1387 05

1387 05

Uploaded by

rp801113717Copyright:

Available Formats

1387 05

1387 05

Uploaded by

rp801113717Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1387 05

1387 05

Uploaded by

rp801113717Copyright:

Available Formats

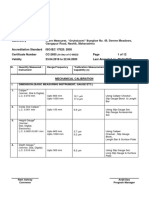

SCOPE OF ACCREDITATION TO ISO/IEC 17025:2017

& ANSI/NCSL Z540-1-1994

MSI-VIKING GAGE

3252 S. Miami Blvd. Suite 125

Durham, NC 27703

Steven Sandlin Phone: 9197979600

CALIBRATION

Valid To: December 31, 2023 Certificate Number: 1387.05

In recognition of the successful completion of the A2LA evaluation process, accreditation is granted to this

laboratory to perform the following calibrations1, 9:

I. Acoustics

Parameter/Equipment Range CMC2 (±) Comments

Sound Level Meters 94 dB @ 1000 Hz 0.47 dB Sound level

calibrator

II. Dimensional

Parameter/Equipment Range CMC2, 4 (±) Comments

Bore Micrometers Up to 12 in (32 + 7.5D) μin Master rings

Up to 304.8 mm (0.82 + 0.19D) μm

Dial Bore Gages

(Bore Gage w/ Indicator) 0.000 01 in 7.1 μin Indicator calibrator

0.000 05 in 30 μin

0.0001 in 58 μin

0.0005 in 290 μin

0.001 in 580 μin

0.000 25 mm 0.18 μm

0.001 mm 0.75 μm

0.0025 mm 1.5 μm

0.01 mm 7.2 μm

0.025 mm 14 μm

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 1 of 18

Parameter/Equipment Range CMC2, 4 (±) Comments

Calipers3 Up to 24 in (6.8 + 9.5L) μin Caliper checker,

(24 to 80) in (230 + 20L) μin gage blocks

Up to 610 mm (0.17 + 0.24L) μm

(610 to 2032) mm (5.9 + 0.52L) μm

Caliper Checkers Up to 12 in (6.1 + 1.2L) μin Electronic indicator

Up to 304.8 mm (0.15 + 0.03L) µm amplifier, gage

blocks

Caliper Gage3 – Up to 7.5 in (16 + 14D) μin Gage blocks,

Internal, External Up to190.5 mm (0.41 + 0.35D) µm ring gages

Depth Step Gages (0.5 to 11.5) in (12 + 3.0L) μin Electronic indicator

(12.7 to 290) mm (0.30 + 0.003L) μm amplifier, gage

blocks

Cylindrical Ring Gages3 Up to 0.425 in 14 μin Universal length

(0.600 to 17.5) in (14 + 0.89D) μin machine, master

rings, gage blocks

Up to 10.80 mm 0.36 μm

(15.24 to 480) mm (0.36 + 0.023D) μm

Disc, Plug and Pin Up to 20 in (7.7 + 1.0D) μin Universal length

Gages3 Up to 508 mm (0.20 + 0.025D) μm machine

Electronic Indicator Up to 0.01 in 9.3 μin Gage blocks,

Amplifier3 Up to 0.254 mm 0.24 μm optical flat

Go/No-go Gages Up to 12 in (17 + 1.1L) μin Vision system

Up to 304.8 mm (0.44 + 0.028L) μm

Up to 20 in (7.7 + 1.0D) μin Universal length

Ext. Measurement (0.20 + 0.076D) μm machine

Up to 11.5 in (12 + 3.0L) μin Electronic indicator

Int. Measurement (0.30 + 0.003L) μm amplifier, gage

blocks

Up to 6 in 0.000 30 in Rings, plugs,

hand tools

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 2 of 18

Parameter/Equipment Range CMC2, 4 (±) Comments

Optical Flats Up to 3 in 4.4 μin Master optical flat

Up to 76.2 mm 0.12 μm

Gage Blocks – Length Up to 20 in (7.7 + 1.0D) μin Universal length

Only Up to 508 mm (0.20 + 0.025D) μm machine

Height Gages3 Up to 40 in (260 + 0.35L) μin Gage blocks

Up to 1016 mm (6.6 + 0.0089L) μm

Indicators/LVDTs3 0.000 01 in 7.1 μin Indicator calibrator

0.000 05 in 30 μin

0.0001 in 58 μin

0.0005 in 290 μin

0.001 in 580 μin

0.000 25 mm 0.18 μm

0.001 mm 0.75 μm

0.0025 mm 1.5 μm

0.01 mm 7.2 μm

0.025 mm 14 μm

Length Standards3 Up to 20 in (7.7 + 1.0D) μin Universal length

Up to 508 mm (0.20 + 0.025D) μm machine

Levels3 Up to 12 in 140 μin Surface plate, sine

Up to 304.8mm 3.5 µm bar, gage blocks

Adjustable Thread Rings Up to 4 in 120 µin Set using master plug

3.0 µm gages. ASME/ANSI

B1.2-1983 and

ASME/ANSI B1.3-

2007

