Rapid Crack Propagation in Plastic Pipe: Predicting Full-Scale Critical Pressure From S4 Test Results

Uploaded by

E.s. BinbillahRapid Crack Propagation in Plastic Pipe: Predicting Full-Scale Critical Pressure From S4 Test Results

Uploaded by

E.s. BinbillahRAPID CRACK PROPAGATION IN PLASTIC PIPE:

PREDICTING FULL-SCALE CRITICAL PRESSURE FROM

S4 TEST RESULTS

A. IVANKOVIC and G. P. VENIZELOS

Mechanical Engineering Department, Imperial College of Science, Technology and Medicine, London

SW7 2BX, U.K.

AbstractThe small-scale steady-state (S4) test, evaluating rapid crack propagation (RCP) perform-

ance, is now an international standard for the specication of polyethylene fuelgas distribution pipe.

There is an emerging consensus, amongst users and material developers, that RCP must be guarded

against and that the S4 test is useful for doing so. Argument continues, however, about the S4 critical

pressure requirement, p

cS4

, which should be specied to qualify pipe for a given operating pressure.

Due to the complexity of the phenomenon, the use of numerical simulation is inevitable. The numerical

model has to account for the dynamic deformation and fracture of the structure, the gas dynamics of

the pressurising medium and their interaction. # 1998 Elsevier Science Ltd. All rights reserved

Keywordsrapid crack propagation, plastic pipe, nite volume, critical pressure prediction, full-scale

test, S4 test.

1. INTRODUCTION (STRATEGY FOR PREDICTING FULL-SCALE

CRITICAL PRESSURE)

MOST BURIED pipelines for gas and water distribution are now made from advanced grades of

polyethylene. Although extremely tough, these materials may under certain conditions, be sus-

ceptible to rapid crack propagation (RCP). A fast-running crack, if initiated by impact or other-

wise, can continue to ``unzip'' a pipeline at speeds of 100300 m/s for an indenite distance,

under stresses much lower than material's ultimate strength. New standards for pipe systems,

specify a critical pressure, above which sustained RCP becomes possible, using the small-scale

steady-state (S4) test [1, 2]. However, S4 results have to be correlated with full-scale results.

These full-scale tests are extremely expensive and time consuming and a glut of experimental

results would tend to confuse rather than clarify the situation. Appropriate modelling has to be

included in the analysis. The critical pressure can be determined from a balance between the

crack driving force, G, exerted by the loaded structure, and the dynamic crack resistance of the

material, G

D

. We are implementing the following procedure in order to achieve this objective:

1. perform S4 tests to obtain critical conditions;

2. perform a numerical simulation of the S4 test at critical conditions, to obtain the dynamic

crack resistance of the material;

3. compare this crack resistance with the crack driving force, obtained via a numerical simu-

lation of the full-scale test, in order to establish critical conditions (in the full-scale test).

Determine the correlation factor between the S4 and full-scale tests.

Computationally, this problem is extremely demanding, as it involves dynamic interaction of a

non-linear elastic pipe with the contained compressible uid and the surrounding quasi-uid

backll. Southwest Research [3] developed a package using shell nite element analysis for the

pipe and a nite dierence method for the uid. Although marketed as a denitive solution, the

model suers from several serious shortcomings:

1. the use of shell elements restricts its applicability to thin-wall pipes;

2. the use of two dierent methods and programs, linked by means of interfaces to account for

uid-structure interaction, complicates the modelling and reduces solution economy;

3. there are internal discrepancies between G values computed by dierent procedures.

Engineering Fracture Mechanics Vol. 59, No. 5, pp. 607622, 1998

# 1998 Elsevier Science Ltd. All rights reserved

Printed in Great Britain

0013-7944/98 $19.00 +0.00

PII: S0013-7944(97)00159-8

607

We have been in contact with this work, whilst developing our own novel code, which uses nite

volume discretisation. This method has dominated computational uid dynamics and heat trans-

fer problems since its introduction, and accounts for at least 80% of uid ow computations

encountered in literature. But it has only recently been proven successful in solid body stress

analysis problems[4]. This paper presents an initial stage in the development of a unied compu-

tational model for coupled uid-structure analysis of RCP, in uid pressurised plastic pipes. The

model is based on nite volume (FV) discretisation.

2. THE FINITE VOLUME METHOD

The application of the FV method in structural analysis of complex domains, employing

unstructured meshes with cells of arbitrary topology, can be found in [5, 6]. Its application to

non-linear solids in[7, 8], and the analysis of coupled uid ow, heat transfer and stress analysis

in[9]. Detailed description of FV modelling of fracture problems, including dynamic fracture, is

given in [10, 11]. A brief description of the FV method, as applied to the analysis of RCP in a

linear elastic material, is given here. The formulation presented is restricted to small strains and

no distinction is made between deformed and undeformed congurations.

Consider a solid body, or its arbitrary part, of volume V, bounded by a surface S, with the

unit vector normal n pointing outwards. The momentum equation in its integral form represents

the balance of inertia, surface and body forces:

d

dt

_

V

r

du

dt

dV =

_

S

s n dS

_

V

rf dVY (1)

where r is mass density, u is the displacement vector, s is the symmetric stress tensor and f is

the body force. Behaviour of polyethylene is approximated by Hooke's law:

s = 2mE ldivuIX (2)

Here, m and l are Lame's constants, and the strain tensor E is dened as:

E =

1

2

[gradu (gradu)

T

]X (3)

Combining eqs (1)(3) and neglecting body forces, the following equation in terms of the

unknown displacement vector is obtained:

d

dt

_

V

r

du

dt

dV =

_

S

{m[gradu (gradu)

T

] ldivuI] n dSX (4)

This equation is of hyperbolic nature and requires displacements and velocities at the initial

instant of time t = t

0

at all points of the solution domain.

