0 ratings0% found this document useful (0 votes)

2 viewsITP For NGR

ITP For NGR

Uploaded by

engbahaa.mbCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

ITP For NGR

ITP For NGR

Uploaded by

engbahaa.mb0 ratings0% found this document useful (0 votes)

2 views1 pageCopyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

2 views1 pageITP For NGR

ITP For NGR

Uploaded by

engbahaa.mbCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 1

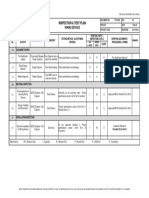

ITP - Inspection & Test Plan

THE CONSTRUCTION MANAGER: THE CONTRACTOR:

Contract No.:

Transmittal no.:

ITP Ref. No.:

Date Issued:

ITP Details

Inspection & Test Plan for NGR

Test or Action

Specification and/or Verification

Item No. Activity Description Inspection Acceptance Criteria Frequency Verification Document

Drawing No. Personnel

Method

B A C

A Visual and Mechanical Inspection

Compare equipment nameplate date with Manufacturer

1.0 Inspection the same as approved before energization CM/ SBG/ QA/QC H H S Appoved shop drawings

drawings and specifications. recomendation

Manufacturer

2.0 Inspect physical and mechanical condition. Inspection no defects before energization CM/ SBG/ QA/QC H H S Appoved shop drawings

recomendation

Inspect anchorage, alignment, grounding, and Manufacturer

3.0 Inspection completeness before energization CM/ SBG/ QA/QC H H S Appoved shop drawings

required area clearances. recomendation

Manufacturer

4.0 Verify the unit is clean Inspection completeness before energization CM/ SBG/ QA/QC H H S Appoved shop drawings

recomendation

Verify that current transformer ratios correspond Manufacturer

6.0 Inspection completeness before energization CM/ SBG/ QA/QC H H S Checklist

to drawings. recomendation

Verify the Resistor Rating as per the approved Manufacturer

7.0 Inspection completeness before energization CM/ SBG/ QA/QC H H S Checklist

drawings. recomendation

Verify that all required grounding and shorting Manufacturer

8.0 Inspection completeness before energization CM/ SBG/ QA/QC H H S Checklist

connection provided. recomendation

Verify all shorting blocks are in correct position, Manufacturer

9.0 Inspection completeness before energization CM/ SBG/ QA/QC H H S Checklist

either grounding or open as required. recomendation

Verify tightness of accessible bolted electrical

connections by calibrated torque-wrench Manufacturer

10.0 test manufacturer recomendation before energization CM/ SBG/ QA/QC H H S Checklist

method in accordance with manufacturer’s recomendation

published data or Table 100.12.

Verify the Equipment’s are satisfied with the Manufacturer

11.0 Inspection manufacturer recomendation before energization CM/ SBG/ QA/QC H H S Appoved shop drawings

specifications and approved drawings. recomendation

B Electrical Test

Perform insulation-resistance tests on Current Manufacturer

1.0 test manufacturer recommendation before energization CM/ SBG/ QA/QC H H W test results

Transformers & Resistors recomendation

Perform electrical tests on Current transformers Manufacturer

2.0 test manufacturer recommendation before energization CM/ SBG/ QA/QC H H W test results

& Resistors. recomendation

Manufacturer

3.0 Perform HI-Pot test test manufacturer recommendation before energization CM/ SBG/ QA/QC H H W test results

recomendation

C Test Values – Visual and Mechanical

Compare bolted connection resistance values to

values of similar connections. Investigate

values which deviate from those of similar Manufacturer

1.0 test manufacturer recomendation before energization CM/ SBG/ QA/QC H R R test results

bolted connections by more than 50 percent of recomendation

the

lowest value. (7.1.1.7.1)

Bolt-torque levels shall be in accordance with

manufacturer’s published data. In the absence

Manufacturer

2.0 of test manufacturer recomendation before energization CM/ SBG/ QA/QC H R R test results

recomendation

manufacturer’s published data, use Table

100.12. (7.1.1.7.2

D Test Values - Electrical

Compare bolted connection resistance values to

values of similar connections. Investigate

values which deviate from those of similar Manufacturer

1.0 test manufacturer recomendation before energization CM/ SBG/ QA/QC H R R test results

bolted connections by more than 50 percent of recomendation

the

lowest value.

