Meropa 460

Meropa 460

Uploaded by

aziz malikCopyright:

Available Formats

Meropa 460

Meropa 460

Uploaded by

aziz malikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Meropa 460

Meropa 460

Uploaded by

aziz malikCopyright:

Available Formats

Meropa®

Extreme Pressure Industrial Gear Oil

Product Data Sheet

Customer benefits Product features:

Maintains gear set efficiencies • Meropa®oils are high

performance, mild EP,

High thermal stability EP system maintains clean gear and bearing surfaces,

industrial gear lubricant

minimizing deposits which interfere with effective lubrication. High oxidation

formulated with a sulfur-

stability limits in-service viscosity increases, which lead to energy losses.

phosphorus additive system,

Protects metal surfaces which also provides rust

and oxidation inhibition,

Extremely effective EP system forms a protective film in areas of metal-to-metal

a corrosion and oxidation

contact, minimizing wear rates and maintaining efficient transfer of power. Good

inhibitor and a metal

water separation and effective rust inhibitors protect surfaces against rust and

passivator.

corrosion. High thermal stability additive system reduces the formation of high

temperature compounds which can be corrosive to bearing materials. The • Meropa® is specifically

effective corrosion inhibitor provides additional protection for metal components. designed primarily for

industrial gear lubrication

Effective oxidation stability

services where loads and

Effective oxidation inhibitors and copper passivator minimize oil oxidation, limiting shock loadings are high.

viscosity increase and can extend oil drain intervals.

Applications

Can include:

• Enclosed industrial gear drives

• Open gear drives (heavy grades)

• Spur, bevel, helical, worm and industrial hypoid gear cases

• Industrial type reduction gearboxes on mining equipment, cement mills, ball

and rolling mills, crushers, conveyors, kilns, winches, machine tools and marine

equipment

• Chain drives, sprockets, slide guides and flexible couplings

• Plain and rolling element bearings

• For bath, splash, circulation or spray lubrication, as applicable to the grade

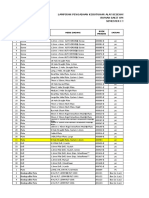

Typical key properties

MEROPA® ENVIRONMENT, HEALTH

and SAFETY

Information is available on

ISO Grade 68 100 150 220 320 460 680 1000 3200 this product in the Material

Safety Data Sheet (MSDS)

Product Code 530400 530409 530401 530402 530403 530404 530405 530406 530408 and Customer Safety Guide.

Customers are encouraged

(Former) AGMA Lubricant No. 2EP 3EP 4EP 5EP 6EP 7EP 8EP 8AEP 10EP to review this information,

follow precautions and comply

David Brown Grade 2E 3E 4E 5E 6E 7E 8E 9E –

with laws and regulations

FZG Pass Stage 12 12 12 12 12 12 12 12 12 concerning product use and

disposal. To obtain a MSDS for

Pour Point, °C -15 -15 -15 -15 -15 -15 -12 -3 0 this product, visit:

www.chevronlubricants.com

Timken OK Load, kg 31.8 31.8 31.8 34.0 34.0 34.0 34.0 34.0 34.0

Viscosity,

mm²/s @ 40°C 68 100 150 220 320 439 650 955 3050

mm²/s @ 100°C 8.8 11.4 14.9 19.2 24.3 29.8 36.5 44.0 –

Viscosity Index 101 100 99 98 97 96 91 85 –

1508

Performance standards

• ANSI/AGMA 9005-E02 EP

• AIST 224 (formerly U.S. Steel 224) (Grades 68 to 320)

• David Brown, Table E, approved (Grades 68 to 1000)

• DIN 51517 Part 3 CLP (Grades 68 to 680)

This bulletin was prepared in good faith

from the best information available at

the time of issue. While the values

and characteristics are considered

representative, some variation, not

affecting performance, can be expected.

It is the responsibility of the user to

ensure that the products are used in the

applications for which they are intended.

