Document numbering & Control Procedure-Panametrics-1

Uploaded by

Prudvesh ChDocument numbering & Control Procedure-Panametrics-1

Uploaded by

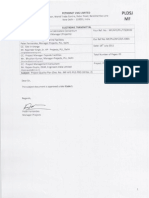

Prudvesh Ch‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev.

Page

Package

PEPL / 000 / II / 000 / CP / 001 0 1 of 14

PROJECT :

LOCATION :

DOCUMENT NUMBERING AND CONTROL PROCEDURE

Document Category Document Review Status

1 Approved / Reviewed

Approval

2 Approved / Reviewed with comments as marked

Review

3 Not Approved / Resubmit

Information

4 Retained for Information / Records

Date: Name:

This approval does not absolve the Contractor from meeting their contractual

obligations of delivering a complete, safe and efficiently operating units/facilities

meeting all requirements of the contract.

Pages modified under this revision:

0 ISSUED FOR INFORMATION

Date

Rev STATUS WRITTEN BY CHECKED BY APPROVED BY AUTHORIZED BY

DD/MM/YYYY

DOCUMENT REVISIONS

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 2 of 14

CONTENT

1. OBJECTIVE

2. SCOPE

3. PROJECT INTRODUCTION

4. ABBREVIATION

5. RESPONSIBILITIES

6. DOCUMENT CONTROL PROCEDURE

6.1 DOCUMENT RECEIVING

6.2 DOCUMENT CIRCULATING/ ACCESS

6.3 DOCUMENT DISTRIBUTING

7. PROJECT COORDINATION AND DOCUMENT NUMBERING PROCEDURE

7.1 PROJECT PROCEDURE/QAP/ITP/PQR/WPS/MS NUMBERING

7.2 PROJECT QUALITY CONTROL FORMS NUMBERING

7.3 REQUEST FOR INSPECTION (RFI) / FIELD INSPECTION NOTE (FIN) NUMBERING

7.4 STAGE WISE INSPECTION REPORT NUMBERING

7.5 IMIR NUMBERING

8. RECORD KEEPING AND TRACKING

8.1 ELECTRONIC FILE NAME

8.2 ARRANGEMENT FOR SIDE LABEL AND COVER PAGE

8.3 DOCUMENT INDEX

8.4 DOCUMENT TRANSMITTAL

8.5 DOCUMENT CHECKLIST

8.6 LETTER IN-OUT REGISTER

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 3 of 14

1. OBJECTIVE

To define & describe the documentation procedures, Shop document numbering (i.e. QAP,

ITP, Job procedure, stage Inspection formats/reports etc.) and responsibilities of concerned

for effective document control, preparation, issue and approvals of drawings, documents etc.

2. SCOPE

This work procedure outlines and describes the document control flow procedure for

documents developed by ‘Panametrics. Document numbering as well as incoming and outgoing

correspondence & transmittals to Client/TPI.

4. ABBREVIATION

PM Project Manager RCM Resident Construction Manager

GM General Manager DC Document Controller

QM Quality Manager HSEM HSE Manager

QA/QC Quality Assurance & Quality Control PMS Project Monitoring System

EIC Engineer-In-Charge AFC Approved for Construction

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 4 of 14

NCR Non Conformity Report ACS Action Control Sheet

QOC Quality Observation Card RFI Request for Inspection

MOM Minutes of Meeting HOD Head Of Department

QAP Quality Assurance Plan ITP Inspection Test Plan

TPIA Third Party Inspection Agency PEPL ‘Panametrics

5. RESPONSIBILITIES

The Planning Manager shall be responsible for the overall implementation of this work

procedure, liaison/co-ordination with the Document controller & HOD's to ensure the efficient

control and security of all drawings & documents.

5.1 The Quality Manager shall be responsible to review the operability of the system and

Conduct assessment of the system on a regular basis.

5.2 The Construction Manager or Discipline Lead will be responsible to ensure the latest

drawings to be available at shop work location for construction.