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 3 of 18

Parameter/Equipment Range CMC2, 4 (±) Comments

Micrometers3 – Up to 24 in (0.83 + 16L) μin Gage blocks

Up to 609.6 mm (0.021 + 0.41L) μm

(24 to 48) in (5.4 + 15L) μin Gage blocks

Up to 1219.2 mm (0.14 + 0.38L) μm

Groove Up to 4 in (0.96 + 16L) μin Gage blocks

Up to 101.6 mm (0.025 + 0.41L) μm

Depth Up to 12 in (2.0 + 16 L) μin Gage blocks

Up to 304.8 mm (0.06 + 0.41L) μm

Inside Up to 20 in (12 + 1.0D) μin Universal length

Up to 500 mm (0.30 + 0.025D) μm machine

Specialty Micrometers Up to 4 in (0.96 + 16L) μin Gage blocks

Up to 101.6 mm (0.02 + 0.41L) μm

Parallels Up to 20 in 19 μin Electronic

Up to 508 mm 0.48 μm indicator amplifier

Plain Pins Class ZZ3 Up to 2 in (32 + 9.0L) μin Laser micrometer

Up to 50.8 mm (0.82 + 0.23L) µm

Steel Rules3 Up to 12 in (17 + 1.1L) μin Vision system

Up to 304.8 mm (0.44 + 0.0011L) μm

(12 to 39) in 150 μin Direct comparison

(304.8 to 990.6) mm 3.7 um

Steel Tapes3 Up to 26 ft 0.04 in Direct comparison

(26 to 100) ft 0.055 in

Thickness and Feeler Up to 20 in (7.7 + 1.0D) μin Universal length

Gage3 Up to 508 mm (0.20 + 0.025D) μm machine (ULM)

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 4 of 18

Parameter/Equipment Range CMC2, 4 (±) Comments

Thread Plugs3 –

Major Diameter Up to 8 in (7.6 + 1.3D) μin Universal length

Up to 203.2 mm (0.21 + 0.033D) µm machine

Pitch Diameter Up to 80 TPI (68 + 1.2D) μin Universal length

Up to 4.0 mm pitch (1.7 + 0.03D) µm machine, thread

measuring wires

Tapered Thread Plug Up to 4 in (68 + 1.2D) μin Universal length

Gage – Pitch Diameter Up to 101.6 mm (1.7 + 0.03D) µm machine, gage

blocks

Step Up to 1 in 15 μin

Up to 25.4 mm 0.38 µm Gage blocks

Radius Gages Up to 12 in (17 + 1.1L) μin Vision system

Up to 304.8 mm (0.43 + 0.028L) μm

Surface Finish (2 to 500) µin 5.0 µin Master surface

Testers3 – Ra, Ry, Rz (0.05 to 12.5) µm 0.13 µm finish patch

Surface Finish Standards3 (2 to 500) µin 4.2 µin Direct comparison

– Ra, Ry, Rz (0.05 to 12.5) µm 0.11 µm to master surface

patch

Bolt Protrusion Gauges Up to 12 in (17 + 1.1L) μin Vision system

Up to 304.8 mm (0.43 + 0.028L) μm

Profilometers/ (1 to 669) mils (7.9 + 0.92L) μin Master foils

Coating Thickness (17.0 mm) (0.20 + 0.023L) μm M=nominal

Standards thickness in mils

Foils/shims

Spheres and Balls Up to 6 in (7.9 + 0.92L) μin ULM

Up to 150 mm (0.20 + 0.023L) μm

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 5 of 18

III. Dimensional Testing/Calibration1

Parameter/Equipment Range CMC2, 8 (±) Comments

Surface Finish – Measure5 (2 to 500) µin 4.2 µin Master surface finish

(0.05 to 12.5) µm 0.11 µm patch

Flatness – Measure5 Up to 20 in 28 μin Electronic indicator

Up to 508 mm 0.71 μm

Up to 2 in 4.4 μin Optical flat

Up to 50.8 mm 0.11 μm

Parallelism – Measure5 Up to 20 in 14 μin Electronic indicator

Up to 508 mm 0.36 μm amplifier

Straightness – Measure5 Up to 12 in 22 μin Electronic indicator

Up to 304.8 mm 0.56 μm amplifier

Durometer Calibration: ASTM D2240

(A, B, C, D)

Indentor Extension and Up to 0.2 in 65 µin Optical inspection

Shape – under magnification

Extension Diameter of the Base 45 µin

Diameter of the Frustrum: 0.5 in

Diameter of The Top 45 µin

of The Frustrum: 0.5 in

Angle Diameter of The Base 45 µin

of The Cone: 0.5 in

35° Right Circular Cone Angle 0.015°

Conical Frustrum

30° Cone Cone Angle 0.015°

Radius Tip Radius: 0.25 in 16 µin

Indentor Display Indenter Thickness 45 µin

Indenter Radius 16 µin

Spring Calibration – Force (0 to 100) duro units 0.4 duro units Balance or electronic

