Nor Sand

Nor Sand

Uploaded by

rdey36886Copyright:

Available Formats

Nor Sand

Nor Sand

Uploaded by

rdey36886Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Nor Sand

Nor Sand

Uploaded by

rdey36886Copyright:

Available Formats

PLAXIS

CONNECT Edition V21.00

User Defined Soil Models - NorSand: An elasto-plastic model for soil

behaviour with static liquefaction

Last Updated: June 16, 2023

Table of Contents

Chapter 1: Introduction ............................................................................................................ 3

1.1 General concepts ..................................................................................................................................................................... 4

1.2 Mathematical Notation ......................................................................................................................................................... 5

Chapter 2: Model Formulation ..................................................................................................7

2.1 Operating friction ratio Mi ................................................................................................................................................10

2.2 Softening parameter S ........................................................................................................................................................ 11

2.3 Soil state measurements ................................................................................................................................................... 12

Chapter 3: Model Parameters ................................................................................................. 14

3.1 Critical state locus: parameters Γ, λe or Ca, Cb and Cc ......................................................................................... 14

3.2 Dilation limit: parameter χtc ............................................................................................................................................ 14

3.3 Strength parameter: Mtc and N ......................................................................................................................................15

3.4 Plastic hardening: parameter Ho and HΨ ..................................................................................................................15

3.5 Elasticity: properties G100, nG and ν ...........................................................................................................................15

3.6 Typical Values ........................................................................................................................................................................ 16

Chapter 4: Model performance and numerical validation ....................................................... 20

4.1 Model Performance ............................................................................................................................................................. 20

4.2 Numerical validation ...........................................................................................................................................................24

Chapter 5: UDSM implementation in PLAXIS finite element code ............................................27

5.1 Material Parameters ............................................................................................................................................................27

5.2 State variables ........................................................................................................................................................................29

Chapter 6: Finite Element Analyses ......................................................................................... 31

Chapter 7: References .............................................................................................................35

PLAXIS 2 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Introduction

1

NorSand (NS) is a critical state soil model within the wider theory of work-hardening plasticity. Critical State Soil

Mechanics (CSSM) applies across the spectrum of soil types and states, from soft clays through to dense sands.

Originating in work by the US Army Corp of Engineers for Franklin Falls dam (Lyman, 1938 (on page 35)),

their canonical relation of the critical state to soil behaviour combines with the Taylor-Bishop strength model

(Bishop, 1950 (on page 35)), using the stability postulate (Drucker, 1951 (on page 35)), to give a general

framework with the particular attribute of computing the effect of void ratio on soil behaviour from fundamental

principles. NorSand (NS) is a strict implementation of CSSM, using the state parameter (the difference between

the void ratio and its critical value at the current stress, Figure 1 (on page 3)) as a key controlling variable.

Figure 1: Definition of state parameter ψ, and over-consolidation ratio R (figure after Jefferies, 2016).

The "Sand'' in the NS name is only there to emphasize NS ability to properly represent dilation found with dense

soils, although the most prominent use of the model has been to simulate static liquefaction of loose silts (e.g.,

Fundao Dam, Morgenstern et al, 2016; Cadia Dam, Morgenstern et al, 2019; and Brumadinho Dam, Robertson et

al, 2020). Soil properties in NS are mostly standard in the geotechnical community and do not vary with void

ratio or confining stress. All properties are defined under triaxial compression (as conventional in geotechnical

laboratory testing). In principle, a minimum of three triaxial compression tests are required; practically, a few

more are needed to give precision and redundancy.

NS is a state model, and thus requires the initial/in situ state parameter to be defined as an input; most users

will derive this input from CPT data but other methods can be used. The inputs of the model specifying the initial

states are denoted through the subscript o to emphasize that they are initial values specified by the user. NS is an

effective stress model, computing undrained behaviour and offering also options as to how soil behaviour is

represented, in particular the form of the operating zero-dilation friction ratio and the nature of the critical state

PLAXIS 3 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Introduction

General concepts

locus. This NS implementation is for standard monotonic loading, drained or undrained, with a particular focus

on static liquefaction. Specifically, this release is consistent with the version of NS given in Appendix C of Jefferies

and Been (2016) (on page 35) with minor updates for improved computational performance.

1.1 General concepts

Before detailing the proposed implementation of the model, some general concepts related to the elasto-plastic

theory are recalled hereafter:

• The strain is additively split in the elastic and plastic components, respectively:

εijt = εijel + ε pl⋅

ij

• The stress σij is computed with isotropic elasticity:

σij = Cijkl ε el ⋅

kl

• The yield surface f is used to define the elastic domain and admissibility of the stress state.

• The plastic flow of the model is prescribed through a flow rule:

ε̇ ijpl = Λ ( )

∂g

∂ σij

where g represents the plastic potential function and prescribes the direction of the plastic flow. Λ stands for the

plastic multiplier which allows one to calculate the amount of plastic strain.

• A similar equation is also defined to govern the evolution of the variable Γi of the model: Γi = Λh i , where hi

is the hardening vector of the model.

• The state of the material is governed by the so-called Khun-Tucker hardening conditions:

f (σij , Γk ) ≤ 0, Λ f (σij , Γk ) = 0, Λ≥0

if f < 0 then the material state is elastic (i.e., Λ = 0 ), otherwise f = 0 means that the state of the material

can be in plastic or neutral loading (i.e., Λ = 0 corresponds to neutral loading while Λ > 0 is the condition for

plastic loading). Plastic or neutral loading can be determined by considering further conditions, the so-called

persistency conditions:

ḟ (σij , Γk ) ≤ 0, Λ ḟ (σij , Γk ) = 0, Λ≥0

where

ḟ < 0 = Elastic unloading.

ḟ = 0 , Λ > 0 = Plastic loading.

ḟ = 0 , Λ = 0 = Neutral loading.

PLAXIS 4 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Introduction

Mathematical Notation

1.2 Mathematical Notation

It is common practice in geomechanical modeling to express the stress dependency of the yield and plastic

potential surfaces as a function of stress invariants, i.e., the mean stress p, the stress deviator q and the Lode's

{

angle θ. They are defined as:

tr (σ ) σij δij σxx + σ yy + σ yy

p= 3

= 3

= 3

3 3

q= 2 (sij sij ) = 2

s

θ=

1

3

arcsin 6 ( tr (s

tr (s

3)

2)3/2 )

where sij is the deviator component of the stress state (i.e., sij = σij - p·δij , δij is Kronecker's symbol) and the trace

tr(·) gives the sum of the diagonal terms of the matrix (i.e., tr(σij) = σxx + σyy + σzz = 3P).

A general representation of the stress deviator and its norm is reported as:

σxx - p σxy σxz

sij = σ yx σ yy - p σ yz

σzx σzy σzz - p

s = (σxx - p )2 + (σ yy - p )2 + (σzz - p )2 + 2(σxy

2 2

+ σzy + 2

σzx )

Analogously, similar quantities are defined also for the strain tensor εij:

{ εv = εxx + ε yy + εzz

εq =

2

3 (εsij εsij ) =

2

3

εs

where ευ represents the volumetric strain, εs is the strain deviator which is defined as: εs = εij - ( εv ⋅ δij )

ij ij /3 .

εxx - εv / 3 εxy εxz

εs = ε yx ε yy - εv / 3 ε yz

ij

εzx εzy εzz - εv / 3

εs = (ε xx -

εv 2

3

+ ) (ε yy - 3

) (ε

εv 2

+ zz - 3

)

εv 2

+2(εxy2 + εzy2 + 2

εzx )

For triaxial stress paths (σxx = σyy < σzz, σxz = σxy = σyz = 0), the general definition of invariants can be simplified

as:

p = (σzz + 2σxx ) / 3 q = |σzz - σxx |

εv = (εzz + 2εxx ) / 3 εq = 2|εzz - εxx | / 3

PLAXIS 5 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Introduction

Mathematical Notation

In this context, the deviatoric and volumetric plastic strain are computed as:

{ ( ∂∂ gp )

p

ε̇ v = Λ

Dp =

∂g

/ ∂g

ε̇ v = Λ ( ∂ q )

∂p ∂q p ∂g

where Dp represents the so-called dilatancy function.

Hereafter, a positive compression convention will be adopted in accordance with the usual soil mechanics

framework. All stress measures are considered as effective and, for the sake simplicity, the superscript ',

commonly used in soil mechanics notation, will be omitted.