5.3 The Planning Engineer will be responsible for the day to day activities of the

document control office including receiving, reproduction, issuing and transmitting of all

drawings and documents.

Planning Engineer will be responsible for filing and managing all original drawings

and approved documents received from Client/TPIA.

The Planning Engineer will be responsible to manage and update the Document Control

Database. All Incoming/ Outgoing letters shall be distributed (as marked by SHOP-

Head/GM) vide exclusive mail box by DC. All documents are generated by PEPL and

approvals shall be distributed (as marked by SHOP-Head/GM).

5.4 All concern Leads shall fulfil the requirement of document control and numbering

system as described below and QM shall ensure the numbering system are in place by

means of Inter department auditing as per the audit plan.

5.5 The field Engineer shall be responsible to ensure that current revisions are available/

Followed at work locations and numbering arrangements shall be followed strictly.

6. DOCUMENT CONTROL PROCEDURE

The general sequence of activities for control of documents from/ to PEPL will be as follows:

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 5 of 14

6.1 DOCUMENTS RECEIVING

All documents shall be received by Planning Engineer and date of receipt shall be

mention on every document/ Cover sheet.

Planning Engineer shall communicate through E-mail to Planning Manager / concerned

discipline copy to QM, SHOP-Head/GM.

Planning Engineer shall maintain the Document IN-OUT register with initial of concern,

except drawings received from TPIA.

Separate register shall be maintained for Drawing/ Isometrics received from TPIL with

transmittal no., received date and E-mail date with Initial (for document received

through e-mail).

6.2 DOCUMENT CIRCULATING/ ACCESS

Approved documents shall be scanned and shared by an e-mail communication (with

Link to access) to all PEPL Employees & mark copy to SHOP-Head/GM. Original

document shall be kept at designated area/file.

Original documents access shall be given after only getting authorization from Quality

Manager.

Commented Documents shall be circulated to concerned discipline through SHOP-Head/GM

With proper checklist.

All correspondence from TPIL to P E P L shall be gone through DC under guidance of

SHOP-Head/GM.

Any E-mail/ Letter/ Documents shall not be disclosed to TPIA, Vendor & Sub-Agency

without permission of SHOP-Head/GM.

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 6 of 14

Document Sharing Process

•Mention Received Date & Time

Approved

•Pdf Format Read Only

•Original Kept in Archive at specified area

Scan (Pdf)

•Share Pdf file to access all OCCPL Employees

•Remove obsolete document from Share folder and kept in obsolete folder.

Share •Share Folder- Having Terminology

Discipline

Document Type

Document No. / Name

6.3 DOCUMENT DISTRIBUTING

Planning Engineer shall Issue all drawings to site with proper transmittal through

Shop Head/GM & copy to concerned Engineer in charge.

Planning Engineer Shall Re-issue (Latest revisions) of drawings, Isometrics to site

within a day of received documents and ensuring to mark copy to Engineer in charge.

Planning Engineer shall Re-submit the revised site generated documents to TPIA through

letter marked to Shop Head/GM. Discipline leads ensure that revised data shall be

clouded with revision no. nearby clouds

1

Planning Engineer to ensure to get back all old revision documents from site and

ensure update of IN- OUT register.

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 7 of 14

All obsolete documents shall be kept in designated area/ file after stamping as “VOID”.

All correspondence to TPIL/CLIENT shall be through Planning Engineer under guidance of Shop

Head/GM.

PDF copy of letters & Documents Sent/Received shall be internally distributed by DC for

information.

All documents shall flow as per attached document Flow Chart-1.

Flow Chart-1:-

DOCUMENT FLOW CHART Released date: Rev.-

-

Shop Documents to be prepared by PEPL

Head/GM -

Approved after Internal (Concerned Departments) & forward

Comments incorporated

CLIENT - DC

Documents. for internal review.

AFC Drawings &

Document Preparation

Documents.