Produced by:

Chevron Lubricants

- Asia Pacific

GEN/Asia Pacific/CHV/PDSv1_08/2007

For more information, go to www.chevronlubricants.com © 2007-2015 Chevron Products Company. Singapore. All rights reserved.

You might also like

- Copper SlagDocument1 pageCopper Slagoggay94No ratings yet

- PNS 49 2019 (Preview) PDFDocument3 pagesPNS 49 2019 (Preview) PDFFrancis Bernales25% (4)

- PDS Caltex Delo Starplex EP 3Document3 pagesPDS Caltex Delo Starplex EP 3Juan Carlo PanchoNo ratings yet

- Caltex Regal Ro 46Document3 pagesCaltex Regal Ro 46HyungTae JangNo ratings yet

- PDS CALTEX Turbine OilDocument3 pagesPDS CALTEX Turbine OilAndaru Gunawan0% (1)

- Meropa ISO 320 Technical DatasheetDocument5 pagesMeropa ISO 320 Technical DatasheetaskodidcNo ratings yet

- Chevron MeropaDocument4 pagesChevron MeropaKaly7No ratings yet

- Delo Gold: Multifunctional Diesel Engine OilDocument2 pagesDelo Gold: Multifunctional Diesel Engine OilsanathcgrNo ratings yet

- Texamatic 1888: Automatic Transmission & Power Steering FluidDocument2 pagesTexamatic 1888: Automatic Transmission & Power Steering Fluidhoussem houssemNo ratings yet

- Synlube WS 220Document2 pagesSynlube WS 220martin.baeza81No ratings yet

- TDS Sinopec EP Golden GreaseDocument2 pagesTDS Sinopec EP Golden Greasehuuphuc.chemlubeNo ratings yet

- Rando HD: Premium Anti-Wear Hydraulic FluidDocument2 pagesRando HD: Premium Anti-Wear Hydraulic FluidbdsisiraNo ratings yet

- AP Industrial Gear Oil (FVA54 Micro-Ptting)Document3 pagesAP Industrial Gear Oil (FVA54 Micro-Ptting)Yoong TanNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanNo ratings yet

- Oli Caltex Meropa 220Document4 pagesOli Caltex Meropa 220a3.msaputraNo ratings yet

- Textran TDH Premium: Universal Tractor Transmission OilDocument3 pagesTextran TDH Premium: Universal Tractor Transmission OilRobert RobertsNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- TDS Sinopec HP-R Grease enDocument2 pagesTDS Sinopec HP-R Grease ennghia100% (1)

- Örnek 2Document3 pagesÖrnek 2Emrah1980No ratings yet

- Mobilgear 600 XP Series: Product DescriptionDocument4 pagesMobilgear 600 XP Series: Product DescriptionIvan BecerraNo ratings yet

- AP-S Industrial Gear OilDocument3 pagesAP-S Industrial Gear OilYoong TanNo ratings yet

- Mobil Mobilgear 600XP DatasheetDocument3 pagesMobil Mobilgear 600XP Datasheetphankhoa83-1No ratings yet

- Roller Bearing GreaseDocument2 pagesRoller Bearing GreaseYoong TanNo ratings yet

- Sinopec Extreme Pressure Lithium GreaseDocument3 pagesSinopec Extreme Pressure Lithium GreaseYoong TanNo ratings yet

- TDS Multipurpose Lithium GreaseDocument3 pagesTDS Multipurpose Lithium Greasehuuphuc.chemlubeNo ratings yet

- Ficha Tecnica Castrol Optigear BM RangeDocument3 pagesFicha Tecnica Castrol Optigear BM RangeVictor Manuel Gonzalez PerezNo ratings yet

- Multifak EP: Specialty Industrial GreaseDocument2 pagesMultifak EP: Specialty Industrial GreaseMahmoud TaroutiNo ratings yet

- Ti EVO 3409e Emgard 7148 XFE 75W-80July2023Document2 pagesTi EVO 3409e Emgard 7148 XFE 75W-80July2023Pía RivadeneiraNo ratings yet

