0 ratings0% found this document useful (0 votes)

2 viewsSai Highway & Builders DSR

Sai Highway & Builders DSR

Uploaded by

Abubakkar MaityCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Sai Highway & Builders DSR

Sai Highway & Builders DSR

Uploaded by

Abubakkar Maity0 ratings0% found this document useful (0 votes)

2 views2 pagesOriginal Title

Sai Highway & Builders Dsr

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views2 pagesSai Highway & Builders DSR

Sai Highway & Builders DSR

Uploaded by

Abubakkar MaityCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

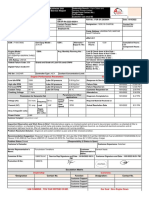

SER/F/01

DAILY SERVICE REPORT REV04/18.11.14

SERVICE ORDER SE220704267212 05-07-2022 14:07

NO: DATE:

SAI HIGHWAY AND BUILDERS

CUSTOMER: PVT.LTD. SERVICE ENGINEER: Mr ABUBAKKAR MAITY .

ENGG MOBILE NO: 7364055774

TY PE OF CALL: NEW - ERE & COMM

SITE ADDRESS: Podaiyahat,,,Godda EQUIPMENT MODEL: SLM4300

MODEL-MACHINE SLM4300-2158

SERIAL NO:

GST NO: 9 DIGIT CRM 809675500

SERIAL NO:

MACHINE Godda MANUFACTURE 2158

LOCATION: SERIAL NO:

PRIME MOVER

PERSON INCHARGE: Amarjeet kumar SERIAL NO:

5H.4356/2220144

PHONE: 9534386502 MFG DATE: May-22

CUSTOMER EMAIL DATE OF 05-07-2022

ID: COMMISSIONING:

ADDITIONAL EMAIL shbpl.208@gmail.com NATURE OF JOB: Service and Repairs

ID:

CALL ATTRIBUTE: General NATURE OF Inspection

PROBLEM:

HMR1: 10.55 HMR2: CMR: 809675500

TRAVEL TIME: JOB TIME: TRAVEL TIME:

DATE: REMARK:

FROM: TO: FROM: TO: FROM: TO:

05-07-2022 01:19 08:19 08:19 14:19 14:19 20:19

DET AILED SERVICE REPORT :

CUSTOMER COMPLAINT:

Commisioning

ACTION TAKEN:

Visit the site at first check machine hydraulic oil level engine oil level and Diesel level all foundok then

start the machine and check machine hour meter Perking break Check mounting bolts tightness

of hydraulic pump, Motors and Gear boxes all found full tight condition is ok.then Checkbattery,

Alternator and self motor cables

tightness condition found ok. Check battery cut off switch condition found ok. Check overall machine oil

leakages before cranking engine and also check condition of material feeding and unloading hopper

found ok. Check condition of engine fan wings and Fan belt tightness before engine

cranking Check Propeller shaft joint bolts tightness before engine cranking all should be found ok. Check

all pedal operations found working smoothly. Check Hand accelerator and all four wheel bolts tightness

engine smoke condition temperature gauge working condition Check function of battery charging

Indicator weighing meter and printer working conditions bucket

operation test gear

changing mixing loading unloading switch and battery working found ok air

filter

head light machine forward Reverse test ok check horn, and all fuse over ride all sensor working

properly all working smoothly and found ok. Now machine condition is over all found ok. Then I have

trained the operator to do all the maintenance as per

the time of the

machine and Check properly everything on the machine every day c

OTHER REMARKS / RECOMMENDATION::

Coolent level was low

W ind screen - front was broken

Cabin small mirror angel was broken

Drum scratch found

Reason of all these problem may be transportation problem

PARTS AND EQUIPMENT DETAILS:

Customer Requirement Part No. Description Quantity Model

OTHER CATEGORY DETAILS:

Category Information Required

CUSTOMER PHOTO & SIGNATURE SERVICE ENGINEER PHOTO & SIGNATURE

CUSTOMER REMARKS:

Amarjeet kumar Mr ABUBAKKAR MAITY

CUSTOMER CONTACT NAME: SERVICE ENGINEER NAME: .