PLAXIS 6 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

2

Like other work-hardening plasticity models, NS is characterized by: pressure dependent elasticity, a yield

surface, a plastic flow-rule and a hardening law. A central feature of NS is that it is based on a work dissipation

postulate, which is a generalized formulation of the Taylor-Bishop strength mode (Bishop, 1950 (on page 35)),

thus requiring that the stress and strain measures must be 'work conjugate' for all stress combinations. For this

purpose, the invariants introduced by Resende and Martin (1985) (on page 35) are adopted in the model

formulation. While the stress invariants p and q are those that are standard in plasticity theory (and used in

p p

other PLAXIS models) the matching invariants of strain increments ε̇ v and ε̇ q are less familiar. NS uses the

simple postulate that plastic work is only dissipated in distortion resulting to one form of stress-dilatancy which

is the fundamental flow-rule adopted. This is largely the same as Original Cam Clay (Schofield and Wroth, 1968

(on page 35)), the difference being that NS allows the dissipation parameter (the zero-dilatancy 'frictional

dissipation' stress ratio Mi) to vary with soil state under control of the soil property N rather than being just a

function of the stress ratio Mtc which corresponds to critical state friction (Figure 2 (on page 8)). The third

stress invariant, the Lode angle θ, does no work and is thus unconstrained by the work dissipation postulate

other than the particular symmetries of triaxial compression and extension; the effect of θ is represented by an

empirical modifying function for the flow-rule based on data from plane strain tests in sand (Conforth, 1961 (on

page 35)).

NS also adopts Drucker’s stability postulate such that the work-conjugate plastic strain increment vector is

always normal to the yield surface in the p-q plane. The basic NS yield surface is derived by using the adopted

normality and the work-dissipation postulate, with the yield surface scaled by the 'image' stress pim which is the

stress state when Dp=0 (this is sometimes called the 'pseudo steady state' or the 'phase-change'). The

requirement to limit dilation, in accordance with state-dilatancy (i.e., D p < χtc Ψ = D pmin ) is met by limiting the

yield surface hardening such that pim< pmx with pmx defined as a function of the miminum dilatancy;

correspondingly, the hardening law has the form of a first-order rate equation, but with an evolving target. This

gives NS a form of double-hardening where the yield surface evolves quickly to its current limiting size

(conceptually associated with the formation of particle contacts) and tracks the evolution of this hardening limit

which depends entirely on the state parameter. Thus, the yield surface can be established under any stress

regime with the evolution to the critical state arising under distortional strain for increasing value of the stress

ratio η=q/p; loading paths of constant or decreasing η are 'consolidation' without the soil tending to its critical

state. Because the yield surface is decoupled from the critical state locus (CSL), an additional soil property is

needed to describe the rate at which the yield surface responds to distortional strain: the hardening modulus, H.

The corollary of this decoupling is that the CSL can have whatever form is needed to represent a soil, the only

restriction being that the CSL must be a monotonic decreasing function of mean stress to be physically

reasonable. Two popular forms of the CSL are implemented and they are reported here below with the entire set

of constitutive equations defining NS model:

PLAXIS 7 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

Figure 2: llustration of the yield surface and limiting stress ratios for (a) very loose sands and (b) very dense sands

(Figure after Jefferies, 2015)

• Yield Surface:

f = q − ηp with η = M i 1 + ln ( )

pim

p

Eq. [1]

PLAXIS 8 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

{

• Flow rule:

p

z3,tc =

2Dtcp − 3

2Dtcp + 6

; Dtcp = D p ( )

M i,tc

Mi

ε̇ 3

= z3,tc − ( z3,tc − z3,te )cos ( 3θ

+

π

)

( )

p 2 4

ε̇ 1 2Dtep + 6 M i,te

z3,te = ; Dtep = D p

2Dtep − 3 Mi Eq. [2]

{ a(θ) = (sin(θ) + 3cos(θ )) / 3

dε 3

p aD p − 1 + (cD p − 1)

dε 1

ε̇ 2 b(θ ) = − 2sin(θ ) / 3

p

=

ε̇ 1 1 − bD p c(θ) = (sin(θ) − 3cos(θ )) / 3

where the dilatancy function D P is defined as D P = M i − η.

• Critical state locus:

{

Option (a) e c = Γ − λln ( p ) Ψ = e − ec ( p )

Option (b) ec = Ca − Cb ( )

pref

p Cc with

Ψi = e − ec ( pim)

Eq. [3]

• Hardening:

ṗ im = H

p Mi

pim M i,tc ( pmx − pim) − Ssoft p

ε̇ q p mx = pexp − ( χtc

M i,tc

Ψ ) Eq. [4]

It is worth remarking that the flow rule expressed as a function of the ratio of plastic strain increments (Eq. [2])

can be recast through a gradient of the plastic potential, consistently with an elasto-plastic framework. By

employing the invariants introduced by Resende and Martin (1985) (on page 35) and the normality rule used

to calculate the deviatoric plastic strain increment (i.e., ε̇ q = Λ ∂ f

p

( / ∂ q) = Λ), the plastic flow is rewritten as:

( )

∂g ∂g

˙p q + pD p ∂ σ1

˙p εq ∂ σ1

ε1 σ1 + z2σ2 + z3σ3

∂g ∂g

˙p ˙p z2 ∂ σ

ε2 = z2ε 1 =Λ 1 =Λ ∂ σ2 Eq. [5]

˙p ∂g

ε3 ˙p ∂g

z3ε 1 z3 ∂ σ ∂ σ3

1

Soil elasticity usually shows a dependence of both bulk and shear moduli on mean effective stress (i.e., K and G,

respectively), as well as some dependence on void ratio. A constant Poisson's ratio is adopted to relate G and K

to avoid unconservative elastic idealization. The shear modulus G is defined through a power-law expression

which uses an exponent nG to further characterize soil behaviour. No effect of void ratio on G and K is included

in this PLAXIS release of NS as such effects are generally minor within any defined soil stratum:

• Elasticity:

G = Gref ( ) p

pref

nG

Eq. [6]

K = 2G ( 31−+ 6νν )

PLAXIS 9 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

Operating friction ratio Mi

2.1 Operating friction ratio Mi

Two options are offered for the zero-dilatancy friction ratio Mi (Figure 3 (on page 10)), which are both based

on the idea suggested by Li and Dafalias (2000) (on page 35) that Mi should depend on Ψ.

Figure 3: Formulation of friction ratio Mi according to Li and Dafalias (2000) and Bishop (1950)

Mi requires a two-stage evaluation: at first, the critical state friction ratio Mc computed as a function of Lode

angle θ (Jefferies and Shuttle, 2011 (on page 35)):

M tc

M c = M (θ) = M tc 1 − 3 + M tc

cos ( 3θ2 + π4 ) Eq. [7]

with Mc=Mtc in case of triaxial compression (i.e., θ= π/6) and Mc=3Mtc/(Mtc+3) in case of triaxial extension (i.e.,

θ=-π/6). An intermediate step is required because if the critical friction ratio is expressed as a function of Ψ then

neutral loading will cause the yield surface to change size (which is inadmissible) since p varies during neutral

loading, thus resulting to a change of Ψ. For this reason, the state parameter at a particular point on the yield

surface is used (so it does not vary during neutral loading) and which is, conveniently, the image condition:

Ψi = e − CSL ( pim) Eq. [8]

where CSL is the chosen representation of the CSL() that gives ec (i.e., Option (a) or (b) reported in Eq. [3]).

A matching mapping of the soil dilatancy must also be used with Ψi, and which is:

X tc

Xi = 1 − λ X tc / M tc

Eq. [9]

At last, this Mc is now changed to an "operating" value Mi. As dense soils closely follow Nova's flowrule, NS

always uses the following equation for the operating value Mi:

Ψ < 0 → Mi = M 1 + ( N Xi

M tc

Ψi ) Eq. [10]

PLAXIS 10 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

Softening parameter S

The situation in loose soils is less clear, with some soils showing less ability to dissipate plastic work as they get

progressively looser while others seem to more closely follow the Taylor-Bishop framework of a constant

dissipation rate regardless how loose; both these frameworks are offered as options and the user can choose the

one which best fits the soil being modeled. The two options are:

• Option A: Taylor-Bishop

Ψ ≥ 0 → M i = M (θ ) Eq. [11]

• Option B: Extended Dafalias

Ψ ≥ 0 → M i = M (θ) 1 −( N Xi

M tc

Ψi ) Eq. [12]

If Ψ=0, NS yield surface intersects the CSL and Mi=Mc, consistently with the basic idealization of CSSM. Although

taking Mtc as a constant soil property is the dominant view in the literature, some test data suggests that very

loose void ratios may reduce Mtc (see Figure 16 of Been et al (1991) (on page 35)). Reduced Mtc, if present, will

be most evident in soil states showing static liquefaction with large brittleness. The user can choose the

proposed options (i.e., Option A or B) based on laboratory test data and switch between the two options

according to the sign of Mtc: Extended Dafalias correspond to Mtc>0, while Taylor-Bishop is selected with Mtc<0.

