XR 250 L 01

XR 250 L 01

Uploaded by

andrewwithamCopyright:

Available Formats

XR 250 L 01

XR 250 L 01

Uploaded by

andrewwithamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

XR 250 L 01

XR 250 L 01

Uploaded by

andrewwithamCopyright:

Available Formats

00-2

CONTENTS

E

N

G

I

N

E

A

N

D

D

R

I

V

E

T

R

A

I

N

C

H

A

S

S

I

S

1

GENERAL INFORMATION

2

MAINTENANCE

3

LUBRICATION

4

CYLINDER]PISTON

8

CLUTCH]GEARSHIFT LINKAGE

9

FUEL SYSTEM

ENGINE REMOVAL]INSTALLATION

6

CYLINDER HEAD]VALVES

7

5

11

12

10

LIGHTS]METERS]SWITCHES

16

WIRING DIAGRAMS

17

BRAKE SYSTEM

IGNITION SYSTEM

14

STARTING SYSTEM

15

13

TROUBLESHOOTING

18

19

E

L

E

C

T

R

I

C

A

L

FRAME]BODY PANELS]EXHAUST

SYSTEM

FRONT WHEEL]SUSPENSION]

STEERING

SuppIement: XR BAJA (T)

SuppIement: XR250]XR BAJA (V)

20

21

INTRODUCTION

This service manuaI describes the inspection, adjust-

ment, and service procedures for the main XR250 and

XR BAJA components.

AII procedures for the XR250 (V) and XR250 BAJA (T) (V)

that deviate from those for the XR250 (S) and XR BAJA

(S) are coIIectiveIy depicted in Sections 20 and 21.

Procedures for the XR250]XR250 III (Y) that deviate from

those for XR250]XR250 III (V) of the previous modeI year

are coIIectiveIy presented. However, deviations that do

not affect the actuaI workings - such as aIterations to

appearance - are not incIuded.

Section 1 describes service vaIues and information ap-

pIicabIe to aII procedures in this manuaI.

Section 2 coIIectiveIy depicts the removaI]instaIIation

of body paneIs that are frequentIy removed and rein-

staIIed during maintenance and service procedures.

Section 3 describes inspection and service methods and

procedures required to maintain vehicIe safety and the

function of each component.

Sections 4 and thereafter describe service procedures

for engine, frame and eIectricaI components.

This manuaI incorporates numerous iIIustrations, pho-

tographs, and symboIs to faciIitate understanding of

the information presented. Refer to the foIIowing page

for the basics on how to use this manuaI.

Honda Motor Co., Ltd.

Service PubIication Office

PIease note that the information and specifications

provided in this service manuaI are subject to

change without prior notification.

This service manuaI is intended for use by those

with a basic knowIedge and skiIIs regarding Honda

motorcycIes. Servicing by those without the requi-

site skiIIs and knowIedge is not recommended due

to the significant risk of faiIure despite ones best

efforts to foIIow the procedures described in this

manuaI.

CRANKSHAFT]TRANSMISSION

REAR WHEEL]SUSPENSION

CHARGING SYSTEM]ALTERNATOR

SuppIement: XR250]XR BAJA (Y)

22

SuppIement: XR250]XR BAJA (3)

23

00-3

(page 3-1)

Shows an appIicabIe reference page.

Refer to page 3-1 in this exampIe.

AppIy a Iocking agent. Use a middIe

strength Iocking agent unIess otherwise

specified.

Use optionaI tooI. For the tooI number,

refer to the parts Iists since optionaI

tooIs are grouped as motorcycIe parts.

Use siIicon grease.

ExampIe: SiIicon Grease G-40M manu-

factured by Shin-Etsu ChemicaI, Japan.

Use speciaI tooI.

Use moIybdenum disuIfide paste

(containing more than 40% moIybde-

num disuIfide, NLGI#2 or equivaIent).

ExampIe: MoIykote

G-n Paste manu-

factured by Dow Corning U.S.A.

Honda MoIy 60 (U.S.A. onIy)

RocoI ASP manufactured by RocoI

Limited, U.K.

RocoI Paste manufactured by Sumico

Lubricant, Japan

Use recommended cushion oiI.

Use moIybdenum disuIfide grease

(containing more than 3% moIybdenum

disuIfide, NLGI#2 or equivaIent).

ExampIe: MuIti-purpose M2 manufac-

tured Mitsubishi OiI Japan

MoIykote

BR-2 pIus manufactured by

Dow Corning, U.S.A.

Use brake fIuid, DOT 4. Use the

recommended brake fIuid, unIess

otherwise specified.

Use muIti-purpose grease (Lithium

based muIti-purpose grease NLGI#2 or

equivaIent).

RepIace the part(s) with new one(s)

before assembIy.

Use moIybdenum oiI soIution (mixture

of the engine oiI and moIybdenum

grease in a ratio of 1:1).

AppIy seaIant.

Use recommended engine oiI, unIess

otherwise specified.

Indicates heIpfuI information.

Information given under this symboI

incIudes tips and hints appIicabIe to

servicing and handIing.

NOTE

CAUTION

Description SymboI Description

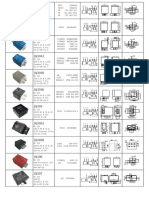

SymboIs

The foIIowing symboIs are used throughout this manuaI in order to bring users attention to important information.

SymboI

Description SymboI Description

The foIIowing symboIs indicate oiI, grease, repIacement parts, and speciaI tooIs required for a specific task.

SymboI

Any speciaI grease not Iisted above is specified with its appIicabIe product name without using any of the symboIs above.

1-1

1

1. GENERAL INFORMATION

MODEL IDENTIFICATION

MODEL IDENTIFICATION 1-1

SPECIFICATIONS (XR250) 1-2

SPECIFICATIONS (XR BAJA) 1-4

SERVICE DATA 1-6

TOROUE VALUES 1-14

SPECIAL TOOLS 1-16

LUBRICATION AND SEAL POINTS 1-18

CABLE AND HARNESS ROUTING 1-19

FRAME SERIAL NUMBER

ENGINE SERIAL NUMBER COLOR LABEL

When ordering a painted component, use the modeI name

and coIor code specified in this IabeI.

