Wind 5

Wind 5

Uploaded by

dwight.sahidCopyright:

Available Formats

Wind 5

Wind 5

Uploaded by

dwight.sahidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Wind 5

Wind 5

Uploaded by

dwight.sahidCopyright:

Available Formats

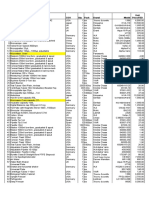

Types

The three primary types: VAWT Savonius, HAWT towered;

VAWT Darrieus as they appear in operation

Wind turbines can rotate about either a horizontal or a vertical axis, the former being both older and more common. [37] They can also

include blades or be bladeless.[38] Household-size vertical designs produce less power and are less common.[39]

Horizontal axis

Components of a horizontal axis wind turbine (gearbox, rotor

shaft and brake assembly) being lifted into position

The rotor of a gearless wind turbine being set. This particular turbine was prefabricated in

Germany, before being shipped to the U.S. for assembly.

Offshore Horizontal Axis Wind Turbines (HAWTs) at Scroby Sands Wind Farm, England

Onshore Horizontal Axis Wind Turbines

in Zhangjiakou, Hebei, China

Large three-bladed horizontal-axis wind turbines (HAWT) with the blades upwind of the tower (i.e. blades facing the incoming wind)

produce the overwhelming majority of wind power in the world today.[4] These turbines have the main rotor shaft and electrical

generator at the top of a tower and must be pointed into the wind. Small turbines are pointed by a simple wind vane, while large

turbines generally use a wind sensor coupled with a yaw system. Most have a gearbox, which turns the slow rotation of the blades

into a quicker rotation that is more suitable to drive an electrical generator. [40] Some turbines use a different type of generator suited

to slower rotational speed input. These don't need a gearbox and are called direct-drive, meaning they couple the rotor directly to

the generator with no gearbox in between. While permanent magnet direct-drive generators can be more costly due to the rare earth

materials required, these gearless turbines are sometimes preferred over gearbox generators because they "eliminate the gear-

speed increaser, which is susceptible to significant accumulated fatigue torque loading, related reliability issues, and maintenance

costs".[41] There is also the pseudo direct drive mechanism, which has some advantages over the permanent magnet direct drive

mechanism.[42]

Most horizontal axis turbines have their rotors upwind of the supporting tower. [43] Downwind machines have been built, because they

don't need an additional mechanism for keeping them in line with the wind. In high winds, downwind blades can also be designed to

bend more than upwind ones, which reduces their swept area and thus their wind resistance, mitigating risk during gales. Despite

these advantages, upwind designs are preferred, because the pulsing change in loading from the wind as each blade passes behind

the supporting tower can cause damage to the turbine.[44]

Turbines used in wind farms for commercial production of electric power are usually three-bladed. These have low torque ripple,

which contributes to good reliability. The blades are usually colored white for daytime visibility by aircraft and range in length from 20

to 80 meters (66 to 262 ft). The size and height of turbines increase year by year. Offshore wind turbines are built up to 8 MW today

and have a blade length up to 80 meters (260 ft). Designs with 10 to 12 MW were in preparation in 2018,[45] and a "15 MW+"

prototype with three 118-metre (387 ft) blades is planned to be constructed in 2022.[needs update][46] The average hub height of horizontal

axis wind turbines is 90 meters.[47]

You might also like

- Situational Judgement TestDocument130 pagesSituational Judgement TestRJM100% (3)

- Truck Frame and Suspension Repair ManualDocument5 pagesTruck Frame and Suspension Repair Manualsample nameNo ratings yet

- Tertullian - A Historical and Li - Barnes, Timothy DavidDocument340 pagesTertullian - A Historical and Li - Barnes, Timothy DavidAntonioIennaco100% (6)

- Types of Wind Turbines: Wind Flow Patterns and Speeds Vary Greatly Across The United StatesDocument6 pagesTypes of Wind Turbines: Wind Flow Patterns and Speeds Vary Greatly Across The United StatesllllaaaaNo ratings yet

- Hawt Vawt PDFDocument4 pagesHawt Vawt PDFDilipraja KolliNo ratings yet

- Wind Turbine ClassificationDocument9 pagesWind Turbine ClassificationShailesh BaseraNo ratings yet