2.2 Softening parameter S

The hardening limit of the yield surface pmx depends on p as well as the soil’s properties and void ratio. At

variance with drained loading, for which the evolution of pmi is governed by the smooth change enforced

through the first-order hardening law during undrained loading, the rate of change of p can easily become faster

than the basic hardening law, thus leading to pmi > pmx (contrary to the basic principle of the hardening limit).

For this reason, a softening term Ssoft is added to the hardening law resulting to a further decrease of the image

stress pmi during undrained conditions (i.e., for drained loading Ssoft ≡0). As a matter of fact, NS is derived from

the CSSM axioms with the exception of this term Ssoft. For this reason, whether to use Ssoft or not is a choice for

the user:

D p ≤ 0 → Ssoft = S = 0 X tc

( )( ) D

η K ω =1−λM S =1 Eq. [13]

D p > 0 → Ssoft = S ⋅ ω Mi p

p

pim tc

The possibility to add this further contribution in the softening response can be activated by the user through

the flag S listed in the graphical interface (see section UDSM implementation in PLAXIS finite element code (on

page 27)). NS does achieve the critical state with S = 0 (which is the "pure" version of the theory) with a rate

less rapid than usually encountered in triaxial tests showing static liquefaction. Figure 4 (on page 12)

illustrates the performance of NS for a very loose soil according to the selected value of the flag S.

PLAXIS 11 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

Soil state measurements

Figure 4: Mechanical behaviour during an undrained triaxial test using the softening flag S=1.

2.3 Soil state measurements

NS requires three state measures to specify the starting point for the calculations.

1. The geostatic stress state: It is assigned using a single value of Ko; this is equivalent to assume a "green field"

level-ground site as the starting point for any boundary value problem. In the case of constructed works, this

is reasonable for the individual layers of soil placed, with the evolution of the stresses computed as further

layers are placed. In the case of natural ground, ideally there should be a self-bored pressuremeter data

through which evaluate the geostatic stress state. The geostatic stress-state gives initial values for po and qo,

and thus ηo. These are then used to compute the normally consolidated yield surface image stress as:

NC

pim = po exp ( ηo

Mi

−1) Eq. [14]

The geostatic stress state depends on more than over-consolidation ratio, and the familiar K o = 1 − sin ( ϕ ) is

rarely a good representation. However, if there are no further information to determine Ko, the user can

adopt Ko=0.7 as initial value which for loose or normally-consolidated soils can be considered a reasonable

approximation.

2. The initial overconsolidation: Overconsolidation pushes the yield surface away from the current stress-

state thus:

NC

pim,o = R ⋅ pim Eq. [15]

where R≥ 1 is the input over-consolidation ratio. It is worth noting that what is reported as heavily

overconsolidated (i.e., soils characterized by R>>1) is actually more accurately viewed as a dense soil. Thus, if

modelling heavily over-consolidated deposits, it is suggested to use a dense choice for Ψo combined with

more modest estimate of R to determine the initial position of the yield surface. The user can further verify

PLAXIS 12 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Formulation

Soil state measurements

the effect of the overconsolidation by using the Soil Test facility in PLAXIS to better understand how these

choices can affect the stress-strain response of the soil during the calibration process.

3. The state parameter Ψo : The initial value of the state parameter it is assigned using a single value for each

stratum. Although it is common to use void ratio as the ``input'' state variable for CSSM, the use of initial void

ratio requires a precise knowledge of the CSL due to the key-role of the state parameter in controlling soil

behaviour (not the void ratio itself). The problem therein is that natural variation in soil gradation within a

single stratum results in a range of CSL's. However, it is found that common depositional conditions for the

soil produces the same soil state parameter despite the natural changes in gradation - in essence, both void

ratio and the CSL change together. This shows up in CPT soundings which profiles commonly show near

constant values of Ψ within identifiable strata. For this reason, Ψ becomes the basic input for boundary value

problems using CSSM.

In the case of existing grounds, it is assumed to have CPT data as the starting point of a numerical modeling.

In the case of new works, the state parameter must be estimated for the fill and it will be usual to base those

estimates on prior experience which has been tested using the CPT. If just modelling laboratory tests (i.e., to

confirm a calibration) the state parameter is calculated from the measured void ratio and fitted CSL. The

state parameter will show natural variability and the assigned Ψo should be "characteristic" in the sense of

the structural eurocode (i.e., EN1997); choosing Ψo such that about 80-90 % of the stratum is more dilatant is

often appropriate (see Chapter 5 of Jefferies & Been, 2016 (on page 35)).

PLAXIS 13 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Parameters

3

NS soil parameters are independent of void ratio and confining stress, and thus constant for any soil. It is often

helpful to optimize the value of these parameters through a calibration process in which laboratory experiments

are considered to simulate the soil behavior at different conditions. The soil properties are all defined/measured

under triaxial compression; NS contains the mapping of these triaxially determined properties to general stress

states. All parameters are dimensionless other than: i) the two alternative parameters Γ or Ca of the CSL model

that have an implicit stress-level of 1 kPa and 0 kPa, respectively; and, ii) the reference elastic shear modulus

G100 that has units of stress. With the only exception of the hardening modulus, most of the NS parameters are

conventionally known/understood and are readily found simply by appropriate plotting of test data. An accurate

description of the calibration process can be found in Chapter 9 of Jefferies & Been (2016) (on page 35) which

gives more details about this procedure. It is a good practice to formally model every test, drained and

undrained, to validate the inferred soil properties. In doing this, the precision in the laboratory for measurement

of initial test conditions is about ΔΨ=± 0.02, so allowing some small changes in the reported initial conditions is

both allowable and often helps to understand the soil properties.

3.1 Critical state locus: parameters Γ, λe or Ca, Cb and Cc

Two options for the critical state void ratio ec are presently offered, one being the conventional semi-log form

and the other a power-law that is becoming widely used (Eq. [3]). It is worth noting that care is needed to avoid

choosing void ratios above the CSL when modelling undrained loading with the power-law CSL, as the specified

state may imply zero critical state strength and thus cause numerical instability. The CSL can be determined

reliably, but particular laboratory procedures ("End of Test Freezing") are required; Reid et al (2020) document

achievable reliability, with laboratory procedures described in Appendix B of Jefferies & Been (2016) (on page

35). CSSM derivations lead to natural logarithms, but conventional representation of laboratory data is to use

base 10; care is needed when specifying the semi-log CSL. The two properties are simply related with λe= λ10/2.3.

3.2 Dilation limit: parameter χtc

NS limits dilation using a first-order rate approach; this is equivalent to what some refer to as the Hvorslev

p

surface. Because of the compression-positive convention,"maximum'' dilation is Dmin , and it is defined under

triaxial compression. The dilation limit is given by:

p

Dmin = χtc Ψ Eq. [16]

PLAXIS 14 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Parameters

Strength parameter: Mtc and N

The soil property χtc is determined by carrying out dense drained tests and then plotting the measured dilatancy

limit versus the state parameter at that limit (i.e., not the initial state parameter of the test). Although this

parameter affects loose soils behaviour, it is difficult to separate from other properties influencing loose soil

behaviour and which prevents direct determination from simple plotting. Thus, even if the focus of interest is

loose soil some tests on dense samples are helpful. However, silts can be challenging with present laboratory

procedures sometimes being unable to produce dense samples of some silts; in this situation χtc has to be

inferred from modelling loose soils by iteratively adjusting χtc to best-fit the test data after all other properties

have been determined.

3.3 Strength parameter: Mtc and N

Although CSSM models generally only incorporate the critical friction ratio, test data does not support this view

in detail. For this reason, NS uses Nova's extension with a second parameter N has been introduced:

p (under triaxial conditions )

ηmax = M tc − 1(1 − N )Dmin Eq. [17]

p

The usual method to determine Mtc and N is the Bishop's method, in which Dmin and ηmax data from a set of

drained triaxial tests on dense soil are plotted to calibrate Mtc and N, being those parameters the best trend line

fitting the experimental data (see Figure 6 (on page 18) and Figure 7 (on page 18) ). It is possible to estimate

Mtc directly from tests on loose soils drained or undrained, since that is the end-point of their stress-paths. In

this case, caution is needed because: i) the conversion of measured load to calculated axial stress depends on the

"area ratio correction", which correction may not be a good representation of how the sample deformed; and, ii)

in the case of undrained tests the mean effective stress depends on the difference between the measurements of

two transducers and accuracy may be much degraded. If no dense tests are available, N≈0.3 is a plausible initial

estimate (it is a value that commonly arises in reported data).

