0 ratings0% found this document useful (0 votes)

0 viewsUgft 602 u2 Desc

Ugft 602 u2 Desc

Uploaded by

Arjun jadhavHACCP is a systematic approach to identify and control food safety hazards across the food chain, applicable in various industries. The principles of HACCP include identifying hazards, establishing critical control points, determining critical limits, monitoring these points, and taking corrective actions when limits are not met. Each principle is essential for ensuring food safety and compliance with health regulations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Ugft 602 u2 Desc

Ugft 602 u2 Desc

Uploaded by

Arjun jadhav0 ratings0% found this document useful (0 votes)

0 views3 pagesHACCP is a systematic approach to identify and control food safety hazards across the food chain, applicable in various industries. The principles of HACCP include identifying hazards, establishing critical control points, determining critical limits, monitoring these points, and taking corrective actions when limits are not met. Each principle is essential for ensuring food safety and compliance with health regulations.

Original Description:

ss

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

HACCP is a systematic approach to identify and control food safety hazards across the food chain, applicable in various industries. The principles of HACCP include identifying hazards, establishing critical control points, determining critical limits, monitoring these points, and taking corrective actions when limits are not met. Each principle is essential for ensuring food safety and compliance with health regulations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views3 pagesUgft 602 u2 Desc

Ugft 602 u2 Desc

Uploaded by

Arjun jadhavHACCP is a systematic approach to identify and control food safety hazards across the food chain, applicable in various industries. The principles of HACCP include identifying hazards, establishing critical control points, determining critical limits, monitoring these points, and taking corrective actions when limits are not met. Each principle is essential for ensuring food safety and compliance with health regulations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

UGFT 602: Food Quality Assurance

Descriptive Answer : Unit- 2

1. What is HACCP ? Discuss its relevance in context of food safety.

Ans : 1. HACCP is a systematic preventive approach to identify, evaluate and control food

safety hazards that are caused biological, chemical and physical agents.

2.That can cause the finished product to be unsafe and designs measures to reduce these

risks to a safe level.

3.The HACCP system can be used at all stages of a food chain, from production and

preparation processes including packaging, distribution etc.

4.HACCP has been increasingly applied to industries other than food such as cosmetics and

pharmaceuticals.

5. Examines every step in food operation and identifies the step that are critical to food

safety.

6. Implements effective control measure and monitors procedure at those step.

2. Write note on Principle 1 of HACCP.

Ans : 1.Identify the hazards that affects the process.

2.Identify the steps that hazards likely to occur.

3.Determine the measures that are necessary to control the hazards.

4.Identifying the hazard reasonably likely to occur in its particular process and determining

how it will control those hazards to prevent, eliminate or reduce them to an acceptable level.

5.Can be used to modify a process or product to further assure or improve safety.

3. Write note on principle 2,3 of HACCP.

Ans: Principle 2

1.The hazard that work identified the hazard analysis must be address in the HACCP plan.

2.A hazard is control by one or more critical control point (cap).

3.A CCP is define as a point, step, producers in a food process at which control can be applied.

4.As a result a food safety hazard can be prevented, eliminated, a reduce to acceptable level.

5.CCP is are location in a process at which some accept of control can be applied to control

food safety hazard that have been determined reasonably likely occur.

6.The number of CCP needed depend on the processing steps and control needed to assure

food safety.

7.EX- Include product temperature, certification of incoming product, microbiological testing

and testing for foreign object such as metal contamination.

Principle 3

1.The third principle of HACCP is to determine the Critical Limits (CLs) in the process. A critical

limit is used to distinguish between safe and unsafe operating conditions at a CCP. Critical

Limits must be established for each control measure important to manage food safety at a

Critical Control Point.

2.A critical limit ensures that a biological, chemical or physical hazard is controlled by a CCP.

Each CCP should have at least one critical limit. Critical limits must be something that can be

monitored by measurement or observation. They must be scientifically and/or regulatory

based. Examples include: temperature, time, pH, water activity or available chlorine.

4. Write note on principle 4,5 of HACCP.

Ans: Principle 4 :

1. Monitoring is a planned sequence of measurements or observations at critical control

points to ensure that the critical limits are continuously achieved.

2. The purpose of monitoring is to confirm that the critical limits are being continuously

achieved and to detect any loss of control to enable effective corrective action to be taken.