Manufacturer

2.0 Electrical tests on Resistors test manufacturer recomendation before energization CM/ SBG/ QA/QC H R R test results

recomendation

Results of electrical tests on instrument

Manufacturer

3.0 transformers shall be in accordance with test manufacturer recomendation before energization CM/ SBG/ QA/QC H R R test results

recomendation

Section 7.10.

Manufacturer

4.0 Heaters shall be operational. test manufacturer recomendation before energization CM/ SBG/ QA/QC H R R test results

recomendation

Legend: H - Hold Point (signature required to proceed) S - Surveillance (random attendance, no signature) B- Subcontractor

W - Witness (attendance expected, signature on check sheet) R - Record Review A - Contractor

C - Constraction Management

You might also like

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys80% (5)

- Supplement For Maintenance Manual DC D 200-300 Error Codes and SchematicsDocument184 pagesSupplement For Maintenance Manual DC D 200-300 Error Codes and SchematicsOmar Ahmed BanawanNo ratings yet

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (6)

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- Inspection and Test Plan For TRAFFIC SIGNSDIRECTIONAL SIGNS-RajDocument4 pagesInspection and Test Plan For TRAFFIC SIGNSDIRECTIONAL SIGNS-RajRaj100% (1)

- Valens VIIDocument118 pagesValens VIIGuy Fletcher100% (3)

- ITP for Lube Oil Pump CPDocument3 pagesITP for Lube Oil Pump CPengbahaa.mbNo ratings yet

- ITP PFCDocument2 pagesITP PFCengbahaa.mbNo ratings yet

- ITP GCPDocument1 pageITP GCPengbahaa.mbNo ratings yet

- ITP For MDBDocument3 pagesITP For MDBengbahaa.mbNo ratings yet

- ITP For LV DB (generator)Document2 pagesITP For LV DB (generator)engbahaa.mbNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- ITP Low Tempt Test - RevDocument6 pagesITP Low Tempt Test - RevAgus GunawanNo ratings yet

- Inspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Document4 pagesInspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Delta akathehuskyNo ratings yet

- ITP DetailDocument5 pagesITP Detailambar patnaikNo ratings yet

- QCR W 2036Document1 pageQCR W 2036Madhan KannanNo ratings yet

- Inspection and Test Plan For: Façade Precast (PC)Document4 pagesInspection and Test Plan For: Façade Precast (PC)grcibsfactoryNo ratings yet

- ITP-1093-201-14AB Rev00 - (JV Rev01) Lighting TrayDocument2 pagesITP-1093-201-14AB Rev00 - (JV Rev01) Lighting TrayRonnel LeanoNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- Itp TankageDocument7 pagesItp TankageIr FankovicNo ratings yet

- Process Control Plan Excel TemplateDocument13 pagesProcess Control Plan Excel TemplateTalal Najeeb100% (1)

- Itp LCSDocument2 pagesItp LCSJeffry M.No ratings yet

- ITP - Installation of LPG Gas System and Control AccessoriesDocument2 pagesITP - Installation of LPG Gas System and Control Accessoriessheik.rasithNo ratings yet

- ITP 1093 201 14AB (Checklist) - Lighting TrayDocument2 pagesITP 1093 201 14AB (Checklist) - Lighting TrayRonnel LeanoNo ratings yet

- ITP - 031 (Earthing)Document2 pagesITP - 031 (Earthing)mohamed wahebNo ratings yet

- SM Naga ItpDocument2 pagesSM Naga Itpjiao longNo ratings yet

- Radiant Square at City of Lights Itp For Pri Commissioning and Testing Commissioning of Rmu and TransformerDocument2 pagesRadiant Square at City of Lights Itp For Pri Commissioning and Testing Commissioning of Rmu and TransformerJeffry M.No ratings yet