- The Wind Turbine v-3Document1 pageThe Wind Turbine v-3mendhi123No ratings yet

- Unit 4Document24 pagesUnit 4mcojmhNo ratings yet

- Chapter 1Document19 pagesChapter 1NishantShahNo ratings yet

- Comparison of Horizontal Axis Wind Turbines and Vertical Axis Wind TurbinesDocument5 pagesComparison of Horizontal Axis Wind Turbines and Vertical Axis Wind TurbinesTito KurniawanNo ratings yet

- Vertical Axis Wind TurbineDocument12 pagesVertical Axis Wind Turbinedisse_detiNo ratings yet

- VAWTsDocument11 pagesVAWTsEdana SharmaNo ratings yet

- Rotor Electrical Generator Wind Vane Servo Motor: Vertical-Axis Wind TurbinesDocument6 pagesRotor Electrical Generator Wind Vane Servo Motor: Vertical-Axis Wind TurbinesZainab IrfanNo ratings yet

- Design of Vertical Axis Wind Turbine Blades (Chapter 3)Document10 pagesDesign of Vertical Axis Wind Turbine Blades (Chapter 3)Htet Myet AgNo ratings yet

- Wind EnergyDocument6 pagesWind EnergyDiyabarta NaoremNo ratings yet

- General Introduction of Vertical Axis Wind TurbineDocument4 pagesGeneral Introduction of Vertical Axis Wind TurbineSarvesh PandeyNo ratings yet

- Wind Turbine ComponentsDocument28 pagesWind Turbine ComponentsMadhumita KaruppusamyNo ratings yet

- Aerodynamic Modeling and Analysis of Vertical Axis Wind TurbineDocument13 pagesAerodynamic Modeling and Analysis of Vertical Axis Wind Turbineprabhat ranjan mishraNo ratings yet

- Review of Literature: Aerodynamically DragDocument4 pagesReview of Literature: Aerodynamically DragJayr PurisimaNo ratings yet

- Eee Project ON WIND FARM FIRST YEAR B.TECHDocument10 pagesEee Project ON WIND FARM FIRST YEAR B.TECHsamarpit_anandNo ratings yet

- This OneDocument4 pagesThis OneReiak CostanillaNo ratings yet

- 1.1 General IntroductionDocument30 pages1.1 General IntroductionHEBIN RAJ HNo ratings yet

- Literature ReviewDocument5 pagesLiterature ReviewMaazAhmed67% (3)

- Project ReportDocument35 pagesProject ReportIndranil BhattacharyaNo ratings yet

- Types of Wind TurbinesDocument5 pagesTypes of Wind Turbinesvvps777No ratings yet

- Wind TurbinesDocument16 pagesWind TurbinesFernanda Lucero SierraNo ratings yet

- Horizontal Axis Wind Turbines (HAWT)Document5 pagesHorizontal Axis Wind Turbines (HAWT)sharma5544No ratings yet

- Vertical Axis Wind TurbinesDocument39 pagesVertical Axis Wind TurbinesyourmothersucksNo ratings yet

- Figure:1 History of Wind TurbinesDocument43 pagesFigure:1 History of Wind TurbinesGayathri M GayuNo ratings yet

- Darrieus Wind TurbineDocument5 pagesDarrieus Wind TurbineCarlos Castillo PalmaNo ratings yet

- PDF Vertical Axis Wind Turbines DDDocument38 pagesPDF Vertical Axis Wind Turbines DDKunal AhiwaleNo ratings yet

- Module3 1Document48 pagesModule3 1Sravan SatheeshNo ratings yet

- Vertical Axis Wind Turbines PDFDocument40 pagesVertical Axis Wind Turbines PDFslitantNo ratings yet

- EE535 Wind TurbinesDocument17 pagesEE535 Wind TurbinesSathya Raj SimiNo ratings yet

- Vertical Axis Wind Turbine - Wikipedia, The Free EncyclopediaDocument5 pagesVertical Axis Wind Turbine - Wikipedia, The Free EncyclopedianareshpeddapatiNo ratings yet

- Industrial Placement Project On Savonius Vertical-Axis Wind Turbine For Low Power ApplicationsDocument44 pagesIndustrial Placement Project On Savonius Vertical-Axis Wind Turbine For Low Power ApplicationsUchenna AdimmaduNo ratings yet