PEPL Planning- Mgr PEPL Planning- PEPL-

Superseded Drawings.

Instructed to for Engineer Planning/QAQC/

further processing. Submit documents to TPIA AFC Drawings & Execution

for Review/Approval/ Documents. Departments.

Information/Record.

Documents Submit

To

CLIENT/TPIA

- DC

CLIENT/TPIA

Reviewed &

Approved copy

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 8 of 14

7. PROJECT DOCUMENT NUMBERING PROCEDURE

7.1 PROJECT PROCEDURE/QAP/ITP/PQR/WPS/MS NUMBERING

The arrangement of the Project Procedure numbering shall be as follows:

The fields shall be separated by Slashes only (/), Diacritical characters such as _ * % () -

.?! § And blanks shall be strictly prohibited.

Unit number shall be three digits as:

000 -COMMON

For e.g.:-

Table-1:-

PEPL Project No. Package Unit Doc. Type Serial No. Revision

(Initial)

CP- Common

Procedure

JP- Job

Procedure

QAP- Quality

Assurance Plan

ITP- Inspection

PEPL 000 II 000 Test Plan 001 & 00 & above

PQR- above

Procedure

Qualification

Record

WPS- Welding

Procedure

Specification

MS- Method

Statement

7.2 PROJECT QUALITY CONTROL FORMS NUMBERING

The arrangement of the Project Quality Control Forms Numbering shall be as follows:

The fields shall be separated by Slashes only (/), Diacritical characters such as _ * % () -

.?! § and blanks shall be strictly prohibited.

Unit number shall be three digits as:

000 –COMMON

CONFIDENTIAL – Not to disclose without authorization

‘Panametrics INITIAL Project No. Unit Doc. type Serial No. Rev. Page

Package

PEPL / 000 / II / 000 / CP / 001 0 9 of 14

For e.g.: -

Table-2:-

‘Panametri Project No. Package Unit Category Serial No. Revision

cs(Initial)

GN – General

WH – Ware House

WC – Welding

Consumable

PEPL 942 II 000 WQ – Welder 001 & 00 & above

Qualification above

STR - Structural

E - Equipment

P - Piping

TP – Test Package

FP – Fire Proofing

7.3 REQUEST FOR INSPECTION (RFI) / FIELD INSPECTION NOTE (FIN) NUMBERING

The arrangement of the RFI/Field Inspection Note report numbering shall be as follows:

The fields shall be separated by Slashes only (/), Diacritical characters such as _ * % () -

.?! § and blanks shall be strictly prohibited.

Unit number shall be three digits as:

000 -COMMON

All RFI/Field Inspection Note (FIN) reports shall be arranged and maintained as per work

location indicated F – Field, for site works which covers site Inspection and S – Shop

Inspection. It shall be separate numbering for field and shop. Unit No. shall be used 000-

COMMON for all units for ease of handling (Refer Table-3). For e.g.: -

PEPL/000/S/FIN/00001…..99999, PEPL/000/F/FIN/00001 …..99999

Table-3:-

ONSHORE (INITIAL) UNIT No. INSPECTION SERIALNo

F- FIELD / FIN

PEPL 000 00001-upto- 99999

S- SHOP/ FIN

7.4 STAGE WISE INSPECTION REPORT NUMBERING

The arrangement of the Stage wise Inspection report numbering shall be as follows:

CONFIDENTIAL – Not to disclose without authorization

PANAMETRICS

INITIAL Project No. Package Unit Doc. type Serial No. Rev. Page

PEPL / 000 / 0 / 000 / CP / 001 0 10 of 14

942 0

The fields shall be separated by Slashes only (/), Diacritical characters such as _ * % () -.?!

§ and blanks shall be strictly prohibited.

Unit number shall be two or three digits (Refer Table-4).

Table-4:-

Unit No. Area/Location

000 COMMON

11

12

13

14

Identified numbers will use strictly.