force cell

(0 to 5000) gf 0.3 gf

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 6 of 18

IV. Electrical – DC/Low Frequency

Parameter/Equipment Range CMC2, 7 (±) Comments

DC Voltage – Generate3 (0 to 329.999) mV 25 µV/V + 1 µV Fluke 5522A

(0 to 3.2999) V 14 µV/V + 2 µV

(0 to 32.9999) V 16 µV/V + 20 µV

(30 to 329.9999) V 22 µV/V + 150 µV

(100 to 1020) V 22 µV/V + 1.5 mV

DC Voltage – (0 to 200) mV 7 µV/V + 0.50 µV Fluke 8508A

Measure3 (0.2 to 2) V 4.1 µV/V + 0.40 µV

(2 to 20) V 4.1 µV/V + 4.0 µV

(20 to 200) V 5.9 µV/V + 40 µV

(200 to 1050) V 5.9 µV/V + 0.53 mV

DC Current – Generate3 (0 to 3.299 99) mA 0.030 % + 0.080 µA Fluke 5500A

(3.3 to 33) mA 0.030 % + 12 µA

(33 to 330) mA 0.040 % + 31 µA

330 mA to 2.2 A 0.06 % + 120 µA

(0 to 11) A 0.06 % + 330 µA

DC Current –Measure3 (10 to 100) µA 25 µA/A + 0.8 nA Agilent 3458A opt

100 µA to 1 mA 23 µA/A + 5.0 nA 002

(1 to 10) mA 23 µA/A + 50 nA

(10 to 100) mA 37 µA/A + 0.50 µA

(0.1 to 1) A 0.013 % + 10 µA

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 7 of 18

Parameter/Range Frequency CMC2, 7 (±) Comments

AC Voltage –

Generate3

(1.0 to 32.999) mV (10 to 45) Hz 0.11 % + 6 µV Fluke 5522a

45 Hz to 10 kHz 0.023 % + 6 µV

(10 to 20) kHz 0.029 % + 6 µV

(20 to 50) kHz 0.13 % + 6 µV

(50 to 100) kHz 0.43 % + 12 µV

(100 to 500) kHz 0.97 % + 50 µV

(33 to 329.999) mV (10 to 45) Hz 0.040 % + 8 µV

45 Hz to 10 kHz 0.018 % + 8 µV

(10 to 20) kHz 0.02 % + 8 µV

(20 to 50) kHz 0.043 % + 8 µV

(50 to 100) kHz 0.097 % + 32 µV

(100 to 500) kHz 0.25 % + 70 µV

(0.33 to 3.299 99) V (10 to 45) Hz 0.04 % + 50 µV

45 Hz to 10 kHz 0.019 % + 60 µV

(10 to 20) kHz 0.023 % + 60 µV

(20 to 50) kHz 0.036 % + 50 µV

(50 to 100) kHz 0.085 % + 130 µV

(100 to 500) kHz 0.29 % + 600 µV

(3.3 to 32.9999) V (10 to 45) Hz 0.04 % + 650 µV

45 Hz to 10 kHz 0.019 % + 600 µV

(10 to 20) kHz 0.029 % + 600 µV

(20 to 50) kHz 0.043 % + 600 µV

(50 to 100) kHz 0.11 % + 1.6 mV

(33 to 329.999) V 45 Hz to 1 kHz 0.024 % + 2 mV

(1 to 10) kHz 0.025 % + 6 mV

(10 to 20) kHz 0.03 % + 6 mV

(20 to 50) kHz 0.038 % + 6 mV

(50 to 100) kHz 0.25 % + 50 mV

(330 to 1020) V 45 Hz to 1 kHz 0.037 % + 10 mV

(1 to 5) kHz 0.03 % + 10 mV

(5 to 10) kHz 0.037 % + 10 mV

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 8 of 18

Parameter/Range Frequency CMC2, 7 (±) Comments

AC Voltage – Measure3

Up to 200 mV (1 to 10) Hz 0.026 % + 14 µV Fluke 8508A

(10 to 100) Hz 0.021 % + 4.0 µV

100 Hz to 10 kHz 0.02 % + 4 µV

(10 to 30) kHz 0.07 % + 8 µV

(30 to 100) kHz 0.96 % + 20 µV

200 mV to 2 V (1 to 10) Hz 0.026 % + 14 µV

(10 to 40) Hz 0.012 % + 20 µV

(40 to 100) Hz 0.015 % + 20 µV

100 Hz to 2 kHz 0.01 % + 20 µV

(2 to 10) kHz 0.02 % + 20 µV

(10 to 30) kHz 0.03 % + 40 µV

(30 to 100) kHz 0.06 % + 40 µV

(100 to 300) kHz 0.31 % + 2 mV

(2 to 20) V (1 to 10) Hz 0.024 % + 120 µV

(10 to 40) Hz 0.012 % + 20 µV

(40 to 100) Hz 0.015 % + 20 µV

100 Hz to 2 kHz 0.01 % + 20 µV

(2 to 10) kHz 0.02 % + 200 µV

(10 to 30) kHz 0.03 % + 40 µV

(30 to 100) kHz 0.06 % + 40 µV

(100 to 300) kHz 0.31 % + 2 mV

(20 to 200) V (1 to 10) Hz 0.024 % + 12 mV

(10 to 40) Hz 0.012 % + 2 mV

(40 to 100) Hz 0.011 % + 2 mV

100 Hz to 2 kHz 0.01 % + 2 mV

(2 to 10) kHz 0.02 % + 2 mV

(10 to 30) kHz 0.03 % + 4 mV

(30 to 100) kHz 0.07 % + 20 mV

(100 to 300) kHz 0.47 % + 0.2 V

(200 to 1000) V (1 to 10) Hz 0.025 % + 74 mV

(10 to 40) Hz 0.02 % + 21 mV

40 Hz to 10 kHz 0.015 % + 21 mV

(10 to 30) kHz 0.036 % + 42 mV

(30 to 100) kHz 0.091 % + 0.21 V

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 9 of 18

Parameter/Range Frequency CMC2, 7 (±) Comments

AC Current – Generate3

(29 to 329.99) µA (10 to 20) Hz 0.25 % + 0.10 µA Fluke 5522a

(20 to 45) Hz 0.18 % + 0.1 µA