- Wind Energy: Presented By: SAHIT DEVGAN (307/20) SHIFALI SHARMA (308/20)Document20 pagesWind Energy: Presented By: SAHIT DEVGAN (307/20) SHIFALI SHARMA (308/20)sahitNo ratings yet

- Wind Mill With 3 BladesDocument43 pagesWind Mill With 3 BladesABnB InnovationsNo ratings yet

- Wind Turbine: 1. Horizontal-Axis Wind Turbines (HAWT)Document5 pagesWind Turbine: 1. Horizontal-Axis Wind Turbines (HAWT)gopalchandramahatoNo ratings yet

- Module3 - 1 UpdatedDocument71 pagesModule3 - 1 UpdatedSravan SatheeshNo ratings yet

- WINDPOWERDocument34 pagesWINDPOWERnas SNo ratings yet

- Wind 7Document1 pageWind 7dwight.sahidNo ratings yet

- Main Components of A Wind TurbineDocument8 pagesMain Components of A Wind Turbinetejap314No ratings yet

- Maglev Vertical Axis Wind Turbine (VAWT) Horizontal Axis Wind Turbine (HAWT)Document59 pagesMaglev Vertical Axis Wind Turbine (VAWT) Horizontal Axis Wind Turbine (HAWT)Mr. K.S. Raghul Asst Prof MECHNo ratings yet

- S & W MODULE 5 NotesDocument12 pagesS & W MODULE 5 NotesYashas GowdaNo ratings yet

- 10 Ideas S4031911Document2 pages10 Ideas S4031911enricoporta2001No ratings yet

- Ajol File Journals - 691 - Articles - 245228 - Submission - Proof - 245228 8152 588527 1 10 20230405Document8 pagesAjol File Journals - 691 - Articles - 245228 - Submission - Proof - 245228 8152 588527 1 10 20230405Tito KurniawanNo ratings yet

- TurboDocument7 pagesTurboARUN GANESH S MECHNo ratings yet

- Prsentation Wind TurbineDocument10 pagesPrsentation Wind TurbineMuhammad Ammad RasheedNo ratings yet

- Power Plant. If The Mechanical Energy Is Used To Drive Machinery, Such As For GrindingDocument3 pagesPower Plant. If The Mechanical Energy Is Used To Drive Machinery, Such As For GrindingClement StephensonNo ratings yet

- Wind Energy Basics 17098081908633826765e99a3e9806bDocument53 pagesWind Energy Basics 17098081908633826765e99a3e9806bPrasann KatiyarNo ratings yet

- Wind Turbine 2Document8 pagesWind Turbine 2Abhishek KhelgeNo ratings yet

- Horizontal and Vertical Axis Wind Turbines 1Document11 pagesHorizontal and Vertical Axis Wind Turbines 1Jeferson Tondo AlvesNo ratings yet

- UNIT-3 W P: IND OwerDocument44 pagesUNIT-3 W P: IND OwerPankaj RupaniNo ratings yet

- Introduction, History, and Theory of Wind PowerDocument6 pagesIntroduction, History, and Theory of Wind PowerhooshyarNo ratings yet

- PV DesignDocument17 pagesPV DesignEyad BarqawiNo ratings yet

- Wind TurbineDocument38 pagesWind TurbineRaunaq Singh100% (1)

- General ReadingsDocument14 pagesGeneral ReadingsSandalika UdaniNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- S-Nacar V Gallery FramesDocument20 pagesS-Nacar V Gallery Framesdwight.sahidNo ratings yet

- Wind 9Document2 pagesWind 9dwight.sahidNo ratings yet

- Hernandez V San JuanDocument2 pagesHernandez V San Juandwight.sahidNo ratings yet

- 011 - Delgado V RustiaDocument1 page011 - Delgado V Rustiadwight.sahidNo ratings yet

- Oropesa V OropesaDocument2 pagesOropesa V Oropesadwight.sahidNo ratings yet

- 3agabon V NLRCDocument132 pages3agabon V NLRCdwight.sahidNo ratings yet

- 9moresco V CagalawanDocument18 pages9moresco V Cagalawandwight.sahidNo ratings yet

