Eaton Gen 3 Autoshift Ultrashift Automated Transmission Troubleshooting Guide Trts 0930 en Us

Eaton Gen 3 Autoshift Ultrashift Automated Transmission Troubleshooting Guide Trts 0930 en Us

Uploaded by

jorgihio31Copyright:

Available Formats

Eaton Gen 3 Autoshift Ultrashift Automated Transmission Troubleshooting Guide Trts 0930 en Us

Eaton Gen 3 Autoshift Ultrashift Automated Transmission Troubleshooting Guide Trts 0930 en Us

Uploaded by

jorgihio31Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Eaton Gen 3 Autoshift Ultrashift Automated Transmission Troubleshooting Guide Trts 0930 en Us

Eaton Gen 3 Autoshift Ultrashift Automated Transmission Troubleshooting Guide Trts 0930 en Us

Uploaded by

jorgihio31Copyright:

Available Formats

Troubleshooting Guide

Eaton Gen III Automated

Transmissions

TRTS0930 EN-US

May 2022

UltraShift®

AutoShift®

TRTS0930 General Information |

Model:

F-5405B-DM3 RTO-14910B-AS3

F-6405B-DM3 RTO-14910B-DM3

FM-14D310B-LST RTO-14910C-AS3

FM-15D310B-LST RTO-16910B-AS3

FO-16D313E-LEP RTO-16910B-DM3

FO-5406B-DM3 RTO-16910C-AS3

FO-6406A-AW3 RTO-18910B-AS3

FO-6406B-AW3 F-5505B-DM3

FO-8406A-AW3 F-6505B-DM3

FOM-16D313E-LEP RTLO-18918A-AS3

RTLO-14918A-AS3 RTLO-20918A-AS3

RTLO-16913L-DM3 RTLO-22918A-AS3

RTLO-16918A-AS3 RTLOM-16913L-DM3

RTO-10910B-DM3 RTO-10910B-AS3

RTO-12910B-AS3 RTOM-16910B-DM3

RTO-12910B-DM3

2022.05.18 © 2022 Eaton. All rights reserved 1

TRTS0930 Table of Contents

Table of Contents

General Information Fault Code 28 - Clutch System . . . . . . . . . . . . . . . . . .100

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . .1 Fault Code 29 - Remote Throttle Enable . . . . . . . . . . .106

Transmission Models . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Fault Code 31 - Momentary Engine Ignition

Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . .3 Interrupt Relay (MEIIR) Test . . . . . . . . . . . . . . . . . . .110

Fault Code Retrieval/Clearing . . . . . . . . . . . . . . . . . . . . .5 Fault Code 32 - Loss of Switch Ignition Power Test. .116

Retrieving Fault Codes Manually. . . . . . . . . . . . . . . 5 Fault Code 33 - Low Battery Voltage Supply . . . . . . .120

Clearing Fault Codes Manually . . . . . . . . . . . . . . . . 6 Fault Code 34 - Weak Battery Voltage Supply . . . . . .126

Retrieving Fault Codes with ServiceRanger . . . . . . 6 Fault Code 35 - J1939 Communication Link. . . . . . . .132

Clearing Fault Codes with ServiceRanger . . . . . . . . 7 Fault Code 36 - J1939 Engine Message . . . . . . . . . . .138

Fault Code Isolation Procedure Index. . . . . . . . . . . . . . .8 Fault Code 37 - Power Supply . . . . . . . . . . . . . . . . . .144

Symptom-Driven Diagnostics Index. . . . . . . . . . . . . . .10 Fault Code 41 - Range Failed to Engage . . . . . . . . . . .150

Product Diagnostic (PD) Mode . . . . . . . . . . . . . . . . . .11 Fault Code 42 - Splitter Failed to Engage . . . . . . . . . .156

Fault Code 43 - Range Solenoid Valve . . . . . . . . . . . .162

Fault Code 44 - Inertia Brake Solenoid Coil . . . . . . . .168

Pretest Procedures

Fault Code 45 - High Capacity (HCIB) or Low

Electrical Pretest . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Capacity (LCIB) Inertia Brake Failure . . . . . . . . . . . . .174

TECU Power Harness . . . . . . . . . . . . . . . . . . . . . . 13

Fault Code 46 - Splitter Direct and Indirect

Heavy-Duty Electric Clutch Actuator (ECA) Power

Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fault Code 51 - Rail Position Sensor . . . . . . . . . . . . .184

Preferred +12 Volt Connections . . . . . . . . . . . . . . 16

Fault Code 52 - Gear Position Sensor. . . . . . . . . . . . .190

Preferred +24 Volt Connections . . . . . . . . . . . . . . 18

Fault Code 56 - Input Shaft Speed Sensor . . . . . . . . .196

TECU Ignition Circuit . . . . . . . . . . . . . . . . . . . . . . 20

Fault Code 57 - Main Shaft Speed Sensor . . . . . . . . .202

J1939 Data Link . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fault Code 58 - Output Shaft Speed Sensor . . . . . . . .206

J1939 Troubleshooting . . . . . . . . . . . . . . . . . . . . 21

Fault Code 61 - Rail Select Motor. . . . . . . . . . . . . . . .212

Electrical Pretest . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fault Code 63 - Gear Select Motor . . . . . . . . . . . . . . .218

Power-Up Sequence Test . . . . . . . . . . . . . . . . . . . . . . .26

Fault Code 68 - Grade Sensor . . . . . . . . . . . . . . . . . .224

Fault Code 71 - Unable to Disengage Gear . . . . . . . . .228

Fault Isolation Procedures Fault Code 72 - Failed to Select Rail . . . . . . . . . . . . . .234

Fault Code 11 - No TECU Operation . . . . . . . . . . . . . . .34 Fault Code 73 - Failed to Engage Gear . . . . . . . . . . . .240

Fault Code 12 - Improper ECU Configuration . . . . . . . .38 Fault Code 74 - Engine Speed Response Fault . . . . . .246

Fault Code 13 - J1939 Shift Control Device . . . . . . . . .42

Fault Code 75 - Power Down In Gear . . . . . . . . . . . . .250

Fault Code 14 - Invalid Shift Lever Voltage Fault Code 81 - Gear Engagement Detected . . . . . . . .254

(without Park Pawl) . . . . . . . . . . . . . . . . . . . . . . . . . . .46 Fault Code 83 - Shift Lever Missing . . . . . . . . . . . . . .258

Fault Code 14 - Invalid Shift Lever Voltage

Fault Code 84 - Shift Control Device

(with Park Pawl). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52 Not Configured. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

Fault Code 15 - HIL Shift Device Configuration . . . . . .58 Fault Code 85 - Shift Control Device Incompatible . . .266

Fault Code 16 - High Integrity Link (HIL) . . . . . . . . . . .62

Fault Code 99 - Direction Mismatch . . . . . . . . . . . . . .270

Fault Code 17 - Start Enable Relay (SER) Circuit . . . . .70

Fault Code 18 - ECA Communication Fault . . . . . . . . . .74

Fault Code 19 - CAN ECA Message Fault . . . . . . . . . . .78

Fault Code 21 - Auto Neutral Park Brake Switch. . . . . .82

Fault Code 22 - ABS CAN Message Fault . . . . . . . . . . .88

Fault Code 26 - Clutch Slip . . . . . . . . . . . . . . . . . . . . . .92

Fault Code 27 - Clutch Disengagement . . . . . . . . . . . .96

2022.05.18 © 2022 Eaton. All rights reserved. i

Table of Contents TRTS0930

Symptom Isolation Procedures AutoShift 18-Speed Wiring Diagram with

Up/Down Button Test. . . . . . . . . . . . . . . . . . . . . . . . . 274 Push Button Shifter . . . . . . . . . . . . . . . . . . . . . . 376

Start Enable Relay Contact Test . . . . . . . . . . . . . . . . . 278 Eaton Cobra Lever Wiring Diagram . . . . . . . . . . 378

J1587 Data Link Test . . . . . . . . . . . . . . . . . . . . . . . . . 286 OEM Shift Lever Wiring Diagram . . . . . . . . . . . . 379

Front Box Control Test . . . . . . . . . . . . . . . . . . . . . . . . 292 Eaton Push Button Wiring Diagram . . . . . . . . . . 380

AutoShift Will Not Engage a Gear OEM J1939 Shift Input Device

from Neutral Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . 298 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 382

UltraShift DM3 Will Not Engage a Gear Proper Clutch Operation . . . . . . . . . . . . . . . . . . . . . . 383

from Neutral Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . 306 Check For Proper Clutch Operation . . . . . . . . . . 383

UltraShift AW3 Clutch Engagement Test . . . . . . . . . . 312 Confirm Proper Clutch Adjustment and Clutch Brake