In order to solve eq. (4), its discrete counterparts have to be obtained and, therefore, a

coordinate system must be chosen. Although components of vectors and tensors related to a

global cartesian system are preferred as they lead to a strong conservation form of momentum

equation, cylindrical coordinate system (y, r, z) is chosen because of a specic geometry of the

problem, resulting in a structured mesh. The solution domain is divided into a number of con-

tiguous cylindrical control volumes (CVs) or cells with six cell-faces S

k

(k = 1, F F F , 6). The time

domain is subdivided into an arbitrary number of time steps, dt. The computational nodes are

placed at cells' centres, where displacement and stress components are stored, while boundary

nodes required for the specication of boundary conditions reside at centres of boundary cell-

faces. When eq. (4) is applied to an arbitrary cell containing centre point P

o

, it takes the form:

d

dt

_

V

Po

r

du

dt

dV =

6

k=1

_

S

k

{m[gradu (gradu)

T

] ldivuI] n dSX (5)

It is worth noticing that eq. (5) is still exact. In order to solve it, integrals have to be approxi-

mated and a distribution of dependant variables and physical properties in space and time have

to be assumed. In the FV procedure adopted, both surface and volume integrals are calculated

employing the mid-point rule, and a piece-wise-linear spatial distribution of displacements is

A. IVANKOVIC and G. P. VENIZELOS 608

employed, guaranteeing a second order accurate spatial discretisation. Physical properties at the

cell-faces are obtained by harmonic interpolation. For temporal variation of dependent vari-

ables, a fully implicit time discretisation is adopted and all dependent variables are expressed in

the current time step t

m

, except in the transient term, where a two-time-level linear variation of

the deformation velocity with time is adopted (m is the time step counter). The magnitude of

the time step is restricted only by the requirement temporal accuracy. In the rst time step, at

time t

1

=t

o

+dt, u

o

and u

1

have to be prescribed. Boundary conditions are implemented by sub-

stituting traction or displacements on the boundary cell faces with prescribed values, [eq. (5)].

Now, eq. (5) can be replaced by the following algebraic equation which relates displacement

vector u

Po

, at the centre of the cell, with those of neighbouring cells, u

Pk

:

a

P

o

u

m

Po

6

k=1

a

k

u

m

P

k

= b

P

o

Y a

P

o

=

6

k=1

a

k

r

m

V

P

o

dt

2

m

Y (6)

Coecients a

k

and the source term b

P

o

are functions of geometry and material properties, and

in addition b

P

o

contains unknown dependent variables. As a result of FV discretisation three

mutually coupled sets of N in general non-linear algebraic equations with three unknown displa-

cement components (u

y

, u

r

and u

z

) are obtained, where N is the number of CVs. A segregated

solution procedure [4] is employed to solve these equations; equations are linearised and sets of

equations for each dependent variable are temporarily decoupled by assuming that coecients

and source terms are known, i.e. they are calculated using dependent variable values from the

previous iteration or the previous time step. In the rst iteration, initial values are used, while

values from the previous iteration are used in the rest of the solution. As a consequence, a sys-

tem of linear algebraic equations is obtained for each displacement component in the form:

Au = bY (7)

where:

1. A is a seven-diagonal, diagonally-dominant [eq. (6)], positive-denite, symmetric-sparse,

NN matrix;

2. vector u contains values of current displacement vector components;

3. b accommodates sources at N nodes.

The segregated solution approach enables reuse of the same storage for A and b, for all du com-

ponents, resulting in very small requirements on computer memory (only 8N storage locations

are required). Equation (7) is solved for each u component in turn, using a line-by-line TDMA

iterative solver, which takes advantage of the structured mesh employed in this study. There is

no need to solve eq. (7) to a tight tolerance, since A and b are only approximations (based on

the solution from the previous iteration), hence reduction of residuals by one order of magni-

tude is sucient. After eq. (7) is solved for all three displacement components, the elements of

the coecient matrix A and the source vector b are updated. The procedure is repeated until

overall convergence criteria is reached, i.e. the sum of absolute residuals for all equations is

below the prescribed tolerance (typically 10

3

). In order to promote stability of the solution

method, an under-relaxation is often necessary. In the transient solution, the calculation is then

advanced to the next time step.

3. MODELLING RAPID CRACK PROPAGATION ALONG A PIPE

RCP along a pressurised pipe involves a complex interaction between the pipe and the con-

tained uid. Behind the crack tip, the uid expands against the deforming pipe aps and escapes

to the atmosphere through the crack opening. This process also causes a decompression wave

which sweeps ahead of the crack tip, reducing the initial pressure p

o

. The deformation of the

crack aps is driven by the uid and resisted by the stiness and inertia of the pipe wall, as well

as the rigidity and inertia of the surrounding backll. According to 1D ow analysis [12] the

reduced pressure at the crack tip, p

1

, is given by the relationship:

Rapid crack propagation in plastic pipe 609

p

1

p

o

=

2

g1

g1

g1

a

c

o

_ _

2g

g1

a ` c

o

1 a b c

o

_

_

_

(8)

Here, g is a gas constant, a is the crack speed and c

o

is the speed of sound in the gas. The

remaining pipe pressure behind the crack tip does not collapse instantly, but decays gradually

over a characteristic length L. This has to be accounted for in the analysis as the exhausting gas

develops a substantial crack driving force.

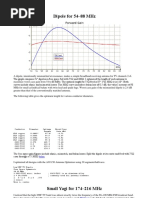

Our numerical analysis relies on a prescribed crack length history. The contained uid is

represented by a pattern of pressure forces, which are uniform ahead of the crack front (p

1

) and

decay linearly behind it, over the decompression length L (Fig. 1). The validity of the linear ap-

proximation, for the pressure prole behind the crack tip, comes from experimental

observation[1316].

3.1. Transient rapid crack propagation

In the present study, a xed-mesh, cell-release FV technique, is employed for the analysis of

an axial crack with a straight front, propagating along a pipe. The eect of the backll is not

taken into account at this stage. Due to symmetry, only half of the pipe is modelled.

The solution to the quasi-static loading of the uncracked pipe, by uniformly applied press-

ure p

1

, provides the initial conditions for the transient calculation. The crack is initiated from a

notch of zero length and propagated by releasing a row of cells, along the straight through-

thickness crack front, according to the specied crack length history (generation mode analysis).