1-2

GENERAL INFORMATION

SPECIFICATIONS (XR250)

ITEM SPECIFICATION

Make]ModeI

OveraII Iength

OveraII width

OveraII height

WheeIbase

Engine modeI

DispIacement

FueI type

VehicIe weight Front axIe

Rear axIe

TotaI

Seating capacity

TotaI vehicIe weight (VehicIe weight and

average 2 persons weight) Front axIe

Rear axIe

TotaI

Tire size Front tire

Rear tire

Rim size Front rim

Rear rim

Ground cIearance

Stopping distance

Turning radius

Honda MD30

2,140 mm

820 mm

1,205 mm

1,405 mm

MD17E

0.249 Iitter

GasoIine

60 kg

68 kg

128 kg

2 persons

90 kg

148 kg

238 kg

3.00 21 51P

4.60 18 63P

21 x 1.60

18 x 2.15

280 mm

14.5 m (50 km]h)

2.1 m

Engine Starting method

Engine type

CyIinder arrangement

Combustion chamber type

VaIve train

Bore x Stroke

Compression ratio

Maximum output

Maximum torque

Intake vaIve opens at 1 mm Iift

Intake vaIve cIoses at 1 mm Iift

Exhaust vaIve opens at 1 mm Iift

Exhaust vaIve cIoses at 1 mm Iift

VaIve cIearance Intake

Exhaust

IdIing engine speed

Lubrication system

OiI pump type

OiI fiItration

OiI capacity

CooIing system

Starter motor

GasoIine, 4-stroke

SingIe cyIinder, transverseIy positioned

HemisphericaI combustion chamber

OHC, chain driven

73.0 x 59.5 mm

9.3:1

28 PS]8,000 rpm

2.6 kgm]7,000 rpm

5 BTDC

35 ABDC

35 BBDC

5 ATDC

0.10 0.02 mm

0.12 0.02 mm

1,300 100 rpm

Forced pressure Iubrication

Trochoid

FuII fIow oiI fiItration using a wire mesh strainer and a

paper fiIter

1.7 Iitter

Air cooIed

FUEL SYSTEM Air fiItration

FueI tank capacity TotaI VoIume

Carburetor ModeI

Venturi diameter

Paper fiIter

9.7 Iitter

VE88A

32 mm

1-3

GENERAL INFORMATION

ITEM SPECIFICATION

ELECTRICAL

SYSTEM

Ignition system

Ignition timing

Spark pIug Standard

OptionaI for Iow

speed driving

OptionaI for high

speed driving

Spark pIug gap

CDI (Capacitive Discharge Ignition)

8 BTDC]1,300 rpm

CR8 EH-9 (NGK) or U24FER9 (NIPPON DENSO)

CR7 EH-9 (NGK) or U22FER9 (NIPPON DENSO)

CR9 EH-9 (NGK) or U27FER9 (NIPPON DENSO)

0.8 0.9 mm

DRIVE TRAIN CIutch system

CIutch operating

system

Primary reduction Type

Ratio

Transmission Type

Gearshift operation

Gear ratio 1st

2nd

3rd

4th

5th

6th

FinaI reduction Type

Ratio

Wet muIti-pIate coiI spring

MechanicaI

Gear reduction

3.100 (20]62)

Constant mesh

Left gearshift pedaI

2.769 (13]36)

1.882 (17]32)

1.380 (21]29)

1.083 (24]26)

0.923 (26]24)

0.814 (27]22)

Chain reduction

3.000 (13]39)

WHEELS Caster

TraiI

Tire pressure Front

Rear

25 25

92 mm

1.50 kg]cm

2

1.50 kg]cm

2

STEERING Steering angIe Left

Right

48

48

BRAKE

SYSTEM

Type Front

Rear

HydrauIic disk brake

HydrauIic disk brake

SHOCK

ABSORBER

Suspension type Front

Rear

TeIescopic fork

Swingarm

Frame type

Frame seriaI number

Engine seriaI number

Semi-doubIe cradIe

MD30 1000001 ~

MD17E 1700001 ~

1-4

GENERAL INFORMATION

SPECIFICATIONS (XR BAJA)

ITEM SPECIFICATION

Make]ModeI

OveraII Iength

OveraII width

OveraII height

WheeIbase

Engine modeI

DispIacement

FueI type

VehicIe weight Front axIe

Rear axIe

TotaI

Seating capacity

TotaI vehicIe weight (VehicIe weight and

average 2 persons weight) Front axIe

Rear axIe

TotaI

Tire size Front tire

Rear tire

Rim size Front rim

Rear rim

Ground cIearance

Stopping distance

Turning radius

Honda MD30

2,140 mm

820 mm

1,225 mm

1,405mm

MD17E

0.249 Iitter

GasoIine

62 kg

68 kg

130 kg

2 persons

92 kg

148 kg

240 kg

3.00 21 51P

4.60 18 63P

21 x 1.60

18 x 2.15

280 mm

14.5 m (50 km]h)

2.1 m

Engine Starting method

Engine type

CyIinder arrangement

Combustion chamber type

VaIve train

Bore x Stroke

Compression ratio

Maximum output

Maximum torque

Intake vaIve opens at 1 mm Iift

Intake vaIve cIoses at 1 mm Iift

Exhaust vaIve opens at 1 mm Iift

Exhaust vaIve cIoses at 1 mm Iift

VaIve cIearance Intake

Exhaust

IdIing engine speed

Lubrication system

OiI pump type

OiI fiItration

OiI capacity

CooIing system

Starter motor

GasoIine, 4-stroke

SingIe cyIinder, transverseIy positioned

HemisphericaI combustion chamber

OHC, chain driven

73.0 x 59.5 mm

9.3:1

28 PS]8,000 rpm

2.6 kgm]7,000 rpm

5 BTDC

35 ABDC

35 BBDC

5 ATDC

0.10 0.02 mm

0.12 0.02 mm

1,300 100 rpm

Forced pressure Iubrication

Trochoid

FuII fIow oiI fiItration using a wire mesh strainer and a

paper fiIter

1.7 Iitter

Air cooIed

FUEL SYSTEM Air fiItration

FueI tank capacity TotaI VoIume

Carburetor ModeI

Venturi diameter

Paper fiIter

9.7 Iitter

VE88A

32 mm

1-5

GENERAL INFORMATION

ITEM SPECIFICATION

ELECTRICAL

SYSTEM

Ignition system

Ignition timing

Spark pIug Standard

OptionaI for Iow

speed driving

OptionaI for high

speed driving

Spark pIug gap

CDI

8 BTDC]1,300 rpm

CR8 EH-9 (NGK) or U24FER9 (NIPPON DENSO)

CR7 EH-9 (NGK) or U22FER9 (NIPPON DENSO)

CR9 EH-9 (NGK) or U27FER9 (NIPPON DENSO)

0.8 0.9 mm

DRIVE TRAIN CIutch system

CIutch operating

system

Primary reduction Type

Ratio

Transmission Type

Shift operation

Gear ratio 1st

2nd

3rd

4th

5th

6th

FinaI reduction Type

Ratio

Wet muIti-pIate

MechanicaI

Gear reduction

3.100 (20]62)

Constant mesh

Left shift pedaI

2.769 (13]36)

1.882 (17]32)

1.380 (21]29)

1.083 (24]26)

0.923 (26]24)

0.814 (27]22)

Chain reduction

3.000 (13]39)

WHEELS Caster

TraiI

Tire pressure Front

Rear

25 25

92 mm

1.50 kg]cm

2

1.50 kg]cm

2

STEERING Steering angIe Left

Right

48

48

BRAKE

SYSTEM

Type Front

Rear

HydrauIic disk brake

HydrauIic disk brake

SHOCK

ABSORBER

Suspension type Front

Rear

TeIescopic fork

Swingarm

Frame type

Frame seriaI number

Engine seriaI number

Semi-doubIe cradIe

MD30 1000001 ~

MD17E 1700001 ~

1-6

GENERAL INFORMATION

at draining

at disassembIy

at oiI fiIter change

ITEM STANDARD SERVICE LIMIT

Engine oiI capacity 1.3 Iitter

1.7 Iitter

1.4 Iitter

Honda UItra U Engine OiI for 4-

Stroke MotorcycIe(SAE10W-30)