The serial number is the progressive number for the same kind of inspection report and

Serial numbers shall be based on FIVE digits from 00001 up to 99999 (Refer Table-5).

Work location shall be indicating as F – Field, for site works which covers site fabrication

and erection works and S – Shop, for shop fabrication and assembly works, it shall be

prefix before stage inspection (Refer Table-5).

For e.g.: - PEPL/ XX/F/PR/0001…… OR PEPL/ XXX/S/RC/0001…….

Table-5:-

PEPL Unit No. Work Stage for Inspection Serial No.

(Initial) Location

DT - Document Transmittal

RFI - Request for Inspection

SQOR - Site Quality Observation Report

MQR - Monthly Quality Report

NCR- Non conformity Form/Report

QWR- Quality Walk down Report

QTBT- Quality Tool Box Talk

WPS – Welding Procedure Specification

PQR - Procedure Qualification Record

S – Shop

SPPPIR - Surface Preparation And Primer Painting Inspection Report

Refer 00001-upto-

F - Field FPIR – Finish Paint Inspection Report

PEPL Table-4 99999

TMECVR – Testing & Measuring Equipment Calibration Verification Report

DP - Deviation Permit

MRAWR - Site Modification, Rework, Additional Work Report

IMIR – Inward Material Inspection Report

DRR - Daily Receipt Report

MIV – Material Issue Voucher

MRV - Material Return Voucher

ESDRR - Excess /Short/ Damage/ Reject Report

MARF - Material Approval Request Format

EBHR - Electrode Backing and Holding Register

EQTR – Electrode Qualification Test Record

CCLS - Consumable Control Log Sheet

CIS - Consumable Issue Slip

WQT - Welder Qualification Test Record

CONFIDENTIAL – Not to disclose without authorization

PANAMETRICS

INITIAL Project No. Package Unit Doc. type Serial No. Rev. Page

PEPL / 000 / 0 / 000 / CP / 001 0 11 of 14

942 0

ONSHORE Unit No. Work Stage for Inspection Serial No.

(Initial) Location

WPQ - Welder / Welding Operator Performance Qualification Record

WIC - Welder ID Card

WPQR - Welder Performance Qualification Record

WATR - Welder Approval Test Record

SFWVR – Structural Fabrication And Weld Visual Inspection Report -

SHOP

SEWVR - Structural Erection And Weld Visual Inspection Report - FIELD

TTRS - Torque Tightening Report For Structure

SAIR - Structural Alignment Inspection Record

GIR - Grouting Inspection Record

SSHP - Steel Structure Handing Over Protocol

SEARV - Static Equipment Alignment Report( Vertical )

SEARH -Static Equipment Alignment Report( Horizontal )

PARH - Pump Alignment Report ( Horizontal )

EGR - Equipment Grouting Report

FR – Fit up Inspection Report (PIPING)

WV- Weld Visual Inspection Report (PIPING)

PSFWVR - Pipe Support Fabrication And Weld Visual Inspection Report.

PSIVR - Pipe Support Installation And Visual Inspection Report.

