldingDocument11 pagesSafe Work Method Statement (SWMS) : ScaffoldingBIPIN BALANNo ratings yet

- WHS 2016 Working at Heights SWMSDocument14 pagesWHS 2016 Working at Heights SWMSlupiNo ratings yet

- WHS 2016 Boom Lift SWMSDocument13 pagesWHS 2016 Boom Lift SWMSvinothkumarNo ratings yet

- WHS 2016 Demolition SWMS-1Document12 pagesWHS 2016 Demolition SWMS-1Cherylea haassNo ratings yet

- Safe Work Method Statement (SWMS) : DemolitionDocument11 pagesSafe Work Method Statement (SWMS) : DemolitionSafety HaveLockNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- Sample Swms Heights Mobile ScaffoldDocument7 pagesSample Swms Heights Mobile Scaffoldmani narayananNo ratings yet

- Safe Work Method Statement Working at Heights TemplateDocument9 pagesSafe Work Method Statement Working at Heights TemplateeddieNo ratings yet

- 89 Scaffold safety-JOB PROCEDUREDocument2 pages89 Scaffold safety-JOB PROCEDUREkusdiyantaNo ratings yet

- WSWP For Hamisa Installation of Lift FramesDocument6 pagesWSWP For Hamisa Installation of Lift FramesVictor Thembinkosi MakhubeleNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- MSRA - Ceiling Access Fixing and Repairing WorksDocument7 pagesMSRA - Ceiling Access Fixing and Repairing WorksharoonNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Save Work Method of StatementDocument11 pagesSave Work Method of Statementpaansaeng50% (4)

- SWMS Piling Machine Assembly RKDocument14 pagesSWMS Piling Machine Assembly RKrakeshkhanna78100% (1)

- JSA For Screeding With MeshDocument4 pagesJSA For Screeding With MeshMohammed Minhaj100% (1)

- WSWP For Hamisa Cutting of ConcreateDocument8 pagesWSWP For Hamisa Cutting of ConcreateVictor Thembinkosi MakhubeleNo ratings yet

- SWMS Mobile ScaffoldingDocument14 pagesSWMS Mobile Scaffoldingnur agusNo ratings yet

- Safety and Health Plan ExampleDocument26 pagesSafety and Health Plan ExampleManuel Luis AbiogNo ratings yet

- OHS Coordination Plan Template - 0Document3 pagesOHS Coordination Plan Template - 0DespinaNo ratings yet

- JSA For Insulation of VesselDocument6 pagesJSA For Insulation of Vesselyc safetyNo ratings yet

- 008 SWMS General Onsite Activities and RepairsDocument13 pages008 SWMS General Onsite Activities and Repairssiame festusNo ratings yet

- Scaffold Erection and DismantlingDocument2 pagesScaffold Erection and DismantlingAmo MolemaNo ratings yet

- Maintenance PlanDocument7 pagesMaintenance Planmothibakgomo MoarabiNo ratings yet

- Demolition Using Plant PDFDocument8 pagesDemolition Using Plant PDFianllagasNo ratings yet

- Assembly of Steel StructuresDocument2 pagesAssembly of Steel StructuresDelta akathehuskyNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- SWMS 010 MLT Block Erection RKDocument28 pagesSWMS 010 MLT Block Erection RKrakeshkhanna78No ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- R A - Mobile CraneDocument1 pageR A - Mobile CraneNick KrugerNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn Ahsan100% (1)

- Scaffolding - RADocument2 pagesScaffolding - RAGarald BokNo ratings yet

- Facility Inspection ChecklistDocument8 pagesFacility Inspection ChecklistTimNo ratings yet

- Rams MewpDocument11 pagesRams MewpRynoNo ratings yet

- Block Work MethodDocument12 pagesBlock Work MethodsherNo ratings yet

- Recommendation SheetDocument14 pagesRecommendation Sheetnagavijayababu108No ratings yet

- Painting (General Safety) SWMS 10183-4 - SAMPLEDocument6 pagesPainting (General Safety) SWMS 10183-4 - SAMPLEKunal PanchalNo ratings yet

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- Rams TelehandlerDocument9 pagesRams TelehandlerRynoNo ratings yet

- SWMS Piling Works RKDocument22 pagesSWMS Piling Works RKrakeshkhanna78100% (3)

- OHS Coordination Plan Template - 0Document3 pagesOHS Coordination Plan Template - 0vuhanvu2003No ratings yet

- Access Scaffolding 7-11Document2 pagesAccess Scaffolding 7-11kharbush100% (1)

- Busduck Instalion JSADocument5 pagesBusduck Instalion JSAasifreza96No ratings yet

- ALDAR OSH Alert - Precast ElementsDocument1 pageALDAR OSH Alert - Precast ElementserwinNo ratings yet