Contact. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 384

AutoShift AS3 Shift Complaint Test . . . . . . . . . . . . . . 316

Clutch Grease Interval Service Procedure . . . . . 385

UltraShift DM3 Shift Complaint Test . . . . . . . . . . . . . 326

ServiceRanger Procedure . . . . . . . . . . . . . . . . . . . . . 386

UltraShift AW3 Shift Complaint Test . . . . . . . . . . . . . 336

Operator-Triggered Procedure . . . . . . . . . . . . . . 386

Shift Lever Back Light Test . . . . . . . . . . . . . . . . . . . . 344

Appendix

Connector Pin Descriptions . . . . . . . . . . . . . . . . . . . . 350

Transmission Controller 38-Way (Vehicle

Interface Connector) . . . . . . . . . . . . . . . . . . . . . 350

Push Button Shift Control 30-Way Connector . . 351

Cobra Lever 8-Way Connector . . . . . . . . . . . . . . 351

Transmission Controller 38-Way (Eaton

Supplied Assembly) . . . . . . . . . . . . . . . . . . . . . . 352

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

UltraShift DM3 6-Speed Wiring Diagram with Analog

Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354

UltraShift DM3 6-Speed Wiring Diagram with

Push Button Shifter . . . . . . . . . . . . . . . . . . . . . . 356

UltraShift AW3 6-Speed Wiring Diagram with Analog

Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

UltraShift AW3 6-Speed Wiring Diagram with

Push Button Shifter . . . . . . . . . . . . . . . . . . . . . . 360

AutoShift 10-Speed Wiring Diagram with

Analog Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . 362

AutoShift 10-Speed Wiring Diagram with

Push Button Shifter . . . . . . . . . . . . . . . . . . . . . . 364

UltraShift 10-Speed Wiring Diagram with

Analog Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . 366

UltraShift 10-Speed Wiring Diagram with

Push Button Shifter . . . . . . . . . . . . . . . . . . . . . . 368

UltraShift 13-Speed Wiring Diagram with

Analog Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . 370

UltraShift 13-Speed Wiring Diagram with

Push Button Shifter . . . . . . . . . . . . . . . . . . . . . . 372

AutoShift 18-Speed Wiring Diagram with

Analog Shifter . . . . . . . . . . . . . . . . . . . . . . . . . . 374

ii © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 General Information | Warnings and Cautions

Warnings and Cautions

WARNING: Follow the specified procedures in the indicated When parking the vehicle or leaving the cab:

! order to avoid personal injury

• Place shift lever in neutral

CAUTION: Follow the specified procedures in the indicated

! order to avoid equipment malfunction or damage.

• Set the parking brake

CAUTION: Do not release the parking brake or attempt to

Note: Additional relevant information not covered in the ! select a gear until the air pressure is at the correct level.

service procedure.

Before starting a vehicle: To avoid damage to the transmission during

towing:

• Ensure adequate fuel level

1. Place shift lever in neutral

• Sit in the driver

2. Lift the drive wheels off of the ground or discon-

• Place shift lever in neutral nect the driveline

• Set the parking brake Do not operate the vehicle if Alternator light is lit or if

gauges indicate low voltage.

Before working on a vehicle or leaving the cab

with engine running:

• Ensure ignition is off while hands are within the

clutch housing area.

• Place shift lever in neutral

• Set the parking brake

• Block the wheels

2022.05.18 © 2022 Eaton. All rights reserved. 1

Transmission Models | General Information TRTS0930

Transmission Models

Heavy-Duty 13-Speed DM3/LEP and 18-Speed AS3 Heavy-Duty 10-Speed AS3/DM3

Medium-Duty 6- and 5-Speed DM3 Medium-Duty 6-Speed AW3

2 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 General Information | Diagnostic Procedures

Diagnostic Procedures

Purpose: Observe the transmission gear display. Purpose: Confirm that the engine will crank and

A B start.

1. Key on. 1. Attempt to start engine

2. Observe gear display. • No engine crank, lever is in neutral and gear

display is “N” (neutral). See “Start Enable

Note: An “88” may show up in the dash at key on.

Relay Contact Test” on page 278.

This indicates the Transmission Electronic

Control Unit (TECU) has completed • No engine crank, lever is in neutral and gear

power-up. If the transmission and gear dis- display is blank. See “Power-Up Sequence

play power-up at the same time, you may Test” on page 26.. If no problems found, refer

not see an “88”. to OEM for gear display problem.

• If blank gear display, go to Step B. • No engine crank and lever is NOT in neutral.

- Verify shift lever or push button is in neutral.

• If “-” (1 dash) on gear display, go to Step D. - Turn key off and wait 2 minutes.

• If “--” (2 dashes) or “**” (2 stars) on gear dis- - Hold clutch half way to the floor. (If

play, go to Step D. equipped)

- Turn key on.

• “#” (gear number) on gear display - If problem continues, call 1-800-826-HELP

- Verify shift lever or push button is in neutral. (4357)

- Turn key off and wait 2 minutes.

- Hold clutch half way to the floor. (If • Engine cranks and gear display is blank. Refer

equipped) to OEM for gear display problem.

- Turn key on. • Engine cranks and gear display is “N” (neu-

- If problem continues, call 1-800-826-HELP tral), go to Step C.

(4357)

• Fault Code F on gear display, go to Step D.

• Neutral “N” on gear display, go to Step B.

2022.05.18 © 2022 Eaton. All rights reserved. 3

Diagnostic Procedures | General Information TRTS0930

Purpose: Confirm the transmission will engage a Purpose: Check for active or Inactive fault codes.

C gear from neutral. D

1. Engage a gear. 1. Check for active fault codes.

Note: AutoShift will not engage a gear from neutral Note: If no problem found, refer to OEM for display

test. UltraShift will not engage a gear from problem.

neutral test. UltraShift PLUS Product will not

• If codes are present, See “Fault Code Isolation

engage a gear from neutral test, or UltraShift

Procedure Index” on page 8.

AW3 Clutch Engagement test depending on

transmission type. • If no codes and gear display is “-” (1 dash)

- Verify shift lever or push button is in neutral.

• Unable to engage gear (ie. flashing gear dis-

- Turn key off. Wait 2 minutes.

play with down arrows, or solid “N”).

- Hold clutch half way to the floor. (If

• Solid “#” (gear number) but no drive. See equipped)

“Front Box Control Test” on page 292. Gear - Turn on key.

engaged and drives, go to Step E. - If problem continues, call 1-800-826-HELP

(4357)

See “Front Box Control Test” on page 292.

• If no codes and gear display is“--” (2 dashes)

or “**” (2 stars), See “Power-Up Sequence

Test” on page 26.

Purpose: Drive vehicle and attempt to duplicate a

E fault code.

1. Record and clear Inactive fault codes.

2. Drive vehicle and attempt to reset code.

• If no codes are present, test complete.

• If Inactive transmission component or Fault

Codes, record codes an call 1-800-826-HELP

(4357).

• If active transmission component or Fault

Codes, See “Fault Code Isolation Procedure

Index” on page 8.

4 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 General Information | Fault Code Retrieval/Clearing

Fault Code Retrieval/Clearing

Retrieving Fault Codes Manually 6. Observe the sequence of flashes on the service

light and record the codes. A 1- to 2-second pause

Retrieve fault codes by enabling the system’s self-diagnos-

separates each stored code, and the sequence

tic mode.

automatically repeats after all codes have been

Note: You can also use a PC- based service tool, such as flashed.

ServiceRanger to retrieve fault codes.

1. Place the shift lever in neutral. 1 Flash

2. Set the parking brake. SERVICE

3. Turn key on with engine off.

Short

Note: If the engine is already running, you may still Code 13 pause

retrieve codes; however, do not engage the (1/2 sec)

starter if the engine stalls. 3 Flashes

4. To Retrieve Active Codes: Key on. Turn key off and SERVICE SERVICE SERVICE

on 2 times within five seconds ending with the key

on. After 5 seconds, the Service light begins flash-

ing two-digit fault codes. If no faults are active, the

service light will flash code 25 (no codes). This is

also the procedure to enter, See “Product Diagnos-

tic (PD) Mode” on page 11. for details. Long Pause

(3-4 sec)

Note: An “88” may show up in the dash at key on,

which is a normal power-up test of the display.

2x

off on 2 Flashes

SERVICE SERVICE

Short

Code 21 pause

5. To Retrieve Inactive Codes: Turn key on. Turn the (1/2 sec)

key off and on 4 times within five seconds ending

1 Flash

with the key in the on position. After 5 seconds, the

Service light begins flashing two-digit fault codes. SERVICE

If no faults are active, the service light will flash

code 25 (no codes).

4x

off on

• Two digit fault codes will be displayed in the gear

display. Some vehicle may be equipped with a ser-

vice light.

2022.05.18 © 2022 Eaton. All rights reserved. 5

Fault Code Retrieval/Clearing | General Information TRTS0930

Clearing Fault Codes Manually Retrieving Fault Codes with

The following procedure clears all Inactive fault codes from ServiceRanger

the TECU’s memory. Active fault codes are automatically

This section determines if the TECU is communicating on

cleared when the fault has been corrected.

the vehicle's J1939 data link and if the component has set

Note: You may use a PC-based service tool, such as Ser- any fault codes. Proper system operation requires the TECU

viceRanger, to clear fault codes. to communicate with other ECUs on the vehicle's J1939

data link.

1. Place shift lever in neutral.

Note: This procedure requires ServiceRanger 3.0 or later

2. Set parking brake. and an approved RP1210A communications adapter

3. Turn key on with engine off. that supports J1939 communications.

4. Turn key off and on 6 times within 5 seconds end- Detecting Components

ing with key on.