Surface forces on the released cell faces are decayed linearly from their maximum values, at

the instant of release, to zero, as the crack traverses the cell face. This is a conventional pro-

cedure in modelling RCP and it is known as the holding back force approach. The energy

absorbed by a propagating crack is calculated from the local work done by this force:

G =

N

t

i=1

dW

h

dA

_ _

i

=

2

b da

N

t

i=1

_

u

y

o

F

h

du

y

_ _

i

I

2

bdz

N

t

i=1

t

n

t

p

[F

m

h

(u

m

y

u

m1

y

)]

i

X (9)

Here, (W

h

)

i

is the work done by the holding back force (F

h

)

i

acting on the released cell face i,

dA = b da is the fracture surface created upon crack growth da, dz is the axial length of the

crack tip cells, N

t

is the number of cells through the thickness, u

y

is the half crack tip opening

displacement, t

p

, t

n

are the release times of the ``present'' and ``next'' crack front cell respect-

Fig. 1. Pipe solution domain (D, pipe outer diameter; b, pipe wall thickness; d , crack speed; p

1

, crack

tip pressure; L, decompression length; 6: steady-state case).

A. IVANKOVIC and G. P. VENIZELOS 610

ively, and m the current time step. G can also be calculated from the global energy balance:

G =

dW

e

dA

dE

s

dA

dE

k

dA

Y (10)

where:

W

e

=

_

c

F

e

duY E

s

=

1

2

_

V

s X E dVY E

k

=

1

2

_

V

r u u dVY

are total external work, strain and kinetic energy, respectively, F

e

is the external force, u is the

velocity vector and c is the deformation path of boundary points. Agreement between the two

approaches for calculating G, is a necessary condition for the accuracy of the solution.

3.2. Steady-state rapid crack propagation

In steady-state RCP, at constant speed a , an observer travelling with the crack tip, encoun-

ters no local changes in the stress/strain/deformation/pressure eld. As a result, explicit time

dependency is eliminated from the analysis and the inertia force is expressed as:

(F

in

)

P

o

=

d

dt

_

V

Po

r

du

dt

dV = a

2

d

dz

_

V

Po

r

du

dz

dVX (11)

Here, z is the crack propagation direction, and this term is normally discretised using a central

dierencing scheme. However, at higher crack speeds this is blended with a linear upwind dier-

encing scheme, for stability reasons. Numerical simulation was performed on a control volume

containing a section of the pipe with the crack tip (Fig. 2). If the position of this control volume

is xed to the crack tip, the shape of the contained pipe section will remain unchanged. This

allows the dynamic crack driving force G to be calculated from a ``snap-shot'' of the stress/

strain eld in the pipe section, via the global energy balance.

For a crack growth da, G is computed as:

GI

2

bda

{dW

e

[(dE

s

)

f

(dE

s

)

b

] [(dE

k

)

f

(dE

k

)

b

]]Y (12)

with:

dW

e

=

_

L

z=0

_

p

y=0

p(z)r dy dz du

r

I

N

L

k=1

N

p

j=1

p

k

(rdy)

jk

dz

jk

(du

r

)

jk

Y (13)

with:

[(du

r

)

jk

= (u

r

)

jk(ada)

(u

r

)

jk(a)

]

Fig. 2. Control volume for steady-state analysis of RCP in pipe.

Rapid crack propagation in plastic pipe 611

and summation is done over N

L

cells along the distance L, and N

p

cells around the circumfer-

ence. Subscripts f and b refer to the front- and back-end regions of the section. The factor of 2

in eq. (18), accounts for modelling only half of the pipe.

4. FINITE VOLUME SIMULATION OF THE FULL-SCALE PIPE TEST FOR RCP

Simulations were performed for a 250 SDR 11 pipe (D = 250 mm, D/b = 11), with a nom-

inal pressure p

o

=1 bar, and a constant decompression length L = 1.5 D. The following mechan-

ical properties of PE were used in the analysis: E = 2.5 GPa, # = 0.4 and r = 940 kg/m

3

. A

uniform mesh was employed, as recommended for problems of transient RCP, in order to avoid

spurious oscillations. Typically, three cells were used through the pipe wall, 5075 around the

circumference and 100200 per meter of pipe length. At higher crack speeds, the transient simu-

lation requires a longer pipe since transient eects take longer to settle. In the steady-state simu-

lation however, we use a xed pipe length of 3D + L + D, regardless of crack speed. This

contains the crack and the region of pressure outow (Figs 1 and 2).

4.1. Irwin/Corten case

Firstly, we validated the FV model against the IrwinCorten analysis which yields an esti-

mate of the crack driving force[17]. The analysis neglects the eects of gas discharge and transi-

ent pipe motion, and is therefore only applicable for a zero decompression length (L = 0) and a

steady crack growth. It further assumes that the crack is driven solely by the strain energy

stored in the pipe wall, giving:

G

o

=

1

8

pp

2

o

D

2

i

D

m

Eb

2

Y (14)

where D

i

and D

m

are the inner and mean pipe diameter, respectively. A steady-state FV compu-

tation with a =0 and L = 0 is the numerical equivalent to the IrwinCorten analysis. Equation

(14) results in G = 28.9 J/m

2

while the numerical ``IrwinCorten'' simulation yields G = 31.8 J/

m

2

. The agreement between the two is quite reasonable, given the approximative nature of the

analytical solution.

5. CRACK DRIVING FORCE, G: STEADY-STATE VS TRANSIENT COMPUTATION

The accuracy of the transient results is demonstrated by comparing G values as computed

via the holding back force and the global energy balance approaches [eqs (9) and (10), respect-

ively]. As can be seen in Fig. 3 the G-curves computed by the two methods are in good agree-

ment. In the rest of this paper all data of crack driving force are those obtained via the holding-

Fig. 3. Holding back force vs global energy balance approach (a =50 m/s).

A. IVANKOVIC and G. P. VENIZELOS 612

back force approach. Also shown in Fig. 3, is the G value from the steady-state simulation, and

it agrees well with the plateau observed in the transient solution. Figure 4 shows the crack open-

ing prole at various crack tip positions during RCP. Clearly, inside the steady-state ``window''

(2ia/Di3) the crack opening prole does not change; it just translates along the pipe. It is

exactly within this window that the crack driving force goes through a plateau (Fig. 3). It is also

evident, that the simple approximation of the crack driving force by eq. (20), which yields a G

value of 28.9 kJ/m

2

, is inadequate.