- Product Data Sheet: Synthetic Gear OilDocument2 pagesProduct Data Sheet: Synthetic Gear OilDiegoNo ratings yet

- Alpha SMR Heavy X 180KGDocument2 pagesAlpha SMR Heavy X 180KGSerama Tú VõNo ratings yet

- Worm Gear OilDocument2 pagesWorm Gear OilDavidNo ratings yet

- Mobilfluid 428 Mobilfluid 428 Mobilfluid 428 Mobilfluid 428Document4 pagesMobilfluid 428 Mobilfluid 428 Mobilfluid 428 Mobilfluid 428Victor ZhicayNo ratings yet

- Servo Coat 120Document1 pageServo Coat 120BhaveshBalasNo ratings yet

- Super Tractor 15W 40Document3 pagesSuper Tractor 15W 40yuzaidaayubNo ratings yet

- Bpxe 9TQS2KDocument3 pagesBpxe 9TQS2KJayson VegillaNo ratings yet

- BreakerLub-F (EN - Nov'13)Document2 pagesBreakerLub-F (EN - Nov'13)dmb1692No ratings yet

- Sinopec HP-R GreaseDocument3 pagesSinopec HP-R GreaseYoong TanNo ratings yet

- 423-Renolin CLP-1Document1 page423-Renolin CLP-1Moutaz IsmailNo ratings yet

- 4406 Synthetic HD Industrial Gear OilDocument2 pages4406 Synthetic HD Industrial Gear OilYoong TanNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- Lithium Base With Molybdenum Disulfide GreaseDocument2 pagesLithium Base With Molybdenum Disulfide GreaseYoong TanNo ratings yet

- Gear OilDocument2 pagesGear OilQuy CocanhNo ratings yet

- Sinopec Crystal GreaseDocument2 pagesSinopec Crystal GreaseImran ImranNo ratings yet

- Chevron Meropa EP PDSDocument2 pagesChevron Meropa EP PDSArie'f Armand ArsyatNo ratings yet

- Sinopec Super Grease NLGI 2Document2 pagesSinopec Super Grease NLGI 2Yoong TanNo ratings yet

- Marfak 00, 0, 1Document2 pagesMarfak 00, 0, 1Hector IbarraNo ratings yet

- Castrol Optigear Synthetic X 320 Wto - TDSDocument3 pagesCastrol Optigear Synthetic X 320 Wto - TDSHector JNo ratings yet

- Marfak MP EP 3Document2 pagesMarfak MP EP 3aziz malikNo ratings yet

- Polystyrene CRYSTAL 1160: DescriptionDocument2 pagesPolystyrene CRYSTAL 1160: DescriptionlyesNo ratings yet

- Sinopec Golden GreaseDocument2 pagesSinopec Golden GreaseYoong TanNo ratings yet

- Bpxe B6ctalDocument2 pagesBpxe B6ctalVusal HasanovNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- PDS - Mobilgrease XHP 460 SeriesDocument3 pagesPDS - Mobilgrease XHP 460 SeriesJuanSantillanNo ratings yet

- Castrol Axle EPX 80W-90Document1 pageCastrol Axle EPX 80W-90indeskeyNo ratings yet

- Ap Getoel EpDocument1 pageAp Getoel EpSami KahtaniNo ratings yet

- TDS Mfe 711 (New)Document2 pagesTDS Mfe 711 (New)Wahyudi Rendiana NyotoNo ratings yet

- Thuban Gl5 Ep: Extreme Pressure Automotive Gear OilDocument3 pagesThuban Gl5 Ep: Extreme Pressure Automotive Gear OilYudha “ilik” SeptaNo ratings yet

- AP-XX-Mobilgear-EP-SeriesDocument2 pagesAP-XX-Mobilgear-EP-Serieshongyu duanNo ratings yet

- Optigear Synthetic X 320 WTO-pds-EngDocument2 pagesOptigear Synthetic X 320 WTO-pds-Engmathankarthik5No ratings yet