PSCP - Piping Spool Clearance For Painting

PSCE - Piping Spool Clearance For Erection

FRIR - Ferrite Inspection Report

S – Shop

Refer

PPR – Pickling & Passivation Report 00001-upto-

PECPL Table-4 F - Field OFIR - Orifice Flange Inspection Report 99999

VER – Valve Erection Report

TTRP - Torque Tightening Report For Piping

PTIJR - AG/ UG Piping TIE IN Joint Inspection Report

PCR - Protective Coating Report

HTR - Holiday Test Report

ATR - Adhesion Test Report

CPC - Cement Pour Card

RFPT- Reinforcement Pad Testing

PMIIR – Positive Material Identification Inspection Report

NDER – Non-Destructive Examination Request

RTPQ – Radiography Test Procedure Qualification

RTOR - Radiography Test Offering Report

RTIR - Radiography Test Interpretation Report

UTR – Ultrasonic Test Report

LPTR – Liquid Penetrant Test Report

MPTR – Magnetic Particle Test Report

PQPWHT – Procedure Qualification For PWHT

OFPWHT - Offering For PWHT

PWHTHR - PWHT AND Hardness Test Report

LOD – List Of Drawings

CMC - Checklist For Mechanical Clearance

PL - Punch List

PHFR – Pre Hydro Test Flushing Report

PTR - Hydrostatic / Pneumatic Pressure Test Report

NDTCC - Non-Destructive Test Clearance Checklist

MAPT – Modification After Pressure Test

FHS – Flange History Sheet

LHS - Line History Sheet

SHS – Support History Sheet

RFPH - Reinforcement Pad History

IRSC - Intimation Regarding System Completion

FC - Final Checklist

RFPCC - Ready For Pre-Commissioning Certificate

RFCC - Ready For Commissioning Certificate

CCC - Completion Of Commissioning Certificate

CPPTP – Cover Page For Pressure Test Package -AG Piping

FPIR - Fire Proofing Inspection Record

CONFIDENTIAL – Not to disclose without authorization

PANAMETRICS

INITIAL Project No. Package Unit Doc. type Serial No. Rev. Page

PEPL / 000 / 0 / 000 / CP / 001 0 12 of 14

942 0

7.5 IMIR NUMBERING

The arrangement of the Inward Material Inspection Report numbering shall be as follows:

The fields shall be separated by Slashes only (/), Diacritical characters such as _ * % () -

.?! § and blanks shall be strictly prohibited.

Unit number shall be three digits as:

000 -COMMON

All Inward Material Inspection reports shall be arranged and maintained

PEPL/942/II/000/IMIR/00001 ………………………..999999,

UNIT No. shall be used 000- COMMON for all units for ease of handling.

8. RECORD KEEPING AND TRACKING

It is important and mandatory to keep a clear and update Inspections Tracking System in order

to:

Monitor the implementation of the Approved Documents

Easily file and find the “Thousands Documents and Inspection issued Reports”

Make easier the Final Documentation Handover

8.1 ARRANGEMENT FOR SIDE LABEL AND COVER PAGE

System for box files side labelling and cover page to ease of access to the required

document and avoid searching each files. For e.g.:-

DISCIPLINE

DOCUMENT COVER PAGE

DISCIPLINE: FOLDER SR.NO.

TITLE (Type of Document) TITLE: FOLDER VOLUME.

DOCUMENT Sr.No. CLIENT :

FROM :

TO : EPCC :

FOLDER SR. NO. : SUB-CONTRACTOR :

FOLDER VOLUME : PROJECT NAME :

SCOPE TITLE :

CONFIDENTIAL – Not to disclose without authorization

PANAMETRICS

INITIAL Project No. Package Unit Doc. type Serial No. Rev. Page

PEPL / 000 / 0 / 000 / CP / 001 0 13 of 14

942 0

8.2 DOCUMENT INDEX

PANAMETRICS.

DOCUMENT INDEX

SL. NO. DOCUMENT DESCRIPTION DOCUMENT NOS. TOTAL PAGES

FROM TO

8.3 DOCUMENT TRANSMITTAL

PANAMETRICS

DOCUMENT TRANSMITTAL

MARK TO (Name) :

DOCUMENT TRANSMITTAL NO. :

ISSUED TO (Agency) :

ISSUE DATE :

DOCUMENT NO. DOCUMENT

SL. NO. DESCRIPTION REV NO.OF NO.OF COPIES REMARKS

SHEETS

ISSUER RECEIVER

Signature & Name Signature &

Name

Date Date

CONFIDENTIAL – Not to disclose without authorization

PANAMETRICS

INITIAL Project No. Package Unit Doc. type Serial No. Rev. Page

PEPL / 000 / 0 / 000 / CP / 001 0 14 of 14

942 0

8.4 DOCUMENT CHECKLIST

Document checklist is only for PEPL internal review of any document which shall be

circulated to concerned Engineer’s as decided by Construction Manager/ Leads.