45 Hz to 1 kHz 0.16 % + 0.1 µA

(1 to 5) kHz 0.37 % + 0.15 µA

(5 to 10) kHz 0.97 % + 0.20 µA

(10 to 30) kHz 1.9 % + 0.40 µA

(0.33 to 3.2999) mA (10 to 20) Hz 0.24 % + 0.15 µA

(20 to 45) Hz 0.15 % + 0.15 µA

45 Hz to 1 kHz 0.13 % + 0.15 µA

(1 to 5) kHz 0.25 % + 0.20 µA

(5 to 10) kHz 0.60 % + 0.30 µA

(10 to 30) kHz 1.2 % + 0.60 µA

(3.3 to 32.9999) mA (10 to 20) Hz 0.22 % + 2.0 µA

(20 to 45) Hz 0.11 % + 2.0 µA

45 Hz to 1 kHz 0.050 % + 2.0 µA

(1 to 5) kHz 0.10 % + 2.0 µA

(5 to 10) kHz 0.25 % + 3.0 µA

(10 to 30) kHz 0.49 % + 4.0 µA

(33 to 329.99) mA (10 to 20) Hz 0.22 % + 20 µA

(20 to 45) Hz 0.11 % + 20 µA

45 Hz to 1 kHz 0.05 % + 20 µA

(1 to 5) kHz 0.15 % + 50 µA

(5 to 10) kHz 0.25 % + 100 µA

(10 to 30) kHz 0.49 % + 200 µA

(0.33 to 1.099 99) A (10 to 45) Hz 0.22 % + 100 µA

45 Hz to 1 kHz 0.063 % + 100 µA

(1 to 5) kHz 0.73 % + 1.0 mA

(5 to 10) kHz 3.0 % + 5.0 mA

(1.1 A to 2.999 99) A (10 to 45) Hz 0.22 % + 100 µA

45 Hz to 1 kHz 0.08 % + 100 µA

(1 to 5) kHz 0.73 % + 1.0 mA

(5 to 10) kHz 3.0 % + 5.0 mA

(3 to 10.9999) A 45 Hz to 1 kHz 0.13 % + 2.0 mA

(1 to 5) kHz 3.6 % + 2.0 mA

(11 to 20.5) A 45 Hz to 1 kHz 0.19 % + 5.0 mA

(1 to 5) kHz 3.6 % + 5.0 mA

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 10 of 18

Parameter/Range Frequency CMC2, 7 (±) Comments

AC Current – Measure3

(0 to 200) μA 1 Hz to 10 kHz 0.067 % + 20 nA Fluke 8508A

(10 to 30) kHz 0.20 % + 20 nA

(30 to 100) kHz 0.44 % + 20 nA

200 μA to 2 mA 1 Hz to 10 kHz 0.033 % + 0.2 μA

(10 to 30) kHz 0.088 % + 0.2 μA

(30 to 100) kHz 0.47 % + 0.2 μA

(2 to 20) mA 1 Hz to 10 kHz 0.033 % + 2 μA

(10 to 30) kHz 0.072 % + 2 μA

(30 to 100) kHz 0.47 % + 2 μA

(20 to 200) mA (1 to 10) Hz 0.049 % + 20 μA

10 Hz to 10 kHz 0.031 % + 20 μA

(10 to 30) kHz 0.098 % + 20 μA

200 mA to 2 A 10 Hz to 2 kHz 0.063 % + 0.2 mA

(2 to 10) kHz 0.074 % + 0.2 mA

(10 to 30) kHz 0.3 % + 0.2 mA

(2 to 20) A 10 Hz to 2 kHz 0.085 % + 2 mA

(2 to 10) kHz 0.26 % + 2 mA

Parameter/Equipment Range CMC2, 7 (±) Comments

Resistance – Generate3 (0 to 10.9999) Ω 54 µΩ/Ω + 0.001 Ω Fluke 5522A, 4-wire

(11 to 32.9999) Ω 52 µΩ/Ω + 0.0015 Ω

(33 to 109.9999) Ω 35 µΩ/Ω + 0.0014 Ω

110 Ω to 1.099 99 kΩ 35 µΩ/Ω + 0.002 Ω

(1.1 to 10.9999) kΩ 35 µΩ/Ω + 0.02 Ω

(11 to 109.9999) kΩ 36 µΩ/Ω + 0.2 Ω

110 kΩ to 1.0999 MΩ 40 µΩ/Ω + 2 Ω Fluke 5522A, 2-wire

(1.1 to 3.2999) MΩ 74 µΩ/Ω + 30 Ω

(3.3 to 10.9999) MΩ 0.016 % + 50 Ω

(11 to 32.9999) MΩ 0.032 % + 2.5 kΩ

(33 to 109.9999) MΩ 0.062 % + 3 kΩ

(110 to 329.999) MΩ 0.37 % + 100 kΩ

(330 to 1100) MΩ 1.8 % + 500 kΩ

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 11 of 18

Parameter/Equipment Range CMC2, 7 (±) Comments

Resistance – Measure3 (0 to 2) Ω 20 µΩ/Ω + 4 µΩ Fluke 8508A

(2 to 20) Ω 12 µΩ/Ω + 14 µΩ

(20 to 200) Ω 9.6 µΩ/Ω + 50 µΩ

200 Ω to 2 kΩ 9.4 µΩ/Ω + 0.5 mΩ

(2 to 20) kΩ 9.4 µΩ/Ω + 5 mΩ

(20 to 200) kΩ 9.4 µΩ/Ω + 50 mΩ

200 kΩ to 2 MΩ 10 µΩ/Ω + 1 Ω

(2 MΩ to 20 MΩ 25 µΩ/Ω + 100 Ω

(20 to 200) MΩ 0.013 % + 10 kΩ

200 MΩ to 2 GΩ 0.16 % + 1 MΩ

(2 to 20) GΩ 0.14 % + 10 MΩ

Capacitance – Generate3 (220.0 to 399.9) pF 0.62 % + 10 pF Fluke 5522A

(0.4 to 1.0999) nF 0.62 % + 0.01 nF

(1.1 to 3.2999) nF 0.62 % + 0.01 nF

(3.3 to 10.9999) nF 0.32 % + 0.1 nF

(11 to 109.999) nF 0.31 % + 0.1 nF

(110 to 329.999) nF 0.32 % + 0.3 nF

(0.33 to 1.099 99) µF 0.32 % + 1 nF

(1.1 to 3.299 99) µF 0.32 % + 3 nF

(3.3 to 10.9999) µF 0.32 % + 10 nF

(11 to 32.9999) µF 0.49 % + 30 nF

(33 to 109.999) µF 0.56 % + 100 nF

(110 to 329.999) µF 0.56 % + 300 nF

(.33 to 1.099 99) mF 0.57 % + 1 µF

(1.1 to 3.299 99) mF 0.56 % + 3 µF

(3.3 to 10.9999) mF 0.56 % + 10 µF

(11 to 32.9999) mF 0.91 % + 30 µF

(33 to 110) mF 1.3 % + 100 µF

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 12 of 18