G data were generated for a range of crack speeds from 0285 m/s (50285 m/s in the tran-

sient case). Transient results, normalised by G

o

, are presented in Fig. 6. We can see in Fig. 6

that the initial transient nature of crack propagation is eventually followed by steady-state beha-

viour. Oscillations of G are mainly due to the genuine pipe motion; they commence after the

closing crack aps come into contact. The lesser oscillations, observed in the nal stages of

crack growth, are due to end eects. The eect of pipe motion on crack driving force is investi-

gated in Fig. 5. At conditions where G peaks 240 m/s crack speed and 3D decompression

lengththere are considerable oscillations. These oscillations are solely due to contact between

the crack aps as they completely disappear when the aps are allowed to overlap.

Fig. 4. Crack opening displacement vs crack length.

Fig. 5. Transient G vs crack length with and without crack ap overlap.

Rapid crack propagation in plastic pipe 613

A comparison between transient and steady-state G results, over a range of crack speeds, is

shown in Fig. 7. A very good agreement is demonstrated except in the peak region (at about

250 m/s) where the transient result does not show a distinct steady-state ``window'' (Fig. 6). At

this region, the system does not attain steady-state due to the pipe motion demonstrated in

Fig. 5. The shape of the G vs a curve is dictated mainly by inertia eects. In the early stages of

crack growth, inertia resists the opening of the crack aps, to a degree which increases with

crack speed as can be seen from the slope at which G rises (Fig. 6). However, once the crack

aps have opened, it is inertia again that prevents them from closing, hence causing the crack

driving force to settle at a higher plateau. The combined eect of the two mechanisms yields the

rising part of the curve (Fig. 7). At speeds above 250 m/s, substantial amount of energy is con-

sumed by inertia, the crack opening is severely restricted, and G drops rapidly (Fig. 7).

Figure 7 demonstrates once more, how eq. (14) grossly underestimates the crack driving

force, especially at high crack velocities. It has been shown though, that the IrwinCorten analy-

sis is very applicable in the case of water pressurised pipe where decompression behind the

crack tip is almost instantaneous[18].

Fig. 7. Transient and steady-state, G vs crack speed.

Fig. 6. Transient, G vs crack length.

A. IVANKOVIC and G. P. VENIZELOS 614

5.1. Eect of loading area (pressure, decompression length)

Pressure magnitude and decompression length have a similar eect on crack driving force.

So should one expect, since changing any of the two aects the loading area in the same manner

[Fig. 8(b)]. Halving the pressure reduces the crack driving force by exactly a factor of four

[Fig. 8(a)] while halving the decompression length reduces the crack driving force by about a

factor of four [Fig. 8(a)]. The dependency of crack driving force to pressure squared is also pre-

dicted by the IrwinCorten analysis [eq. (14)].

6. FINITE VOLUME SIMULATION OF THE S4 PIPE TEST FOR RCP

6.1. Additional constraints and input of experimental measurements

In our pipe model the pressure forces are represented as a distribution of surface tractions

(Fig. 1). The axial displacements at the bottom axial face (opposite from crack initiation) and

the circumferential displacements of the symmetry plane (except behind the crack tip) are zero.

The edge of the pipe diametrically opposite the crack path can be either xed or free in the

radial direction or only restricted from displacing downwards (pipe on rigid foundation). The

model of the S4 test has to account as well for the displacement constraints imposed by the ap-

paratus on the test pipe (Fig. 9). The additional boundary conditions are:

Fig. 8. Eect of pressure and decompression length on crack driving force (PE63, 160 SDR 11, 08C).

Fig. 9. Schematic of the standard S4 test apparatus and the radial constraints on the test pipe.

Rapid crack propagation in plastic pipe 615

Outward radial displacements are:

1. completely eliminated at the ends of the test pipe due to the end caps, and

2. contained by a cage, to within 5% of the nominal external diameter, at discrete positions

along the test pipe.

Inward radial displacements are:

1. restrained by 1% of the nominal internal diameter, along the anvil zone, where the crack is

initiated, and

2. by 2.5% at discrete positions along the gauge length, due to the decompression baes.

Alternative set ups of the apparatus (e.g. internal seals) are also provided for. The eect of

dierent set ups can be examined by (de)activating the appropriate constraints.

The accuracy of the FV simulation of the S4 test, is again demonstrated by comparing the crack

driving force as computed via the holding-back force and as computed via the global energy bal-

ance. The discrepancy between the two is less than 5% (Fig. 10); particularly small for such a

complex model of dynamic crack propagation.

The experimental values of crack speed and decompression length are also fed into the

code. An example is shown in Fig. 11. Figure 11(a) shows the experimental and idealised crack

speed proles and Fig. 11(b) shows the experimental and idealised decompression length pro-

les. The decompression length is a function of crack speed and pressure. This function has

been obtained both experimentally and analytically[16].

6.2. Comparison between S4 and full-scale results

As we saw in Fig. 8(a), crack driving force in the full-scale test, scales to the square of the

pressure. The trend is maintained in the S4 test (Fig. 12) but the way that driving force develops

with crack growth is dierent. Crack driving force increases much more rapidly in the full-scale

test, because unlike in the S4 test (Fig. 9), the pipe is not restrained from aring outwards. The

constraint of aring in the S4 test, also results in the absence of an inertia peak. In both cases,

the driving force settles to the same plateau.

6.3. Eect of test rig constraints: anvil volume

We used the FV model to simulate the eect of anvil volume. The high volume anvil, speci-

ed by the S4 standard, was ``replaced'' with one of low volume. The S4 setups compared, are

Fig. 10. Comparison between G as computed via the holding back force and as computed via the global

energy balance (PE63, 160 SDR 11, 08C, 3 bar, constant crack speed and decomp. length, S4 setup as

in Fig. 17).

A. IVANKOVIC and G. P. VENIZELOS 616

shown in Figs 9 and 13, respectively. Crack speed input was as in Fig. 11(a) and the decompres-

sion length was kept constant at 1.5 D. The increased air volume in the second setup is rep-

resented by a high value of decompression length over the anvil zone [see Fig. 11(b)].

As can be seen in Fig. 14, the crack driving force rises much earlier in the case of the low

volume anvil. Still though, it does not rise at the rate observed in the full-scale test, again due

to the end cap constraint. This ``choking'' of the driving force occurs at the downstream-end of

the test pipe as well.

6.4. Eect of test rig constraints: pressure seals

The eect of internal expansion seals (Fig. 15) instead of end caps (Fig. 9) was also simu-

lated. For both cases, crack speed input was again as in Fig. 11(a) and the decompression length

xed at 1.5 D.