PANAMETRICS

DOCUMENT CHECKLIST

DOCUMENT NO.&

NAME :

DOCUMENT RELEASE

DATE :

PURPOSE :

RECEIVED BY

SL. NO. INITIALS/ ISSUED COMMENTS REVIEW SIGNATURE DC

DATE DATE (DATE & SIGN)

8.5 LETTER IN-OUT REGISTER

Letter register shall be maintained in soft copy only and monthly circulated to the concern

leads in prescribed format as:

A) Letter – OUT Register to CLIENT/TPIA

Sl. PEPL TPIA PEPL Letter Date Reply

No Letter Ref. Letter Ref. No. Subject

No.

B) Letter – IN Register from CLIENT/TPIA

Sl. CLIENT/T PEPL Letter TPIA Letter Date Reply

No PIA Ref. No. Subject

Letter Ref.

No.

CONFIDENTIAL – Not to disclose without authorization

You might also like

- QA QC Civil Site Engineer Interview NotesNo ratings yetQA QC Civil Site Engineer Interview Notes10 pages

- NEOM-NEN-PRC-030 - 00A Project Doc Numbering and Revision Procedure50% (2)NEOM-NEN-PRC-030 - 00A Project Doc Numbering and Revision Procedure18 pages

- Process Performance Qualification ProtocolNo ratings yetProcess Performance Qualification Protocol7 pages

- James Wright The Impact of Artificial Intelligence Within The Recruitment Industry Defining A New Way of Recruiting100% (1)James Wright The Impact of Artificial Intelligence Within The Recruitment Industry Defining A New Way of Recruiting40 pages

- QS10 Procedure for Incoming Material Control 0000-916-8035-1-21-1001 Rev00No ratings yetQS10 Procedure for Incoming Material Control 0000-916-8035-1-21-1001 Rev009 pages

- QS12 Procedure for In process Inspection 0000-916-8035-1-21-1002 Rev00No ratings yetQS12 Procedure for In process Inspection 0000-916-8035-1-21-1002 Rev009 pages

- ENG PR 009 4 Preparation & Handling of Requisition: Technip KT India LTDNo ratings yetENG PR 009 4 Preparation & Handling of Requisition: Technip KT India LTD5 pages

- QACON 04-Control of Documents and ArchievingNo ratings yetQACON 04-Control of Documents and Archieving3 pages

- Site Inspection Report: Principal Contractor Details100% (1)Site Inspection Report: Principal Contractor Details55 pages

- 2082-PM-CQP-7011 Rev.0 - Constructin Quality PlanNo ratings yet2082-PM-CQP-7011 Rev.0 - Constructin Quality Plan22 pages

- 15.4 GPSPE CC QUA 005 Template Site Quality Documentation ProcedureNo ratings yet15.4 GPSPE CC QUA 005 Template Site Quality Documentation Procedure11 pages

- SECTION 12 DOCUMENT CONTROL& INFORMATION TECHNOLOGYNo ratings yetSECTION 12 DOCUMENT CONTROL& INFORMATION TECHNOLOGY13 pages

- DPR-04 Control of Non Conforming Product-06No ratings yetDPR-04 Control of Non Conforming Product-0614 pages

- VAL 205 Management of Validation Protocols and Reports SampleNo ratings yetVAL 205 Management of Validation Protocols and Reports Sample3 pages

- GF-GEN-G-PR-0521 Document Control Procedure Rev 0No ratings yetGF-GEN-G-PR-0521 Document Control Procedure Rev 027 pages

- Template Validation Plan For Equipment or Process100% (3)Template Validation Plan For Equipment or Process14 pages

- 4201-232-V8-7100-08014 - 001 - CODE 2 - ITP For Central Battery SystemNo ratings yet4201-232-V8-7100-08014 - 001 - CODE 2 - ITP For Central Battery System6 pages

