01-70 ES Supa Plus PE & PVC

01-70 ES Supa Plus PE & PVC

Uploaded by

huzaifaksa435Copyright:

Available Formats

01-70 ES Supa Plus PE & PVC

01-70 ES Supa Plus PE & PVC

Uploaded by

huzaifaksa435Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

01-70 ES Supa Plus PE & PVC

01-70 ES Supa Plus PE & PVC

Uploaded by

huzaifaksa435Copyright:

Available Formats

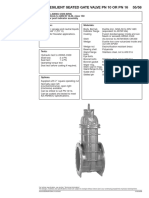

AVK GATE VALVE PN 16 WITH SUPA PLUSTM COUPLING 01/70

To DIN 3352 part 4

With tensile Supa PlusTM coupling for uPVC- and PE-pipes

For pipes PE 100 - PN 6.3, PN 10 and PN 16 and for PE 80 - PN 6.3 and PN 10 to DIN 8074

For pipes Sigma 100 - PN 6 and PN 10. Sigma 125 - PN 7.5 and PN 10

Use: Materials:

For water and neutral liquids. Body, bonnet Ductile iron, min. GGG-40, to DIN

Total angular deflection of 2 x ± 3.5 and bracket 1693, EN-GJS-400: EN 1563: 1998

degrees. Coating Electrostatically applied epoxy resin

An AVK support bush is always to be to DIN 30677 and GSK - internally

used on PE-pipes, whenever using a and externally

tensile resistant sealing ring. Stem Stainless steel, DIN X 20 Cr 13

Highest allowable temperature as for Stem sealing NBR wiper ring, 2 NBR O-rings inside

the pipe used, however max. 70°C. and 2 outside a plastic bearing,

EPDM rubber manchette

Wedge Ductile iron, GGG-50, core fully

Tests: vulcanized with EPDM rubber,

with integral wedge nut of

Hydraulic test to DIN 3230 part 4: dezincification resistant brass,

Seat: PN CZ 132 to BS 2874

Body: 1.5 X PN Thrust collar Dezincification resistant brass,

Operation torque test CZ 132 to BS 2872

Bonnet bolts Stainless steel A2, sealed with

hot melt

Bonnet gasket EPDM rubber

Optional extras: Tensile sealing Gun metal, DIN 17005 RG5 /

ring EPDM rubber

Handwheel

Extension spindle Nut Stainless steel (AISI 316), A4 grade

Stem cap 80 PTFE coated

Support bush Square neck bolt Stainless steel, A2 grade 80

and washer

Cap Plastic

Approvals:

All materials are WRC approved

DVGW-W270 approved EPDM rubber

available on request

For further specifications, see section "Technical information".

The designs, materials and specifications shown are subject to change without notice due to our continuing programme of product development.

AVK INTERNATIONAL A/S/2003-02-07 310170BB

AVK GATE VALVE PN 16 WITH SUPA PLUSTM COUPLING 01/70

To DIN 3352 part 4

With tensile Supa PlusTM coupling for uPVC- and PE-pipes

For pipes PE 100 - PN 6.3, PN 10 and PN 16 and for PE 80 - PN 6.3 and PN 10 to DIN 8074

For pipes Sigma 100 - PN 6 and PN 10. Sigma 125 - PN 7.5 and PN 10

Component list

1. Wedge 8. Cap 15. O-ring

2. Body 9. Bonnet bolt 16. Slide bearing

3. Wedge nut 10. Bonnet gasket 17. O-ring

4. Tensile sealing ring 11. Screw cover 18. Wiper ring

5. Bracket 12. Bonnet 19. Stem

6. Nut 13. Stem seal

7. Square neck bolt 14. Thrust collar

F 19

18

17

16

15

14

13

H 12

11

10

7

E

6

5

A

L

1 2 3 4

Theoretic

OD A E H L F Number weight

Ref.nos. DN PE/uPVC mm mm mm mm mm of bolts kilos

01-050-70016 40 50 64 44 236 182 14 2 x 2 M16 7

01-063-70016 50 63 68 52 241 182 14 2 x 2 M16 8

01-075-70016 65 75 70 58 271 182 17 2 x 2 M16 9

01-090-70016 80 90 78 68 297 200 17 2 x 2 M16 14

01-110-70016 100 110 90 94 334 208 19 4 x 2 M16 24

01-125-70016 125 125 91 102 375 208 19 4 x 2 M16 28

01-140-70016 125 140 95 107 375 220 19 4 x 2 M16 35

01-160-70016 150 160 124 118 448 260 19 4 x 2 M16 40

01-200-70016 200 200 124 158 562 309 24 6 x 2 M16 65

01-225-70016 200 225 133 172 562 309 24 6 x 2 M16 74

01-250-70016 250 250 143 174 664 339 27 6 x 2 M16 98

01-280-70016 250 280 155 184 664 339 27 6 x 2 M16 105

01-315-70016 300 315 184 208 740 380 27 6 x 2 M16 166

You might also like

- Long-Life Asphalt Pavements - Technical2007Document24 pagesLong-Life Asphalt Pavements - Technical2007Sen Hu100% (1)