3.4 Plastic hardening: parameter Ho and HΨ

Plastic hardening modulus is the only NS-specific property as it relates only to the NS hardening law. These

properties Ho and HΨ are dimensionless and both are needed because most soils show a dependence of

hardening on the state parameter. There is also an element of softening associated with increasing η, and better

fits are obtained to test data if that is recognized. Thus, the following is used for the hardening modulus:

H = H o − H ΨΨ Eq. [18]

It is suggested to, first fitting/calibrating NS to a soil just by setting HΨ=0 and varying Ho until the trend for H

with Ψ becomes clear. An element of Original Cam Clay, with its use as 1/(λ-κ) as the plastic hardening modulus,

carries over to NS and a good starting point is usually Ho= 2/λ. Both Ho and HΨ are determined by optimizing a

set of drained triaxial tests which include loose and dense states.

PLAXIS 15 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Parameters

Typical Values

3.5 Elasticity: properties G100, nG and ν

NS anchors elasticity to Gref ≡ G100 , which is the value of the mean effective stress at the reference pressure pref

equal to 100 kPa (a widespread convention), combined with an exponent nG for a power-law trend, thus

introducing the stress-dependency on this modulus. To avoid issues with non-conservative elasticity, a constant

Poisson’s ratio ν is used to compute the elastic bulk modulus K from G. Thus, elasticity is:

G = Gref ( )

p

pref

nG

, K = (

2 1+υ

3 1 − 2υ

)G Eq. [19]

Geophysical measurements, whether in situ (seismic CPT or seismic dilatometer) or in the laboratory ("bender

elements''), have come to dominate geotechnical engineering and thus the elastic shear modulus is now the basic

elastic input. However, there is an effect of confining stress-level on the modulus in most cases. The elastic

model used assumes that a set of geophysical measurements have been reduced to this two-property model, that

allows a single parameter set to be used in a soil stratum as opposed to having to model the soil in thinner layers

each with its own G. Commonly, ν is not measured and 0.2 is adopted as "not unreasonable'' based on the

extensive testing of Ticino sand.

3.6 Typical Values

Soil mechanical properties are influenced by grain shape, grain mineralogy, and particle size distribution among

other factors. However, the effects of these geological measures on mechanical properties remain imprecise

although different soil type provides a basis for a classification of the corresponding parameters. An example is

presented in Table 1 (on page 16) where NS parameters are calibrated by soil type.

Table 1: Examples of NS parameters by soil type

Soil: Natural Sands λ10 Mtc N χtc H

Erksak (D50=330 μ m) 0.050 1.23 0.30 4.5 100-650 ψ

Nerlerk (D50=270 μ m) 0.045 1.26 0.35 4.1 85-75 ψ

Ticino (D50=530 μ m) 0.055 1.27 0.33 4.0 55-850ψ

Ottawa (D50=530 μ m) 0.028 1.13 0.25 4.7 130-1400ψ

Fraser River (D50=270 μ m) 0.080 1.46 0.50 3.2 95-400ψ

Soil: Natural Silts λ10 Mtc N χtc H

John Hart 0.18 1.31 0.3 2.5 50

Coquitlam 0.2 1.2 0.3 2.0 45

PLAXIS 16 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Parameters

Typical Values

Soil: Tailing Silts λ10 Mtc N χtc H

EKO 0.480 1.37 0.00 0.8 30

FKX 0.550 1.26 0.40 2.5 17-100ψ

NCS 0.246 1.35 0.30 2.5 20-100ψ

NCP 0.175 1.40 0.30 2.5 30-200ψ

RCR 0.159 1.25 0.30 4.0 25

TC1 0.105 1.51 0.35 7.7 73-500ψ

The CSL remains the least clearly controlled behaviour by geological measures. In Figure 5 (on page 17) a

selection of CSL's for various soils, from sands to clays, is presented. As can be seen, the semi-log representation

of the CSL is a reasonable approximation for at least a one-order of magnitude range in mean pressure and this

adequacy is independent of soil type. Analyses involving a wider range of confining stress may require the

power-law representation of the CSL. The "altitude" of the CSL (i.e., properties Γ or Ca) are unrelated to

geological classification of soil type, but there is a trend to greater compressibility (the properties λ or Cb) as the

soil becomes finer; however, well-graded soils can be much stiffer than their fines content might first indicate. It

is useful to best-fit a semi-log CSL to soil data over the range 40 – 400 kPa even though a power-law CSL may be

needed for a better precision; the values quoted in Table 1 (on page 16) are based on this and show the range of

soil properties for different type of soils.

1.1 London SILTY

SAND

CLAY

SILTY SAND

SILTY CLAY

0.9

void ratio [ - ]

Nerlerk Ticino Guindon

Changi NCS

Weald

0.7 Erksak

Gold Tailings

Rose Creek

Fraser River Candia TC1

0.5 Endako

Bennett

0.3

1 2 3 4 1 2 3 4

10 10 10 10 10 10 10 10

mean effective stress, p: kPa mean effective stress, p: kPa

Figure 5: CSLs for different soils: (a) sands and silty sands, (b) silties, clays and silty clays (data after Jefferies, 2020).

The critical friction ratio (i.e., property Mtc) of sandier soils is much influenced by grain shape, with this effect

well illustrated by Cho et al. (2006) (on page 35) who provides a useful database. Tailings, being normally

crushed materials with angular particles, often have markedly greater friction than natural soils. Equally, there is

often an effect of void ratio with very loose soils showing reduced Mtc compared to that in a compact to dense

state (see Figure 16 of Been et al. (1991) (on page 35)). There has been little systematic investigation of the

influence of geological measures on the volumetric coupling (i.e., the parameter N), with experience in regard to

this property largely confined to sands with less than 15% fines; N≈0.3 appears to be appropriate for many soils.

The state-dilatancy property (i.e., the parameter χtc) captures the tendency with which particles can move past

each other as the soil deforms and appears to be markedly influenced by the particle size distribution with a

further effect from mineralogy of the soil particles. In Figure 6 (on page 18) and Figure 7 (on page 18), a data

PLAXIS 17 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Parameters

Typical Values

p

set available for different type of soils is used to calibrate ηmax and Dmin as reported in Jefferies (2020) (on page

35).

2

(a) (b)

1.8

Guindon Cadia TC1

Fraser River

1.6

Changi NCS

1.4 Erksak

1.2 Endako

Brasted London

1

Weald

0.8

-0.8 -0.6 -0.4 -0.2 0 -0.8 -0.6 -0.4 -0.2 0

Figure 6: CSLs for different soils: (a) sands and silty sands, (b) silties, clays and silty clays (data after Jefferies, 2020)

-0.8

(a) (b) Guindon

Fraser River Changi

-0.6

Cadia TC1

Nerlerk

-0.4 Erksak

Brasted

1

Weald

London

-0.2 NCS

Ticino Endako

0

0 -0.05 -0.1 -0.15 -0.2 0 -0.05 -0.1 -0.15 -0.2

Figure 7: CSLs for different soils: (a) sands and silty sands, (b) silties, clays and silty clays (data after Jefferies, 2020)

The hardening modulus H appears markedly correlated to 1/λ, with compressible soils having smaller values of

H. Although not general for most type of soils which are calibrated with a constant modulus, there appears a

dependence of H on Ψ which can be captured by calibrating the parameter HΨ. Elasticity is much affected by

stress level, commonly to a power-law with an exponent on stress in the range 0.4 < nG < 0.8; when expressed as

a shear rigidity, Ir (i.e., a dimensionless quantity defined as Gmax/p'), a wide range is encountered because of this

effect of stress level. There is also an effect of void ratio and a lesser effect of aging. It is standard practice to

measure the elastic shear modulus using geophysical methods, either vertical seismic profiling (often using a

seismic cone) or with bender elements in the laboratory; it is common to reduce these geophysically measured

values to fit undrained tests depending on soft flag (the reduction is often by a factor of 3 for S=1). Poisson’s

ratio is usually taken in the range 0.15< ν <0.25 without measurements other than validation by fitting the

stress-paths measured in undrained triaxial tests.

A typical range of values characterizing the parameters of NS model to simulate sand behaviour is presented in

Table 2 (on page 19) according to the values proposed in Jefferies and Been (2016) (on page 35).

PLAXIS 18 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model Parameters

Typical Values

Table 2: Model parameters employed in the material point computations presented in Figures. 8-13

Ir ν Γ λe Mtc N χtc H

100-600 0.1-0.3 0.9-1.4 0.01-0.07 1.2-1.5 0.2-0.5 2-5 25-500

It is worth nothing that, as remarked in Jefferies and Been (2016) (on page 35) (see Appendix H), the

mechanical response calculated with NorSand model can replicate the constitutive behaviour of Original Cam

Clay (OCC) by selecting the following set of parameters: N = 0, H = 1 / ( λ − κ ) and Ψo = λ − κ.