DATE: 05-07-2022 DATE: 05-07-2022

CUSTOMER CARE TOLL FREE NUMBER:18001231479

TIME:8am-8pm

You might also like

- Cummins Field Service Report Free Download PDF Template PDFDocument2 pagesCummins Field Service Report Free Download PDF Template PDFNitesh K. Yedati100% (1)

- Dismantling Report Engine 3412 SN 4bz07428 (1ez07166)Document70 pagesDismantling Report Engine 3412 SN 4bz07428 (1ez07166)Chrisdian FaraniNo ratings yet

- LH 514 Technical Specification Sandvik LH514-10Document3 pagesLH 514 Technical Specification Sandvik LH514-10Emanuel Nicolas Villarruel100% (2)

- Jashjit Mukherjee 4300 Comm Report FormDocument3 pagesJashjit Mukherjee 4300 Comm Report FormAbubakkar MaityNo ratings yet

- AA21064 2328 Quality Issue FormDocument4 pagesAA21064 2328 Quality Issue FormAbubakkar MaityNo ratings yet

- Aurobindo FSRDocument3 pagesAurobindo FSRsenthilanbu22No ratings yet

- Hexagon Work Order Service ReportDocument2 pagesHexagon Work Order Service ReportMirna VeronicNo ratings yet

- Work Order - Information IN - APMY20231225000032 - Dynamics 365Document1 pageWork Order - Information IN - APMY20231225000032 - Dynamics 365m-13152694No ratings yet

- Speed GovernerDocument13 pagesSpeed GovernerShaif JagirdarNo ratings yet

- ADM KPI Tracker 26 09 13Document98 pagesADM KPI Tracker 26 09 13a1johnNo ratings yet

- Gseup Se63 2211220337 FSR FormDocument2 pagesGseup Se63 2211220337 FSR Formashishshakya30nov1999No ratings yet

- FSR 8271752 6945899Document2 pagesFSR 8271752 6945899Harsh ChawdaNo ratings yet

- Quotation of Bar Screen & Oil Skimmer For Mount Green Farm Raj Nagar Extension GhaziabadDocument2 pagesQuotation of Bar Screen & Oil Skimmer For Mount Green Farm Raj Nagar Extension GhaziabadVishal shuklaNo ratings yet

- WO-10947482 - Affiniti 50 Ultrasound System-PU522D1381 - SignedCSR - 09-Jul-2024 PDFDocument2 pagesWO-10947482 - Affiniti 50 Ultrasound System-PU522D1381 - SignedCSR - 09-Jul-2024 PDFrubyhall bio-medicalNo ratings yet

- Alignment Report PDFDocument4 pagesAlignment Report PDFmohamadhakim.19789No ratings yet

- Request For N.D.E Services: Mr. PatelDocument1 pageRequest For N.D.E Services: Mr. PatelRifanjshshNo ratings yet

- Site Report SaidipDocument1 pageSite Report SaidipVishal D KhombareNo ratings yet

- Job Report 3Document4 pagesJob Report 3Sahr, Cyprian FillieNo ratings yet

- Distribution Business Unit Cummins Field Service Report Deccan Sales and Services Private Limited (Indore)Document2 pagesDistribution Business Unit Cummins Field Service Report Deccan Sales and Services Private Limited (Indore)Karthii AjuNo ratings yet

- Ettpl FP 1 FSRDocument2 pagesEttpl FP 1 FSRsenthilanbu22No ratings yet

- BPCL FP 3 FSRDocument2 pagesBPCL FP 3 FSRsenthilanbu22No ratings yet

- New rj22Document2 pagesNew rj22auranetworktechnologiesNo ratings yet

- Carborundum Universal FSRDocument2 pagesCarborundum Universal FSRsenthilanbu22No ratings yet

- Crown World FSRDocument2 pagesCrown World FSRsenthilanbu22No ratings yet

- Wa0009.Document1 pageWa0009.nitintailor174No ratings yet

- Renewal Notice - Tw-AnilagrDocument2 pagesRenewal Notice - Tw-AnilagrRakesh VermaNo ratings yet

- FSR Form - 2022-09-13T143129.444Document1 pageFSR Form - 2022-09-13T143129.444Sidhartha SinghNo ratings yet

- FSR FormDocument2 pagesFSR FormPrasoon sysmindNo ratings yet

- Job CardDocument1 pageJob Cardmmr315No ratings yet

- Q218 ReddyDocument1 pageQ218 ReddyavinashNo ratings yet

- SPEED GOV 1 - DeltaDocument1 pageSPEED GOV 1 - DeltaFasten ComputersNo ratings yet

- Aarti Dhamija PolicyDocument2 pagesAarti Dhamija PolicynavyaadhamijaNo ratings yet