- Nk-Wur-Pep-Mep-002 Document Control - Numbering ProcedureNo ratings yetNk-Wur-Pep-Mep-002 Document Control - Numbering Procedure15 pages

- Project Quality Plan Template: Document Title: Document Number: Rev: Date: Prepared byNo ratings yetProject Quality Plan Template: Document Title: Document Number: Rev: Date: Prepared by15 pages

- 07423.cos - Qua.std - Inspection and Tests For Package Supplies100% (1)07423.cos - Qua.std - Inspection and Tests For Package Supplies6 pages

- IES-PM-PCO-001 - Rev.0 - Project Constructability & Operability ReviewNo ratings yetIES-PM-PCO-001 - Rev.0 - Project Constructability & Operability Review5 pages

- ONA-CW247393-BNYCT-BA-7880-00001 - A01 - Method Statement For Tank 10 Bundwall Rehabilitation - 075036No ratings yetONA-CW247393-BNYCT-BA-7880-00001 - A01 - Method Statement For Tank 10 Bundwall Rehabilitation - 07503615 pages

- Method Statement For Chipping Works-CCTV and ACS DevicesNo ratings yetMethod Statement For Chipping Works-CCTV and ACS Devices4 pages

- 1. BCI11N03-CVL-PRC-AEI-001-REV-0-Procedure for Construction of Civil WorksNo ratings yet1. BCI11N03-CVL-PRC-AEI-001-REV-0-Procedure for Construction of Civil Works20 pages

- FR-01-QAQC-015 Rev.2 Method Statement FormNo ratings yetFR-01-QAQC-015 Rev.2 Method Statement Form4 pages

- TEM 225 Validation Report Combined OQ PQ SampleNo ratings yetTEM 225 Validation Report Combined OQ PQ Sample2 pages

- VAL 005 Validation Concept and Procedure SampleNo ratings yetVAL 005 Validation Concept and Procedure Sample4 pages

- 9101 Form 3: Process Effectiveness Assessment ReportNo ratings yet9101 Form 3: Process Effectiveness Assessment Report3 pages

- MySQL Server Audit Assurance Program - Icq - Eng - 1210No ratings yetMySQL Server Audit Assurance Program - Icq - Eng - 121029 pages

- Is A Literature Review Written in First Person100% (1)Is A Literature Review Written in First Person7 pages

- A Practical Tool Kit To Evaluating Police and Community Crime Preventions ProgramsNo ratings yetA Practical Tool Kit To Evaluating Police and Community Crime Preventions Programs144 pages

- Capstone Project Guidelines Final DraftNo ratings yetCapstone Project Guidelines Final Draft38 pages

- Boeing 737 MAX Crisis A Case Study of Project FailureNo ratings yetBoeing 737 MAX Crisis A Case Study of Project Failure8 pages

- O'Maley-steps in Conducting Scoping ReviewNo ratings yetO'Maley-steps in Conducting Scoping Review1 page

- Final Updated report-1.docxMINI ProjectNo ratings yetFinal Updated report-1.docxMINI Project33 pages

- Writing A Case Study Writing A Case StudyNo ratings yetWriting A Case Study Writing A Case Study2 pages

- SD - Integrating 21st Century Skills in Classroom-Based AssessmentNo ratings yetSD - Integrating 21st Century Skills in Classroom-Based Assessment103 pages

- Massoud Sobhi Salem: Senior Electrical EngineerNo ratings yetMassoud Sobhi Salem: Senior Electrical Engineer3 pages

- Mixed Methods of Research - Designs and Sources of InformationNo ratings yetMixed Methods of Research - Designs and Sources of Information19 pages

- Replacing Performance Ratings How Amazon, Deloitte and Google Do It - ETSNo ratings yetReplacing Performance Ratings How Amazon, Deloitte and Google Do It - ETS4 pages

- NEOM-NEN-PRC-030 - 00A Project Doc Numbering and Revision ProcedureNEOM-NEN-PRC-030 - 00A Project Doc Numbering and Revision Procedure