PLAXIS 19 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

4

4.1 Model Performance

The constitutive behaviour of NS is described in this section through a series of material point analyses aimed to

further illustrate the elasto-plastic characteristics of the presented model. For this purpose, the set of

parameters reported in Table 3 (on page 20) is used for these computations. Although these parameters are

not calibrated to fit a particular soil, they are selected within the range of values typical for sand-like materials

which have been proposed in Jefferies and Been (2016) (on page 35) and reported in Table 2 (on page 19).

Table 3: Model parameters employed in the material point computations presented in Figures. 8-13

pref

Gref /p ref nG ν Γ λe Mtc N χtc H0 Hψ R S ψo

[kPa]

350 100 0.5 0.2 1 0.03 1.2 0.35 4 300 0 1 0 -0.15

The constitutive performance of the model is detailed in Figure 8 (on page 21) in which a drained triaxial

compression test is computed for a dense sand (Ψo=-0.15) and for a given confining pressure equal to po=200

kPa. In this figure, the stress path and the corresponding yield surface are plotted in combination with the

hardening variables (i.e., the image stress pim and its maximum value pmax, Figure 8 (on page 21)) thus

showing their evolution throughout the loading path. To further emphasize the effect of limiting dilatancy

through a limit hardening, pim and pmax are also plotted in Figure 8 (on page 21) with the difference pmax - pim

characterizing the incremental hardening reported in Eq. [4]. It is shown that the vanishing of this difference

corresponds to the peak of the stress-strain response (Figure 8 (on page 21)) and mark the beginning of the

post-peak behavior of the material. It is worth remarking that, at large strain, the material reaches the critical

state (i.e., the intersection between the stress path and the CSL marked in Figure 8 (on page 21) as qcs) and, as

a result, the variables Ψ and Ψi (Figure 8 (on page 21)) tend to zero while the image stress pim tends to the

mean effective stress at critical state. For the sake of clarity, the same test is repeated in Figure 9 (on page 21)

by enforcing 50% of axial strain, thus better highlighting the material behavior at critical state when loaded at

large strain.

To further show the model performance, a set of drained and undrained triaxial tests performed at different

confining pressure is plotted in Figure 10 (on page 22)-Figure 11 (on page 22) for both dense and loose

states (i.e., for two values of the state parameter, Ψo=0.15 and Ψ o=-0.15, respectively) which emphasize the

ability of the model to simulate liquefaction failure resulting from the excess pore-pressure in undrained stress

paths and the capability to dilate and compact along drained triaxial compressions. Similarly, the ability of the

model to simulate the mechanical response of a soil at different initial density is illustrate in Figure 12 (on page

PLAXIS 20 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

Model Performance

23) and Figure 13 (on page 23) where a sensitivity analysis is proposed by varying the initial value of the

state parameter.

750 Stress path (a)

750 (b) 1

Yield surface

0.5

500 500

0

250 250

L

-0.5

CS

0 0 -1

0 300 600 900 0 0.02 0.04 0.06 0.08 0.1

800

(c) (d)

-0.06

600

k

400 -0.1

200

-0.14

0

-200 -0.18

0 0.02 0.04 0.06 0.08 0.1 0 0.02 0.04 0.06 0.08 0.1

Figure 8: Model response during a drained triaxial test characterized by an initial confining pressure equal to

po=200 kPa for a dense sand (i.e., Ψo=-0.15)

750

500

q [kPa]

250

0

0 0.1 0.2 0.3 0.4 0.5

Figure 9: Drained triaxial test plotted in Figure 8 loaded up to 50% of axial strain

PLAXIS 21 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

Model Performance

1200 1200

Undrained Undrained

900 900 300 kPa

q [kPa]

q [kPa]

600 600 200 kPa

Confining 100 kPa

300 pressure 300

0 0

0 300 600 900 0 0.005 0.01 0.015 0.02 0.025

p [kPa]

1000 0.04

Drained Drained

= 300 kPa

750 0.03

q [kPa]

0.02

200 kPa

500

0.01

250 100 kPa

0

0 -0.01

0 0.02 0.04 0.06 0.08 0.1 0 0.02 0.04 0.06 0.08 0.1

Figure 10: Constitutive behaviour of NS model in dense conditions at different confining pressures

120 120

Undrained Undrained

90 90

q [kPa]

q [kPa]

60 60

Confining

30 30 pressure

0 0

0 50 100 150 200 250 300 0 0.02 0.04 0.06 0.08 0.1

p [kPa]

400 0

Drained Drained

300 -0.01

q [kPa]

=300 kPa -0.02

200

200 kPa

-0.03

100 kPa

100 -0.04

0 -0.05

0 0.02 0.04 0.06 0.08 0.1 0 0.02 0.04 0.06 0.08 0.1

Figure 11: Constitutive behaviour of NS model in loose conditions at different confining pressures

PLAXIS 22 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

Model Performance

160 160

Undrained (loose) Undrained (loose)

120 120

q [kPa]

q [kPa]

0.1

80 80

0.15

40 40 0.1

0.2 0.15

0.2

0 0

0 50 100 150 200 0 0.02 0.04 0.06 0.08 0.1

p [kPa]

400 0

Drained (loose) Drained (loose)

300 0.2

-0.02

q [kPa]

0.1 0.15

200 0.15

0.1

-0.04

100 0.2

0 -0.06

0 0.02 0.04 0.06 0.08 0.1 0 0.02 0.04 0.06 0.08 0.1

Figure 12: Constitutive behaviour of NS model in loose conditions for different values of Ψo

1200 1200

Undrained (dense) -0.2 Undrained (dense) -0.2

800 -0.15 800 -0.15

q [kPa]

q [kPa]

-0.10

-0.10

400 400

-0.05 -0.05

0 0

0 200 400 600 800 1000 0 0.005 0.01 0.015 0.02 0.025

p [kPa]

800 0.06

-0.2 Drained (dense) Drained (dense) -0.2

-0.15

600 0.04 -0.15

q [kPa]

-0.10

400 -0.05 -0.10

0.02

-0.05

200

0

0 -0.01

0 0.02 0.04 0.06 0.08 0.1 0 0.02 0.04 0.06 0.08 0.1

Figure 13: Constitutive behaviour of NS model in dense conditions for different values of Ψo

PLAXIS 23 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

Numerical validation

4.2 Numerical validation

To validate the numerical implementation of NS in PLAXIS Finite element, a series of material point analyses

have been performed to compare the model behavior with the results obtained through a Visual Basic for

Applications (i.e., VBA) spreadsheet in which a fully explicit algorithm (i.e., a Step Forward Euler method) is

considered to integrate different stress paths. Provided by the authors of the model, the VBA script is here used

to compute triaxial stress-paths for both drained and undrained conditions (i.e. TXD and TXU), as well as

undrained direct simple shear tests (i.e., UDSS). As NS is implemented in PLAXIS to cope with more general

stress-strain conditions, the comparison of the constitutive response obtained by using the two integration

strategies can be used to validate the current implementation of the model. This comparison is shown in Figure

14 (on page 25) where the triaxial tests for both loose and dense conditions are computed with the parameters

reported in Table 4 (on page 24). A similar result is also shown in Figure 15 (on page 25) where an

undrained direct simple shear test is computed by considering both responses resulting from the activation of

the softening flag (i.e., S = 0 and S = 1). Similar material point tests have been performed by using the power-law

CSL (Eq. [4]) which parameters are reported in Table 5 (on page 24).

Table 4: List of parameters used for the numerical validation of NS Model

pref

Gref /p ref nG ν Γ λe Mtc N χtc H0 Hψ R S

[kPa]

200 100 0.6 0.1 1.115 0.076 1.4 0.3 2.5 30 200 1 1

Table 5: List of parameters used for the numerical validation of NS Model

pref

Gref /p ref nG ν Ca Cb Cc Mtc N χtc H0 Hψ R S

[kPa]

200 100 0.5 0.15 0.90 0.14 0.15 1.28 0.3 4.6 100 625 1.2 1

PLAXIS 24 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

Numerical validation

600 600

(a) TXU (b) TXU

PLAXIS

VBA

400 400

q [kPa]

q [kPa]

Dense

Dense

200 Loose 200 Undrained

conditions

0 0

0 200 400 600 0 0.05 0.1 0.15 0.2

p [kPa]

800 (c) 0.1 (d)

Loose

Dense 0.08

600

0.06

Drained

q [kPa]

400 0.04 conditions

Loose

0.02

200

0

TXD TXD Dense

0 -0.02

0 0.05 0.1 0.15 0.2 0 0.05 0.1 0.15 0.2

Figure 14: Constitutive response resulting from drained and undrained triaxial tests: comparison between PLAXIS

and VBA script.