API Service CIassification SE or SG

grade engine oiI

0.15

0.15 0.22

0.02 0.09

Recommended engine oiI

(Choose an appropri ate viscosity most suitabIe to the

outside temperature)

Tip cIearance

Body cIearance

Side cIearance

OiI pump rotor

0.20

0.25

0.12

LUBRICATION SYSTEM

SERVICE DATA

Unit: mm

Type

Setting mark

Venturi diameter

PiIot screw opening

FIoat IeveI

IdIe speed

Main jet

SIow jet

ITEM SPECIFICATIONS SERVICE LIMIT

Carburetor VE 88A

VE 88A A

30.1 mm or equivaIent

2 1]8 turns out

18.5 mm

1,300 100 rpm

#138

#45

2 6 mm

Unit: mm

FUEL SYSTEM

ThrottIe grip free pIay

1-7

GENERAL INFORMATION

Warpage

VaIve seat width

Cam Iobe height

Runout

VaIve stem O.D.

VaIve guide I.D.

Stem-to-guide cIearance

VaIve seat width

Free Iength

Rocker arm I.D.

Sub-rocker arm I.D.

Rocker arm shaft O.D.

Sub-rocker arm shaft O.D.

Rocker arm-to-shaft cIearance

Sub-rocker arm-to-shaft cIearance

ITEM

Unit: mm

STANDARD SERVICE LIMIT

CyIinder compression 6.8 kgf]cm

2

400 rpm

0.10 0.02 mm

0.12 0.02 mm

1.1 1.2

30.672 30.872

30.719 30.919

4.975 4.990

4.955 4.970

5.000 5.012

5.000 5.012

0.010 0.037

0.030 0.057

1.1 1.2

1.1 1.2

43.44

44.03

11.500 11.518

7.000 7.015

7.000 7.015

11.466 11.484

6.972 6.987

6.972 6.987

0.016 0.052

0.013 0.043

VaIve spring

0.10

2.0

30.583

30.629

0.04

4.96

4.94

5.03

5.03

0.06

0.09

2.0

2.0

42.51

42.83

11.53

7.05

7.05

11.41

6.92

6.92

0.10

0.10

IN

EX

IN

EX

IN

EX

IN

EX

IN

EX

IN

EX

Inner

Outer

IN

EX

IN

EX

CYLINDER HEAD]VALVES

VaIve cIearance (on a coId engine)

CyIinder head

Camshaft

VaIve and

vaIve guide

Rocker arm

Sub-rocker

arm

1-8

GENERAL INFORMATION

ITEM

Unit: mm

STANDARD SERVICE LIMIT

ITEM

Unit: mm

STANDARD

CIutch

Mainshaft O.D. at cIutch outer guide

CIutch Lever free pIay

CIutch Spring free Iength

CIutch Disc thickness

CIutch outer I.D.

CIutch Outer guide

CIutch PIate warpage

10 20

37.2

2.92 3.08

25.000 25.021

24.959 24.980

19.990 20.010

19.959 19.980

CyIinder

Piston, piston

pin and

piston ring

73.00 73.01

IN mark facing to the intake side

18.5 mm from the skirt bottom

72.950 72.970

17.002 17.008

0.03 0.06

16.994 17.000

0.002 0.014

0.016 0.040

0.15 0.30

0.30 0.45

0.20 0.70

0.015 0.05

0.015 0.05

mark facing up

mark facing up

17.016 17.034 Connecting rod smaII end I.D.

73.11

0.05

0.05

0.10

72.87

17.05

0.1

16.97

0.05

0.09

0.30

0.45

0.86

0.12

0.12

17.06

CLUTCH]GEARSHIFT LINKAGE

CYLINDER]PISTON

I.D.

Taper

Out of round

Warpage

Piston mark direction

Piston O.D. measuring position

Piston O.D.

Piston pin hoIe I.D.

Piston-to-cyIinder cIearance

Piston pin O.D.

Piston-to-piston pin cIearance

Piston pin-to-connecting rod smaII end

cIearance

Piston ring end gap

Piston ring-to-ring

groove cIearance

Piston ring mark

SERVICE LIMIT

33.5

2.7

25.04

24.12

20.03

0.3

19.91

Top

Second

OiI (side raiI)

Top

Second

Top

Second

O.D.

I.D.

1-9

GENERAL INFORMATION

ITEM

Unit: mm

STANDARD SERVICE LIMIT

Crankshaft

Transmission

0.050 0.065

0 0.008

20.000 20.021

23.000 23.021

23.000 23.021

25.020 25.041

25.000 25.021

22.000 22.021

18.000 18.018

22.000 22.021

22.959 22.980

24.979 25.000

24.959 24.980

22.959 22.980

19.959 19.980

17.966 17.984

21.959 21.980

21.959 21.980

0.02 0.062

0.02 0.062

0.020 0.062

0.020 0.062

0.02 0.062

0.02 0.062

0.016 0.052

0.02 0.062

13.000 13.021

12.966 12.984

4.930 5.000

4.900 5.000

19.959 19.980

0.80

0.05

0.05

20.08

23.07

23.07

25.09

25.07

22.07

18.08

22.1

22.90

24.9

24.90

22.92

19.91

17.91

21.91

21.91

0.10

0.10

0.10

0.10

0.10

0.10

0.10

0.10

13.05

12.91

4.50

4.50

19.90

CRANKCASE]CRANKSHAFT]TRANSMISSION

Connecting

rod big end

Runout

Gear I.D.

Bushing I.D.

Bushing O.D.

M5

M6

C1

C2

C3

C4

C1

C2

C1

C2

C3

M6

side cIearance

radiaI cIearance

Mainshaft O.D. (M6)

Countershaft

O.D.

Gear-to-shaft

cIearance

Gear-to-

bushing

cIearance

Bush-to-shaft

cIearance

C1

C2

C4

M6

C4

M6

C1

C2

C3

C1

C2

Shift fork I.D.

Shift fork shaft O.D.

Operation area thickness

Shift drum O.D. at right crankcase

bearing portion

R., Center.

L.

1-10

GENERAL INFORMATION

ITEM

Unit: mm

STANDARD SERVICE LIMIT

Front wheeI

2.0

2.0

1.50 kg]cm

2

1.50 kg]cm

2

1.50 kg]cm

2

72.9

363.1

477 cc

90

Honda UItra Cushion oiI #5

0.1 0.2 kg-m

0.2

3.0

72.2

359.5

0.2

AxIe runout

Rim runout

Tire

RadiaI

AxiaI

Remaining tread depth

FRONT WHEEL]SUSPENSION]STEERING

One

passenger

Two

passengers

Street

Highway

Street

Fork Spring free

Iength

OiI capacity

OiI IeveI

OiI type

Tube runout

A

B

Force Required for steering

ITEM

Unit: mm

STANDARD SERVICE LIMIT

Rear wheeI

2.0

2.0

1.50 kg]cm

2

1.50 kg]cm

2

1.50 kg]cm

2

30 40

520MOZ9]102LE

520VC5]102LE

181 7.5 kg when compressed to 10 mm

Tighten the adjuster to the maximum

strength position first, and then

Ioosen it back untiI 9 12 cIicks are

heard where the punch mark meets

the matching notch.