- Inspection and Test Plan (Itp)Document2 pagesInspection and Test Plan (Itp)Abdul Gafoor ShaikhNo ratings yet

- Arch & ColumnDocument2 pagesArch & ColumnRonnel LeanoNo ratings yet

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 17-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 17-Mar-16 MechGOSP3 QC Mechanical100% (2)

- Forte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationDocument2 pagesForte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationfrancisbautistaNo ratings yet

- MTB-22A70-PR-ITP-P0009 - ITP for Installation & LT of Drainage Pipes and FittingsDocument2 pagesMTB-22A70-PR-ITP-P0009 - ITP for Installation & LT of Drainage Pipes and Fittingspeligaschristopher12No ratings yet

- 7) ITP For Wiring Accessories InstallationDocument1 page7) ITP For Wiring Accessories Installationislam mohamedNo ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanReduddboy100% (1)

- ITP - 028 (Lighting Fixtures)Document2 pagesITP - 028 (Lighting Fixtures)mohamed wahebNo ratings yet

- TG2048-ITP-MEP-EL-008 (Test Plan)Document2 pagesTG2048-ITP-MEP-EL-008 (Test Plan)Waqar KhanNo ratings yet

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- 5 ITP Block WorkDocument2 pages5 ITP Block Workahmsami91No ratings yet

- ITP-False Celing-NS-MSS-A-003-R-01Document2 pagesITP-False Celing-NS-MSS-A-003-R-01MANAS K. DUTTA100% (1)

- ITP-1093-201-14AB Rev00 - (JV Rev00) Lighting TrayDocument2 pagesITP-1093-201-14AB Rev00 - (JV Rev00) Lighting TrayRonnel LeanoNo ratings yet

- BMC-ITP-PIP-001Document3 pagesBMC-ITP-PIP-001paramet.bmcNo ratings yet

- ITP - 030 (Fire Alarm)Document4 pagesITP - 030 (Fire Alarm)mohamed wahebNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez67% (3)

- ITP isolatorDocument1 pageITP isolatorpeligaschristopher12No ratings yet

- Cathodic Protection ItpDocument9 pagesCathodic Protection ItpHarmalNo ratings yet

- SB P2a Itp Civ Exc 0002Document3 pagesSB P2a Itp Civ Exc 0002adnanNo ratings yet

- Rock Fall Barrier ITPDocument2 pagesRock Fall Barrier ITPVishnudas MgNo ratings yet

- ITP For CCTV System Testing & CommissioningDocument1 pageITP For CCTV System Testing & CommissioningTamer EidNo ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Spec Pump Final 23112020 Section 4 TabcDocument16 pagesSpec Pump Final 23112020 Section 4 TabcThilagarajah TharumarajahNo ratings yet

- Itp For HbeDocument3 pagesItp For HbeMohammed Abdul WaheedNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Gauge SATR-A-2002 22-Jan-18 MechaneeshNo ratings yet

- Installation of BMS System. CorrectedDocument5 pagesInstallation of BMS System. Correctedahsan308No ratings yet

- BMC-ITP-PIP-001Document8 pagesBMC-ITP-PIP-001paramet.bmcNo ratings yet

- Satr A 2002Document2 pagesSatr A 2002ansar aliNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Fabrication of Steel Structure and Steel Equipmentitp PDF FreeDocument4 pagesFabrication of Steel Structure and Steel Equipmentitp PDF FreeAhmed GhareebNo ratings yet

- Protection Wire Mesh ITPDocument3 pagesProtection Wire Mesh ITPVishnudas MgNo ratings yet

- ISA Certified Control Systems Technician (CCST): Certification Exam Prep: 500 Practice Exam Questions and ExplanationsFrom EverandISA Certified Control Systems Technician (CCST): Certification Exam Prep: 500 Practice Exam Questions and ExplanationsNo ratings yet

- Anticipation: Basic 3D Animation Using BlenderDocument15 pagesAnticipation: Basic 3D Animation Using BlenderAnnie VoinovaNo ratings yet

- Extrusion Processes: Metal FormingDocument43 pagesExtrusion Processes: Metal FormingisraelNo ratings yet