- Scaffold Erection and DismantlingDocument6 pagesScaffold Erection and DismantlingsathishkumarNo ratings yet

- PT EMI - MoS - I - Lifting Plan Container 20Ft & 40Ft - FinalDocument21 pagesPT EMI - MoS - I - Lifting Plan Container 20Ft & 40Ft - Finalnellaika puspa dewiNo ratings yet

- Demolition Dos and DontsDocument28 pagesDemolition Dos and DontsSivaprasadNo ratings yet

- Procedure - ScaffoldDocument7 pagesProcedure - ScaffoldYani EsbeNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- Entrep Study GuideDocument16 pagesEntrep Study GuidejaylamarieNo ratings yet

- Ibn KhaldunDocument14 pagesIbn KhaldunQosim Oyelakin100% (1)

- Case StudyDocument7 pagesCase StudyCharmie Sta TeresaNo ratings yet

- Ledger Account Accounting Workbooks Zaheer SwatiDocument10 pagesLedger Account Accounting Workbooks Zaheer SwatiZaheer SwatiNo ratings yet

- Skills Competition QuizbeeDocument34 pagesSkills Competition QuizbeeMELISSA ZAMORANo ratings yet

- Safe Space ActDocument14 pagesSafe Space ActChriscelle Ann PimentelNo ratings yet

- CA Final SFM Solution July 2021 Old SyllabusDocument23 pagesCA Final SFM Solution July 2021 Old SyllabusAbhishekNo ratings yet

- English Notes 2.4 - ClaimDocument2 pagesEnglish Notes 2.4 - ClaimaxxNo ratings yet

- 01 Chapter4Document141 pages01 Chapter4Dewi Maspufah100% (2)

- Rosetta Stone of Women BehaviourDocument11 pagesRosetta Stone of Women Behaviourgift2umaNo ratings yet

- Lahore School of EconomicsDocument1 pageLahore School of EconomicsJohn MarryNo ratings yet

- L11 Manor Living 2024Document10 pagesL11 Manor Living 2024bvani03No ratings yet

- Lab Assistant: Exam Conducted 4-11-2006Document5 pagesLab Assistant: Exam Conducted 4-11-2006Ricardo CarrollNo ratings yet

- Super Secret Crisis War!: Cow & Chicken #1 PreviewDocument7 pagesSuper Secret Crisis War!: Cow & Chicken #1 PreviewGraphic Policy100% (1)

- Fnce 726 - Advanced Corporate Finance: FALL 2013Document12 pagesFnce 726 - Advanced Corporate Finance: FALL 2013kathiepengNo ratings yet

- Test Answers For English Spelling Test (U.S. Version) 2015Document18 pagesTest Answers For English Spelling Test (U.S. Version) 2015Anas RiazNo ratings yet

- G.R. No. L-11658 February 15, 1918, LEUNG YEE, Plaintiff-Appellant, vs. Frank L. Strong Machinery Company and J. G. WILLIAMSON, Defendants-AppelleesDocument30 pagesG.R. No. L-11658 February 15, 1918, LEUNG YEE, Plaintiff-Appellant, vs. Frank L. Strong Machinery Company and J. G. WILLIAMSON, Defendants-AppelleesDarius PoncianoNo ratings yet

- Renewable and Non Renewable ResourcesDocument40 pagesRenewable and Non Renewable ResourcesChristian John Musngi50% (2)

- ProofDocument1 pageProofxhxbxbxbbx79No ratings yet

- BBC Learning EnglishDocument11 pagesBBC Learning EnglishLilia LiliaNo ratings yet

- Cyber Crime Research PaperDocument14 pagesCyber Crime Research PaperAshish singhNo ratings yet

- PMKSY - Micro Irrigation Drip System in Paddy By: Tmt. J.Vijaya Rani I.A.S Additional Director of Agriculture (PM)Document14 pagesPMKSY - Micro Irrigation Drip System in Paddy By: Tmt. J.Vijaya Rani I.A.S Additional Director of Agriculture (PM)ramoo.csaNo ratings yet

- MR Ratan 1Document5 pagesMR Ratan 1Nisha AggarwalNo ratings yet

- IT Audit ChecklistDocument40 pagesIT Audit ChecklistPatricia Zhonga100% (6)

- BCPC Resolution Reommending PlanDocument3 pagesBCPC Resolution Reommending Planjomar78% (9)

- CFP The Subject S of Phenomenology. New PDFDocument1 pageCFP The Subject S of Phenomenology. New PDFBrian MüllerNo ratings yet

- Fuentes v. CADocument4 pagesFuentes v. CAKonrad IbabaoNo ratings yet

- Annual Income Tax ReturnDocument6 pagesAnnual Income Tax ReturnJojo ReyesNo ratings yet