300 200

PLAXIS S=0 Undrained DSSU

PLAXIS S=1

conditions

VBA 150

200

q [kPa]

τ [kPa]

100

S=0

100

50

S=1

0 0

0 50 100 150 200 250 0 0.02 0.04 0.06 0.08 0.1

p [kPa] γxy [-]

Figure 15: Constitutive response resulting from undrained direct simple shear test: comparison between PLAXIS and

VBA script.

PLAXIS 25 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Model performance and numerical validation

Numerical validation

500 500

PLAXIS TXU Power-law CSL TXU

VBA

400 400

q [kPa]

q [kPa]

300 Dense 300 Dense

200 200

100 Loose 100 Loose

0 0

0 100 200 300 400 500 600 0 0.01 0.02 0.03 0.04 0.05

p [kPa] [-]

Figure 16: Constitutive response resulting from undrained triaxial tests and a power-law CSL: comparison between

PLAXIS and VBA script.

PLAXIS 26 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

UDSM implementation in PLAXIS finite element

5

code

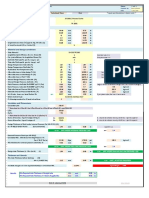

5.1 Material Parameters

NS model has been implemented as a User Defined Soil Model (UDSM) in PLAXIS finite element. The CSLs

reported in Eq. [3] (i.e., the logarithmic and power-law formulations) are implemented in the same UDSM (i.e.,

the same DLL file called norsand.dll), and one of the two options can be selected in "Model in DLL": i) NorSand-

CSL(a) to use the logarithmic expression of the CSL characterized by the parameters Γ and λe (Figure 17 (on

page 27) ) or ii) NorSand-CSL(b) for the power-law CSL defined with the parameters Ca, Cb and Cc (Figure 17

(on page 27) ).

Logarithmic CSL

Power-law CSL

(a) (b)

Figure 17: Model parameters for both CSL formulations: (a) Logaritmic CSL, (b) Power-law CSL

PLAXIS 27 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

UDSM implementation in PLAXIS finite element code

Material Parameters

The parameters reported in Figure 17 (on page 27) are listed as follows:

Gref Reference value of the shear modulus at the reference pressure.

pref Reference mean pressure (generally the common value of 100 kPa is used).

nG Exponent of the power-law elasticity.

ν Poisson's ratio.

Mtc Friction ratio at critical state in triaxial conditions.

N Material parameter controlling the maximum stress ratio as a function of the minimum dilatancy.

χtc Material parameter which governs the slope of the minimum dilatancy as a function of the state

parameter.

H0 Hardening parameter.

H Ψ Hardening parameter.

R Over-consolidation ratio.

Ψo Initial value of the state parameter.

The two formulations of the CSL are characterized by the following parameters:

• Logarithmic expression of the CSL (equation Eq. [3], option a).

Γ Void ratio corresponding to a mean pressure equal to 1 kPa.

λe Slope of the critical state (e-ln(p)).

• Power-law expression of the CSL (equation Eq. [3], option b).

Ca Void ratio corresponding to a mean pressure equal to 0 kPa.

Cb Parameter of the power-law expression.

Cc Exponent of the power-law.

The parameter Mtc is here used for two purposes:

• To use the sign of Mtc in order to switch between Extended Dafalias or Modified Bishop. If Mtc>0 (e.g., Mtc=1.2)

as Extended Dafalias is considered, while the same value with opposite sign automatically selects the Modified

Bishop expression (e.g., Mtc=-1.2). It is worth remarking that the two formulations are equivalent in case of

dense soils (i.e., Ψo<0) while they result to modify the soil behavior in case of loose soils.

• To assign the value of the parameter Mtc (i.e., Mtc=|Mtc|).

The parameter S is used as a flag therefore only 0/1 can be selected. When a different value is prescribed, S is

automatically set to zero. Similarly, this flag is constrained to be used only in undrained conditions, therefore its

effect is not taken into account in drained conditions.

PLAXIS 28 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

UDSM implementation in PLAXIS finite element code

State variables

5.2 State variables

To better visualize the results obtained from a finite element simulation, a set of state variables can be plotted by

selecting in PLAXIS Output the option User-defined parameters (i.e., from Stress > Stress State parameters >

User-defined parameters, Figure 18 (on page 29)). Here below the entire list of variables:

Figure 18: List of User-defined paarmeters which can be ploted in PLAXIS output

where

σmi = The image stress is the hardening variable of the model.

evoid ratio = Current void ratio of the model.

Ψ = State parameters.

η = Stress ratio.

η/Mθ = Stress ratio normalized with Eq. [7]

θ = Lode's angle.

Dp = Dilatancy function.

K = Bulk modulus.

G = Shear modulus.

plast = Plastic points.

- = Used for internal purposes.

It is worth remarking that, at the beginning of a given calculation phase, the value of the void ratio stored in

User-defined parameters is initialized by inverting Eq. [3] where Ψ is equal to the initial value of the state

parameter (i.e., the Ψ0 prescribed by the user), and the mean pressure results from the initial stress state. The

advantage of this strategy is that the void ratio evoid ratio is automatically re-scaled with the soil depth, thus

avoiding subdividing the soil cluster in layers each characterized by a different value of the initial void ratio. For

this reason, it is normal to observe different values between this variable (i.e., evoid ratio from State parameters)

and the void ratio reported in PLAXIS Output through the tab Deformation > Total strain which initial value is

set in PLAXIS Input through the tab dedicated to material models (i.e., General > Advanced > einit). At variance

PLAXIS 29 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

UDSM implementation in PLAXIS finite element code

State variables

with evoid ratio, the value of einit is kept constant for all the points characterizing the initial state of a given cluster

associated to a given material.

It is important to observe that, as many other constitutive frameworks, NS is a model which mobilizes the

material strength through the evolution of the hardening variable σmi, for this reason it is not possible to use NS

within the Strength Reduction Factor (SRF) method where the strength reduction is performed by a decrease of

material parameter.

PLAXIS 30 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Finite Element Analyses

6

To show the performance of the implemented model to capture the liquefaction potential of loose sediments, an

initial boundary value problem simulating a slope failure is computed with PLAXIS 2D and is presented in this

section. The initial and boundary conditions are similar to the problem presented in Jefferies and Been (2016)

and they are depicted in Figure 19 (on page 32). The loading process is aimed to simulate a flow liquefaction

process which is triggered by applying a displacement of 20 cm on the top of the slope through a rigid slab with

the soil parameters representing a quartz sand with trace of silts (see Table 6 (on page 31)). To simulate flow

liquefaction, undrained conditions are prescribed to the entire finite element domain.

The initialization of the stress state is performed through three different phases:

• An initial phase performed with calculation type k0 initialization in which the formula of Jacky is used to

calculate k0. The value of k0 = 1 − sin ( ϕ ) = 0.5 is used in this example and corresponds to a friction angle

ϕ = 30 ° selected to have a value close to the one obtained from the stress ratio at critical state (i.e.,

sin ( ϕ ) = 3M tc / ( 6 + M tc )) .

• A plastic loading phase with no loading aimed to have an initial stress state in equilibrium with the soil

weight according NS behaviour.

• A plastic loading phase in which the loading is applied until the soil reaches a failure state. In this phase, a

reset of the state variables is checked in the numerical inputs to guarantee a correct calculation of the state

variable with a previous stress state.

Table 6: Model parameters proposed in Jefferies and Been (2016) to solve the slope failure problem presented in

Figure 19

pref

Gref /pref nG ν Γ λe Mtc N χtc H0 Hψ R S

[kPa]

300 100 1.0 0.15 0.875 0.03 1.27 0.35 4 100 0 1 0

PLAXIS 31 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Finite Element Analyses

80 m

2m Water table

A

8m

0.25

2m

2m

24 m

2m

2m

20 m

28 m

Figure 19: Initial and boundary conditions of the finite element problem solved with PLAXIS 2D

The results of the computed problem are shown in Figure 20 (on page 33) where the state of the soil at the end

of the loading is characterized by the stress points in plastic loading (Figure 20 (on page 33)), the norm of

cumulated displacements (Figure 20 (on page 33)) and the normalized stress ratio (Figure 20 (on page 33)).

Figure 20 (on page 33) shows the region below the foundation undergoing through failure and enables to

identify the undrained shear bands characterizing the failure process at the end of the loading. The mechanism

of failure can be observed also in Figure 20 (on page 33) where the normalized stress ratio is plotted to

quantify the residual frictional capabilities before reaching the critical stress ratio (i.e., when η/Mθ≈ 1 the

material reaches the critical state). It is shown that the stress points below the foundation are characterized by

higher values of the normalized stress ratio (η/Mθ≈ 0.94) which tends to decrease in zones of the soils farther

from the foundation.