3. Procedures for monitoring should be established and all relevant staff should be trained

in the appropriate methods as well as in the appropriate recording of results.

4. The nature and frequency of monitoring will depend on the critical limits that are subject

to the monitoring.

5. The most important steps in food production to monitor are:

- cooking

- cooling

- reheating

6. The frequency of monitoring will depend on a number of factors:

1. Nature of the product : The frequency of monitoring may be reduced if the products

are all of a uniform size.

2. Nature of the process: for example monitoring may be reduced for automated

processes compared with manual ones.

3. Nature of production: Monitoring may be carried out per batch and hence the size and

number of batches produced during a day may influence the frequency of monitoring.

4. History of previous checks: Once an initial frequency of monitoring is established it will

be possible to either increase or reduce down the frequency depending on the results

obtained.

Principle 5:

1. The action taken again to make food safe and to get the process back under control.

2. A deviation from a critical limit for Critical Control Point occurs there shall be a corrective

action.

3. Immediate actions taken if processes fail to achieve food safety.

4. Specific: Corrective actions are required for each affected CCP, and for each and every

deviation at each CCP.

Immediate and comprehensive: The time for corrective action is dependent upon the

monitoring frequency. All food products affected and produced within the monitoring time

period must be brought under control. Holding and storage provisions for pending product

must be included.

Documented: Every corrective action for every deviation must be recorded on an

appropriate form.

You might also like

- Develop and Implement A Food Safety PlanDocument15 pagesDevelop and Implement A Food Safety Planneha75% (4)

- Haccp ExamDocument10 pagesHaccp ExamWendy Tandy100% (1)

- Hazard Analysis Critical Control PointDocument37 pagesHazard Analysis Critical Control PointMark Nikko ManginsayNo ratings yet

- Belcher - A Critical Evaluation of Sex Offender Treatment Programmes Used in PrisonsDocument29 pagesBelcher - A Critical Evaluation of Sex Offender Treatment Programmes Used in PrisonsAlvin NicolaNo ratings yet

- HACCPDocument59 pagesHACCPbieche43No ratings yet

- Chapter 4 Food Safety and Quality SystemDocument45 pagesChapter 4 Food Safety and Quality SystemIman Fatihah100% (1)

- 4.0 Food Safety and Quality SystemDocument44 pages4.0 Food Safety and Quality SystemSiti Aisyah MahamudNo ratings yet

- Principles of Haccp: Principle 1 - Conduct A Hazard AnalysisDocument6 pagesPrinciples of Haccp: Principle 1 - Conduct A Hazard AnalysisAttia MunawerNo ratings yet

- HACCPDocument7 pagesHACCPKanjana K BNo ratings yet

- Eating Establishment RegulationsDocument9 pagesEating Establishment RegulationsThelano RapizNo ratings yet

- HACCP PrinciplesDocument2 pagesHACCP PrinciplesnisbabaNo ratings yet

- HACCP PrinciplesDocument2 pagesHACCP PrinciplesnisbabaNo ratings yet

- 12 Steps To Develop A HACCP PlanDocument8 pages12 Steps To Develop A HACCP PlanDeavoNo ratings yet

- Haccp Hazardanalysisandcriticalcontrolpointsalman 180716065517Document29 pagesHaccp Hazardanalysisandcriticalcontrolpointsalman 180716065517NIMRAHNo ratings yet

- HACCP and Kitchen SafetyDocument12 pagesHACCP and Kitchen SafetycecedrakeNo ratings yet

- Module TleDocument5 pagesModule TlejhelaicolomaNo ratings yet

- The Seven Principles of HACCPDocument2 pagesThe Seven Principles of HACCPMagawng Ning Ja Hting NanNo ratings yet

- Haccpppt 201213172644Document18 pagesHaccpppt 201213172644sohani WaghelaNo ratings yet

- 5947020Document28 pages5947020Rajendra TimilsinaNo ratings yet

- Hazard Analysis Critical Control Point 1Document12 pagesHazard Analysis Critical Control Point 1Francis BigualNo ratings yet

- Test Food Safety 2Document7 pagesTest Food Safety 2Danial Iqhwan100% (1)

- Chapter 7-GMP and HACCPDocument5 pagesChapter 7-GMP and HACCPFarzana HossainNo ratings yet