Fig. 11. Input histories of crack speed and decompression length for the FV code (PE63, 160 SDR 11,

08C, 3 bar).

Fig. 12. Comparison between full scale and S4 results.

Fig. 13. Schematic of the S4 set up with a low volume anvil (compare to Fig. 9).

Rapid crack propagation in plastic pipe 617

As can be seen in Fig. 16 there is a marked dierence in the way crack driving force devel-

ops over the last diameter of crack growth. The choke associated with the end caps is absent in

the setup of internal seals. Based on this evidence, the gauge length in the S4 test was increased

from 4.5 to 5 D, so that the critical crack length that distinguishes propagation from arrest,

does not lie within the region of inuence of the end cap.

Fig. 14. Eect of anvil volume on computed crack driving force (PE63, 160 SDR 11, 08C, crack speed

prole as in Fig. 11(a), constant decompression length and S4 setup as in Figs 9 and 13).

Fig. 15. Schematic of the S4 test conguration with internal seals (compare to Fig. 9).

Fig. 16. Eect of pressure seals on computed crack driving force; (PE63, 160 SDR 11, 08C, crack speed

prole as in Fig. 11(a), constant decompression length and S4 as in Figs 9 and 15).

A. IVANKOVIC and G. P. VENIZELOS 618

7. PREDICTION OF FULL-SCALE CRITICAL PRESSURE

The steps for predicting critical pressure are:

1. Evaluate the dynamic fracture resistance of the pipe. This is achieved by simulating the criti-

cal conditions measured in the S4 test. Experimental records from a test performed just

above critical pressure are shown in Fig. 17. We input these records in the FV model and

compute the crack driving force (Fig. 18) which yields the dynamic fracture resistance, since

G

D

=G at criticality. A value of G

D

of 5 kJ/m

2

is taken as representative of Fig. 18.

2. In order to predict critical conditions we have to obtain the crack driving force at representa-

tive decompression lengths. According to experimental evidence [13, 16] these are: 3D for the

S4 test and 4D for the full-scale test. The predicted critical pressure is the pressure that

satises critical conditions, i.e. G

max

=G

D,min

, and the predicted crack speed is the speed at

G = G

max

(Fig. 19). Results are summarised in Table 1 (note that pipe diameter and grade

are dierent in the two cases). The prediction for the S4 test is very good but in the case of

the full-scale it is conservative by a factor of ve.

We believe that the inaccurate pressure prediction for the full-scale test is mainly due to:

1. the eect of backll in the full-scale test; and

2. the non-linear-elastic behaviour of the pipe material.

Fig. 17. Input histories of crack speed and decompression length for the FV code; (PE80/B, 250 SDR

11, 08C, 1.25 bar).

Fig. 18. Computed crack driving force just above critical conditions; (PE80/B, 250 SDR 11, 08C, 1.25

bar, crack speed and decompression length prole as in Fig. 17 and S4 setup as in Fig. 11).

Rapid crack propagation in plastic pipe 619

7.1. Eect of backll and non-linear material properties

(1) In the full-scale test the pipe is buried under gravel, of a size range of 2040 mm, and to

a depth of 100 mm from its top [19]. The eect of backll is certainly not negligible and has

been of interest to many investigators concerned with ductile RCP in steel pipes. There is indir-

ect evidence (measurements of crack speed and pipe deformation) suggesting that critical press-

ure is higher for a buried pipe[20]. Freund presented a simplied ``backll'' model [21] and came

to the conclusion that the kinetic energy uptake of the soil dominates the energy consumed in

its plastic deformation. We believe that this conclusion is even more valid for the case of RCP

in plastic pipe, where pipe deformation is limited. A good review of experimental results and

simplied models accounting for backll are given by Alder et al. [22]. Measurements of backll

pressure, in full-scale tests of ductile RCP in steel pipes (1989), indicate that the loading exerted

on the pipe by the backll is considerable[23]. Backll eects can be studied by:

(2) Incorporating pipe/backll interaction in a numerical model of pipe RCP. As a rst ap-

proximation, we have simulated backll as distributed mass which is attached on the pipe and

``ies-o'' when the outward radial acceleration of the pipe wall becomes negative (Fig. 20).

Fig. 19. Method for predicting critical pressure; (a) S4 test, PE80/A, 160SR11; (b) Full-Scale test,

PE80/B, 250SDR11.

Table 1.

Crack speed [ m/s] Critical pressure [bar]

Predicted Measured Predicted Measured

S4 140 175 1.72 1.75

Full-scale 220 260 1.80 9.00

Fig. 20. (a) Schematic of FV backll model (transverse pipe section); (b) Eect of backll on crack

driving force (PE80, 160SDR11, p

t

=3 bar, L = 1.5 D, mass ration (backll/pipe) = 3.5).

A. IVANKOVIC and G. P. VENIZELOS 620

Results from this initial model show that crack driving force is considerably reduced (Fig. 20)

and as a result the prediction of full-scale critical pressure improves by a factor of two. On a

more advanced level, backll will be represented as a quasi-uid in a coupled uid/structure in-

teraction model of pipe RCP.

(3) Performing full-scale tests under xed conditions with and without backll. This is

almost certainly the most dicult route to pursue due to the cost and complexity of the full-

scale test.

(4) Performing S4 tests with and without backlla more practical alternative. For this

purpose we have modied our 110 mm S4 rig to investigate the eect of gravel backll on the

critical pressure of PE80 pipe. The rst results have shown an increase in critical pressure by

40% (from 2 to 2.75 bar) in 110 SDR 17.6 pipe under 3 diameters deep backll.

(5) In the present work, we have assumed that PE can be described as linear-elastic, despite

it being a non-linear material. We have developed a version of the pipe code that can account

for non-linear material properties. Initial results show that non-linearity only becomes signicant

at elevated pressures but more work on the issue is necessary.

8. CONCLUSIONS

The nite volume method is a powerful tool for modelling rapid crack propagation in the

S4 and full-scale pipe tests. We have achieved good prediction of critical conditions in the S4

test, but have not yet obtained satisfactory prediction of critical conditions in the full-scale test.

This we believe is mainly due to backll eects in the full-scale test which had not, up to now,

been accounted for in the model. Evidence from an approximate backll model suggests a con-

siderable improvement in the predicted critical pressure. S4 test results with backll have shown

an increase in critical pressure. Another area of uncertainty is the relationship between pressure,

crack speed and decompression length. A coupled model of uid/structure interactioncur-

rently under developmentwill resolve this issue.