To differentiate the plastic points according to the hardening process, the existing symbols used in PLAXIS

Output are employed with a different meaning:

• Failure points (red square □ ): plastic points at critical state.

•

Hardening points (downward green triangle ▿

): plastic points.

•

Liquefaction points (downward purple triangle ▿ ): plastic points characterized by a stress ratio greater

than the instability line.

it is worth nothing that liquefaction points are plotted also when the finite element analysis is performed in

drained conditions thus highlighting potential liquefaction phenomena occurring if soil conditions switch from

drained to undrained.

PLAXIS 32 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Finite Element Analyses

170*10e-3 m

127.5

85

42.5

Norm of cumulated

displacements (b)

Water table

Zoom

Stress points in

plastic state (a)

0.75

0.93 0.93

0.93

0.57 0.47 0.57

0.37

0.47

0.47

Normalized

stress ratio (c)

Figure 20: Numerical solution of the finite element problem shown in Figure 17: (a) the distribution of Gauss point

in plastic loading, (b) the norm of cumulated displacements, (c) normalized stress ratio.

To further emphasize the effect of the initial porosity, the same computation has been solved with one single

value of Ψo for all the layers varying the value of the state parameter to simulate soils from dense to loose

conditions (i.e., Ψo=0.0, Ψo=0.3, Ψo=0.5 and Ψo=0.7). The results are plotted in where the stress path of a stress

point below the foundation (i.e., point A in Figure 19 (on page 32) ) is reported for the three different values of

Ψo, thus highlighting the different trend of behaviour related to different initial void ratios.

PLAXIS 33 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

Finite Element Analyses

30

25

20

15

10

10 15 20 25 30 35 40

Figure 21: Stress paths of the stress point below the foundation (i.e., point A reported in Figure 16) corresponding to

different values of the state parameter (i.e., Ψo=0.0, Ψo=0.3, Ψo=0.5 and Ψo=0.7).

ACKNOWLEDGEMENTS

Dr. Jefferies M. and Dr. Shuttle D. are gratefully acknowledged for their support, suggestions and time dedicated

during the implementation of NS model.

PLAXIS 34 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

References

7

1. Been, K., Jefferies, M. G., and Hachey, J. (1991). The critical state of sands. Géotechnique, 41(3):365-381.

2. Bishop, A. W. (1950). Reply to discussion on "measurement of shear strength of soils" by a.w. skemptonand

and a.w. bishop. Géotechnique, 2:90-108.

3. Cho, G.-C., Dodds, J., and Santamarina, J. C. (2006). Particle shape effects on packing density, stiffness, and

strength: Natural and crushed sands. Journal of Geotechnical and Geoenvironmental Engineering, 132(5).

4. Conforth, D. H. (1961). Plane strain failure characteristics of a saturated sand. PhD thesis, University of

London.

5. Drucker, D. C. (1951). A more fundamental approach to stress-strain relations. In Proceedings of the First US

National Congress of Applied Mechanics, pages 487-491. ASME, ASME.

6. Jefferies, M. (2020). On the fundamental nature of state parameter. Geotechnique. under review.

7. Jefferies, M. and Been, K. (2016). Soil Liquefaction, a Critical State Approach. Applied geotechnics series. CRC

Press.

8. Jefferies, M. and Shuttle, D. (2011). On the operating critical friction ratio in general stress states.

Géotechnique, 8(61):709-713.

9. Jefferies, M., Shuttle, D., and Been, K. (2015). Principal stress rotation as cause of cyclic mobility. Geotechnical

Research, 2(2):66-96.

10. Li, X. S. and Dafalias, Y. F. (2000). Dilatancy for cohesionless soils. Géotechnicque, 50(4):449-460.

11. Lyman (1938). Construction of franklin falls dam. Technical report, US Army corps of engineers.

12. Resende, L. and Martin, J. B. (1985). Formulation of drucker& prager cap model. Journal of Engineering

Mechanics, 111(7):855-881.

13. Schofield, A. N. and Wroth, C. P. (1968). Critical state soil mechanics. McGrow-Hill, London.

PLAXIS 35 User Defined Soil Models - NorSand: An elasto-plastic

model for soil behaviour with static liquefaction

You might also like

- Beyond Success Lesson 3 Priorities PDFDocument7 pagesBeyond Success Lesson 3 Priorities PDFPeter PicaNo ratings yet

- 7585.PLAXISCEV21.00 Norsand User-ManualDocument30 pages7585.PLAXISCEV21.00 Norsand User-ManualBOOBOONo ratings yet

- Lit Review ExampleDocument11 pagesLit Review ExampleKobie DrysdaleNo ratings yet

- Computers & Geotechnics - Apriadi Et Al (2013)Document11 pagesComputers & Geotechnics - Apriadi Et Al (2013)Dedi ApriadiNo ratings yet

- Barlat - 1991 - A SIX-COMPONENT YIELD FUNCTION PDFDocument20 pagesBarlat - 1991 - A SIX-COMPONENT YIELD FUNCTION PDFYasser BouktirNo ratings yet

- Non-Associated Plasticity For Soils, Concrete and RockDocument64 pagesNon-Associated Plasticity For Soils, Concrete and RockErnest NsabimanaNo ratings yet

- Soil PlasticityDocument28 pagesSoil Plasticityrameshbabu_1979No ratings yet

- ReviewDocument13 pagesReviewBelay MekonenNo ratings yet

- Hypo PlaxisDocument29 pagesHypo PlaxisRasdinantaTariganNo ratings yet

- PM4 SiltDocument57 pagesPM4 Siltraulicha7No ratings yet

- A Critical State Sand Plasticity Model Accounting For Fabric EvolutionDocument21 pagesA Critical State Sand Plasticity Model Accounting For Fabric EvolutionmohanNo ratings yet

- PLAXIS 2023.1 Barcelona Basic ModelDocument54 pagesPLAXIS 2023.1 Barcelona Basic ModelHuy Hiep NguyenNo ratings yet

- A Simple Critical State Based Double-Yield-Surface ModelDocument16 pagesA Simple Critical State Based Double-Yield-Surface ModelMelete GashawNo ratings yet

- Introduction To Computational Plasticity: Raffaele Casciaro Dipartimento Di Strutture, Universit' A Della CalabriaDocument50 pagesIntroduction To Computational Plasticity: Raffaele Casciaro Dipartimento Di Strutture, Universit' A Della CalabriaantonellodelreNo ratings yet

- Plastic Hardening Model - Theory and Examples PDFDocument36 pagesPlastic Hardening Model - Theory and Examples PDFkrainajackaNo ratings yet

- A Continuous Hyperplasticity Model For Sands Under Cyclic LoadingDocument6 pagesA Continuous Hyperplasticity Model For Sands Under Cyclic LoadingLTE002No ratings yet

- Basic Computational PlasticityDocument40 pagesBasic Computational PlasticityadnanhasanovicNo ratings yet

- COMPARISONBETWEEN2DAND3DANALYSISOFAMONO PILEUNDERLATERALCYCLICLOAD PaperDocument10 pagesCOMPARISONBETWEEN2DAND3DANALYSISOFAMONO PILEUNDERLATERALCYCLICLOAD PaperMaruda8382No ratings yet

- A Constitutive Model For Sand in Triaxial CompressionDocument24 pagesA Constitutive Model For Sand in Triaxial CompressionLiz RvNo ratings yet

- Nor Sand Geot 1993Document14 pagesNor Sand Geot 1993Rafael BiazottoNo ratings yet

- Nadu Vina Man I 2001Document9 pagesNadu Vina Man I 2001Anas SakimNo ratings yet

- 06 - 3D Embankment ConsolidationDocument28 pages06 - 3D Embankment ConsolidationRaynaldo JodistiroNo ratings yet

- A Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Document25 pagesA Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Melete GashawNo ratings yet

- Nelsen Zornberg 2020Document10 pagesNelsen Zornberg 2020SophiaNo ratings yet

- 1998 1 PDFDocument33 pages1998 1 PDFZakwan GusnadiNo ratings yet

- 48 471 486 Lődör MóczárDocument17 pages48 471 486 Lődör MóczárBelaniza GasparNo ratings yet

- Nor Sand Geot 1993Document14 pagesNor Sand Geot 1993kcalvaypNo ratings yet

- Assessment of Liquefaction Triggering: The UBC3D-PLM Constitutive Model Versus Semi-Empirical Methods Based On SPT-N ValuesDocument11 pagesAssessment of Liquefaction Triggering: The UBC3D-PLM Constitutive Model Versus Semi-Empirical Methods Based On SPT-N ValuesSamiul IslamNo ratings yet