- 55-35 GS (2005)Document2 pages55-35 GS (2005)huzaifaksa435No ratings yet

- 16-29 PomDocument2 pages16-29 Pomhuzaifaksa435No ratings yet

- 33-30 Es VRSDocument2 pages33-30 Es VRShuzaifaksa435No ratings yet

- 55-34 GS (2005)Document2 pages55-34 GS (2005)huzaifaksa435No ratings yet

- 06-89 EsDocument2 pages06-89 Eshuzaifaksa435No ratings yet

- End Restraint Gate ValvesDocument2 pagesEnd Restraint Gate ValvesSami KahtaniNo ratings yet

- Avk Service Connection Angle Valve PN 16 11/30Document2 pagesAvk Service Connection Angle Valve PN 16 11/30huzaifaksa435No ratings yet

- 16-50 PomDocument2 pages16-50 Pomhuzaifaksa435No ratings yet

- 38-80 ES FW X FLGDocument2 pages38-80 ES FW X FLGhuzaifaksa435No ratings yet

- 36-80 Es FWDocument2 pages36-80 Es FWhuzaifaksa435No ratings yet

- 32-10 Es AcDocument2 pages32-10 Es Achuzaifaksa435No ratings yet

- 16-80 PomDocument2 pages16-80 Pomhuzaifaksa435No ratings yet

- 55-30 Es (2004)Document2 pages55-30 Es (2004)huzaifaksa435No ratings yet

- 16-90 PomDocument2 pages16-90 Pomhuzaifaksa435No ratings yet

- 33-00 Es DiDocument2 pages33-00 Es Dihuzaifaksa435No ratings yet

- Avk Triple Socketed Gate Valve PN 10 and PN 16 18/20: To DIN 3352 Part 4 With Socket Ends For PVC-pipesDocument2 pagesAvk Triple Socketed Gate Valve PN 10 and PN 16 18/20: To DIN 3352 Part 4 With Socket Ends For PVC-pipeshuzaifaksa435No ratings yet

- Avk Service Connection Angle Valve PN 16 11/00Document2 pagesAvk Service Connection Angle Valve PN 16 11/00huzaifaksa435No ratings yet

- 16-01 PomDocument2 pages16-01 Pomhuzaifaksa435No ratings yet

- 16-7X BrassDocument2 pages16-7X Brasshuzaifaksa435No ratings yet

- 702 ES Knife AIDocument2 pages702 ES Knife AIhuzaifaksa435No ratings yet

- 32-60 GS Ci 2531Document2 pages32-60 GS Ci 2531huzaifaksa435No ratings yet

- 15-43 - 73 GS (2005)Document4 pages15-43 - 73 GS (2005)huzaifaksa435No ratings yet

- 32-80 SabsDocument2 pages32-80 Sabshuzaifaksa435No ratings yet

- 01-80 ES 310180EB Oct 2003Document2 pages01-80 ES 310180EB Oct 2003huzaifaksa435No ratings yet

- Avk Service Connection Valve PN 10 03/20: To DIN 3352 Part 4 For +GF+/PVP-SystemDocument2 pagesAvk Service Connection Valve PN 10 03/20: To DIN 3352 Part 4 For +GF+/PVP-Systemhuzaifaksa435No ratings yet

- Avk Gate Valve PN 25 02/67Document2 pagesAvk Gate Valve PN 25 02/67huzaifaksa435No ratings yet

- Avk Combi-Tee With Flanged Ends PN 10 and PN 16 18/40: Flanges and Drilling To ISO 7005-2 (EN 1092-2: 1997, DIN 2501)Document2 pagesAvk Combi-Tee With Flanged Ends PN 10 and PN 16 18/40: Flanges and Drilling To ISO 7005-2 (EN 1092-2: 1997, DIN 2501)huzaifaksa435No ratings yet

- 01-80 ES Euro PEDocument2 pages01-80 ES Euro PEhuzaifaksa435No ratings yet

- Avk Service Connection Valve With Pe-Pipes PN 10 36/8XDocument2 pagesAvk Service Connection Valve With Pe-Pipes PN 10 36/8Xhuzaifaksa435No ratings yet

- 02-20 EsDocument2 pages02-20 Eshuzaifaksa435No ratings yet

- 32-40 Es Ci 2531Document2 pages32-40 Es Ci 2531huzaifaksa435No ratings yet

- 38-90 GasDocument2 pages38-90 Gashuzaifaksa435No ratings yet

- 15-72 Flange Gate ValveDocument4 pages15-72 Flange Gate Valvehuzaifaksa435No ratings yet