Parameter/Equipment Range CMC2 (±) Comments

Electrical Calibration of

Thermocouples and

Thermocouple Indicating

Systems3 Fluke 5522A

Type B (600 to 800) °C 0.54 °C

(800 to 1820) °C 0.44 °C

Type C (0 to 1000) °C 0.41 °C

(1000 to 1800) °C 0.62 °C

(1800 to 2316) °C 1 °C

Type E (-250 to -100) °C 0.61 °C

(-100 to 650) °C 0.22 °C

(650 to 1000) °C 0.28 °C

Type J (-210 to -100) °C 0.34 °C

(-100 to -30) °C 0.22 °C

(-30 to 150) °C 0.19 °C

(150 to 760) °C 0.23 °C

(760 to 1200) °C 0.29 °C

Type K (-200 to -100) °C 0.41 °C

(-100 to -25) °C 0.24 °C

(-25 to 120) °C 0.22 °C

(120 to 1000) °C 0.33 °C

(1000 to 1372) °C 0.49 °C

Type L (-200 to -100) °C 0.47 °C

(-100 to 800) °C 0.34 °C

(800 to 900) °C 0.25 °C

Type N (-200 to -100) °C 0.51 °C

(-100 to 410) °C 0.21 °C

(410 to 1300) °C 0.36 °C

Type R (0 to 250) °C 0.71 °C

(250 to 1000) °C 0.45 °C

(1000 to 1767) °C 0.51 °C

Type S (0 to 250) °C 0.59 °C

(250 to 1400) °C 0.47 °C

(1400 to 1767) °C 0.57 °C

Type T (-250 to -150) °C 0.77 °C

(-150 to 0) °C 0.31 °C

(0 to 400) °C 0.22 °C

Type U (-200 to 0) °C 0.69 °C

(0 to 600) °C 0.36 °C

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 13 of 18

Parameter/Equipment Range CMC2 (±) Comments

Electrical Calibration of

RTD Indicating Systems3

–

Pt 385, 100 Ω (-200 to 0) °C 0.069 °C Fluke 5522A

(0 to 100) °C 0.092 °C

(100 to 300) °C 0.11 °C

(300 to 400) °C 0.12 °C

(400 to 630) °C 0.15 °C

(630 to 800) °C 0.28 °C

Pt 3926, 100 Ω (-200 to 0) °C 0.069 °C

(0 to 100) °C 0.092 °C

(100 to 300) °C 0.11 °C

(300 to 400) °C 0.12 °C

(400 to 630) °C 0.15 °C

Pt 3916, 100 Ω (-200 to -190) °C 0.31 °C

(-190 to -80) °C 0.061 °C

(-80 to 0) °C 0.063 °C

(0 to 100) °C 0.074 °C

(100 to 260) °C 0.086 °C

(260 to 300) °C 0.098 °C

(300 to 400) °C 0.11 °C

(400 to 600) °C 0.12 °C

(600 to 630) °C 0.28 °C

Pt 385, 200 Ω (-200 to 100) °C 0.059 °C

(100 to 260) °C 0.071 °C

(260 to 300) °C 0.15 °C

(300 to 400) °C 0.16 °C

(400 to 600) °C 0.17 °C

(600 to 630) °C 0.19 °C

Pt 385, 500 Ω (-200 to -80) °C 0.059 °C

(-80 to 100) °C 0.071 °C

(100 to 260) °C 0.074 °C

(260 to 400) °C 0.10 °C

(400 to 600) °C 0.10 °C

(600 to 630) °C 0.14 °C

Pt 385, 1000 Ω (-200 to 0) °C 0.049 °C

(0 to 100) °C 0.061 °C

(100 to 260) °C 0.063 °C

(260 to 300) °C 0.074 °C

(300 to 600) °C 0.086 °C

(600 to 630) °C 0.28 °C

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 14 of 18

Parameter/Equipment Range CMC2 (±) Comments

Electrical Calibration of

RTD Indicating Systems3

– (cont)

PtNi 385, 120 Ω (Nil20) (-80 to 100) °C 0.11 °C Fluke 5522A

(100 to 260) °C 0.17 °C

Cu 427, 10 Ω (-100 to 260) °C 0.36 °C

V. Mechanical

Parameter/Equipment Range CMC2, 6, 8 (±) Comments

Pressure – Measuring (0 to 30) psi 0.07 psi Multifunction

Equipment3 (0 to 100) psi 0.07 psi calibrator

(0 to 200) psi 0.10 psi

(0 to 300) psi 0.06 psi

Up to 10 000 psi 16 psi Deadweight tester

Vacuum – Measuring (-30 to 0) in Hg 0.030 in Hg Multifunction

Equipment3 calibrator

Torque Wrenches3 (4 to 50) lbf·in 0.65 lbf·in Torque transducers

(30 to 250) lbf·in 0.68 lbf·in

(80 to 1000) lbf·in 0.72 lbf·in

(50 to 250) lbf·ft 0.73 lbf·ft

Torque Transducers3 Up to 50 lbf·in 0.81 % Torque arms and

(50 to 250) lbf·in 0.18 % masses

(250 to 1000) lbf·in 0.51 %

Up to 250 lbf·ft 0.20 %

Mass – Measure Up to 5 g 4.2 µg Scales w/ std

(5 to 50) g (0.02 + 0.0038M) mg weights

(50 to 200) g (0.01 + 0.0032M) mg

(201 to 20 000) g (0.48 + 0.007M) mg

22 680.7 g (50 lbs) 350 mg

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 15 of 18

Parameter/Equipment Range CMC2, 4, 6, (±) Comments

Scales and Balances3 Up to 1000lbs 0.018 % + 0.6R Class 6 weights

1g 0.002 mg ASTM Class 1

2g 0.023 mg weights (applied

5g 0.042 mg loads)