- HACCPImp GuideDocument9 pagesHACCPImp Guidem.monir.saNo ratings yet

- HACCPDocument11 pagesHACCPAyaaaa OmeyyNo ratings yet

- 1305 HACCP, TQM, GMP, RISK ASSESMENT CompressedDocument12 pages1305 HACCP, TQM, GMP, RISK ASSESMENT Compressedakramsharek84No ratings yet

- HACCPDocument28 pagesHACCPShafakatNo ratings yet

- Economical Haccp Plan For A Hostel KitchenDocument3 pagesEconomical Haccp Plan For A Hostel KitchenAshna SinghalNo ratings yet

- GMP N HACCPDocument3 pagesGMP N HACCPrhib47957No ratings yet

- HACCPDocument8 pagesHACCPUsama AjmalNo ratings yet

- HACCP (Hazard Analysis and Critical Control Point)Document11 pagesHACCP (Hazard Analysis and Critical Control Point)Aarzoo DbHlxrBFTl100% (1)

- HaccpDocument8 pagesHaccpYant RUma ButarNo ratings yet

- HACCP Stands ForDocument12 pagesHACCP Stands ForsadiqblouchNo ratings yet

- DIKSHADocument15 pagesDIKSHARaj KamalNo ratings yet

- HACCPDocument8 pagesHACCPKaye NicolasNo ratings yet

- Roll No.44Document5 pagesRoll No.44overthinkinpenguinNo ratings yet

- HACCP System Lecture HandoutDocument17 pagesHACCP System Lecture HandoutRichard Simon Kisitu100% (1)

- Food Quality Control TFT 512Document10 pagesFood Quality Control TFT 512omonzejele jenniferNo ratings yet

- What Is HACCP?Document2 pagesWhat Is HACCP?Tetsuya KurokoNo ratings yet

- Hilda Samden R1806D5522255 Assignment 3 Introduction To Food ScienceDocument7 pagesHilda Samden R1806D5522255 Assignment 3 Introduction To Food Sciencesteven msusaNo ratings yet

- Haccp FsslecDocument18 pagesHaccp FsslecHans JayNo ratings yet

- KakkoL GMP in Food PDFDocument0 pagesKakkoL GMP in Food PDFErwin Koko TkciNo ratings yet

- Haccp PPP - 2Document14 pagesHaccp PPP - 2solivan_051704No ratings yet

- Implement Food Hygiene ProceduresDocument59 pagesImplement Food Hygiene ProceduresShirmeenanwer100% (1)

- HACCPDocument50 pagesHACCPchalilateef123No ratings yet

- HACCPDocument47 pagesHACCPAnonymous El6p9Bl100% (2)

- Keyword THC 2 REVIEWDocument8 pagesKeyword THC 2 REVIEWKarylle Letigio AdiNo ratings yet

- Chapter 4 HaccpDocument41 pagesChapter 4 HaccpSPMUSER9ANo ratings yet

- Process Control in The Food Industry - HACCPDocument4 pagesProcess Control in The Food Industry - HACCPJonatan VenegasNo ratings yet

- Term PaperDocument35 pagesTerm PaperAyesha CampbellNo ratings yet

- History of The Haccp SystemDocument18 pagesHistory of The Haccp SystemScribdTranslationsNo ratings yet

- Haccp GMP Ssop 2007Document7 pagesHaccp GMP Ssop 2007aidaNo ratings yet

- Haccp 1Document20 pagesHaccp 1guzman.regina.lauriaNo ratings yet

- Q1B. Sc. Hospitality Studies (Fifth Semester)Document6 pagesQ1B. Sc. Hospitality Studies (Fifth Semester)krantieducation2024No ratings yet

- Food Safety ProgramsDocument6 pagesFood Safety ProgramsMarianosAntonioFigueroaEspinosaNo ratings yet

- Fan Unit 1Document3 pagesFan Unit 1Kathir ChandruNo ratings yet

- UNIT 3 HACCPDocument3 pagesUNIT 3 HACCPsinghroushan127No ratings yet

- HACCPDocument61 pagesHACCPAbd-alruhman Hossny100% (1)

- 7 Stages of Quality Control Checks For Meat and PoultryDocument2 pages7 Stages of Quality Control Checks For Meat and PoultrysureshNo ratings yet

- Audit of HACCP-IDocument11 pagesAudit of HACCP-IAgronomist ahmed hassanNo ratings yet