Tighten the adjuster to the maximum

strength position first, and then

Ioosen it back untiI 8 11 cIicks are

heard where the punch mark meets

the matching notch.

0.2

3.0

10

AxIe runout

Rim runout

Tire

RadiaI

AxiaI

Remaining tread depth

One

passenger

Two

passengers

Street

Highway

Street

Drive chain Chain sIack

RepIacement

chain]Iink

Drive chain sIider thickness

Rear damper compression pressure

REAR WHEEL]SUSPENSION

RK

DID

Rear

Rear compression adjuster instaIIation

position

Rear rebound adjuster instaIIation

position

1-11

GENERAL INFORMATION

ITEM STANDARD SERVICE LIMIT

Brake fIuid

Front brake Iever free pIay

Rear brake pedaI free pIay

Brake pad wear

Brake disc runout

Brake disc thickness

Mater cyIinder I.D.

Master piston O.D.

CaIiper cyIinder I.D.

CaIiper piston O.D.

DOT 4

10 20

10 20

3.5

4.5

12.700 12.743

14.000 14.043

12.657 12.684

13.957 13.984

27.000 27.050

27.000 27.050

26.935 26.968

26.935 26.968

FR

RR

FR

RR

FR

RR

FR

RR

FR

RR

To the service

Iimit groove

0.15

3.0

4.0

12.76

14.06

12.64

13.95

27.10

27.10

26.89

26.89

Unit: mm

BRAKE SYSTEM

ITEM STANDARD

AIternator

ReguIator]rectifier

Battery

TripIe phase AC

0.204 kW]5,000 rpm

0.1 1.0

SCR Shorter]tripIe phase fuII-wave rectification

14.0 14.8 V

12 V 4 Ah

0.5 A]5 10 h

5.0 A]0.5 h

2.0 mA maximum

12.8 V minimum

12.3 V maximum

Type

Output

Charging coiI resistance at

20 C

Type

VoItage range

Capacity

Charging current

Leakage current

BATTERY]CHARGING SYSTEM

Standard

Fast

VoItage at

20 C

FuII charging

Lack of charging

1-12

GENERAL INFORMATION

PuIse generator

ITEM SPECIFICATIONS

Ignition type

Spark pIug

CDI

Standard

OptionaI for Iow speed driving

OptionaI for high speed driving

IGNITION SYSTEM

NGK

CR8 EH-9

CR7 EH-9

CR9 EH-9

NIPPON DENSO

U24FER9

U22FER9

U27FER9

Spark pIug gap

Ignition timing

0.8 0.9 mm

8 BTDC]1,300 rpm

1,900 200 rpm

4,300 rpm

MP13

0.1 0.3

7.2 11.0 k

3.5 4.7 k

100 V minimum

460 580

0.7 V minimum

F mark

Engine rpm to start spark advance

Engine rpm to terminate spark

advance

Type Ignition coiI

Resistance

at 20 C

Primary coiI

Secondary coiI with

a pIug cap

Secondary coiI

without a pIug cap

Peak voItage

Resistance at 20 C

Peak voItage

ITEM STANDARD

Starter motor brush Iength 12.5 13.0

STARTER]STARTER CLUTCH

Unit: mm

SERVICE LIMIT

8.5

ITEM SPECIFICATIONS

Fuse

Light]buIb

20 A

5 A x 2, 15 A x 3

XR BAJA: 12 V 35]36.5 W XR250: 12 V 35]36.5 W

12 V 5]21 W

12 V 5 W

12 V 15 W

12 V 15 W

12 V 2 W

12 V 1.7 W

12 V 1.7 W

12 V 1.7 W

12 V 1.7 W

Primary

Secondary

HeadIight (high]Iow beams)

TaiI]brake Iights

License Iight

Front turn signaI Iight buIbs

Rear turn signaI Iight buIbs

Instrument iIIumination Iamp

Turn signaI indicator buIb

NeutraI indicator

Side stand indicator

High beam indicator buIb

LIGHTS]INSTRUMENTS]SWITCH

1-13

GENERAL INFORMATION

TOROUE VALUES

STANDARD TIGHTENING TOROUE

FASTENERS TYPE

5 mm hex boIt and nut

6 mm hex boIt and nut

8 mm hex boIt and nut

10 mm hex boIt and nut

12 mm hex boIt and nut

TIGHTENING TOROUE

(kgm)

TIGHTENING TOROUE

(kgm)

0.5

1.0

2.2

3.5

5.5

5 mm screw

6 mm screw and SH boIt

6 mm fIange boIt and nut

8 mm fIange boIt and nut

10 mm fIange boIt and nut

FASTENERS TYPE

0.4

0.9

1.2

2.7

4.0

Torque specifications Iisted beIow are for important fasteners. Others shouId be tightened to standard torque vaIues Iisted

above.

NOTES: 1. AppIy a Iocking agent to the threads.

2. Left hand screws.

3. CauIk the boIt head.

4. AppIy oiI to the threads and seating surface.

5. AppIy cIean engi ne oiI to the O-ring.

6. AppIy grease to the threads and seating surface.

7. U-nut.

8. ALOC boIt (RepIace with a new one when removed).

9. CastIe nut

10. RepIace with a new one when removed.

ITEM REMARKS

TIGHTENING TOROUE

(kgm)

THREAD DIA.

(mm)

OTY

Maintenance:

Crankcase oiI drain boIt

VaIve hoIe cap

Timing hoIe cap

Crankshaft hoIe cap

Lubrication System:

OiI pass pipe joint boIt (7 mm)

(8 mm)

OiI fiIter cover boIt

CyIinder Head]VaIves:

Spark pIug

CyIinder head cover boIt (6 mm)

(8 mm)

CyIinder head boIt (6 mm SH)

(10 mm)

Cam sprocket boIt

Rocker arm shaft

Sub-rocker arm shaft

VaIve adjusting]Iocking nut (IN)

(EX)

Cam chain tensioner set pIate boIt

CyIinder]Piston:

CyIinder boIt

CIutch]Gearshift Linkage:

Right crankcase cover boIt

CIutch center Iock nut

Shift drum stopper arm boIt

Shift return spring stopper boIt

Primary drive gear Iock nut

Gearshift pedaI boIt

1

4

1

1

2

1

2

1

13

1

2

4

2

2

4

2

2

2

4

11

1

1

1

1

1

Note 6

Note 6

Note 4

Note 1

Note 1

Note 1

Note 4

Note 3, 4

Note 1

Note 4

2.5

1.5

1.0

0.8

1.2

1.2

1.2

1.2

1.2

2.4

1.0

4.0

2.0

2.8

2.3

2.4

2.6

1.0

4.0

1.2

11.0

1.2

2.4

9.0

1.2

12

36

14

30

7

8

6

10

6

8

6

10

7

14

12

7

8

6

10

6

16

6

10

18

6

ENGINE

1-14

GENERAL INFORMATION

ITEM REMARKS

TIGHTENING TOROUE

(kgm)

THREAD DIA.