1. Connect the service PC to the vehicle's 9-way

6x J1939 diagnostic port connector with an approved

RP1210A communications adapter.

off on

2. Start the ServiceRanger program and verify that a

connection has been established with the vehicle's

J1939 data link.

• If the TECU is not detected by ServiceRanger,

Note: If the codes have been successfully cleared, the proceed to the Electrical Pretest procedure to

Service light will come on and stay on for five ensure the TECU has power, and that all com-

seconds. The gear display will show 25 (no ponents are properly connected the vehicle's

codes). J1939 data link.

5. Turn the key off and allow the system to power Viewing Fault Codes

down.

View the Vehicle Fault Codes screen in ServiceRanger and

verify if any Active or Inactive codes have been set.

1. If an Active code is present, record the vehicle fault

information and proceed to Diagnostic Procedure

in this manual for the Active code. Do not clear any

codes at this time.

2. If only Inactive codes are present, record the vehi-

cle fault information and clear all fault codes. Road

test the vehicle to verify proper operation.

6 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 General Information | Fault Code Retrieval/Clearing

Clearing Fault Codes with ServiceRanger

After all repairs have been made and the system is function-

ing normally, clear all vehicle codes before placing the vehi-

cle back into service.

Clearing Fault Code

1. Connect the service PC to the vehicle and start Ser-

viceRanger.

2. View the Vehicle Fault Codes screen and select

Clear All.

3. Refresh the screen to verify all Inactive codes have

been cleared, and that no Active codes are present.

2022.05.18 © 2022 Eaton. All rights reserved. 7

Fault Code Isolation Procedure Index | General Information TRTS0930

Fault Code Isolation Procedure Index

Fault Codes SPN PID SID FMI Description

11 629 254 12 No ECU operation

12 629 254 13, 14 Improper ECU configuration

13 751 231 8, 11 J1939 Shift Control device

14 751 18, 19 2, 3, 4, 5 Invalid Shift Lever voltage

(without Park

Pawl)

14 18, 19 2, 3, 4, 5 Invalid Shift Lever voltage

(with Park (will show “F” in display)

Pawl)

15 751 18 9 HIL Shift Device communication

16 625 248 2 High Integrity Link (HIL)

17 1321 237 3, 4, 14 Start Enable Relay Coil

18 520200 34 9 ECA communication

19 520273 248 9 CAN ECA message

21 70 70 14 Auto Neutral Park Brake Switch

22 563 49 9, 14 ABS CAN message fault

25 NO CODES

26 522 55 10 Clutch slip

27 788 55 7, 13 Clutch disengagement

28 788 52,55 3, 4, 5, 7 Clutch system

29 969 372 4, 5 Remote throttle enable

31 1485 218 2, 3, 4, 5, 14 Momentary Engine Ignition Interrupt Relay

(MEIIR)

32 158 43 2 Loss of Switch Ignition power test

33 168 168 4 Low Battery voltage supply

34 168 168 14 Weak Battery voltage supply

35 639 231 2 J1939 communication link

36 639 231 14 J1939 engine message

37 627 251 5 Power supply

41 768 35 7 Range failed to engage

41 769 36 7 Range failed to engage

42 770 37 7 Splitter failed to engage

42 771 38 7 Splitter failed to engage

43 768 35 3, 4, 5 Range High Solenoid Valve

43 769 36 3, 4, 5 Range Low Solenoid Valve

44 787 54 3, 4, 5 Inertia Brake Solenoid Coil

45 787 54 7 Intertia Brake performance

46 770 37 3, 4, 5 Splitter Direct Solenoid Valve

8 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 General Information | Fault Code Isolation Procedure Index

Fault Codes SPN PID SID FMI Description

46 771 38 3, 4, 5 Splitter Indirect Solenoid Valve

51 60 60 2, 3, 4, 10 Rail Position Sensor

52 59 59 2, 3, 4, 7 Gear Position Sensor

56 161 161 2, 3, 4, 5,10 Input Shaft Speed Sensor

57 160 160 2, 3, 4, 5 Main Shaft Speed Sensor

58 191 191 2, 3, 4, 5, 6, 8 Output Shaft Speed Sensor

61 772 39 1, 5, 6, 12 Rail Select Motor

63 773 40 1, 5, 6, 12 Gear Select Motor

64 788 34 2, 7, 12 ECA fault

65 5052 192 5, 2 ECA Speed Sensor fault

66 520271 34 3, 4 ECA Battery Voltage fault

67 520274 158 3, 4, 5 ECA Ignition Voltage fault

68 520274 227 14 Grade Sensor

68 520321 227 13, 14 Grade Sensor

71 560 60 7 Unable to disengage gear

72 772 59 7 Failed to select rail

73 781 58 7 Failed to engage gear

74 518 93 7 Engine speed response fault

74 898 190 7 Engine torque response fault

75* 560 60 14 Power down in gear

81 780 47 7 Gear engagement detected

83 751 18 14 Shift Lever missing

83 752 19 7, 12 Shift Lever missing

84 751 18 13 Shift Control device not configured

84 752 19 13 Park mechanism not calibrated

85 751 18 12 Shift Control device incompatible

99 781 58 14 Direction mismatch

* This code will only be set Inactive

• J1939 Source Address (SA) for Eaton transmis-

sions is 3

• J1587 Module Identifier (MID) for Eaton transmis-

sions is 130

2022.05.18 © 2022 Eaton. All rights reserved. 9

Symptom-Driven Diagnostics Index | General Information TRTS0930

Symptom-Driven Diagnostics Index

Symptom Isolation Procedure

Unable to shift transmission with Up/Down button Up/Down Button Test

Engine starting system complaint Start Enable Relay Contact Test

No J1587 communication J1587 Data Link Test

Gear display shows a dash Front Box Control Test

AutoShift will not engage a gear from Neutral AutoShift Will Not Engage a Gear from Neutral Test

UltraShift DM will not engage a gear from Neutral UltraShift DM Will Not Engage a Gear from Neutral Test

UltraShift AW3 will not engage a gear from Neutral UltraShift AW3 Clutch Engagement Test

AutoShift AS3 shift complaint AutoShift AS3 Shift Complaint Test

UltraShift DM shift complaint UltraShift DM Shift Complaint Test

UltraShift AW3 shift complaint UltraShift AW3 Shift Complaint Test

Shift Lever back light does not work Shift Lever Back Light Test

UltraShift PLUS will not engage a gear from Neutral UltraShift PLUS Will Not Engage a Gear from Neutral

Test

UltraShift PLUS shift complaint UltraShift PLUS Shift Complaint Test

10 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 General Information | Product Diagnostic (PD) Mode

Product Diagnostic (PD) Mode

Product Diagnostic (PD) Mode • If the fault is detected during PD Mode the gear dis-

play will display the active fault. The warning tone

PD Mode is used to help diagnose Inactive codes that may

will only sound when the fault is active and the tone

have been set during normal driving. This diagnostic mode

will stop when the fault is Inactive. The fault will

increases the sensitivity of the fault sensing capability

stay in the gear display until the system is powered

This procedure tests loose, degraded and intermittent con- down.

nections. Use the Active Fault Isolation Procedure to guide

Note: Active codes set during PD Mode will not be

you to the wiring and connectors that are associated with

stored as Inactive.

the Inactive fault codes. Flex the wiring harness and con-

nectors and attempt to recreate the fault after activating PD 7. If a fault is detected, exit PD Mode and perform the

Mode. corresponding Fault Isolation Procedure.

PD Mode is only to be used by a trained service technician 8. To exit PD Mode, turn the key off.

in an authorized dealer.

This procedure is to be used prior to performing fault isola- PD Mode works with the following

tion procedures for component-type codes when there are Inactive codes:

no Active codes present.

11, 13, 14, 15,16, 17, 18, 19, 21, 22, 29, 33, 34, 35, 36, 43,

44, 46, 51, 52, 56, 57, 58, 61, 63, 65, 66, 67, 74, and 99.

To enter PD Mode:

Note: Vehicle will not start in PD Mode. You must turn vehi-

cle key off to exit PD Mode.

1. Vehicle must be stationary, engine off, set vehicle

parking brake.

2. Turn the key off and on 2 times, starting with key

on and ending with key on.

Note: Dash may display an 88 at key on. This is a nor-

mal power-up test of the display.

3. The gear display will flash a 25 then a solid PD

(Product Diagnostic Mode) and the mode will be

activated.

4. The service light shall flash code 25 once indicating

no codes. The service light shall then illuminate

solid to indicate PD Mode until such time that an

Active code is detected or PD Mode is exited.

5. Refer to PD Mode section in Fault Isolation proce-

dure for the Inactive fault to be diagnosed.

6. PD will remain in gear display until an active fault

has been set during the PD Mode fault isolation

procedure.

2022.05.18 © 2022 Eaton. All rights reserved. 11

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Electrical Pretest

Overview

The pretest does not relate to any specific fault code, but

must be completed before performing Fault Code Isolation

table procedures. The pretest verifies the batteries are fully

charged.