REFERENCES

1. Yayla, P. and Leevers, P. S., Engineering and Fracture Mechanics, 1992, 42, 675682.

2. ISO DIS 13477, Thermoplastics pipes for the conveyance of uidsDetermination of the resistance to Rapid Crack

Propagation (RCP)Small-Scale-Steady-State (S4) Test, 1996.

3. O'Donoghue, P. E., Green, S. T., Kanninen, M. F. and Bowles, P. K., Computers and Structure, 1991, 38, 501513.

4. Demirdzic, I., Martinovic, D. and Ivankovic, A., Zavarivanje (Croatia), 1988, 31, 209219.

5. Demirdzic, I. and Muzaferija, S., International Journal of Numerical Methods in Engineering, 1994, 37, 37513766.

6. Demirdzic, I. and Ivankovic, A., Finite Volume Stress Analysis, Lecture Notes, Imperial College, 1996.

7. Demirdzic, I. and Martinovic, D., Computational Methods and Applied Mechanical Engineering, 1993, 109, 331.

8. Dioh, N. N., Ivankovic, A., Leevers, P. S. and Williams, J. G., Proceedings of the Royal Society of London A, 1995,

449, 187204.

9. Demirdzic, I. and Muzaferija, S., Computational Methods and Applied Mechanical Engineering, 1995, 125, 235255.

10. Ivankovic, A., Demirdzic, I., Williams, J. G. and Leevers, P. S., International Journal of Fracture, 1994, 66, 357371.

11. Ivankovic, A. and Williams, J. G., Dynamic Fracture Mechanics, ed. MH, Aliabadi. Computational Mechanics

Publications, Southampton, 1995, pp. 101135.

12. Maxey, W. A., Fracture Initiation, Propagation and Arrest. 5th Symposium on Line Pipe Research. American Gas

Association, Arlington, VA, Nov. 1974, pp. J1J31.

13. Greig, J. M., Fracture Propagation in 250 mm and 315 mm Polyethylene Gas Pipes, Bitish Gas plc, Research and

Technology Division, Engineering Research Station, E472, December 1985.

14. Kanninen, M. F., Leung, C-P., Grigory, S. C., Couque, H. R., Popelar, C. F. and O'Donoghue, P. E., A Fracture

Mechanics Methothology for Preventing Rapid Crack Propagation in PE Gas Distribution Pipes. 12th Plastic Fuel

Gas Pipe Symposium. American Gas Association, Boston Massachusetts, September 1991, pp. 7083.

15. Leevers, P. S., Venizelos, G. and Ivankovic, A., Construction and Building Materials, 1993, 7, 179.

16. Venizelos, G. P., Greenshields, C. J. and Leevers, P. S., An Analytical model of the gas discharge process in the S4

test for Rapid Crack Propagation. In Proceedings of Plastics Pipes IX. The Institute of Materials, London, 1995, pp.

466476.

17. Irwin, G. R. and Corten, H. T., Report to Northern Natural Gas Company and El Paso Natural Gas Company,

1968.

18. Greenshields, C. J. and Leevers, P. S., International Journal of Fracture, 1996, 79, 8595.

19. ISO DIS 13478, Thermoplastics pipes for the conveyance of uidsDetermination of the resistance to Rapid Crack

Propagation (RCP)Full-Scale Test (FST), 1996.

20. Poynton, W. A., A theoretical analysis of shear fracture propagation in backlled gas pipelines, Paper 14. In

Proceedings of the International Symposium on Crack Propagation in Pipelines. Institution of Gas Engineers,

Newcastle Upon Tyne, England, 2627 March 1974.

21. Freund, L. B. and Parks, D. M., Crack Arrest Methothology and Applications, 1980, ASTM STP 711, 359378.

Rapid crack propagation in plastic pipe 621

22. Alder, G. M., Christie, I. F. and Roberts, J. W., Energy Balance Models for Ductile Fracture Propagation in Gas

Pipelines, A study for BG, Department of Civil Engineering and Building Science, Department of Mechanical

Engineering, University of Edinburgh, March 1984.

23. Buzzichelli, G., Demofonti, G., Rizzi, L., Venzi, S., Kanninen, M. F., Cardinal, J. W., O'Donoghue, P. E. and

Morrow, T. B., The Development of a Ductile Pipe Fracture Model, Interim Report on Collaborative Research,

American Gas Association, Contract Nos PR 182-526 and PR 15-527, 31 January 1989.

(Received 12 June 1997, in final form 20 October 1997, accepted 24 October 1997)

A. IVANKOVIC and G. P. VENIZELOS 622

You might also like

- Baya - Bgha - Bvga - Byba - B7wa - Maya - Mfya - MGNo ratings yetBaya - Bgha - Bvga - Byba - B7wa - Maya - Mfya - MG4 pages

- Damage and Fracture Mechanics Techniques For Composite StructuresNo ratings yetDamage and Fracture Mechanics Techniques For Composite Structures81 pages

- Finite Element Analysis: Dr. Latha Nagendran100% (1)Finite Element Analysis: Dr. Latha Nagendran91 pages

- Level Set Method: Advancing Computer Vision, Exploring the Level Set MethodFrom EverandLevel Set Method: Advancing Computer Vision, Exploring the Level Set MethodNo ratings yet

- Coupled Finite Element Analysis of Functionally Graded Fiber Reinforced Composites For Effective Elastic PropertiesNo ratings yetCoupled Finite Element Analysis of Functionally Graded Fiber Reinforced Composites For Effective Elastic Properties10 pages

- Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, CroatiaNo ratings yetFaculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, Croatia10 pages

- Experimental Design Results/Acknowledgements: Local Buckling Behavior of Round Steel Tubes Subjected To Compressive LoadsNo ratings yetExperimental Design Results/Acknowledgements: Local Buckling Behavior of Round Steel Tubes Subjected To Compressive Loads1 page

- 10.1016 J.proeng.2016.12.135 Application of EFGM and XFEM For Fatigue Crack Growth Analysis of Functionally Graded MaterialsNo ratings yet10.1016 J.proeng.2016.12.135 Application of EFGM and XFEM For Fatigue Crack Growth Analysis of Functionally Graded Materials8 pages