10 g 0.065 mg

20 g 0.067 mg

50 g 0.013 mg

100 g 0.22 mg

200 g 0.49 mg

(200 to 500) g 0.80 mg

(1 to 2) kg 18 mg

(2 to 5) kg 19 mg

(5 to 20) kg 150 mg Class 6 weights

VI. Thermodynamics

Parameter/Equipment Range CMC2, , 8 (±) Comments

Relative Humidity – 11 % RH 1.4 % RH Rotronic

Measuring Equipment, 33 % RH HygroPalm/

Fixed Points3 53 % RH saturated salts

75.5 % RH

90 % RH

Relative Humidity – (10 to 90) % RH 1.4 % RH Rotronic HygroPalm

Measure3

Temperature / Humidity (-73 to 190) °C 0.45 °C Rotronic HygroPalm

Recorders3 (11 to 90) % RH 1.4 % RH

Temperature- Measure

Ovens, Furnaces, and (-200 to 420) °C 0.61 °C Fluke 1523 w/ PRT

Freezers3 w/ indicator

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 16 of 18

VII. Time & Frequency

Parameter/Equipment Range CMC2, 8 (±) Comments

Frequency – Measure 10 Hz to 1 MHz 10 µHz/Hz Agilent 53181A w/

option 010

Up to 225 MHz 0.1 µHz/Hz Fluke 8508A

Stop Watches/Time Up to 24 hours 0.35 s Comparison

Measurement3

_____________________

1

This laboratory offers commercial dimensional testing/calibration and on-site calibration services.

2

Calibration and Measurement Capability Uncertainty (CMC) is the smallest uncertainty of measurement

that a laboratory can achieve within its scope of accreditation when performing more or less routine

calibrations of nearly ideal measurement standards or nearly ideal measuring equipment. CMCs represent

expanded uncertainties expressed at approximately the 95 % level of confidence, usually using a coverage

factor of k = 2. The actual measurement uncertainty of a specific calibration performed by the laboratory

may be greater than the CMC due to the behavior of the customer’s device and to influences from the

circumstances of the specific calibration.

3

Field calibration service is available for this calibration. Please note the actual measurement uncertainties

achievable on a customer's site can normally be expected to be larger than the CMC found on the A2LA

Scope. Allowance must be made for aspects such as the environment at the place of calibration and for

other possible adverse effects such as those caused by transportation of the calibration equipment. The

usual allowance for the actual uncertainty introduced by the item being calibrated, (e.g. resolution) must

also be considered and this, on its own, could result in the actual measurement uncertainty achievable on

a customer’s site being larger than the CMC. Field calibration service is available for MSI-Viking Gage,

LLC under their ISO/IEC 17025: 2017 accredited Duncan location, certificate 1387.01. Please review the

corresponding scope of accreditation for specific calibration parameters that are performed in the field.

4

In the statement of CMC, L is the numerical value of the nominal length of the device measured in

inches or millimeters. DL is the diagonal length in inches or millimeters. R is the resolution of the unit

under test. D is the numerical value of the nominal diameter of the device measured in inches or

millimeters. Pitch diameter is measured by the three-wire method. Major diameter is calibrated by direct

measurement. In the statement of CMC, T indicates temperature in degrees Celsius. In the statement of

CMC, H is the Humidity of the reading.

5

This laboratory meets R205 – Specific Requirements: Calibration Laboratory Accreditation Program for

the types of dimensional tests listed above and is considered equivalent to that of a calibration.

6

In the statement of CMC, a percent refers to a percentage of reading unless otherwise noted.

7

The stated measured values are determined using the indicated instrument (see Comments). This

capability is suitable for the calibration of the devices intended to measure or generate the measured value

in the ranges indicated. CMCs are expressed as either a specific value that covers the full range or as a

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 17 of 18

percent or fraction of the reading plus a fixed floor specification.

8

The type of instrument or material being calibrated is defined by the parameter. This indicates the

laboratory is capable of calibrating instruments that measure or generate the values in the ranges indicated

for the listed measurement parameter.

9

This scope meets A2LA’s P112 Flexible Scope Policy.

(A2LA Cert. No. 1387.05) Revised 2/14/2022 Page 18 of 18

Accredited Laboratory

A2LA has accredited

MSI-VIKING GAGE

Durham, North Carolina

for technical competence in the field of

Calibration

This laboratory is accredited in accordance with the recognized International Standard ISO/IEC 17025:2017 General

requirements for the competence of testing and calibration laboratories. This laboratory also meets the requirements of ANSI/NCSL

Z540-1-1994 and R205 – Specific Requirements: Calibration Laboratory Accreditation Program. This accreditation demonstrates

technical competence for a defined scope and the operation of a laboratory quality management system

(refer to joint ISO-ILAC-IAF Communiqué dated April 2017).

Presented this 16th day of December 2021.

_______________________

Vice President, Accreditation Services

For the Accreditation Council

Certificate Number 1387.05

Valid to December 31, 2023

For the calibrations to which this accreditation applies, please refer to the laboratory’s Calibration Scope of Accreditation.