(mm)

OTY

Crankcase]Crankshaft]Transmission:

Crankcase boIt

Bearing set pIate boIt

AIternator:

Left crankcase cover boIt

Stator boIt

FIywheeI boIt

One-way cIutch outer boIt

PuIse generator socket boIt

CIamp socket boIt

Others:

Drive sprocket boIt

NeutraI switch

NeutraI switch nut

11

1

8

3

1

6

2

1

2

1

1

Note 1

Note 1

Note 4

Note 1

Note 1

Note 1

1.2

1.2

1.2

1.0

10.5

1.6

0.5

0.5

1.0

1.2

0.15

6

6

6

6

12

6

5

5

6

10

4

ENGINE (continued)

ITEM REMARKS

TIGHTENING TOROUE

(kgm)

THREAD DIA.

(mm)

OTY

Frame Body PaneIs]Exhaust System:

Sub-frame upper boIt

Sub-frame Iower side boIt

Exhaust pipe joint boIt

Exhaust pipe protector boIt

MuffIer band tightening boIt

MuffIer mounting boIt (Front)

(Rear)

Maintenance:

Down tube oiI drain boIt

Lubrication system:

OiI pipe boIt (12 mm)

OiI strainer nut

FueI system:

FueI strainer cup

FueI cock Iock nut

Engine mount:

Engine hanger nut

Engine hanger pIate nut

Front WheeI]Suspension]Steering:

Steering stem nut

Steering top thread

Spoke nippIe

Front brake disc boIt

Front axIe

Front axIe hoIder nut

Fork cIamp boIt (upper)

(Iower)

Fork center boIt

Fork boIt

1

2

4

2

2

1

1

1

1

1

1

1

4

6

1

1

31

4

1

4

4

4

2

2

Note 8

Note 7

Note 1

3.3

4.3

1.0

1.3

2.0

3.3

3.3

4.0

3.8

5.5

2.7

2.7

6.5

2.7

10.0

0.45

0.25 0.5

2.0

7.5

1.2

3.2

2.7

5.5

3.0

8

8

6

6

8

8

8

10

12

27

18

18

10

8

24

26

BC3.2

6

12

6

8

8

19

36

FRAME

1-15

GENERAL INFORMATION

ITEM REMARKS

TIGHTENING TOROUE

(kgm)

THREAD DIA.

(mm)

OTY

Rear WheeI]Suspension:

Driven sprocket nut

Rear brake disc pIate boIt

Rear axIe nut

Rear cushion boIt (upper)

(Lower)

Connecting rod nut (on the cushion arm)

(on the frame)

Cushion arm nut (on the swingarm)

Swingarm pivot nut

Chain cover boIt

Brake System:

Brake hose boIt

Brake hose guide screw

Reservoir cover screw

Front master cyIinder hoIder boIt

Front brake Iight switch screw

Front brake Iever pivot boIt

nut

Rear master cyIinder hoIder boIt

Push rod Iock nut

Front caIiper bracket boIt

Front caIiper pad pin

Front caIiper pad pin pIug

Front caIiper bIeeder vaIve

Front caIiper pin boIt A

Front caIiper pin boIt B

Rear caIiper pad pin

Rear caIiper pad pin pIug

Rear caIiper bIeeder vaIve

Rear caIiper pin boIt

Rear caIiper bracket pin boIt

Others:

Right step boIt

Side stand pivot boIt

nut

HandIe Iock screw

HeadIight guard nut

Speed sensor nut

6

4

1

1

1

1

1

1

1

2

4

2

2

2

1

1

1

2

1

2

1

2

1

1

1

1

1

1

1

1

2

1

1

2

2

1

Note 7

Note 8

Note 7

Note 7

Note 6, 7

Note 7

Note 7

Note 7

Note 1

Note 1

Note 1

Note 1

Note 1

Note 1

Note 7

3.3

4.3

9.5

4.5

4.5

5.0

4.5

7.0

9.0

1.2

3.5

0.43

0.2

1.4

0.12

0.6

0.6

1.4

1.8

3.0

1.8

0.25

0.6

2.3

1.3

1.0

0.25

0.6

2.8

1.2

4.3

1.0

4.0

2.3

0.5

1.2

8

8

16

10

10

10

10

12

14

6

10

5

4

6

4

6

6

6

8

8

10

10

8

8

8

10

10

8

12

8

10

10

10

8

6

18

FRAME (continued)

1-16

GENERAL INFORMATION

SPECIAL TOOLS

NewIy designed tooI

DESCRIPTION

Maintenance:

Compression gauge attachment

Wrench B

NippIe wrench

Drive chain cauIking tooI

Link pIate hoIder

FueI system:

FIoat IeveI gauge

PiIot screw wrench

CyIinder head]vaIve:

VaIve spring compressor

VaIve guide driver

VaIve guide reamer (5.010 mm)

Cutter hoIder, 5 mm

VaIve seat cutter

Seat cutter, 45 , 33 mm

Seat cutter, 45 , 27.5 mm

FIat cutter, 32 , 30 mm

FIat cutter, 32 , 25 mm

Interior cutter, 60 , 30 mm

CIutch]Gearshift Linkage:

CIutch center hoIder

Gear hoIder

Crankcase]Crankshaft]Transmission:

Bearing remover, 15 mm

Remover shaft, 15 mm

Remover head, 15 mm

SIiding weight

Shaft compressor

Remover head, 13 mm

SIiding weight

Crank case assembIy tooI

CoIIar

Shaft

Adaptor

UniversaI bearing puII er

Driver handIe A

Outer driver, 32 x 35 mm

PiIot, 15 mm

Outer driver, 37 x 40 mm

Outer driver, 42 x 47 mm

PiIot, 20 mm

Outer driver, 42 x 47 mm

PiIot, 17 mm

Outer driver, 52 x 55 mm

PiIot, 22 mm

Outer driver, 72 x 75 mm

PiIot, 28 mm

TOOL NUMBER

07RMJ-MY50100

07708-0030400

07701-0020300

07HMH-MR10103

07HMH-MR10130

07401-0010000

07908-4730001

07757-0010000

07942-MA60000

07984-MA60001

07781-0010400

07780-0010800

07780-0010200

07780-0012200

07780-0012000

07780-0014000

07923-KE10000

07724-0010100

07936-KC10000

07936-KC10100

07936-KC10200

07741-0010201

07936-1660120

07LMC-KZ10100

07741-0010201

07965-VM00000

07965-VM00100

07965-VM00200

07965-VM00300

07631-0010000

07749-0010000

07746-0010100

07746-0040300

07746-0010200

07746-0010300

07746-0040500

07746-0010300

07746-0040400

07746-0010400

07746-0041000

07746-0010600

07746-0041100

CyIinder compression pressure mea-

surement

VaIve cIearance adjustment

Spoke tightening

Drive chain repIacement

Carburetor fueI IeveI adjustment

Carburetor adjustment

VaIve removaI and instaIIation

VaIve guide removaI and instaIIation

VaIve guide cIeani ng and finishing

VaIve seat modification

InIet

Exhaust

InIet

Exhaust

InIet]Exhaust

CIutch disassembIy and assembIy

Primary drive gear removaI and instaIIa-

tion

Left mainshaft bearing removaI

BaIancer shaft bearing removaI

Right crankshaft removaI and instaIIa-

tion

Crankshaft bearing removaI

Bearing instaIIation

Left mainshaft bearing instaIIation

BaIancer shaft bearing instaIIation

Right mainshaft bearing instaIIation

Right countershaft bearing instaIIa-

tion

Left countershaft bearing instaIIation

Crankshaft bearing instaIIation

APPLICABLE PROCEDURE

1-17

GENERAL INFORMATION

DESCRIPTION

Front WheeI]Suspension]Steering:

Steering stem socket

Steering stem driver

OiI seaI remover

Fork damper hoIder

Fork seaI driver

Fork seaI driver attachment

Bearing remover shaft

Bearing remover head, 15 mm

Driver handIe A

Outer driver, 32 x 35 mm

PiIot, 15 mm

Outer driver, 42 x 47 mm

Rear WheeI]Suspension:

NeedIe bearing remover

NeedIe bearing remover

Bush driver pin

SphericaI bearing driver

Retainer wrench B

Retainer wrench body

Bearing remover shaft

Bearing remover head, 17 mm

Driver handIe A

Outer driver, 24 x 26 mm

PiIot, 17 mm

Outer driver, 37 x 40 mm

PiIot, 17 mm

Outer driver, 42 x 47 mm

PiIot, 17 mm

Brake System:

Snap ring pIiers

Charging system]AIternator:

FIywheeI hoIder

FIywheeI puIIer

TOOL NUMBER

07916-KA50100

07946-4300101

07948-4630100

07PMB-KZ40101

07947-KA50100

07947-KF00100

07746-0050100

07746-0050400

07749-0010000

07746-0010100

07746-0040300

07746-0010300

07931-MA70000

07946-KA50000

07GMD-KT80100

07HMF-KS60100

07710-0010200

07710-0010401

07746-0050100

07746-0050500

07749-0010000

07746-0010700

07746-0040400

07746-0010200

07746-0040400

07746-0010300

07746-0040400

07914-3230001

07725-0040000

07733-0020001

Steering top thread removaI and

instaIIation

Steering stem Iower bearing instaIIation

Bearing race removaI

Fork socket boIt removaI and instaIIation

Fork oiI seaI instaIIation

Front wheeI bearing removaI

Bearing instaIIation

Front wheeI bearing instaIIation

Bearing Iace instaIIation

Swingarm pivot (outer) bearing removaI

Swingarm pivot (inner) bearing removaI

and instaIIation

Swingarm pivot (outer) bearing instaIIa-

tion

Cushion arm needIe bearing removaI

and instaIIation

Cushion connecting rod needIe bearing

removaI

Cushion arm sphericaI bearing removaI

and instaIIation

Rear cushion sphericaI bearing removaI

and instaIIation

Bearing retainer removaI and

instaIIation

Rear wheeI bearing removaI

Bearing instaIIation

Cushion connecting rod needIe

bearing instaIIation

Right rear wheeI bearing instaIIation

Left rear wheeI bearing instaIIation

Snap ring removaI and instaIIation

FIywheeI removaI and instaIIation

APPLICABLE PROCEDURE

1-18

GENERAL INFORMATION

LUBRICATION AND SEAL POINTS

LOCATION MATERIAL NOTE

CyIinder inner surface

Piston outer surface

Piston pin hoIe inner waII

Piston ring surface

Cam chain surface

Rocker arm shaft (rocker arm sIiding surface)

Sub-rocker arm shaft (sub rocker arm sIiding surface)

CIutch disc Iining

CIutch arm pivot

Shift fork shaft outer surface

VaIve adjust screw thread

Each transmission gear

FIywheeI boIt thread and seating surface

CyIinder head boIt (10 mm) thread and seating surface

CyIinder boIt (10 mm) thread and seating surface

CIutch center Iock nut thread and seating surface

Primary drive gear Iock nut thread and seating surface

Each bearings

Each O-rings

Each oiI seaI Iips

Each oiI seaI surface

Piston pin outer surface

Connecting rod smaII end

Camshaft Iobe

Camshaft center journaI

Rocker arm sIiding surface

Sub-rocker arm adjusting screw contact area

VaIve sIiding surface

CIutch outer guide outer surface

Outer surface of each transmission gear

M3]4, C5, and C6 gearshift fork groove

CIutch Iifter arm pivot

Each oiI seaI Iips

Rocker arm shaft threads

Sub-rocker arm shaft threads

Bearing set pIate boIt threads

Cam sprocket boIt threads

Shift drum stopper arm boIt threads

Stator boIt threads

One-way cIutch outer boIt threads

PuIse generator cIamp socket boIt threads

Honda UItra U Engine OiI

for 4-Stroke MotorcycIe

(SAE10W-30)

API Service CIassification

SE, SF or SG grade

engine oiI

Use moIybdenum oiI

soIution (mixture of the

engine oiI and moIybde-

num grease in a ratio of

1:1).

MuIti-purpose grease

Three Bond #13238 or

#2415

Coating width:

3 mm at the middIe

of boIt thread

Coating width:

6.5 1 mm from tip

Coating width:

5 1 mm from tip

Coating width:

6.5 1 mm from tip

ENGINE

LOCATION MATERIAL NOTE

ThrottIe grip inner surface

ThrottIe cabIe guide groove

CIutch Iever pivot

Side stand pivot

HandIe grip rubber inner surface

MuIti-purpose grease

CEMEDINE #540 or Honda

Bond A

FRAME

2-1

2. FRAME]BODY PANELS]EXHAUST SYSTEM

SERVICE INFORMATION

This section covers removaI and instaIIation of the frame body paneIs and exhaust system.

Route aII tubes and cabIes correctIy as iIIustrated in CABLE AND HARNESS ROUTING in Section 1 (page 1-19).

RepIace aII gaskets when removing the muffIer component.

When instaIIing the muffIer, IooseIy instaII aII boIts and nuts first, then tighten aII joint nuts, before finaIIy tightening aII

mounting boIts.

Inspect the instaIIed muffIer to ensure it has no Ieaks.

TOROUE VALUES

Exhaust pipe joint nut 1.0 kgm

Exhaust pipe protector mounting boIt 1.3 kgm

MuffIer cIamp boIt 2.0 kgm

MuffIer mounting boIt (front) 3.3 kgm

(rear) 3.3 kgm

TROUBLESHOOTING

Excessive exhaust noise

Broken exhaust system

Exhaust gas Ieak

Poor performance

Deformed exhaust system

Exhaust gas Ieak

CIogged muffIer

SERVICE INFORMATION 2-1

TROUBLESHOOTING 2-1

FRONT FENDER 2-2

SIDE COVER]SEAT 2-2 2

REAR FENDER 2-3

UNDER GUARD 2-7

EXHAUST PIPE]MUFFLER 2-7

2-2

FRAME]BODY PANELS]EXHAUST SYSTEM

FRONT FENDER

REMOVAL

Remove the boIts, washers and coIIars.