- JM48367 Hook MiniscoreDocument16 pagesJM48367 Hook MiniscoreJulien ThoreNo ratings yet

- Republic Act No. 7610 - Child Abuse LawDocument24 pagesRepublic Act No. 7610 - Child Abuse LawLeo Cruz100% (6)

- IntroDocument10 pagesIntroAnthony Wilfred BasmayorNo ratings yet

- RRB Clerk Prelims Memory Based Paper 2023 (English Version) : Numerical AbilityDocument23 pagesRRB Clerk Prelims Memory Based Paper 2023 (English Version) : Numerical Abilitydemodev26077No ratings yet

- RTHD Catalog RLC Prc020 enDocument32 pagesRTHD Catalog RLC Prc020 enCharles Lee50% (2)

- Verizon Foundation - IRS 990 - Year 2008Document317 pagesVerizon Foundation - IRS 990 - Year 2008CaliforniaALLExposedNo ratings yet

- DLL - Abm Oct 16-20Document3 pagesDLL - Abm Oct 16-20Michelle Vinoray PascualNo ratings yet

- Marking Scheme For PMRDocument3 pagesMarking Scheme For PMRLaviram PerryNo ratings yet

- Koch, E (2013) Death and Justice, in Current Issues and Enduring Questions, 10th Edition, S Barnet & D Bedau, EdsDocument5 pagesKoch, E (2013) Death and Justice, in Current Issues and Enduring Questions, 10th Edition, S Barnet & D Bedau, EdsJoey YanNo ratings yet

- Screenshot 2024-10-21 at 8.07.38 AMDocument65 pagesScreenshot 2024-10-21 at 8.07.38 AMDarshan DravidNo ratings yet

- Complementary Feeding HambantotaDocument39 pagesComplementary Feeding Hambantotasampath muthunayakeNo ratings yet

- Chapter 21Document7 pagesChapter 21Jenna SolomonNo ratings yet

- Marxism and The Dialectic - Lucio CollettiDocument27 pagesMarxism and The Dialectic - Lucio Collettigalahad_tannhauser9981No ratings yet

- Interiew QuestionsDocument8 pagesInteriew Questionsalee.dahriNo ratings yet

- Images A-Z Minerals (AA)Document757 pagesImages A-Z Minerals (AA)Abrianto AkuanNo ratings yet

- Integrated Bar of The Philippines vs. Zamora: Statutory ConstructionDocument2 pagesIntegrated Bar of The Philippines vs. Zamora: Statutory ConstructionCarlota Nicolas Villaroman100% (1)

- Sean O'Malley's Resume 7-08Document2 pagesSean O'Malley's Resume 7-08SeanO1100% (2)

- Name Hareem Fatima Roll Num El-021 Section D Second Year Electronics Im PresentationDocument4 pagesName Hareem Fatima Roll Num El-021 Section D Second Year Electronics Im Presentationtooba mukhtarNo ratings yet

- Sample Question Paper 2Document10 pagesSample Question Paper 2Raksha SoniNo ratings yet

- Purchase-Request-MMAW NCIIDocument3 pagesPurchase-Request-MMAW NCIICatherine Mae NacionNo ratings yet

- Charged UpDocument15 pagesCharged UpholeaNo ratings yet

- Wastewater Treatment Strategy - Al Jouf RegionDocument44 pagesWastewater Treatment Strategy - Al Jouf RegionjmsanguinoNo ratings yet

- Sat Test 10 ReadingDocument17 pagesSat Test 10 ReadingMelissa ToledoNo ratings yet

- Analysis of Transient Stability With SSSC and UPFC With Multi-Band PSS in Two Area Multi-Machine SystemDocument5 pagesAnalysis of Transient Stability With SSSC and UPFC With Multi-Band PSS in Two Area Multi-Machine SystemEngr GM SialNo ratings yet

- Tax in WatershedDocument2 pagesTax in WatershedBundanya SavinaNo ratings yet

- No Description COO Qty Pack Brand Model Unit Price/USD: Thermo Scientific OV/100/SS/F/DIG INC/100/SS/DIGDocument4 pagesNo Description COO Qty Pack Brand Model Unit Price/USD: Thermo Scientific OV/100/SS/F/DIG INC/100/SS/DIGlusoegyi 1919No ratings yet