- HACCP FormsDocument10 pagesHACCP FormskavehNo ratings yet

- Whidden 2019 AJ 157 119Document15 pagesWhidden 2019 AJ 157 119ali.mansouribidkhani95No ratings yet

- Sacred Feminine Symbol-ThesisDocument100 pagesSacred Feminine Symbol-ThesisDafne RiquelmeNo ratings yet

- Vision Organizational Chart: Development Engineering and Lao GrobalDocument1 pageVision Organizational Chart: Development Engineering and Lao GrobalSengngeun ImmanivongNo ratings yet

- Educ 11 Report (Performance-Based Tests)Document4 pagesEduc 11 Report (Performance-Based Tests)Jonwille Mark CastroNo ratings yet

- NCM 106 BurnsDocument9 pagesNCM 106 BurnsJudeLaxNo ratings yet

- 0 - Leasing Business FinanceDocument3 pages0 - Leasing Business FinanceJohn Carlo TayoNo ratings yet

- T30 Select: Material Safety Data SheetDocument2 pagesT30 Select: Material Safety Data SheetFSO COMPRESORESNo ratings yet

- 2015 06 07 - SempThermMod - ReportDocument6 pages2015 06 07 - SempThermMod - ReportJhonatan AlexisNo ratings yet

- Invesco India Caterpillar PortfolioDocument1 pageInvesco India Caterpillar PortfolioAnkurNo ratings yet

- FAMILYDocument111 pagesFAMILYWilliam SakalaNo ratings yet

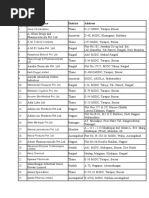

- List of Pharmaceutical Units in IndiaDocument25 pagesList of Pharmaceutical Units in IndiaRomana Zain100% (1)

- Click 2 Invest IllustrationDocument3 pagesClick 2 Invest IllustrationHimanshu AgrawalNo ratings yet

- BombasDocument6 pagesBombaschu42100% (1)

- Christian VirtuesDocument3 pagesChristian VirtuesRyan EnriquezNo ratings yet

- Research Paper On Cloud Computing: June 2021Document7 pagesResearch Paper On Cloud Computing: June 2021AzureNo ratings yet

- AE 233 Strategic Business AnalysisDocument4 pagesAE 233 Strategic Business AnalysisHafie DiranggarunNo ratings yet

- History Module6ADocument47 pagesHistory Module6AVinod ShuklaNo ratings yet

- Lab 1 - Prototype Pollution in Node - Js Hide01.irDocument30 pagesLab 1 - Prototype Pollution in Node - Js Hide01.irDridi MidoNo ratings yet

- Acute Respiratory Distress Syndrome: Jurnal RespirasiDocument11 pagesAcute Respiratory Distress Syndrome: Jurnal RespirasiArmia UsnihidayatiNo ratings yet

- BibliographyDocument4 pagesBibliographyLakshmi NarayananNo ratings yet

- Arguemt EssayDocument4 pagesArguemt Essayapi-296516085No ratings yet

- Learning Plan-Rel Ed 102finalDocument12 pagesLearning Plan-Rel Ed 102finalMichael D. DicenNo ratings yet

- D-6169-98 Selection of Soil and Rock Sampling Devices Used With Drill Rigs For Environmental InvestigationsDocument19 pagesD-6169-98 Selection of Soil and Rock Sampling Devices Used With Drill Rigs For Environmental InvestigationsWaqas Ahmad AbbasiNo ratings yet

- 2321 8539 1 PBDocument13 pages2321 8539 1 PBprincessatlanticsNo ratings yet

- 1 HTF110 IntroDocument8 pages1 HTF110 IntroAmirul FaisalNo ratings yet

- What Is AnxietyDocument1 pageWhat Is AnxietyStacy Ann VergaraNo ratings yet

- Form 2 - Fitness For Duty Assessment: InstructionsDocument3 pagesForm 2 - Fitness For Duty Assessment: InstructionsEKNo ratings yet

- McMaster - About Plastics Doc 8574KACDocument3 pagesMcMaster - About Plastics Doc 8574KACkristechnikNo ratings yet

- Asme B18 2 2 19871 - NutDocument55 pagesAsme B18 2 2 19871 - NutAngelique SutantoNo ratings yet