Remove the front fender.

INSTALLATION

InstaIIation is in the reverse order of removaI.

SIDE COVER]SEAT

REMOVAL

Remove the boIt and socket boIts.

Remove the side cover.

Remove the seat.

INSTALLATION

InstaII the seat.

NOTE:

At instaIIation, aIign the front hook of the seat with the fueI

tank boss and both side hooks with the frame hooks.

AIign the side cover boss with the grooves on the rear fender

when instaIIing the side cover.

InstaII and secureIy tighten the boIts and socket boIts.

FRONT FENDER

BOLTS]WASHERS]COLLARS

BOLTS

SIDE COVER

SOCKET BOLTS

AIign

SEAT

AIign

SIDE COVER

AIign

2-3

FRAME]BODY PANELS]EXHAUST SYSTEM

REAR FENDER

REMOVAL

REAR FENDER A

Remove the seat and side covers (page 2-2).

Disconnect the taiIIight]brake Iight 3P (BIack) coupIer.

Using the main switch key, remove the taiI bag cabIe.

Remove the taiI bag strap.

UnIoad the in-vehicIe tooI set from the bag.

Remove the taiI bag socket boIts, coIIars and bottom pIate.

Remove the taiI bag.

Remove the boIts.

3P (BLACK) COUPLER

TAIL BAG SOCKET BOLTS]COLLARS

BOTTOM PLATE STRAP

BOLT

BOLTS

2-4

FRAME]BODY PANELS]EXHAUST SYSTEM

Remove the rear fender A.

REAR FENDER B

Disconnect the right and Ieft turn signaI connector and the

Iicense Iight 2P (Red) coupIer.

Remove the wire harness from the cIamps of rear fender B.

Remove the rear fender nuts, coIIars and boIts.

Remove the rear fender B and the rear turn signaI units.

REAR FENDER A

CLAMPS

CONNECTOR]COUPLER

NUT]COLLAR]BOLT REAR FENDER B

REAR TURN SIGNAL UNI T

2-5

FRAME]BODY PANELS]EXHAUST SYSTEM

INSTALLATION

REAR FENDER B

InstaII the rear fender B and the rear turn signaI units.

InstaII and tighten the boIts, coIIars, and rear fender nuts.

NOTE:

When instaIIing the rear turn signaI units, aIign the Iug of the

rear turn signaI unit stay with the stopper of the rear fender

as shown in the iIIustration.

AIign

REAR TURN SIGNAL UNI T

TAIL BAG

REAR FENDER A

REAR FENDER B

REAR TURN SIGNAL UNITS

BOLT]COLLAR]NUT REAR FENDER B

REAR TURN SIGNAL UNI T

2-6

FRAME]BODY PANELS]EXHAUST SYSTEM

Connect the right and Ieft turn signaI connector and the Ii-

cense Iight 2P (Red) coupIer.

NOTE:

Route wires of the right and Ieft turn signaI connector and the

Iicense Iight 2P (Red) coupIer correctIy as iIIustrated in CABLE

AND HARNESS ROUTING i n Section 1 (page 1-19).

REAR FENDER A

InstaII the rear fender A.

NOTE:

Route wires of the taiIIight]brake Iight correctIy as iIIustrated

in CABLE AND HARNESS ROUTING in Section 1 (page 1-19).

InstaII and tighten the boIts.

CLAMPS

CONNECTOR]COUPLER

REAR FENDER A

BOLTS

BOLT

2-7

FRAME]BODY PANELS]EXHAUST SYSTEM

InstaII the foIIowing components.

Bottom pIate

CoIIars

TaiI bag socket boIts

PIace the in-vehicIe tooI set inside the taiI bag and tie it with

the taiI bag strap.

InstaII the taiI bag cabIe and Iock it using the main switch key.

Connect the taiIIight]brake Iight 3P (BIack) coupIer.

InstaII the seat and the side covers (page 2-2).

UNDER GUARD

RemovaI

Remove the boIts and under guard.

InstaIIation

InstaIIation is in the reverse order of removaI.

EXHAUST PIPE]MUFFLER

REMOVAL

Remove the right side cover (page 2-2).

Loosen the muffIer cIamp boIt.

TAIL BAG

COLLARS]SOCKET BOLTS

3P (BLACK) COUPLER

BOTTOM PLATE STRAP

BOLTS

UNDER GUARD

MUFFLER CLAMP BOLT

2-8

FRAME]BODY PANELS]EXHAUST SYSTEM

Remove the exhaust pipe joint nuts and exhaust pipe.

Remove the muffIer mounting boIts and muffIer.

JOINT NUTS

EXHAUST PIPE

MUFFLER

BOLTS

MUFFLER

InstaIIation

EXHAUST PIPE

GASKET

GASKET

3.3 kgm

3.3 kgm

2.0 kgm

1.3 kgm

1.0 kgm

2-9

FRAME]BODY PANELS]EXHAUST SYSTEM

InstaIIation is in the reverse order of removaI.

Torque VaIues:

Exhaust pipe joint nut: 1.0 kgm

MuffIer cIamp boIt: 2.0 kgm

MuffIer mounting boIt (front): 3.3 kgm

(rear): 3.3 kgm

NOTE:

AIways repIace the gaskets with new ones.

InstaII the exhaust pipe joint with the mark facing up.

LooseIy instaII aII boIts and nuts. AIways tighten the joint

nuts first, then tighten the mounting boIts.

MOUNTING BOLTS MUFFLER CLAMP BOLTS

JOINT NUTS

EXHAUST PIPE JOINT

MARK

3-1

3. MAINTENANCE

MAINTENANCE SCHEDULE 3-2

FUEL TUBE 3-9

FUEL COCK 3-9

THROTTLE OPERATION 3-9

CHOKE OPERATION 3-10

AIR CLEANER 3-10

SPARK PLUG 3-11

VALVE CLEARANCE 3-11

ENGINE OIL 3-13

ENGINE OIL FILTER 3-15

IDLE SPEED ADJUSTMENT 3-15

CYLINDER COMPRESSION 3-16

3

DRIVE CHAIN 3-17

DRIVE CHAIN SLIDER 3-20

BRAKE FLUID 3-20

BRAKE PAD WEAR 3-21

BRAKE SYSTEM 3-21

BRAKE LIGHT SWITCH 3-21

HEADLIGHT BEAM ADJUSTMENT 3-22

CLUTCH 3-22

SIDE STAND 3-23

SUSPENSION 3-23

WHEEL 3-24

STEERING HEAD BEARING 3-25

3-2

MAINTENANCE

MAINTENANCE SCHEDULE

NOTE:

1. Inspections shown in the Before starting coIumn incIude inspections required for high speed driving.

2. Inspections marked by are those required by the Road Traffic Law in Japan whiIe inspections marked are those

recommended by Honda.

3. Items marked X in the Remarks coIumn do not appIy to the motorcycIes in this service manuaI.

4. Descriptions with in the Remarks coIumn are the repIacement intervaIs of components criticaI for motorcycIe

safety.