- Reviews in Computational ChemistryFrom EverandReviews in Computational ChemistryAbby L. ParrillNo ratings yet

- A First Course in Dimensional Analysis: Simplifying Complex Phenomena Using Physical InsightFrom EverandA First Course in Dimensional Analysis: Simplifying Complex Phenomena Using Physical InsightNo ratings yet

- Article - Random Models Versus Periodic Models For Fibre Reinforced CompositesNo ratings yetArticle - Random Models Versus Periodic Models For Fibre Reinforced Composites9 pages

- 10.1016 J.engfailanal.2017.06.015 Ultimate Bearing Capacity Analysis of A Reactor Pressure Vessel Subjected To Pressurized Thermal Shock With XFEMNo ratings yet10.1016 J.engfailanal.2017.06.015 Ultimate Bearing Capacity Analysis of A Reactor Pressure Vessel Subjected To Pressurized Thermal Shock With XFEM18 pages

- 1979-Hahn-On Transient Analysis of Fluid-Structure SystemsNo ratings yet1979-Hahn-On Transient Analysis of Fluid-Structure Systems9 pages

- Elastic-Plastic Collapse of A Cylindrical Pipe Under External Rigid Body LoadingNo ratings yetElastic-Plastic Collapse of A Cylindrical Pipe Under External Rigid Body Loading66 pages

- Design Considerations in Plastic DesignNo ratings yetDesign Considerations in Plastic Design14 pages

- Method of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsFrom EverandMethod of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsNo ratings yet

- Generalized Force Method On The Example of Plane Geometrically Nonlinear ProblemNo ratings yetGeneralized Force Method On The Example of Plane Geometrically Nonlinear Problem7 pages

- Composite Pressure Hulls For Deep Ocean SubmersiblesNo ratings yetComposite Pressure Hulls For Deep Ocean Submersibles13 pages

- Coda Et Al. - 2022 - Alternative Multiscale Material and Structures ModNo ratings yetCoda Et Al. - 2022 - Alternative Multiscale Material and Structures Mod19 pages

- Composites Science and Technology: Georgios A. Pappas, Arthur Schlothauer, Paolo ErmanniNo ratings yetComposites Science and Technology: Georgios A. Pappas, Arthur Schlothauer, Paolo Ermanni12 pages

- Modeling of Advanced Ultrasonic Testing Methods For Improved Characterization of Pipeline DamageNo ratings yetModeling of Advanced Ultrasonic Testing Methods For Improved Characterization of Pipeline Damage10 pages

- JACM - Volume 5 - Issue 5 - Pages 861-874No ratings yetJACM - Volume 5 - Issue 5 - Pages 861-87414 pages

- The IES Journal Part A: Civil & Structural EngineeringNo ratings yetThe IES Journal Part A: Civil & Structural Engineering6 pages

- Preprint - A Multiscale Virtual Element Method For The Analysis of Heterogeneous MediaNo ratings yetPreprint - A Multiscale Virtual Element Method For The Analysis of Heterogeneous Media40 pages

- Composite Structures: Lina Riaño, Lenaïk Belec, Yoann JoliffNo ratings yetComposite Structures: Lina Riaño, Lenaïk Belec, Yoann Joliff6 pages

- The Current Finite To Fluid: On State of and Structures CouplingNo ratings yetThe Current Finite To Fluid: On State of and Structures Coupling12 pages

- Determination of Burst Pressure of API Steel PipesNo ratings yetDetermination of Burst Pressure of API Steel Pipes10 pages

- Analysis of Finite Element Mesh Spacing Influence On Modeling ResultsNo ratings yetAnalysis of Finite Element Mesh Spacing Influence On Modeling Results4 pages

- Problems in Quantum Mechanics: Third EditionFrom EverandProblems in Quantum Mechanics: Third EditionD. ter Haar3/5 (2)

- Fang Et Al. - 2018 - Investigation On Mechanical Properties of Fibreglass Reinforced Flexible Pipes Under TorsionNo ratings yetFang Et Al. - 2018 - Investigation On Mechanical Properties of Fibreglass Reinforced Flexible Pipes Under Torsion10 pages

- Marine Structures: B. Liu, R. Villavicencio, S. Zhang, C. Guedes SoaresNo ratings yetMarine Structures: B. Liu, R. Villavicencio, S. Zhang, C. Guedes Soares20 pages

- An Overview of Buckling Analysis of Cylinder Subjected To Axially Compressive LoadNo ratings yetAn Overview of Buckling Analysis of Cylinder Subjected To Axially Compressive Load5 pages

- Python For Reservoir Engineering and SurveillanceNo ratings yetPython For Reservoir Engineering and Surveillance7 pages

- Di Mentioning A Simplex Swirl Injector JournalNo ratings yetDi Mentioning A Simplex Swirl Injector Journal15 pages

- Chemistry Equilibrium Reactions Which Factor Influences The Value of The Equilibrium Constant For A Reversible Reaction?No ratings yetChemistry Equilibrium Reactions Which Factor Influences The Value of The Equilibrium Constant For A Reversible Reaction?10 pages

- Whole Unit 2 - Crude Oil and Refining Product TestingNo ratings yetWhole Unit 2 - Crude Oil and Refining Product Testing113 pages

- 254522-FR-EN-HYDRUS Remote Control Guide Type 6 ENNo ratings yet254522-FR-EN-HYDRUS Remote Control Guide Type 6 EN4 pages

- Hope - 4 Grade 12: Quarter 3 Week 1 Module 133% (3)Hope - 4 Grade 12: Quarter 3 Week 1 Module 110 pages

- The Book of Stolen Dreams Teaching Resources100% (1)The Book of Stolen Dreams Teaching Resources13 pages

- 2 Medical Demography Dynamic & Composition-1No ratings yet2 Medical Demography Dynamic & Composition-167 pages

- Commonlit They-Re-Made-Out-Of-Meat StudentNo ratings yetCommonlit They-Re-Made-Out-Of-Meat Student7 pages

- Pole Shift Ning: Antarctic Plate LiftingNo ratings yetPole Shift Ning: Antarctic Plate Lifting7 pages

- 2024_02_20_LIM LFSC Practical Task 1 Grade 12 QP ENG FinalNo ratings yet2024_02_20_LIM LFSC Practical Task 1 Grade 12 QP ENG Final6 pages