All Generation 3 products require the OEM to supply power

to the Electronic Control Unit (ECU) and to the optional

Electric Clutch Actuator (ECA).

Detection

There is no detection process specifically for the basic elec-

trical supply; however, failures of this type are generally

detected by the transmission or driver as some other type

of fault code or symptom.

Fallback

There is no fallback for the electrical pretest; however, it

may affect other systems.

Possible Causes

The pretest can be used for:

• Low batteries

• Starter/Battery connections

• Main power harness to the Transmission Electronic

Control Unit (TECU)

Additional Tools

• Basic hand tools

• Eaton Test Adapter Kit

• Digital Volt/Ohm meter

• Troubleshooting Guide

• Battery Load tester

• ServiceRanger a PC-based service tool

12 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

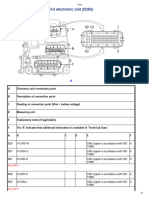

Component Identification

TECU Power Harness

OEM is responsible for overcurrent protection on this cir-

cuit.

+ -

1.

J1

2.

1. 30 AMP Fuse

2. TECU Connector (Vehicle Interface)

2022.05.18 © 2022 Eaton. All rights reserved. 13

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Heavy-Duty Electric Clutch Actuator

(ECA) Power Harness

OEM is responsible for overcurrent protection on this cir-

cuit. ECA products are 12-volt only.

+ -

1.

J1

1. 50 AMP Fuse

14 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

Heavy-Duty Electric Clutch Actuator

(ECA) Power Harness

NOTICE: The TECU and ECA must be wired to a

non-switched power source at the battery. If a disconnect

switch is required, the recommended practice is to wait a

minimum of three minutes before using the disconnect

switch.

It is the OEM responsibility to provide power and ground to

the TECU and ECA from the battery which supplies the

starter.

The power (+) connection must include overload protection

per Federal Motor Carrier Safety Regulations, Section

393.31. The TECU main power and ground must be a direct

connection from the battery posts to the TECU connector.

At 120° C, these conductors must be able to carry 30 amps

@ 9 volts with no more than 0.05 ohms per wire (0.1 ohms

total) for a total voltage drop from the battery posts to the

TECU connector not to exceed 3.0 volts. ECA main power

and ground must be able to carry 50 amps @ 9 volts with

no more than 0.025 ohms per wire (.05 ohms total) at 120°

C. Duration of the 50 amp current draw will not exceed 20

milliseconds.

The main power 30-amp fuse connection for the TECU must

be identified with a tag at the battery.

The main power 50-amp fuse connection for the ECA must

be identified with a tag at the battery.

The battery positive post and negative post must be discon-

nected PRIOR to any type of welding on any Fuller Auto-

mated Transmission-equipped vehicles.

Removal of fuses is not recommended as the method of

disconnecting power from the ECU. Making and breaking a

circuit through tin plated terminals (e.g. ring terminals,

fuses, most connectors) will destroy the plating on the ter-

minal. Opening a switch contact or the main power link is

the recommended method of interrupting power.

Application of more than 36 volts to the system (such as

jump-starting) will cause system shutdown and possible

electrical component damage.

Do not switch off the battery and ignition power and ground

to the TECU during the engine start process.

2022.05.18 © 2022 Eaton. All rights reserved. 15

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Preferred +12 Volt Connections

STARTER BATTERY PLUS 2

GEN 3 ECU BATTERY PLUS

+

+

STARTER BATTERY PLUS 1

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY MINUS

STARTER BATTERY M INUS 1

-

-

STARTER BATTERY M INUS 2

TWO BATTERY BANKS - TWO BATTERIES PER BANK - DUAL JUMPERS TO STARTER

BATTERIES ARE CONNECTED IN PARALLEL BY PAIRS. GEN 3 POWER SUPPLIED BY

BATTERY CLOSEST TO STARTER (BOTH PLUS AND MINUS)

CAB BATTERY PLUS

GEN 3 ECU BATTERY PLUS

STARTER BATTERY PLUS 1

+

+

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY MINUS

STARTER BATTERY M INUS 1

-

ONE BATTERY BANK - FOUR BATTERIES

BATTERIES ARE CONNECTED IN PARALLEL. GEN 3 POWER SUPPLIED FROM

BATTERY CLOSEST TO STARTER WITH CAB POWER. (BOTH PLUS AND MINUS)

CAB BATTERY PLUS

MAG GEN 3 ECU BATTERY PLUS

RELAY

+

STARTER BATTERY PLUS 1

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY MINUS

STARTER BATTERY M INUS 1

-

TWO BATTERY BANKS - TWO BATTERIES PER BANK WITH DISCONNECT

BATTERIES ARE CONNECTED IN PARALLEL BY PAIRS - DISCONNECT FOR CAB AND VEHICLE START -

DISCONNECTED PAIR PROVIDES "DEEP DISCHARGE" CAB COMFORT AND ENTERTAINMENT CAPABILITY.

GEN 3 POWER SUPPLIED FROM BATTERY SET CLOSEST TO STARTER AND COMMON TO CAB POWER

16 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

Preferred +12 Volt Connections

GEN 3 ECU BATTERY MINUS

GEN 3 ECU BATTERY PLUS

+

STARTER BATTERY PLUS

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

BATTERY M INUS STARTER BATTERY MINUS

-

-

VEHICLE BATTERY MINUS

TWO BATTERY BANKS - BATTERY NEGATIVE DISCONNECT SWITCH

BATTERIES ARE DISCONNECTED AT POWER DOWN WHEN VEHICLE STORED INSIDE. GEN 3 POWE R SUPPLIED FROM BATTERY

CLOSEST TO THE STARTER. NEGATIVE CONNECTION AT POINT OF VEHICLE CABLE CONNECTION TO DISCONNECT SWITCH

GEN 3 ECU BATTERY PLUS

(POWER BUS AND

OVER CURRENT

DISTRIBUTION

DEVICES)

MODULE

POWER

STARTER BATTERY PLUS

+

+

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY MINUS

STARTER BATTERY MINUS

-

POWER DISTRIBUTION MODULE

BATTERIES ARE CONNECTED IN PARALLEL, POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE

STARTER. CABLES SIZE AND LENGTH OPTIMIZED FOR LOW VOLTAGE DROP

CAB BATTERY PLUS

GEN 3 ECU BATTERY PLUS Starter Battery Plus

+

+

12 VOLT

12 VOLT

BATTERY

BATTERY

STARTER

-

GEN 3 ECU BATTERY MINUS STARTER BATTERY MINUS

STARTER BATTERY CONNECTION

GEN 3 POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE STARTER.

CAB BATTERY PLUS

GEN 3 ECU BATTERY PLUS

STARTER BATTERY PLUS 1

+

+

12 VOLT

12 VOLT

BATTERY

BATTERY

GEN 3 ECU BATTERY MINUS

STARTER BATTERY MINUS 1

-

ONE BATTERY BANK - TWO BATTERIES

BATTERIES ARE CONNECTED IN PARALLEL. GEN 3 POWER SUPPLIED FROM

BATTERY CLOSEST TO STARTER WITH CAB POWER. (BOTH PLUS AND MINUS)

2022.05.18 © 2022 Eaton. All rights reserved. 17

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Preferred +24 Volt Connections

STARTER BATTERY PLUS

2

STARTER BATTERY PLUS

1

GEN 3 ECU BATTERY

PLUS

+

+

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY

MINUS

STARTER BATTERY MINUS

-

-

1

STARTER BATTERY MINUS

2

TWO BATTERY BANKS - TWO BATTERIES IN SERIES PER BANK - DUAL JUMPERS TO

STARTER

BATTERIES ARE CONNECTED IN SERIES/PARALLEL BY PAIRS. GEN 3 POWER

SUPPLIED BY BATTERY CLOSEST TO STARTER (BOTH PLUS AND MINUS)

CAB BATTERY

PLUS

GEN 3 ECU BATTERY

PLUS

STARTER BATTERY PLUS

1

+

+

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY

MINUS

STARTER BATTERY MINUS

1

-

ONE BATTERY BANK - FOUR BATTERIES - ONE CABLE PAIR TO STARTER

BATTERIES ARE CONNECTED IN SERIES/PARALLEL BY PAIRS. GEN 3 POWER

SUPPLIED FROM BATTERY CLOSEST TO STARTER WITH CAB POWER. (BOTH PLUS

AND MINUS)