- Avk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved RubberDocument2 pagesAvk Resilient Seated Gate Valve, Pn10/16 21/36-001: CTC, Without Stem Cap, WRAS Approved Rubberkhai ruleNo ratings yet

- 02-70 EsDocument2 pages02-70 Eshuzaifaksa435No ratings yet

- Avk Water Meter Valve PN 10 03/28: To DIN 3302 Part 4 Internal Pipe ThreadDocument2 pagesAvk Water Meter Valve PN 10 03/28: To DIN 3302 Part 4 Internal Pipe Threadhuzaifaksa435No ratings yet

- 21-00 EsDocument2 pages21-00 Eshuzaifaksa435No ratings yet

- 45-BC AVK Gate Valve OSYDocument2 pages45-BC AVK Gate Valve OSYAnonymous X3PnFL6No ratings yet

- 23-40 EsDocument2 pages23-40 Eshuzaifaksa435No ratings yet

- Catalogu AVK PDFDocument247 pagesCatalogu AVK PDFDana BaNo ratings yet

- 06-70 GasDocument2 pages06-70 Gashuzaifaksa435No ratings yet

- 23-30 EsDocument2 pages23-30 Eshuzaifaksa435No ratings yet

- Avk Gate Valve PN 10 or PN 16 06/30 - 26/00Document2 pagesAvk Gate Valve PN 10 or PN 16 06/30 - 26/00Popescu OctavianNo ratings yet

- 32-70 Es Ci 2531Document2 pages32-70 Es Ci 2531huzaifaksa435No ratings yet

- 21-36-002 Avkcms enDocument3 pages21-36-002 Avkcms enbrilian pungkyNo ratings yet

- Avk Service Connection Valve PN 4 03/25: To DIN 3352 Part 4 Internal Thread Stem Sealing Exchangeable Under PressureDocument2 pagesAvk Service Connection Valve PN 4 03/25: To DIN 3352 Part 4 Internal Thread Stem Sealing Exchangeable Under Pressurehuzaifaksa435No ratings yet

- 02-21 GSDocument2 pages02-21 GShuzaifaksa435No ratings yet

- 06-30-029 Avk002ax EniDocument2 pages06-30-029 Avk002ax EniFiroz HussainNo ratings yet

- 16-0X BrassDocument2 pages16-0X Brasshuzaifaksa435No ratings yet

- 21-60 EsDocument2 pages21-60 Eshuzaifaksa435No ratings yet

- 06-34 GSDocument2 pages06-34 GShuzaifaksa435No ratings yet

- AVK DenmarkDocument9 pagesAVK DenmarkirislamfwNo ratings yet

- 84-45-003 Avk002ax Eni 432444Document3 pages84-45-003 Avk002ax Eni 432444Gotica ManagementNo ratings yet

- Van Cong Ty Chim Ydk Apt2Document2 pagesVan Cong Ty Chim Ydk Apt2Le NghiNo ratings yet

- 21-30 GSDocument2 pages21-30 GShuzaifaksa435No ratings yet

- 45-59-020 Avk002ax Eni 429978Document2 pages45-59-020 Avk002ax Eni 429978中交一公院贝佳亚项目No ratings yet

- Avk Air ValveDocument3 pagesAvk Air ValveNaqiudin ZainudinNo ratings yet

- 55-58 Es Ai PiDocument2 pages55-58 Es Ai Pihuzaifaksa435No ratings yet

- ES - Model W-M110-10.Document2 pagesES - Model W-M110-10.SANRAJ TECHNONo ratings yet

- Series 158 Valve DVDocument2 pagesSeries 158 Valve DVhuzaifaksa435No ratings yet

- Series 56TR Installation DVDocument1 pageSeries 56TR Installation DVhuzaifaksa435No ratings yet

- Series 52 MkII DVDocument2 pagesSeries 52 MkII DVhuzaifaksa435No ratings yet

- Series 55-55 LD DVDocument2 pagesSeries 55-55 LD DVhuzaifaksa435No ratings yet

- Series 60 A DVDocument2 pagesSeries 60 A DVhuzaifaksa435No ratings yet

- 55-50 250 AA FLGDocument2 pages55-50 250 AA FLGhuzaifaksa435No ratings yet

- 25-00X Fire 250 AA PI MJDocument2 pages25-00X Fire 250 AA PI MJhuzaifaksa435No ratings yet