- Classification and Identification of Mosquitoes of New MexicoNo ratings yetClassification and Identification of Mosquitoes of New Mexico7 pages

- Baya - Bgha - Bvga - Byba - B7wa - Maya - Mfya - MGBaya - Bgha - Bvga - Byba - B7wa - Maya - Mfya - MG

- Damage and Fracture Mechanics Techniques For Composite StructuresDamage and Fracture Mechanics Techniques For Composite Structures

- Invariant Manifold Theory for Hydrodynamic TransitionFrom EverandInvariant Manifold Theory for Hydrodynamic Transition

- Level Set Method: Advancing Computer Vision, Exploring the Level Set MethodFrom EverandLevel Set Method: Advancing Computer Vision, Exploring the Level Set Method

- Coupled Finite Element Analysis of Functionally Graded Fiber Reinforced Composites For Effective Elastic PropertiesCoupled Finite Element Analysis of Functionally Graded Fiber Reinforced Composites For Effective Elastic Properties

- Faculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, CroatiaFaculty of Mechanical Engineering and Naval Architecture, University of Zagreb, Zagreb, Croatia

- Experimental Design Results/Acknowledgements: Local Buckling Behavior of Round Steel Tubes Subjected To Compressive LoadsExperimental Design Results/Acknowledgements: Local Buckling Behavior of Round Steel Tubes Subjected To Compressive Loads

- 10.1016 J.proeng.2016.12.135 Application of EFGM and XFEM For Fatigue Crack Growth Analysis of Functionally Graded Materials10.1016 J.proeng.2016.12.135 Application of EFGM and XFEM For Fatigue Crack Growth Analysis of Functionally Graded Materials

- A First Course in Dimensional Analysis: Simplifying Complex Phenomena Using Physical InsightFrom EverandA First Course in Dimensional Analysis: Simplifying Complex Phenomena Using Physical Insight

- Article - Random Models Versus Periodic Models For Fibre Reinforced CompositesArticle - Random Models Versus Periodic Models For Fibre Reinforced Composites

- 10.1016 J.engfailanal.2017.06.015 Ultimate Bearing Capacity Analysis of A Reactor Pressure Vessel Subjected To Pressurized Thermal Shock With XFEM10.1016 J.engfailanal.2017.06.015 Ultimate Bearing Capacity Analysis of A Reactor Pressure Vessel Subjected To Pressurized Thermal Shock With XFEM

- 1979-Hahn-On Transient Analysis of Fluid-Structure Systems1979-Hahn-On Transient Analysis of Fluid-Structure Systems

- Elastic-Plastic Collapse of A Cylindrical Pipe Under External Rigid Body LoadingElastic-Plastic Collapse of A Cylindrical Pipe Under External Rigid Body Loading

- Method of Moments for 2D Scattering Problems: Basic Concepts and ApplicationsFrom EverandMethod of Moments for 2D Scattering Problems: Basic Concepts and Applications

- Generalized Force Method On The Example of Plane Geometrically Nonlinear ProblemGeneralized Force Method On The Example of Plane Geometrically Nonlinear Problem

- Composite Pressure Hulls For Deep Ocean SubmersiblesComposite Pressure Hulls For Deep Ocean Submersibles

- Coda Et Al. - 2022 - Alternative Multiscale Material and Structures ModCoda Et Al. - 2022 - Alternative Multiscale Material and Structures Mod

- Composites Science and Technology: Georgios A. Pappas, Arthur Schlothauer, Paolo ErmanniComposites Science and Technology: Georgios A. Pappas, Arthur Schlothauer, Paolo Ermanni

- Modeling of Advanced Ultrasonic Testing Methods For Improved Characterization of Pipeline DamageModeling of Advanced Ultrasonic Testing Methods For Improved Characterization of Pipeline Damage

- The IES Journal Part A: Civil & Structural EngineeringThe IES Journal Part A: Civil & Structural Engineering

- Preprint - A Multiscale Virtual Element Method For The Analysis of Heterogeneous MediaPreprint - A Multiscale Virtual Element Method For The Analysis of Heterogeneous Media

- Composite Structures: Lina Riaño, Lenaïk Belec, Yoann JoliffComposite Structures: Lina Riaño, Lenaïk Belec, Yoann Joliff

- The Current Finite To Fluid: On State of and Structures CouplingThe Current Finite To Fluid: On State of and Structures Coupling

- Determination of Burst Pressure of API Steel PipesDetermination of Burst Pressure of API Steel Pipes

- Analysis of Finite Element Mesh Spacing Influence On Modeling ResultsAnalysis of Finite Element Mesh Spacing Influence On Modeling Results

- Problems in Quantum Mechanics: Third EditionFrom EverandProblems in Quantum Mechanics: Third Edition

- Fang Et Al. - 2018 - Investigation On Mechanical Properties of Fibreglass Reinforced Flexible Pipes Under TorsionFang Et Al. - 2018 - Investigation On Mechanical Properties of Fibreglass Reinforced Flexible Pipes Under Torsion

- Finite Elements: Computational Engineering SciencesFrom EverandFinite Elements: Computational Engineering Sciences

- Marine Structures: B. Liu, R. Villavicencio, S. Zhang, C. Guedes SoaresMarine Structures: B. Liu, R. Villavicencio, S. Zhang, C. Guedes Soares

- An Overview of Buckling Analysis of Cylinder Subjected To Axially Compressive LoadAn Overview of Buckling Analysis of Cylinder Subjected To Axially Compressive Load

- Chemistry Equilibrium Reactions Which Factor Influences The Value of The Equilibrium Constant For A Reversible Reaction?Chemistry Equilibrium Reactions Which Factor Influences The Value of The Equilibrium Constant For A Reversible Reaction?

- Whole Unit 2 - Crude Oil and Refining Product TestingWhole Unit 2 - Crude Oil and Refining Product Testing

- 254522-FR-EN-HYDRUS Remote Control Guide Type 6 EN254522-FR-EN-HYDRUS Remote Control Guide Type 6 EN

- 2024_02_20_LIM LFSC Practical Task 1 Grade 12 QP ENG Final2024_02_20_LIM LFSC Practical Task 1 Grade 12 QP ENG Final

- Classification and Identification of Mosquitoes of New MexicoClassification and Identification of Mosquitoes of New Mexico