CAB BATTERY

PLUS

GEN 3 ECU BATTERY

MAG PLUS

STARTER BATTERY PLUS

RELAY 1

+

+

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY

MINUS

STARTER BATTERY MINUS

-

TWO BATTERY BANKS - TWO BATTERIES PER BANK WITH DISCONNECT

BATTERIES ARE CONNECTED IN SERIES/PARALLEL BY PAIRS - DISCONNECT FOR CAB AND VEHICLE

START - DISCONNECTED PAIR PROVIDES "DEEP DISCHARGE" CAB COMFORT AND ENTERTAINMENT

CAPABILITY. GEN 3 POWER SUPPLIED FROM BATTERY SET CLOSEST TO STARTER AND COMMON TO

CAB POWER

18 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

Preferred +24 Volt Connections

GEN 3 ECU BATTERY

MINUS

GEN 3 ECU BATTERY

PLUS

STARTER BATTERY

+

+

PLUS

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

STARTER BATTERY

-

-

MINUS

BATTERY VEHICLE BATTERY

MINUS MINUS

TWO BATTERY BANKS - BATTERY NEGATIVE DISCONNECT SWITCH

BATTERIES ARE DISCONNECTED AT POWER DOWN WHEN VEHICLE STORED INSIDE. GEN 3 POWER SUPPLIED FROM BATTERY

CLOSEST TO THE STARTER. NEGATIVE CONNECTION AT POINT OF VEHICLE CABLE CONNECTION TO DISCONNECT SWITCH

GEN 3 ECU BATTERY

PLUS

(POWER BUS AND

OVER CURRENT

DISTRIBUTION

DEVICES)

MODULE

POWER

STARTER BATTERY

PLUS

+

+

12 VOLT

12 VOLT

12 VOLT

12 VOLT

BATTERY

BATTERY

BATTERY

BATTERY

GEN 3 ECU BATTERY

MINUS

STARTER BATTERY

MINUS

-

POWER DISTRIBUTION MODULE

BATTERIES ARE CONNECTED IN SERIES/PARALLEL, POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE

STARTER. CABLES SIZE AND LENGTH OPTIMIZED FOR LOW VOLTAGE DROP

CAB BATTERY

PLUS

STARTER BATTERY

PLUS

GEN 3 ECU BATTERY

PLUS

GEN 3 ECU BATTERY

STARTER

MINUS

STARTER BATTERY

MINUS

STARTER BATTERY CONNECTION

GEN 3 POWER PLUS AND MINUS CONNECTED ON BATTERY CLOSEST TO THE STARTER.

2022.05.18 © 2022 Eaton. All rights reserved. 19

Electrical Pretest | Electrical Pretest Procedures TRTS0930

TECU Ignition Circuit

1. 2.

J1

35 3.

4.

29 30 31 32 33 34

37 38

23 24 25 26 27 28

13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12

35 36

1 2 3 4 5 6

1. TECU connector (vehicle interface)

2. 10 AMP only, manual resetting circuit breaker OR

10 AMP fuse

3. Ignition Key Switch

Note: Run to main power lead that feeds the ignition

bus (OEM responsible for overcurrent protection

on this line)

4. TECU Connector (vehicle interface) front view

From To

J1-35 VIGN

Battery and ignition power and ground to the TECU must

not be switched off during the engine start process.

20 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

J1939 Data Link

3.

J1939 High

E D

C

J1939 Low F A B

G J

H

+ Battery

C

J1 D

B

10 F

11 G

A

2.

1.

1. TECU connector (vehicle interface)

2. J1587 Data Link

3. 9-Way, for transmission diagnostics

J1939 Troubleshooting

1. Check the resistance of the J1939 Data Link.

2. Key off. Measure resistance between the 9-way

diagnostic connector Pin C and Pin D and record

the reading. The reading should be 60 ohms of

resistance (between 50 and 70.)

3. Check resistance between Pin C and Pin A and the

resistance between Pin D and Pin A. These two

readings should be 10K ohms or greater (open cir-

cuit).

Note: Pin C = J1939+, Pin D = J1939-, Pin A is a chas-

sis ground

• If an Inactive data link fault code is being reported

by the TECU, See “Product Diagnostic (PD) Mode”

on page 11. PDM should be utilized before any fur-

ther steps are taken.

2022.05.18 © 2022 Eaton. All rights reserved. 21

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Electrical Pretest

Purpose: Measure battery voltage. Visually inspect

A the batteries, inline fuse and power and ground

supplies at the batteries and ECA (if equipped). Purpose: Verify proper ground path between the

B batteries and the transmission harness 4-way diag-

nostic connector.

1. Key off.

2. Remove and clean all battery and battery-to-frame

1. Locate diagnostic port on Transmission Harness.

connections.

2. Key on.

3. Remove and clean ground supply to engine ECU.

3. Measure voltage between Pin C and the battery

4. Inspect starter/battery and inline 30 amp fuse

negative post.

holder connections for corrosion or damaged con-

tacts. Also, inspect the 50 amp fuse holder on vehi-

cles equipped with an Electronic Clutch Actuator

(ECA). Warning! - Do Not Load Test at Diagnostic Port

4-Pin Diagnostics Port

5. Measure voltage across batteries. VOLTS

B A V COM A

• If voltage is 11 to 13 volts on a 12- volt system C D

or 22 to 26 on a 24 volt system, refer to OEM Battery Negative Post

guidelines for battery load test. Repair or

replace batteries as required. Go to Step B.

4-way

Transmission ECU 4-Pin Diagnostic Port B - Service Bat. +

(Located at the left rear C - Service Bat. -

Batteries corner of the transmission.) A - Service Ignition +

– +

30 AMP fuse

– +

• If voltage is 0.70 volts or less, go to Step C.

• If voltage is outside of range, repair battery

ground supply to Transmission Electrical Con-

ECA trol Unit (TECU). Repeat test.

B

C

C B A

ECA 3-Way

Connector

50 AMP fuse

Battery power

(Non-switched power)

run to Battery

• If voltage is outside of range, repair or replace

batteries and charging system as required.

Repeat this step.

22 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

Purpose: Measure proper battery voltage at the Purpose: Measure proper ignition voltage at the

C transmission harness 4-way diagnostic connector. D transmission harness 4-way diagnostic connector.

1. Locate diagnostic port on Transmission Harness. 1. Key on.

2. Key on. WARNING: Do not load test at the diagnostic port.

!

3. Measure voltage between Pin B and Pin C. 2. Measure voltage between Pin A and Pin C.

Warning! - Do Not Load Test at Diagnostic Port Warning! - Do Not Load Test at Diagnostic Port

4-Pin Diagnostics Port 4-Pin Diagnostics Port

B A B A

C D C D

4-way 4-way

4-Pin Diagnostic Port B - Service Bat. + 4-Pin Diagnostic Port B - Service Bat. +

(Located at the left rear C - Service Bat. - (Located at the left rear C - Service Bat. -

corner of the transmission.) A - Service Ignition + corner of the transmission.) A - Service Ignition +

• If voltage is within 0.6 volts of battery voltage, • If voltage is within 0.6 volts of battery voltage,

go to Step D. For non-ECA products, test complete. See

“Diagnostic Procedures” on page 3. Go to

• If voltage is outside of range, Repair battery

Step E.

power supply to TECU. Fuse may be blown.

Repeat test. • If voltage is outside of range, repair ignition

power supply to TECU. Fuse may be blown.

Repeat test.

2022.05.18 © 2022 Eaton. All rights reserved. 23

Electrical Pretest | Electrical Pretest Procedures TRTS0930

Purpose: Measure battery voltage supplied to the

E Electronic Clutch Actuator (ECA).

1. Key off.

2. Disconnect battery negative.

3. Disconnect ECA 3-way connector.

4. Reconnect battery negative.

5. Measure voltage between Pin B and Pin C of 3-way

connector.

Transmission ECU

13 30 29

29

30

Terminating

Resistor

E C

E C

B A

B A

Engine Flywheel Speed Sensor

ECA (Eaton Supplied)

F F

G G

B

C ECA 8-Way

Connector

C B A

ECA 3-Way

Connector

50 AMP fuse

Battery power

(Non-switched power)

run to Battery

• If voltage is within 0.6 volts of battery voltage,

test complete. See “Diagnostic Procedures” on

page 3.

• If voltage is outside of range, repair battery

power supply to ECA. Fuse may be blown.

Repeat test.

24 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Electrical Pretest

2022.05.18 © 2022 Eaton. All rights reserved. 25

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Power-Up Sequence Test

Overview

This test does not relate to any specific fault code, but must

be completed if the self check fails at power-up.

Detection

The TECU checks the program memory every time the key

is turned on.

Fallback

This causes an In-Place fallback while moving and a

self-check failure if it occurs during power-up.

Possible Causes

This fault code can be caused by any of the following:

• Vehicle Harness

• Shift Control Device

• TECU

26 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Component Identification

1. 4.

2.

VOLUME

CONTROL

R

3. N

SERVICE

D

SHIFT

H

L

Eaton Fuller

Transmissions

1. Side view of pushbutton shift control

2. Transmission controller 30-way connector

3. Top view of pushbutton shift control

4. Eaton Cobra Lever

2022.05.18 © 2022 Eaton. All rights reserved. 27

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Power-Up Sequence Test

Purpose: Measure battery voltage. Visually inspect Purpose: Measure proper battery voltage at the

A the batteries, inline fuse and power and ground C transmission harness 4-way diagnostic connector.

supplies at the batteries.

1. Locate diagnostic port on Transmission Harness.

1. Key off.

2. Key on.

2. Remove and clean all battery and battery-to- frame

connections. 3. Measure voltage between Pin B and Pin C.

3. Remove and clean ground supply to engine ECU. WARNING: Do not load test at the diagnostic port.

!