You might also like

- Dynamic Settling Test Procedure - Ramp Up To 350 DegFDocument8 pagesDynamic Settling Test Procedure - Ramp Up To 350 DegFRameez AnwarNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Cross Sections and Solids of RevolutionDocument12 pagesCross Sections and Solids of RevolutionfheraineNo ratings yet

- 1387 03Document31 pages1387 03rp801113717No ratings yet

- 1387 01Document34 pages1387 01rp801113717No ratings yet

- 3332 01Document16 pages3332 01rp801113717No ratings yet

- 5666 01Document20 pages5666 01Daniela CamachoNo ratings yet

- 5666 01Document18 pages5666 01Laura MarquezNo ratings yet

- 3022-01 (1) 3Document34 pages3022-01 (1) 3rp801113717No ratings yet

- 2806 01 PDFDocument33 pages2806 01 PDFAmitNo ratings yet

- 1182 01Document11 pages1182 01Anonymous y3tPCbVrNo ratings yet

- 5825 01Document100 pages5825 01OSCAR YOBANY VEGA HERNANDEZNo ratings yet

- 3312 01Document16 pages3312 01rp801113717No ratings yet

- Flaw Detector Scope Sample PG 4-4150-01Document22 pagesFlaw Detector Scope Sample PG 4-4150-01ebbasinghNo ratings yet

- Fugro Suhaimi Scope of AccreditationDocument20 pagesFugro Suhaimi Scope of AccreditationzipaganredentorefreniiNo ratings yet

- 1741 08Document20 pages1741 08rp801113717No ratings yet

- Novastar Scope of Capabilities 1277 01 As of 04.05.2024Document26 pagesNovastar Scope of Capabilities 1277 01 As of 04.05.2024Fernando SagastumeNo ratings yet

- 1741 14Document22 pages1741 14Laura MarquezNo ratings yet

- 1078 01Document51 pages1078 01Jessica ChiluisaNo ratings yet

- 1078-01 3Document54 pages1078-01 3vaibhavinst4No ratings yet

- 1032 01Document7 pages1032 01rp801113717No ratings yet

- 1078 01Document51 pages1078 01ebbasinghNo ratings yet

- 6092 01Document8 pages6092 01Laura MarquezNo ratings yet

- 1297 01Document16 pages1297 01ebbasinghNo ratings yet

- MEMS Digital In-Place Inclinometer SystemDocument2 pagesMEMS Digital In-Place Inclinometer SystemSpeedraw FremyNo ratings yet

- 3467 01Document20 pages3467 01Laura MarquezNo ratings yet

- 4194 01Document8 pages4194 01rp801113717No ratings yet

- 1888 03Document38 pages1888 03rp801113717No ratings yet

- 4038-01 (1) 2Document43 pages4038-01 (1) 2vaibhavinst4No ratings yet

- ScopeDocument25 pagesScopeAlbert E. Cairns JrNo ratings yet

- EGV Calibration CertificateDocument11 pagesEGV Calibration CertificatePhuong NguyenNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument2 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksrohanmanimaniNo ratings yet

- 2367 01Document19 pages2367 01rp801113717No ratings yet

- Test CMM 2016 Hand-OutDocument42 pagesTest CMM 2016 Hand-OutHernanda ImawanNo ratings yet

- 1395 12Document22 pages1395 12rp801113717No ratings yet

- 3467 01Document19 pages3467 01Sheik Mohamed AliNo ratings yet

- 1888 03Document36 pages1888 03Laura MarquezNo ratings yet

- Alpha A2LA CertificateDocument5 pagesAlpha A2LA CertificateNg Wei LihNo ratings yet

- Quantity Measured/ Instrument Range / Frequency Calibration Measurement Capability ( ) RemarksDocument6 pagesQuantity Measured/ Instrument Range / Frequency Calibration Measurement Capability ( ) RemarksRavichandran DNo ratings yet

- 0866 01Document11 pages0866 01ebbasinghNo ratings yet

- Asth 5Document31 pagesAsth 5huidhyiuodghNo ratings yet

- Godrej Nabl ScopeDocument11 pagesGodrej Nabl ScopeRavichandran DNo ratings yet

- Fugro Suhaimi Scope of AccreditationDocument19 pagesFugro Suhaimi Scope of AccreditationzipaganredentorefreniiNo ratings yet

- CL-151-Cert RICI LabDocument16 pagesCL-151-Cert RICI LabzipaganredentorefreniiNo ratings yet

- 4286 04Document19 pages4286 04rp801113717No ratings yet

- 2836 01Document6 pages2836 01rp801113717No ratings yet

- CL 273 Cert - 2Document17 pagesCL 273 Cert - 2rohanmanimaniNo ratings yet

- 4282 01Document11 pages4282 01rp801113717No ratings yet

- Adobe Scan 02-Jul-2022Document5 pagesAdobe Scan 02-Jul-2022Shamsher SinghNo ratings yet

- Perfect 684Document4 pagesPerfect 684Ravichandran DNo ratings yet

- Sl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksDocument12 pagesSl. Quantity Measured / Instrument Range/Frequency Calibration Measurement Capability ( ) RemarksVAIBHAV INSTRUMENTATIONNo ratings yet

- 1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedDocument22 pages1823-01 - A2la - Iso 17025 - Schope - Cert - 2020-2022 - Rlws - Concord-Ca - RevisedLeandroNo ratings yet

- Laboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraDocument12 pagesLaboratory: Micro Measures, "Gruhalaxmi" Bunglow No. 49, Serene Meadows, Gangapur Road, Nashik, MaharashtraVAIBHAV INSTRUMENTATIONNo ratings yet

- 1395 03Document21 pages1395 03rp801113717No ratings yet

- 2010 01Document14 pages2010 01Daniela CamachoNo ratings yet

- Fixed PointsDocument11 pagesFixed Pointsrp801113717No ratings yet

- Tespa 0091 - ChennaiDocument8 pagesTespa 0091 - ChennaiRavichandran DNo ratings yet