- Stress Strain Curve ExampleDocument8 pagesStress Strain Curve ExampleRayhan saiaf binNo ratings yet

- Computers and Geotechnics: Maosong Huang, Yanhua Liu, Daichao ShengDocument13 pagesComputers and Geotechnics: Maosong Huang, Yanhua Liu, Daichao ShengBishwajit ChowdhuryNo ratings yet

- Duncan-Chang - Parameters For Hyperbolic Stress Strain Behaviour of Soft Bangkok ClayDocument5 pagesDuncan-Chang - Parameters For Hyperbolic Stress Strain Behaviour of Soft Bangkok ClayAbdelmoez ElgarfNo ratings yet

- Evaluation of Structural Properties of Lime Stabilized Soils and AggregatesDocument16 pagesEvaluation of Structural Properties of Lime Stabilized Soils and Aggregatesthe master blueNo ratings yet

- Constitutive Law PolycarbonateDocument10 pagesConstitutive Law PolycarbonateajaykumarKBSNo ratings yet

- Application of A Critical State Model To The MerriespruitDocument31 pagesApplication of A Critical State Model To The Merriespruitmaryam.mansoori1994No ratings yet

- The Second Moment of AreaDocument15 pagesThe Second Moment of AreasteveNo ratings yet

- Mixture Design and Testing Procedure For Lime Stabilized Soils PDFDocument16 pagesMixture Design and Testing Procedure For Lime Stabilized Soils PDFJuanma GarcesNo ratings yet

- Numerical Simulation of Strip Footing On Sand For Bearing Capacity AnalysesDocument7 pagesNumerical Simulation of Strip Footing On Sand For Bearing Capacity AnalysesahmedNo ratings yet

- OCClayDocument38 pagesOCClayrdey36886No ratings yet

- Effective Determination of Cyclic-Visco-Plasticity Material Properties Using An Optimisation Procedure and Experimental Data Exhibiting ScatterDocument13 pagesEffective Determination of Cyclic-Visco-Plasticity Material Properties Using An Optimisation Procedure and Experimental Data Exhibiting ScatterOssama RamyNo ratings yet

- Jurnal 8Document12 pagesJurnal 8TAUFIQ HIDAYATNo ratings yet

- Shliomis Model Based Magnetic Jluirf Lubrication Oja Squeeze Jilm in Rotating Rougfi Curved Circular PlatesDocument9 pagesShliomis Model Based Magnetic Jluirf Lubrication Oja Squeeze Jilm in Rotating Rougfi Curved Circular PlatesDrOm ChoudharyNo ratings yet

- P Material Models Manual: LaxisDocument162 pagesP Material Models Manual: Laxisorazio casablancaNo ratings yet

- Combined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureDocument13 pagesCombined Hardening and Softening Constitutive Model of Plasticity: Precursor To Shear Slip Line FailureNaida AdemovicNo ratings yet

- P Material Models Manual: LaxisDocument162 pagesP Material Models Manual: Laxismiquixtli4192No ratings yet

- A Simple and Unified One Dimensional Model To Describe Va 2011 Soils and FouDocument20 pagesA Simple and Unified One Dimensional Model To Describe Va 2011 Soils and FouroshnaNo ratings yet

- Dynamic Roughness APFDocument12 pagesDynamic Roughness APFJoaquinNo ratings yet

- Foundations of Elastoplasticity Subloading Surface Model 3rd Edition Koichi Hashiguchi (Auth.) 2024 Scribd DownloadDocument52 pagesFoundations of Elastoplasticity Subloading Surface Model 3rd Edition Koichi Hashiguchi (Auth.) 2024 Scribd Downloadokogbespt100% (2)

- Material Models in PlaxisDocument136 pagesMaterial Models in PlaxismpvfolloscoNo ratings yet

- 3DF2 5 Validation 3D PlaxisDocument0 pages3DF2 5 Validation 3D Plaxispperic13No ratings yet

- Edited Bubble ModelDocument12 pagesEdited Bubble ModelEva SmithNo ratings yet

- Santos 2014Document5 pagesSantos 2014Gordei SilviuNo ratings yet

- A Temperature-And Pressure-Sensitive Visco-Plasticity Theory Based On Volume-Change Mechanisms For Sedimentary RocksDocument47 pagesA Temperature-And Pressure-Sensitive Visco-Plasticity Theory Based On Volume-Change Mechanisms For Sedimentary RocksKTMONo ratings yet

- Axial - Loaded Pile PLAXIS 2dDocument4 pagesAxial - Loaded Pile PLAXIS 2dMarko AdamovićNo ratings yet

- Introduction To Computational PlasticityDocument51 pagesIntroduction To Computational PlasticityLucas PrataNo ratings yet

- Numog04 FullDocument6 pagesNumog04 FullLTE002No ratings yet

- International Society For Soil Mechanics and Geotechnical EngineeringDocument5 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringRICHARD SEBASTIAN CHAVEZ CASTRONo ratings yet

- Boulanger Ziotopoulou PM4Silt Model CGM-18-01 2018Document109 pagesBoulanger Ziotopoulou PM4Silt Model CGM-18-01 2018JORGE ANTONIO ANAYA QUISPENo ratings yet

- Tutorial 37 Triaxial Tests On SandDocument28 pagesTutorial 37 Triaxial Tests On SandsebastianNo ratings yet

- FluidDocument3 pagesFluidrdey36886No ratings yet

- 3D 0 Gen Info UDSMDocument6 pages3D 0 Gen Info UDSMrdey36886No ratings yet

- Applsci 13 13348 v3Document20 pagesApplsci 13 13348 v3rdey36886No ratings yet

- CFRPDocument20 pagesCFRPrdey36886No ratings yet

- CE 04 303-Mechanics of SolidsDocument2 pagesCE 04 303-Mechanics of Solidsrdey36886No ratings yet

- Bond SlipDocument9 pagesBond Sliprdey36886No ratings yet

- (Asce) 1090-0241 (2005) 131 12 (1466)Document14 pages(Asce) 1090-0241 (2005) 131 12 (1466)rdey36886No ratings yet

- 1 s2.0 S2352012422005975 MainDocument16 pages1 s2.0 S2352012422005975 Mainrdey36886No ratings yet

- 1 s2.0 S2405844023014329 MainDocument35 pages1 s2.0 S2405844023014329 Mainrdey36886No ratings yet

- 41 Days Group-D Time TableDocument5 pages41 Days Group-D Time Tablealways musicNo ratings yet

- Cam18 - Test 1 - Writing - Sample Task 1Document1 pageCam18 - Test 1 - Writing - Sample Task 1Huu Lanh NguyenNo ratings yet

- Electro Pneumatics m3 Student VersionDocument22 pagesElectro Pneumatics m3 Student VersionArt NidayNo ratings yet

- Electrochemistry Practice Sheet SolutionDocument13 pagesElectrochemistry Practice Sheet Solutionanuradharao587No ratings yet

- Subjective Past Papers For Final Term: Edu406: Notes For B.Ed by Nauman MalikDocument40 pagesSubjective Past Papers For Final Term: Edu406: Notes For B.Ed by Nauman Malikshumaila100% (1)

- Multiple Choice 6Document3 pagesMultiple Choice 6Mj CabangananNo ratings yet

- Identity, Self-Concept, and Self-Esteem (Diego A. Odchimar III, 2023)Document101 pagesIdentity, Self-Concept, and Self-Esteem (Diego A. Odchimar III, 2023)Diego A. Odchimar IIINo ratings yet

- Chapterization Detail of ReportDocument3 pagesChapterization Detail of ReportKriti GrotraNo ratings yet

- Progressive Collapse of Multi-Storey Buildings Due To Sudden Column Loss-Part II: ApplicationDocument15 pagesProgressive Collapse of Multi-Storey Buildings Due To Sudden Column Loss-Part II: ApplicationbhargavisattarNo ratings yet

- Math 3 Q2 Module 3Document18 pagesMath 3 Q2 Module 3Joshwa heromo100% (1)

- Analysis For Fatigue Life of A Hexacopter Drone: Department of Mechanical EngineeringDocument54 pagesAnalysis For Fatigue Life of A Hexacopter Drone: Department of Mechanical EngineeringFOODIE USNo ratings yet

- Ideas para Ensayos Sobre Matar A Un RuiseñorDocument8 pagesIdeas para Ensayos Sobre Matar A Un Ruiseñorafmoiwxkf100% (1)

- The Hand of God: Vocabulary Study WorksheetDocument2 pagesThe Hand of God: Vocabulary Study WorksheetAdriana BrebenelNo ratings yet