4. Inspect starter/battery and inline 30-amp fuse • If voltage is within 0.6 volts of battery voltage,

holder connections for corrosion or damaged con- go to Step D.

tacts. • If voltage is outside of range, repair battery

5. Measure voltage across batteries. power supply to TECU. Fuse may be blown.

Repeat test.

• If voltage is 11 to 13 volts on a 12-volt system

or 22 to 26 on a 24-volt system, proceed with

battery load test. Repair or replace batteries as

required. Go to Step B.

• If voltage is outside of range, repair or replace

batteries and charging system as required.

Repeat this step.

Purpose: Measure proper ignition voltage at the

D transmission harness 4-way diagnostic connector.

1. Key on.

2. Measure voltage between Pin A and Pin C.

• If voltage is within 0.6 volts of battery voltage,

Purpose: Verify proper ground path between the go to Step E.

B batteries and the transmission harness 4-way diag-

nostic connector. • If voltage is outside of range, repair Ignition

power supply to ECU. Fuse may be blown.

Repeat test.

1. Locate diagnostic port on Transmission Harness.

2. Key on.

3. Measure voltage between Pin C and the battery

negative post.

• If voltage is 0.70 volts or less, go to Step C.

• If voltage is outside of range, repair battery

ground supply to TECU. Repeat test.

28 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Purpose: Visually identify if the vehicle is equipped Purpose: Visually observe the Service light during

E with a shift lever or push button. G key-on power up.

1. Is vehicle equipped with an Shift Lever? 1. Key on.

• If vehicle is not equipped with a Shift Lever, go 2. Observe Service light.

to Step F.

Note: If Service light is flashing, go to Diagnostics

• If vehicle is equipped with a Shift Lever, go to Procedure.

Step K.

• If Service light illuminates for 1 second and

turns off, test complete.

• If Service light never lights, go to Step H.

• If Service light is on steady, replace Shift Con-

trol. Go to Step V.

Purpose: Visually identify if the push button is an

F Eaton built push button or an OEM built J1939

push button.

1. Is it an Eaton Push Button or OEM J1939 Shift

Device?

Purpose: Measure the voltage supply at the Shift

• If an Eaton Push Button Shift Control, go to H Control device.

Step G.

• If an OEM J1939 Shift Device, refer to OEM for 1. Key off.

troubleshooting procedures. 2. Disconnect Shift Control 30-way connector.

3. Key on.

4. Measure voltage between Pin C1 and Pin J3 on the

Shift Control 30-way.

• If voltage is within 1 volt of battery voltage

replace Shift Control. Go to Step V.

• If voltage is outside of range, go to Step I.

2022.05.18 © 2022 Eaton. All rights reserved. 29

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Purpose: Verify that a proper ground path is being Purpose: Visually identify if the shift lever is an Ea-

I supplied to the Shift Control Device through the Ve- K ton built shift lever or an OEM built shift lever.

hicle Harness and test for a short to ground.

1. Is vehicle equipped with an Eaton supplied Shift

1. Key off. Lever or an OEM supplied Shift Lever.

2. Disconnect negative battery cable. • If Eaton Cobra Lever, go to Step L.

3. Disconnect 38-way Vehicle Harness from TECU. • If OEM Shift Lever, go to Step R.

4. Measure resistance between TECU Pin 25 and Shift

Control connector Pin J3 and from then from Pin

J3 to ground.

• If resistance from Pin 25 to J3 is

0 to 0.3 ohms and resistance from J3 to

ground is OL / Open, go to Step J.

• If resistance is outside of range, repair the Purpose: Visually observe the Service light during

Vehicle Harness. Go to Step V. L key-on power up.

1. Key on.

2. Observe Service light.

Note: If Service light is flashing, See “Diagnostic

Procedures” on page 3.

Purpose: Measure the resistance of the ignition • If Service light illuminates for 1 second and

turns off, test complete.

J voltage supply wire to the Shift Control Device

through the Vehicle Harness and test for a short to • If Service light never comes on, go to Step O.

ground.

• If Service light is on steady, go to Step M.

1. Measure resistance between TECU Pin 31 and Shift

Control connector Pin C1 and then from Pin C1 to

ground.

• If resistance from Pin 31 to C1 is 0 to 0.3

ohms and resistance from C1 to ground is 10K

or OL, replace the TECU. Go to Step V.

• If resistance is outside of range, repair the

Vehicle Harness. Go to Step V.

30 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Purpose: Measure the voltage supply to the Service Purpose: Measure the voltage supply to the Service

M light during key-on power up. O light during key-on power up.

1. Disconnect Shift Lever 8-way connector. 1. Key off.

2. Key on. 2. Disconnect Shift Lever 8-way connector.

3. Measure voltage at Pin 6 and ground. 3. Key on.

• If voltage is within 2 volts of battery voltage for 4. Measure voltage between Pin 3 and Pin 6.

one second, then 0 volts, replace the Eaton

• If within 1 volt of battery replace Eaton Cobra

Cobra Lever. Go to Step V.

Lever, go to Step V.

• If voltage is constant, go to Step N.

• If voltage is outside of range, go to Step N.

Purpose: - Test the Service light voltage supply for

N short to power through the Vehicle Harness.

Purpose: Verify that a proper ground path is being

P supplied to the Shift Lever through the Vehicle Har-

ness and test for a short to ground.

1. Key off.

2. Disconnect negative cable. 1. Key off

3. Disconnect 38-way Vehicle Harness connector. 2. Disconnect 38-way Vehicle Harness connector on

TECU.

4. Measure resistance between Pin 6 and Pin 4.

3. Measure resistance between Pin 3 on the 8-way

• If resistance is OL, replace the: connector and Pin 25 on the 38-way connector and

- Medium-Duty Transmission Electronic Con- from Pin 25 to ground.

trol Unit (TECU)

- Heavy-Duty Transmission Electronic Con- Note: On Peterbilt disconnect Gear Display,

trol Unit (TECU)

• If resistance between Pin 3 and Pin 25 is 0 to

Go to Step V. 0.3 ohms and resistance from Pin 25 to

ground is OL, go to Step Q.

• If resistance is less than 10K, repair the Vehi-

cle Harness and go to Step V. • If resistance is outside of range, repair the

Vehicle Harness between the Vehicle Harness

38-way connector Pin 25 and Vehicle Harness

8-way connector Pin 3. Go to Step V.

2022.05.18 © 2022 Eaton. All rights reserved. 31

Power-Up Sequence Test | Electrical Pretest Procedures TRTS0930

Purpose: Measure the resistance of the ignition Purpose: Measure the voltage supply to the Service

Q voltage supply to the Shift Lever through the Vehi- R light during key-on power up.

cle Harness and test for a short to ground.

1. Key off.

1. Key off.

2. Locate Service light connector on Vehicle Harness.

2. Measure resistance between:

3. Key on.

- Vehicle Harness 38-way connector Pin 31 and

Vehicle Harness 8-way connector Pin 4 4. Measure voltage across Pin A and Pin B on the Ser-

- Vehicle Harness 38-way connector Pin 31 and vice light connector

ground • If voltage is within 2 volts of battery voltage for

• If resistance between Pin 31 and Pin 4 is 0 to 1 second, then 0 volts, test complete.

0.3 ohms and if resistance between Pin 31 and • If no voltage is measured, go to Step S.

ground is OL, replace the:

- Medium-Duty Transmission Electronic Con- • If voltage is within 2 volts of battery voltage

trol Unit (TECU) continuously, go to Step T.

- Heavy-Duty Transmission Electronic Con-

trol Unit (TECU)

Go to Step V.

• If any of the above conditions are not met,

replace the Vehicle Harness between Vehicle

Harness 38-way connector Pin 31 and Vehicle

Harness 8-way connector Pin 4. Go to Step V.

32 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Electrical Pretest Procedures | Power-Up Sequence Test

Purpose: Measure the resistance of the service Purpose: Test for a short to power at the Shift Le-

S light supply wire to the Shift Lever through the Ve- T ver Service light.

hicle Harness and test for a short to ground.

1. Key off.

1. Key off.

2. Disconnect negative battery cable.

2. Disconnect negative battery cable.

3. Disconnect TECU 38-way connector.

3. Disconnect 38-way connector.

4. Measure voltage across Service light connector Pin

4. Measure resistance from Pin A of the OEM connec- A and Pin B.

tor to Pin 23 of the 38-way and from Pin 23 to

ground. • If no voltage is measured, replace the:

- Medium-Duty Transmission Electronic Con-

• If resistance from Pin A to Pin 23 is 0 to 0.3 trol Unit (TECU)

ohms and resistance to ground is 10K or - Heavy-Duty Transmission Electronic Con-

greater, replace the: trol Unit (TECU)

- Medium-Duty Transmission Electronic Con-

trol Unit (TECU) Go to Step V.

- Heavy-Duty Transmission Electronic Con- • If voltage is within 2 volts of battery voltage,

trol Unit (TECU) repair Vehicle Harness as required. Go to Step

Go to Step V. V.

• If resistance is outside of range, repair the

Vehicle Harness and go to Step V.

Purpose: Verify that the system will properly power

V up.

1. Key off.

2. Reconnect all connectors and the negative battery

cable.