- 2010 01Document15 pages2010 01rp801113717No ratings yet

- Trescal Calibration LA 2013 0551 C 1Document53 pagesTrescal Calibration LA 2013 0551 C 1thorster12345No ratings yet

- 4286 04Document18 pages4286 04carlos ricardo herrera castilloNo ratings yet

- MikronixDocument3 pagesMikronixrohanmanimaniNo ratings yet

- MACH KogameDocument8 pagesMACH Kogamelmv2022newNo ratings yet

- Scope 49029 CC 3068 1711737441Document59 pagesScope 49029 CC 3068 1711737441rp801113717No ratings yet

- 4286 04Document19 pages4286 04rp801113717No ratings yet

- Scope CC 2660Document12 pagesScope CC 2660rp801113717No ratings yet

- Scope 54971 CC 2745 1689070219Document30 pagesScope 54971 CC 2745 1689070219rp801113717No ratings yet

- 4282 01Document11 pages4282 01rp801113717No ratings yet

- 2855 02Document5 pages2855 02rp801113717No ratings yet

- 1032 01Document7 pages1032 01rp801113717No ratings yet

- 4870 01Document15 pages4870 01rp801113717No ratings yet

- 3312 01Document16 pages3312 01rp801113717No ratings yet

- 4286-01 2Document28 pages4286-01 2rp801113717No ratings yet

- 3022-01 (1) 3Document34 pages3022-01 (1) 3rp801113717No ratings yet

- 2448-01 2Document3 pages2448-01 2rp801113717No ratings yet

- 3633-02 5Document15 pages3633-02 5rp801113717No ratings yet

- CL 267 Cert - 4Document7 pagesCL 267 Cert - 4rp801113717No ratings yet

- The Amount of Space Enclosed in A Figure. Expressed in Cubic MetersDocument14 pagesThe Amount of Space Enclosed in A Figure. Expressed in Cubic MetersFuriousJC28No ratings yet

- LeaP Math G6 Week 1 Q3Document4 pagesLeaP Math G6 Week 1 Q3Katherine FaithNo ratings yet

- Analytical Geometry of Straight Conical Involute GearsDocument15 pagesAnalytical Geometry of Straight Conical Involute GearsJoy JungNo ratings yet

- Fragmentation WarheadsDocument21 pagesFragmentation Warheadshkrisnas1664No ratings yet

- Fluid Mechanics (QB) 13thDocument16 pagesFluid Mechanics (QB) 13thRaju SinghNo ratings yet

- 1.0 Basic Orthogonal CoordinatesDocument8 pages1.0 Basic Orthogonal Coordinatesjmafeng9No ratings yet

- Spray PatternDocument1 pageSpray PatternkapsarcNo ratings yet

- Right Circular ConeDocument6 pagesRight Circular ConeShannon May Ancheta PasulNo ratings yet

- Mathematical Solids Final Project ReportDocument26 pagesMathematical Solids Final Project ReportPaul NjugunaNo ratings yet

- Fastshapes - Sprocket: Typical ApplicationsDocument23 pagesFastshapes - Sprocket: Typical ApplicationsJimmy MyNo ratings yet

- Apedcet-2023: Instruction BookletDocument38 pagesApedcet-2023: Instruction BookletSankaraSatyadevNo ratings yet

- Chapter 13 Surface Areas and Volumes1Document34 pagesChapter 13 Surface Areas and Volumes1Ashwani KumarNo ratings yet

- April2019 Merged PDFDocument64 pagesApril2019 Merged PDFlinithaNo ratings yet

- Syllabus For All Branches Regulation 2008Document56 pagesSyllabus For All Branches Regulation 2008sudentsideaNo ratings yet

- Mathematics: CBSE Sample Paper-01 Summative Assessment - Ii Class - XDocument4 pagesMathematics: CBSE Sample Paper-01 Summative Assessment - Ii Class - XnathanNo ratings yet

- GR 11 Term 3 2019 Maths Resource PackDocument39 pagesGR 11 Term 3 2019 Maths Resource Packanelemtolo773No ratings yet

- DrawingDocument3 pagesDrawingBipin KarkiNo ratings yet

- Math6 Q4 M3Document12 pagesMath6 Q4 M3aljun.alpajaroNo ratings yet

- Illuminati - 2019: Advanced Mathematics Assignment-2B Conic SectionDocument10 pagesIlluminati - 2019: Advanced Mathematics Assignment-2B Conic SectionRitesh RohanNo ratings yet

- Operating Instructions: Sand Density Cone, 12" (305 MM)Document9 pagesOperating Instructions: Sand Density Cone, 12" (305 MM)luis VeramendiNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/42Document20 pagesCambridge IGCSE: MATHEMATICS 0580/42DanielNo ratings yet

- Dsumc Detailed Lesson Plan in Mathematics 6: Teachers Activity Pupils Activity A. Preliminary A. PrayerDocument8 pagesDsumc Detailed Lesson Plan in Mathematics 6: Teachers Activity Pupils Activity A. Preliminary A. PrayerYan YanNo ratings yet

- Detailed Solutions A-02 June 2003: All Dimensions Are in MMDocument24 pagesDetailed Solutions A-02 June 2003: All Dimensions Are in MMAdzLinkBalaoangNo ratings yet

- 1HDocument18 pages1HFardeen AhmedNo ratings yet

- Development of Surfaces-Engineering DrawingDocument1 pageDevelopment of Surfaces-Engineering DrawingVedang BaleNo ratings yet

- Java AssignmentDocument87 pagesJava AssignmentBadBoy GamingNo ratings yet

- Activity Week 3Document5 pagesActivity Week 3Jessa BasisterNo ratings yet

- Lab Practice # 07 Drawing 3D Shapes ObjectivesDocument4 pagesLab Practice # 07 Drawing 3D Shapes Objectivesگيدوڙو ماڇيNo ratings yet