- James Wright The Impact of Artificial Intelligence Within The Recruitment Industry Defining A New Way of RecruitingJames Wright The Impact of Artificial Intelligence Within The Recruitment Industry Defining A New Way of Recruiting

- QS10 Procedure for Incoming Material Control 0000-916-8035-1-21-1001 Rev00QS10 Procedure for Incoming Material Control 0000-916-8035-1-21-1001 Rev00

- QS12 Procedure for In process Inspection 0000-916-8035-1-21-1002 Rev00QS12 Procedure for In process Inspection 0000-916-8035-1-21-1002 Rev00

- ENG PR 009 4 Preparation & Handling of Requisition: Technip KT India LTDENG PR 009 4 Preparation & Handling of Requisition: Technip KT India LTD

- Site Inspection Report: Principal Contractor DetailsSite Inspection Report: Principal Contractor Details

- 15.4 GPSPE CC QUA 005 Template Site Quality Documentation Procedure15.4 GPSPE CC QUA 005 Template Site Quality Documentation Procedure

- SECTION 12 DOCUMENT CONTROL& INFORMATION TECHNOLOGYSECTION 12 DOCUMENT CONTROL& INFORMATION TECHNOLOGY

- VAL 205 Management of Validation Protocols and Reports SampleVAL 205 Management of Validation Protocols and Reports Sample

- 4201-232-V8-7100-08014 - 001 - CODE 2 - ITP For Central Battery System4201-232-V8-7100-08014 - 001 - CODE 2 - ITP For Central Battery System

- Nk-Wur-Pep-Mep-002 Document Control - Numbering ProcedureNk-Wur-Pep-Mep-002 Document Control - Numbering Procedure

- Project Quality Plan Template: Document Title: Document Number: Rev: Date: Prepared byProject Quality Plan Template: Document Title: Document Number: Rev: Date: Prepared by

- 07423.cos - Qua.std - Inspection and Tests For Package Supplies07423.cos - Qua.std - Inspection and Tests For Package Supplies

- IES-PM-PCO-001 - Rev.0 - Project Constructability & Operability ReviewIES-PM-PCO-001 - Rev.0 - Project Constructability & Operability Review

- ONA-CW247393-BNYCT-BA-7880-00001 - A01 - Method Statement For Tank 10 Bundwall Rehabilitation - 075036ONA-CW247393-BNYCT-BA-7880-00001 - A01 - Method Statement For Tank 10 Bundwall Rehabilitation - 075036

- Method Statement For Chipping Works-CCTV and ACS DevicesMethod Statement For Chipping Works-CCTV and ACS Devices

- 1. BCI11N03-CVL-PRC-AEI-001-REV-0-Procedure for Construction of Civil Works1. BCI11N03-CVL-PRC-AEI-001-REV-0-Procedure for Construction of Civil Works

- Product and Systems Development: A Value ApproachFrom EverandProduct and Systems Development: A Value Approach

- 9101 Form 3: Process Effectiveness Assessment Report9101 Form 3: Process Effectiveness Assessment Report

- MySQL Server Audit Assurance Program - Icq - Eng - 1210MySQL Server Audit Assurance Program - Icq - Eng - 1210

- A Practical Tool Kit To Evaluating Police and Community Crime Preventions ProgramsA Practical Tool Kit To Evaluating Police and Community Crime Preventions Programs

- Boeing 737 MAX Crisis A Case Study of Project FailureBoeing 737 MAX Crisis A Case Study of Project Failure

- SD - Integrating 21st Century Skills in Classroom-Based AssessmentSD - Integrating 21st Century Skills in Classroom-Based Assessment

- Mixed Methods of Research - Designs and Sources of InformationMixed Methods of Research - Designs and Sources of Information

- Replacing Performance Ratings How Amazon, Deloitte and Google Do It - ETSReplacing Performance Ratings How Amazon, Deloitte and Google Do It - ETS