3. Key on.

• If Power-Up Sequence Test completes, test

complete.

• If Power-Up Sequence Test fails go to Step A.

find error in testing.

2022.05.18 © 2022 Eaton. All rights reserved. 33

Fault Code 11 - No TECU Operation | Fault Isolation Procedures TRTS0930

Fault Code 11 - No TECU Operation

J1939: SA 3 SPN 629 FMI 12

J1587: MID130 PID FMI 12

Overview

This fault code indicates an internal failure of the Transmis-

sion Electronic Control Unit (TECU).

Detection

The TECU checks the program memory every time the key

is turned on and throughout operation. If the TECU is able

to detect a failure within its own memory, it sets this fault

code.

Fallback

This fault causes a vehicle In Place fallback while moving

and a self-check failure if it occurs during power-up.

Possible Causes

This fault code can be caused by the following:

• TECU

34 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 11 - No TECU Operation

Component Identification

1.

1. TECU

2022.05.18 © 2022 Eaton. All rights reserved. 35

Fault Code 11 - No TECU Operation | Fault Isolation Procedures TRTS0930

Fault Code 11 - No TECU Operation

Purpose: Check for active or Inactive fault codes

A

1. Key on.

2. Retrieve codes. See “Fault Code Retrieval/Clearing”

on page 5.

• If Fault Code 11 is Active, replace the:

- Medium-Duty Transmission Electronic Con-

trol Unit (TECU)

- Heavy-Duty Transmission Electronic Con-

trol Unit (TECU)

• If Fault Code 11 is Inactive, test complete.

36 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 11 - No TECU Operation

2022.05.18 © 2022 Eaton. All rights reserved. 37

Fault Code 12 - Improper ECU Configuration | Fault Isolation Procedures TRTS0930

Fault Code 12 - Improper ECU Configuration

J1939: SA 3 SPN 629 FMI 13,14

Overview

This fault code indicates the Transmission Electronic Con-

trol Unit (TECU) is not reading valid information from mem-

ory, including the transmission table and calibration values.

Detection

The TECU checks the configuration every time the key is

turned on. If the transmission is not able to detect the

proper configuration, it sets this fault code.

Fallback

This fault causes a power up no crank.

Possible Causes

This fault code can be caused by the following:

• Improper TECU configuration software

38 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 12 - Improper ECU Configuration

Component Identification

1.

1. TECU

2022.05.18 © 2022 Eaton. All rights reserved. 39

Fault Code 12 - Improper ECU Configuration | Fault Isolation Procedures TRTS0930

Fault Code 12 - Improper ECU Configuration

Purpose: Check for active or Inactive fault codes.

A

1. Key on.

2. Retrieve codes. See “Fault Code Retrieval/Clearing”

on page 5.

• If Fault Code 12 is Active, Customer - Call

Eaton at 1-800-826-HELP (4357). CSC - Call

Technician Service.

• If Fault Code 12 is Inactive, test complete.

40 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 12 - Improper ECU Configuration

2022.05.18 © 2022 Eaton. All rights reserved. 41

Fault Code 13 - J1939 Shift Control Device | Fault Isolation Procedures TRTS0930

Fault Code 13 - J1939 Shift Control Device

J1587: MID130 PID 231 FMI 8, 11

J1939: SA 3 SPN751 FMI 8, 11

Overview

This fault indicates communication has been lost, or does

not correspond with the neutral request input from the

J1939 Shift Device.

When troubleshooting an Inactive code, See “Product Diag-

nostic (PD) Mode” on page 11.

Detection

Starting at key on and throughout operation, the Transmis-

sion Electronic Control Unit (TECU) constantly monitors

communication with the J1939 Shift Device. If a neutral

request from the J1939 Shift Device does not match the

neutral signal or is not received from the J1939 Shift

Device, Fault Code 13 is set.

Fallback

This fault causes a downshift-only fallback. Once the trans-

mission re-engages the start gear, there will be no upshifts

as long as the code is active.

Possible Causes

This fault code can be caused by the following:

• OEM J1939 Shift Control Device

• Vehicle Harness

42 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 13 - J1939 Shift Control Device

Component Identification

3.

1.

2.

J1 16

17

J1939

4.

5.

1. TECU Connector (vehicle interface)

2. Bulkhead connector located at firewall

3. OEM J1939 Shift Device

4. Battery Power (Non-switches power run to battery

or starter)

5. Switched Power

2022.05.18 © 2022 Eaton. All rights reserved. 43

Fault Code 13 - J1939 Shift Control Device | Fault Isolation Procedures TRTS0930

Fault Code 13 - J1939 Shift Control Device

Purpose: Verify continuity of Neutral Request Sig- Purpose: Verify continuity of Neutral Request Re-

A nal wire B turn wire

1. Key off. 1. Measure resistance between 38-way connector Pin

17 and corresponding OEM pin at J1939 Shift

2. Disconnect negative battery cable.

Device and Pin 17 and ground (see OEM wiring for

3. Disconnect Vehicle Harness 38-way connector. correct pin location).

4. Measure resistance between 38-way connector Pin OHMS

16 and corresponding OEM pin at J1939 Shift

Device and Pin 16 and ground (see OEM wiring for

V COM A

29 30 31 32 33 34

37 38

correct pin location) 23 24 25 26 27 28

13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12

OHMS 35

1 2 3 4 5 6

36 J1939

V COM A

29 30 31 32 33 34

37 38

23 24 25 26 27 28

OHMS

13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12

35 36

1 2 3 4 5 6 J1939 V COM A

29 30 31 32 33 34

37 38

23 24 25 26 27 28

13 14 15 16 17 18 19 20 21 22

OHMS 7 8 9 10 11 12

35 36

1 2 3 4 5 6

V COM A

29 30 31 32 33 34

37 38

23 24 25 26 27 28

13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12

35 36

1 2 3 4 5 6 • If resistance is 0 to 0.3 ohms between Pin 17

and the corresponding OEM pin and resistance

to ground is 10K ohms or greater, problem

• If resistance is 0 to 0.3 ohms between Pin 16 exists with the J1939 Shift Device, or J1939

and the corresponding OEM pin and resistance Shift Device power, ground or data link wiring.

to ground is 10K ohms or greater, go to Step Contact your OEM for repair strategy. Go to

B. Step V.

• If resistance is out of range, replace the: • If resistance is out of range, replace the:

- Medium-Duty Transmission Harness - Medium-Duty Transmission Harness

- Heavy-Duty Transmission Harness - Heavy-Duty Transmission Harness

Go to Step V. Go to Step V.

44 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 13 - J1939 Shift Control Device

Purpose: Verify repair.

V

1. Key off.

2. Reconnect all connectors and the negative battery

cable.

3. Key on.

4. Clear codes. See “Fault Code Retrieval/Clearing” on

page 5.

5. Drive vehicle and attempt to reset the code.

6. Check for codes. See “Fault Code Retrieval/Clear-

ing” on page 5.

• If no fault codes, test complete.

• If Fault Code 13 appears go to Step A. to find

error in testing.

• If fault code other than 13 appears, See “Fault

Code Isolation Procedure Index” on page 8.

2022.05.18 © 2022 Eaton. All rights reserved. 45

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl) | Fault Isolation Procedures TRTS0930

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

J1587: MID 130 SID 18, 19 FMI 2, 3, 4, 5

J1939: SA 3 SPN 751 FMI 2, 3, 4, 5

Overview

This fault code indicates an electrical failure of the Eaton

Cobra Lever or OEM Shift Lever.

When troubleshooting an Inactive code See “Product Diag-

nostic (PD) Mode” on page 11.

Detection

Starting at key on and throughout operation the Transmis-

sion Electronic Control Unit (TECU) constantly monitors the

signal from the Park Pawl Position Sensor. The transmis-

sion monitors both sensor signals, if one signal to the TECU

is out of range the code will set.

Fallback

This fault may cause a downshift only fallback mode. The

transmission will re-engage the start gear when returned to

a stop, but will not upshift as long as the code is active.

Possible Causes

This fault code can be caused by any of the following:

• Eaton Cobra Lever or OEM Shift Lever

• Vehicle Harness

• TECU

46 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

Component Identification

2.

1.

1. Eaton Cobra Lever 8-way connector

2. TECU 38-way connector

2022.05.18 © 2022 Eaton. All rights reserved. 47

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl) | Fault Isolation Procedures TRTS0930

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

Purpose: Visually identify the lever type: Eaton or Purpose: Verify continuity of auto mode input wire.

A OEM manufactured. C

1. Is vehicle equipped with an Eaton supplied Shift 1. Key off.

Lever or an OEM supplied Shift Lever?

2. Disconnect negative battery cable.

• If Eaton Cobra Lever, go to Step B.

3. Disconnect TECU 38-way connector.

• If OEM Shift Lever, contact OEM for trouble-

4. Remove tester from Shift Lever 8-way connector.

shooting procedures.