- IELTS1 - Progress Test 3 - Reading - HandoutDocument5 pagesIELTS1 - Progress Test 3 - Reading - HandoutnguyenductiensonNo ratings yet

- Presentation of The Obon FestivalDocument10 pagesPresentation of The Obon FestivalsofosNo ratings yet

- Tata 510 SFC TT BS6 Trucks Overview - Specs, Features & ImagesDocument2 pagesTata 510 SFC TT BS6 Trucks Overview - Specs, Features & ImagesTata Light TrucksNo ratings yet

- Silently Recite A Prayer For The Success of The Procedure. To Ensure That The Procedure Will Be Done Smoothly Without ErrorDocument11 pagesSilently Recite A Prayer For The Success of The Procedure. To Ensure That The Procedure Will Be Done Smoothly Without ErrorJemina Rafanan RacadioNo ratings yet

- Four Thousand Years of Environmental Cha PDFDocument11 pagesFour Thousand Years of Environmental Cha PDFImilla LlnNo ratings yet

- Technical ManualDocument151 pagesTechnical ManualGiannis KavathasNo ratings yet

- HPE ProLiant DL380 Gen11-A50004307enwDocument86 pagesHPE ProLiant DL380 Gen11-A50004307enwPedro MarquezNo ratings yet

- HD3MDIH User ManualDocument80 pagesHD3MDIH User ManualArnold CabadingNo ratings yet

- Low Tide High Tide Low Tide High Tide: Tide Time (+08) & Date HeightDocument12 pagesLow Tide High Tide Low Tide High Tide: Tide Time (+08) & Date Heightikhmal siddiqNo ratings yet

- Freebie 12 Universal LawsDocument9 pagesFreebie 12 Universal LawsCindy Garrett90% (10)

- Sa50 PublicationsDocument177 pagesSa50 PublicationsJacob K ThomasNo ratings yet

- Bar EssentialsDocument112 pagesBar EssentialsHannah xyrienneNo ratings yet

- Industries Class 8 QADocument3 pagesIndustries Class 8 QAtwolivegreensNo ratings yet

- Bachelor of Science in Electrical EngineeringDocument2 pagesBachelor of Science in Electrical EngineeringMia De GuzmanNo ratings yet

- 1600320012-240918 foshan stockDocument98 pages1600320012-240918 foshan stockalexspedcuberNo ratings yet

- Séptimo Ingles 21Document6 pagesSéptimo Ingles 21Nadi Salamandra UrregoNo ratings yet

- Yavanajataka PP 3Document3 pagesYavanajataka PP 3drago_rossoNo ratings yet

- Mini ProjectDocument16 pagesMini Projectkunalbele0No ratings yet

- UC 152x152x30: Cross-Section PropertiesDocument2 pagesUC 152x152x30: Cross-Section PropertiesAjay SinghNo ratings yet

- Sri Krsna Caitanya Divya Sahasra-NamaDocument80 pagesSri Krsna Caitanya Divya Sahasra-Namayashodakumar.bvgNo ratings yet

- 2 Mark (ED Questions)Document26 pages2 Mark (ED Questions)Pradeep ravichanderNo ratings yet

- Osseous Fixation Pathways in Pelvic and Acetabular Fracture Surgery Osteology, Radiology and Clinical Applications 2011Document8 pagesOsseous Fixation Pathways in Pelvic and Acetabular Fracture Surgery Osteology, Radiology and Clinical Applications 2011Gonzalo JimenezNo ratings yet

- Module 1 Earth Science UniverseDocument13 pagesModule 1 Earth Science UniverseHA L ELNo ratings yet

- Group 3 - Robot Hotel Report - Ads557 - N4am2284dDocument21 pagesGroup 3 - Robot Hotel Report - Ads557 - N4am2284dNURUL INSYIRAH AHMAD TAJODINNo ratings yet

- Chapter 23Document53 pagesChapter 23haririNo ratings yet

- Kitamura Mycenter HX 630i Stock No 2560Document3 pagesKitamura Mycenter HX 630i Stock No 2560Yang MuzeNo ratings yet