- 15-40 Es - AumaDocument2 pages15-40 Es - Aumahuzaifaksa435No ratings yet

- 21-5G ES ANSI DWGDocument1 page21-5G ES ANSI DWGhuzaifaksa435No ratings yet

- 15-40 Es (1999)Document4 pages15-40 Es (1999)huzaifaksa435No ratings yet

- 21-60 EsDocument2 pages21-60 Eshuzaifaksa435No ratings yet

- 5 Types of Interim MeasuresDocument6 pages5 Types of Interim Measureshuzaifaksa435No ratings yet

- Arbitration ClausesDocument8 pagesArbitration Clauseshuzaifaksa435No ratings yet

- Duw1012 Unit 7 ErgonomicsDocument26 pagesDuw1012 Unit 7 ErgonomicsAzuraNo ratings yet

- R2729 12111992 PDFDocument84 pagesR2729 12111992 PDFV C AgnihotriNo ratings yet

- Christianity Opium or TruthDocument188 pagesChristianity Opium or TruthNyamsick Adrian100% (1)

- PHOTOTHERAPYDocument3 pagesPHOTOTHERAPYkimglaidyl bontuyanNo ratings yet

- Electricity Safety Electric Line Clearance Regulations 2010Document38 pagesElectricity Safety Electric Line Clearance Regulations 2010Atef Ben AmmarNo ratings yet

- Across-Pro CompressDocument60 pagesAcross-Pro CompressJavier Arancibia MartinezNo ratings yet

- World Class ManufacturingDocument9 pagesWorld Class ManufacturinganupraipurNo ratings yet

- Thyroid Disease in Adults PDFDocument316 pagesThyroid Disease in Adults PDFAnonymous ZZCCXMoRosNo ratings yet

- S C R S C: Ymptom Lusters Elated To Pecific AncersDocument6 pagesS C R S C: Ymptom Lusters Elated To Pecific AncersDip Ayan MNo ratings yet

- Magnolia CleopatraDocument2 pagesMagnolia CleopatraVladescu DianaNo ratings yet

- Chuck SipesDocument89 pagesChuck Sipesstarmitt100% (1)

- Inanna Hyper-LuminalDocument49 pagesInanna Hyper-LuminalMaria Eugenia SusNo ratings yet

- Louis I Kahn Trophy 2021-22 BriefDocument7 pagesLouis I Kahn Trophy 2021-22 BriefMadhav D NairNo ratings yet

- Standard Costing and Variance Analysis FormulasDocument2 pagesStandard Costing and Variance Analysis FormulasAnuraag GuptaaNo ratings yet

- 33.proven MSDSDocument7 pages33.proven MSDSAmit HasanNo ratings yet

- 0811-2 Concentrated Solar Energy - HelioDynamicsDocument20 pages0811-2 Concentrated Solar Energy - HelioDynamicsjames_stone4458No ratings yet

- Centrifugal CompressorsDocument27 pagesCentrifugal CompressorsMike Mukesh100% (1)

- Datos AntropometricosDocument1 pageDatos AntropometricosManuel LoGaNo ratings yet

- Analysis of The Thermal Environment in A Mushroom House Using Sensible Heat Balance and 3D CFDDocument8 pagesAnalysis of The Thermal Environment in A Mushroom House Using Sensible Heat Balance and 3D CFDankithachiluka2605No ratings yet

- DNA Extraction Lab SheetDocument1 pageDNA Extraction Lab SheetStrawberry RoNo ratings yet

- ExamView - Chapter - 01-02Document9 pagesExamView - Chapter - 01-02José Yorki Rodríguez RodríguezNo ratings yet

- Animal Totem MeditationDocument6 pagesAnimal Totem MeditationBalajiNo ratings yet

- Artemis User v8p4Document92 pagesArtemis User v8p4De Jesus, Alexander100% (1)

- A RM 105 19 18 096 SourDocument5 pagesA RM 105 19 18 096 SourGuilherme RochaNo ratings yet

- Bombas Serie 26000 y 25505Document37 pagesBombas Serie 26000 y 25505Fernando Cristian Pérez DíazNo ratings yet

- Christine Wahl, Clarice Scriber, Beth Bloomfield (Eds.) - On Becoming A Leadership Coach - A Holistic Approach To Coaching Excellence (2013, Palgrave Macmillan US) PDFDocument319 pagesChristine Wahl, Clarice Scriber, Beth Bloomfield (Eds.) - On Becoming A Leadership Coach - A Holistic Approach To Coaching Excellence (2013, Palgrave Macmillan US) PDFexra100% (6)

- Review Meeting OM Dated 12.02.2019Document17 pagesReview Meeting OM Dated 12.02.2019shiva5059No ratings yet

- Pashmina ReportDocument13 pagesPashmina ReportDEEPALI SINGHNo ratings yet

- Occupied BedDocument2 pagesOccupied BedZJ GarcianoNo ratings yet