- Agent/ Intermediary Name and Code:RAFIKUL DHABAK POS0010692Document7 pagesAgent/ Intermediary Name and Code:RAFIKUL DHABAK POS0010692gobinddas028No ratings yet

- Preliminary Report Tgm1Document56 pagesPreliminary Report Tgm1SIAD SALIMNo ratings yet

- 42 KV, 10 Ka Metal OxideDocument2 pages42 KV, 10 Ka Metal OxideSSE TRD JabalpurNo ratings yet

- BCCD Service Technician Call Slip-1Document38 pagesBCCD Service Technician Call Slip-1Manu IdukkiNo ratings yet

- IEC Plant Engg - Paint Grinding - ModulesDocument5 pagesIEC Plant Engg - Paint Grinding - ModulesAngel AventedorNo ratings yet

- Weldwell Electrod AMC QT3058 DT 08.01Document5 pagesWeldwell Electrod AMC QT3058 DT 08.01ashvinNo ratings yet

- Pintu Sahu JobDocument1 pagePintu Sahu Jobharshneta2No ratings yet

- RDLC - 2022-07-02T190854.835Document2 pagesRDLC - 2022-07-02T190854.835BanshiNo ratings yet

- MR Palutla Subba Rao Your Policy Details: Tata AIG General Insurance Company LimitedDocument3 pagesMR Palutla Subba Rao Your Policy Details: Tata AIG General Insurance Company LimitedParshu NagNo ratings yet

- Service Report # 26 - Zoomlion 6B5.9 C21 Compression Leak Equipment No. 8 ESN - 82234128 2nf JOBDocument4 pagesService Report # 26 - Zoomlion 6B5.9 C21 Compression Leak Equipment No. 8 ESN - 82234128 2nf JOBRico BernasolNo ratings yet

- Job Order GSJ18-11179: Mr. Vibhor SinghDocument1 pageJob Order GSJ18-11179: Mr. Vibhor SinghVibhor SinghNo ratings yet

- WB73G1733Document1 pageWB73G1733Pawan KumarNo ratings yet

- FSR Form - 2022-09-13T113812.755Document2 pagesFSR Form - 2022-09-13T113812.755Sidhartha SinghNo ratings yet

- FSR Form - 2022-09-13T142132.595Document1 pageFSR Form - 2022-09-13T142132.595Sidhartha SinghNo ratings yet

- PO 4700071443 ECC SMS-2 SuppDocument33 pagesPO 4700071443 ECC SMS-2 SuppEngineering Construction CorporationNo ratings yet

- Balmer Lawrie FSRDocument2 pagesBalmer Lawrie FSRsenthilanbu22No ratings yet

- AMC DOCUMENT HsjskkskamDocument2 pagesAMC DOCUMENT HsjskkskamSamar AgrawalNo ratings yet

- AV Steel Amended Po CGLDocument24 pagesAV Steel Amended Po CGLNirmit GandhiNo ratings yet

- Mini Excavator-Nov 23Document1 pageMini Excavator-Nov 23Akash vimalNo ratings yet

- FSR 8139941 6804194Document1 pageFSR 8139941 6804194Harsh ChawdaNo ratings yet

- Ep - Quotation WIP-20603-princessDocument7 pagesEp - Quotation WIP-20603-princessamrgad308No ratings yet

- 1616 JobcardDocument3 pages1616 Jobcardvishaljain112358No ratings yet

- Ues FSRDocument2 pagesUes FSRFaisal ShahzadNo ratings yet

- Amnd 1Document8 pagesAmnd 1rajasekharan kgNo ratings yet

- Pt. Lotus SG Lestari C11 - Txe07368 (966H - Tal02635)Document75 pagesPt. Lotus SG Lestari C11 - Txe07368 (966H - Tal02635)Dimas SetyoNo ratings yet

- Commercial Proposal:: Dhafer Mahdi AL Zlaiq & Partners Gen Cont CoDocument5 pagesCommercial Proposal:: Dhafer Mahdi AL Zlaiq & Partners Gen Cont CogeorgyNo ratings yet

- Job Report 2Document6 pagesJob Report 2Sahr, Cyprian FillieNo ratings yet

- Komtrax Controller TC830 Fitment Report - M.C Serial No.n723088Document6 pagesKomtrax Controller TC830 Fitment Report - M.C Serial No.n723088MOHAN MALAKARNo ratings yet