- Petronas Gear MepDocument3 pagesPetronas Gear MepLetíciaMendesNo ratings yet

- Best Carpet Cleaning MethodsDocument3 pagesBest Carpet Cleaning MethodsAbhinav AatishNo ratings yet

- Three Easy Woodworking Jigs (Popular Woodworking)Document8 pagesThree Easy Woodworking Jigs (Popular Woodworking)Bozidar Vasiljevic100% (3)

- Semiconductor FabricationDocument20 pagesSemiconductor FabricationMahabub HossainNo ratings yet

- PVD and CVDDocument13 pagesPVD and CVDDishika PoddarNo ratings yet

- BC PPT 5th SemDocument30 pagesBC PPT 5th SemAdiba khanNo ratings yet

- 12 All Dance Movements Can Be Labeled As: First Quarter Oral Recitation Grade 12 Physical EducationDocument2 pages12 All Dance Movements Can Be Labeled As: First Quarter Oral Recitation Grade 12 Physical Educationsheridan DienteNo ratings yet

- (TDS) PP-121 Primer BlackDocument1 page(TDS) PP-121 Primer BlackYou UZBNo ratings yet

- Training PODFA: Overview of The Pyroprocessing ComponentsDocument50 pagesTraining PODFA: Overview of The Pyroprocessing ComponentsДен СтаднікNo ratings yet

- EMbrDocument19 pagesEMbrvenu mechNo ratings yet

- Facilities CatalogDocument28 pagesFacilities CatalogpooNo ratings yet

- SEPCO 02 Hoja de Juntas de CompresiónDocument2 pagesSEPCO 02 Hoja de Juntas de CompresiónVictor Flores ResendizNo ratings yet

- Lehf0142 04Document2 pagesLehf0142 04Guido Emanuel SteinbachNo ratings yet

- Duoline 10Document1 pageDuoline 10sigit praNo ratings yet

- Classen 2021 KatalógusDocument154 pagesClassen 2021 KatalógusVirág TiszaNo ratings yet

- Steel Strapping Production LineDocument2 pagesSteel Strapping Production LineAgustine Setiawan50% (2)

- SERVICE FACTOR & Load Class by AGMA-6Document1 pageSERVICE FACTOR & Load Class by AGMA-6Bhushan PableNo ratings yet

- Chase Oldenburg - ResumeDocument1 pageChase Oldenburg - Resumeapi-460957852No ratings yet

- Sae 1010Document11 pagesSae 1010Osvaldo Ulises Lopez BaltazarNo ratings yet

- De Beer Refinish Product Catalogue 2013Document32 pagesDe Beer Refinish Product Catalogue 2013Gemunu WeerethungaNo ratings yet

- 05 Mould StructureDocument7 pages05 Mould StructureAlex Kiko VillalobosNo ratings yet

- CMT Program - CMT PLUG - 4240 MDocument11 pagesCMT Program - CMT PLUG - 4240 Mabbas ansariNo ratings yet

- Asianpaints Products Woodtech PU InteriorDocument2 pagesAsianpaints Products Woodtech PU InteriorHaider ImamNo ratings yet

- RefluxDocument5 pagesRefluxFranco Salerno100% (1)

- Chain CatalogDocument2 pagesChain CatalogJosh CasementNo ratings yet

- Penawaran Pro Health S1 TH 2019Document42 pagesPenawaran Pro Health S1 TH 2019Nur SyuhadaNo ratings yet

- Protective Coating and Lining Work For Power Generation FacilitiesDocument2 pagesProtective Coating and Lining Work For Power Generation FacilitiesLuizao CabeloNo ratings yet

- ACG - Glass Powder DataDocument17 pagesACG - Glass Powder Dataapi-3709410No ratings yet

- Infineon-Additional Product Information SON packages-AN-v00 01-ENDocument23 pagesInfineon-Additional Product Information SON packages-AN-v00 01-ENneluNo ratings yet