5. Measure resistance between:

- ECU 38-way Pin 15 and Shift Lever 8-way con-

nector Pin 1

- ECU 38-way connector Pin 15 and ground

OHMS

V COM A

Purpose: Install the Shift Lever tester and monitor 37

29 30 31 32 33 34

38

B Transmission Range in ServiceRanger. Utilize the 1 8 23 24 25 26 27 28

2 7 13 14 15 16 17 18 19 20 21 22

Shift Lever Tester to verify transmission-lever in- 3

4

6

5 35

7 8 9 10 11 12

36

1 2 3 4 5 6

terface.

OHMS

1. Key off.

V COM A

2. Disconnect Shift Lever 8-way connector. 29 30 31 32 33 34

37 38

23 24 25 26 27 28

3. Connect Shift Lever tester to the 8-way Shift Lever 13 14 15 16 17 18 19 20 21 22

harness. 35

7

1

8

2

9

3

10

4

11

5

12

6

36

4. Connect ServiceRanger, a PC-based Service Tool,

to diagnostic port.

5. Key on. • If resistance between Pin 15 and Pin 1 is 0 to

0.3 ohms and resistance between Pin 15 and

6. Select Monitor Data.

ground is 10K ohm or greater, go to Step D.

7. Observe transmission range selected.

• If any of the above conditions are not met,

• If transmission range selected equals neutral, repair the OEM Vehicle Harness between the

replace Cobra Lever (only if fault code is TECU and the Eaton Cobra Lever.

Active). Go to Step V.

Go to Step V.

• If transmission range selected does not equal

neutral, go to Step C.

48 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

Purpose: Verify continuity of manual mode input Purpose: Verify continuity of common ground

D wire. E wire.

1. Key off. 1. Key off.

2. Measure resistance between: 2. Measure resistance between:

- TECU 38-way Pin 16 and Shift Lever 8-way con- - TECU 38-way Pin 17 and Shift Lever

nector Pin 8 8-way connector Pin 2

- TECU 38-way connector Pin 16 and ground - TECU 38-way connector Pin 17 and ground

OHMS OHMS

V COM A

V COM A

29 30 31 32 33 34 29 30 31 32 33 34

37 38 37 38

1 8 23 24 25 26 27 28 1 8 23 24 25 26 27 28

2 7 2 7

13 14 15 16 17 18 19 20 21 22 13 14 15 16 17 18 19 20 21 22

3 6 3 6

4 5 7 8 9 10 11 12 4 5 7 8 9 10 11 12

35 36 35 36

1 2 3 4 5 6 1 2 3 4 5 6

OHMS OHMS

V COM A V COM A

29 30 31 32 33 34 29 30 31 32 33 34

37 38 37 38

23 24 25 26 27 28 23 24 25 26 27 28

13 14 15 16 17 18 19 20 21 22 13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12 7 8 9 10 11 12

35 36 35 36

1 2 3 4 5 6 1 2 3 4 5 6

• If resistance between Pin 16 and Pin 8 is 0 to • If resistance between Pin 17 and Pin 2 is 0 to

0.3 ohms and resistance between Pin 16 and 0.3 ohms and resistance between Pin 17 and

ground is 10K ohm or greater, go to Step E. ground is 10K ohm or greater, go to Step F.

• If any of the above conditions are not met, • If any of the above conditions are not met,

repair the Vehicle Harness between the Eaton repair the Vehicle Harness between the Eaton

Cobra Lever and TECU. Go to Step V. Cobra Lever and TECU. Go to Step V.

2022.05.18 © 2022 Eaton. All rights reserved. 49

Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl) | Fault Isolation Procedures TRTS0930

Purpose: Check for short circuits in the shift lever Purpose: Verify repair.

F wiring. V

1. Key off. 1. Key off.

2. Measure resistance between: 2. Reconnect all connectors and the negative battery

- Pin 15 and Pin 16 on the TECU 38-way connector. cable.

- Pin 15 and Pin 17 on the TECU 38-way connector. 3. Key on.

- Pin 16 and Pin 17 on the TECU 38-way connector.

4. Clear codes, See “Fault Code Retrieval/Clearing” on

page 5.

OHMS

OHMS

V COM A

V COM A

5. Drive vehicle and attempt to reset the code.

37

29 30

24

31

25

32

26

33

27

34

28

38 37

29 30 31 32 33 34

38

6. Check for codes. See “Fault Code Retrieval/Clear-

23 23 24 25 26 27 28

13

35

14 15

7

16

8

17

9

18

10

19

11

20

12

21

36

22 13

35

14 15

7

16

8

17

9

18

10

19

11

20

12

21

36

22

ing” on page 5.

1 2 3 4 5 6 1 2 3 4 5 6

OHMS • If no codes, test complete.

V COM A

• If code 14 appears, go to Step A. to find error

37

29

23

30

24

31

25

32

26

33

27

34

28

38

in testing.

13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12

35 36

1 2 3 4 5 6

• If code other than 14 appears, See “Fault Code

Isolation Procedure Index” on page 8.

• If resistance on all three is 10K ohm or greater,

replace Shift Lever and go to Step V.

• If any of the three readings is less than 10K

ohm, repair the Vehicle Harness between the

Eaton Cobra Lever and TECU. Go to Step V.

50 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 14 - Invalid Shift Lever Voltage (without Park Pawl)

2022.05.18 © 2022 Eaton. All rights reserved. 51

Fault Code 14 - Invalid Shift Lever Voltage (with Park Pawl) | Fault Isolation Procedures TRTS0930

Fault Code 14 - Invalid Shift Lever Voltage (with Park Pawl)

J1587: MID 130 SID 18, 19 FMI 2, 3, 4, 5

J1939: SA 3 SPN FMI 2, 3, 4, 5

Overview

This fault code indicates a possible failure of the Park Pawl

Position Sensor or OEM circuit. The sensor is a 4 wire dual

hall effect device. When troubleshooting an Inactive code

See “Product Diagnostic (PD) Mode” on page 11.

Detection

Starting at key on and throughout operation the Transmis-

sion Electronic Control Unit (TECU) constantly monitors the

signal from the Park Pawl Position Sensor. The transmis-

sion monitors both sensor signals, if one signal to the TECU

is out of range the code will set.

Fallback

This fault code will cause the transmission to be stuck in

the last known selected position. If the code comes active

while in gear, the transmission will a down shift only fall-

back mode. The transmission will re-engage the start gear

when returned to a stop, but will not upshift as long as the

code is Active.

Possible Causes

This fault code can be caused by any of the following:

• Vehicle Harness

• Park Pawl Position Sensor

• TECU

52 © 2022 Eaton. All rights reserved. 2022.05.18

TRTS0930 Fault Isolation Procedures | Fault Code 14 - Invalid Shift Lever Voltage (with Park Pawl)

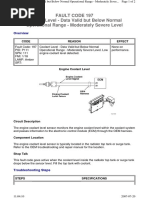

Component Identification

3.

1.

2.

3 4

DEUTSCH

X

2 1

15 4

16 3

F2

17 1

31 2

4.

29 30 31 32 33 34

37 38

24 25 26 27 28

13 14 15 16 17 18 19 20 21 22

7 8 9 10 11 12

35 36

1 2 3 4 5 6

1. Vehicle Harness 38-way Connector

2. 4-Pin Park Pawl Position Sensor Connector

(DTM06-4S)

3. Park Pawl Position Sensor

4. TECU Connector Front View (Vehicle Interface)

4-Way Pin# 38-Way PIN# Type

1 17 Ground

2 31 5 Volt Reference

3 16 Signal 1

4 15 Signal 2

2022.05.18 © 2022 Eaton. All rights reserved. 53

Fault Code 14 - Invalid Shift Lever Voltage (will show “F” in display) | Fault Isolation Procedures TRTS0930

Fault Code 14 - Invalid Shift Lever Voltage (will show “F” in display)

Purpose: Check for active or Inactive fault codes, Purpose: Perform Park Pawl Position Sensor cali-

A noting FMI. C bration.

1. Key on. 1. Perform Park Pawl Position Sensor calibration

2. Retrieve active fault codes and FMIs with Ser- 2. Key on.

viceRanger using the

3. Retrieve active fault codes and FMIs with Ser-

9-way diagnostic connector.

viceRanger using the 9-way diagnostic connector.

• If Fault Code 14 FMI 2 is active, go to Step B.

• If Fault Code 14 FMI 2 is Inactive, go to Step

• If Fault Code 14 FMI 3, 4 or 5 is active, go to V.

Step D.

• If Fault Code 14 FMI 2 is Active, replace Park

• If Fault Code 14 is Inactive, See “Product Diag- Pawl Position Sensor.

nostic (PD) Mode” on page 11.

Purpose: Measure voltage at the Park Pawl Posi-

Purpose: Perform Shift Cable Adjustment proce- D tion Sensor.

B dure.

1. Key off.

1. Key off.

2. Disconnect the Park Pawl Position Sensor 4-way

2. Perform shift cable adjustment procedure per OEM connector.

guidelines.

3. Key on.

3. Key on.

4. At the Park Pawl Position Sensor 4-way connector,

4. Retrieve active fault codes and FMIs with Ser- measure voltage between Pin 1 and Pin 2.

viceRanger using the 9-way diagnostic connector.

• If 4.5 to 5.5 volts, go to Step E.

• If Fault Code 14 FMI 2 is Inactive, go to Step