- Baldwin Filters Product CatalogDocument1,307 pagesBaldwin Filters Product CatalogInkanata Sac100% (1)

- 1997 - Report of The IOC Evaluation Commission For The Games of The XXVIII Olympiad in 2004 OKDocument331 pages1997 - Report of The IOC Evaluation Commission For The Games of The XXVIII Olympiad in 2004 OKFredy Alejandro Pineda RomeroNo ratings yet

- Bba Aceite 2017 WebDocument214 pagesBba Aceite 2017 WebmiguelNo ratings yet

- Ejemplo Directores OperacionesDocument10 pagesEjemplo Directores OperacionesmaxfindllcNo ratings yet

- Visa SampleDocument3 pagesVisa SamplejasodaglobalNo ratings yet

- Vingroup Mobility Business Update - FDocument24 pagesVingroup Mobility Business Update - FWK SinnNo ratings yet

- Revised Driving NC III New 2022 AmendedDocument132 pagesRevised Driving NC III New 2022 AmendedZAIRON DELA BAJAN100% (1)

- SmartWireless Battery Options PDSDocument2 pagesSmartWireless Battery Options PDSAbdul Hakeem MohammedNo ratings yet

- Auto Expo 2023 Components Exhibitor ManualDocument56 pagesAuto Expo 2023 Components Exhibitor ManualAlvish PadaliyaNo ratings yet

- Oxygen SystemsDocument9 pagesOxygen SystemsShruthi S KurupNo ratings yet

- Chennai 10K Run Guide BookDocument13 pagesChennai 10K Run Guide BookMathi Engineers And Builders Private LimitedNo ratings yet

- HSM01 A133900066MS Product OverviewIDocument33 pagesHSM01 A133900066MS Product OverviewIjokoNo ratings yet

- SB COSMO INTERNATIONAL BOOKING REPORT 14-Sep-2023Document1 pageSB COSMO INTERNATIONAL BOOKING REPORT 14-Sep-2023sbcosmointernationalNo ratings yet

- Chapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructuresDocument1 pageChapter 5 Design Guidelines Section 5.2 Structural Subsection 5.2.3 Non-Building StructureskapsarcNo ratings yet

- Corporate DataDocument201 pagesCorporate DataDinesh YadavNo ratings yet

- Yokohama FenderDocument76 pagesYokohama FenderDaniel ChagasNo ratings yet

- Mercedes Benz 204 ESP Control UnitDocument6 pagesMercedes Benz 204 ESP Control UnitReza VaraminiNo ratings yet

- CE 353 Transportation Engineering II: Md. Rabiul IslamDocument9 pagesCE 353 Transportation Engineering II: Md. Rabiul IslamMohamed Isak AliNo ratings yet

- Mobility FullDocument180 pagesMobility FullSivan ZivNo ratings yet

- Instructivo MSL Air Expo 2022Document8 pagesInstructivo MSL Air Expo 2022gallardo.ingreedNo ratings yet

- Genie Z 60-34 Manual de PeçasDocument205 pagesGenie Z 60-34 Manual de PeçasHelio100% (2)

- Spec Sheet Ctis 1 enDocument4 pagesSpec Sheet Ctis 1 enTomNo ratings yet

- Name: - Grade & Section: - Name: - Grade & Section: - Name: - Grade & SectionDocument2 pagesName: - Grade & Section: - Name: - Grade & Section: - Name: - Grade & SectionmsdinxNo ratings yet

- Grand Trunk Exp Third Ac (3A) : Booked From ToDocument1 pageGrand Trunk Exp Third Ac (3A) : Booked From ToBijender BhardwajNo ratings yet

- North by Northwest 1959Document181 pagesNorth by Northwest 1959Nathan LestradeNo ratings yet

- Summer Training Project On ACC Cement Help Center, Adesh Jaiswal, Varanasi.Document75 pagesSummer Training Project On ACC Cement Help Center, Adesh Jaiswal, Varanasi.aadijaiswalNo ratings yet

- 1968 Passenger Car Parts Cat AlogDocument1 page1968 Passenger Car Parts Cat AlogWalter BeijerNo ratings yet

- IHHA 2013 - FunkwalDocument10 pagesIHHA 2013 - FunkwalMd. Shiraz JinnathNo ratings yet

- Topic 3-Steering - Part1Document27 pagesTopic 3-Steering - Part1TasmiaH.Shoily100% (1)