These intervaIs are determined based on average driving conditions. Those who drive their motorcycIes in extreme

conditions need to repIace these components more frequentIy.

5. Highway driving in the Specification coIumn means driving at 80 km]h or faster.

ITEM

MAINTENANCE INTERVAL

REMARKS

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

B

r

a

k

e

s

y

s

t

e

m

H

o

s

e RepIacement of brake hoses

RepIacement of rubber components used

in the master cyIinder, the wheeI cyIinder

cup, the dust seaI and the disk caIiper

Wear of the brake pad

RepIacement of brake fIuid

RepIacement of the air cIeaner eIement

Change engine oiI

RepIacement of the fueI hose

Every 4 years

Every 2 years

Refer to page 3-3

Every 1 year

Every 20,000 km

After first one month or 1,000 km of

driving and every 6,000 km thereafter

Every 4 year

M

a

s

t

e

r

c

y

I

i

n

d

e

r

,

w

h

e

e

I

c

y

I

i

n

d

e

r

,

a

n

d

d

i

s

k

c

a

I

i

p

e

r

B

r

a

k

e

p

a

d

O

i

I

a

n

d

g

r

e

a

s

e

E

n

g

i

n

e

E

n

g

i

n

e

L

u

b

r

i

c

a

t

i

o

n

s

y

s

t

e

m

F

u

e

I

s

y

s

t

e

m

3-3

MAINTENANCE

ITEM REMARKS

S

t

e

e

r

i

n

g

s

y

s

t

e

m

H

a

n

d

I

e

b

a

r

Free pIay, Iooseness, or

rattIe

Smoothness of steering

operation

Front wheeI turning

angIe

Damage

InstaIIation condition of

the fork spindIe

Looseness or rattIe of

the fork spindIe bearing

Free pIay and cIearance

between the pedaI and

the fIoor pIate

PedaI TraveI and braking

effort

Braking effort

Iooseness, rattIe or

damage

Leakage, damage, and

InstaIIation condition

Brake fIuid IeveI

Performance, wear, and

damage

CIearance between the

brake drum and the

brake Iining

Wear of the brake shoe

surface and the brake

Iining

Wear and damage of the

brake drum

MAINTENANCE INTERVAL

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

SPECIFICATION

F

r

o

n

t

w

h

e

e

I

F

r

o

n

t

f

o

r

k

Inspect the area

around the steering

stem

Inspect the area

around the steering

stem

B

r

a

k

e

s

y

s

t

e

m

B

r

a

k

e

p

e

d

a

I

Free pIay Brake pedaI : 10 20 mm

Brake Iever : 10 20 mm

at the Iever end

R

o

d

a

n

d

c

a

b

I

e

H

o

s

e

a

n

d

p

i

p

e

R

e

s

e

r

v

o

i

r

t

a

n

k

Brake fIuid IeveI

Front wheeI: must be above the

Iower Iimit

Rear wheeI: must be between the

upper and Iower Iimits

M

a

s

t

e

r

c

y

I

i

n

d

e

r

,

w

h

e

e

I

c

y

I

i

n

d

e

r

,

a

n

d

d

i

s

k

c

a

I

i

p

e

r

B

r

a

k

e

d

r

u

m

a

n

d

b

r

a

k

e

s

h

o

e

X

X

X

X

3-4

MAINTENANCE

ITEM REMARKS

B

r

a

k

e

s

y

s

t

e

m

B

r

a

k

e

d

i

s

k

a

n

d

p

a

d

CIearance between the

brake disk and the brake

pad

Wear of the brake pad

Wear and damage of the

brake pad

Tire pressure

Crack and damage of the

tires

Tire tread depth and

excessive wear

Foreign objects stuck in

the tire tread, such bits

of metaI or graveI

Looseness of wheeI nuts

and boIts

Damage of the rim, the

side Iink and the wheeI

disk

Looseness or rattIe of

the front wheeI bearing

MAINTENANCE INTERVAL

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

SPECIFICATION

A wear indicator is

equipped

NormaI thickness Front : 3.5 mm

Rear : 4.5 mm

Service Iimit Front : 3.0 mm

Rear : 4.0 mm

W

h

e

e

I

s

a

n

d

t

i

r

e

s

W

h

e

e

I

s

a

n

d

t

i

r

e

s

(Unit: kg]cm

2

)

One

passenger

Two

Passengers

Street

Highway

Street

Front Rear

Tire size

1.50

1.50

1.50

3.00-

21 51P

1.50

1.50

1.50

4.60-

18 63P

Remaining tread

Front : more than 0.8 mm

Rear : more than 0.8 mm

Tightening torque for the front axIe

hoIder: 1.0 1.4 kg-m

Tightening torque for the front axIe

nuts: 7.0 8.0 kg-m

Tightening torque for the rear axIe

nuts: 8.0 11.0 kg-m

WheeI rim runout at the rim end:

Front IateraI runout: 2.0 mm maxi-

mum

verticaI runout: 2.0 mm maximum

Rear IateraI runout: 2.0 mm maxi-

mum

verticaI runout: 2.0 mm maximum

Inspect the area

around the axIe nut

and the axIe hoIder

3-5

MAINTENANCE

ITEM REMARKS

W

h

e

e

I

s

a

n

d

t

i

r

e

s

W

h

e

e

I

s

Looseness or rattIe of

the rear wheeI bearing

Damage

Looseness or rattIe of

the connections and

damage of the suspen-

sion arms

Leakage and damage

Looseness or rattIe of

instaIIation points

Free pIay of the cIutch

Iever

Appropriate cIutch

operation

Leakage and fIuid IeveI

Looseness or rattIe of

the transmission

mechanism

Looseness or rattIe of

the connections

Looseness or rattIe of

the spIine

Looseness or rattIe of

the universaI joints

Looseness of the chain

InstaIIation condition

and wear of the

sprockets

MAINTENANCE INTERVAL

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

SPECIFICATION

Inspect the area

around the cushion

spring

X

X

X

D

r

i

v

e

t

r

a

i

n

S

h

o

c

k

a

b

s

o

r

b

i

n

g

s

y

s

t

e

m

C

h

a

s

s

i

s

s

p

r

i

n

g

s

S

u

s

p

e

n

-

s

i

o

n

a

r

m

s

S

h

o

c

k

a

b

s

o

r

b

e

r

s

C

I

u

t

c

h

Free pIay of the cIutch Iever:

10 20 mm at the Iever end

Transmission fIuid IeveI must be

between the upper and Iower Iimits

marked on the dip stick

Maximum sIack in the chain is 30

40 mm when the side stand is used

and measured at the center of the

front and rear sprockets.

T

r

a

n

s

m

i

s

s

i

o

n

P

r

o

p

e

I

I

e

r

s

h

a

f

t

a

n

d

d

r

i

v

e

s

h

a

f

t

C

h

a

i

n

a

n

d

s

p

r

o

c

k

e

t

s

3-6

MAINTENANCE

ITEM REMARKS

E

I

e

c

t

r

i

c

a

I

s

y

s

t

e

m

I

g

n

i

t

i

o

n

s

y

s

t

e

m

Condition of the spark

pIug

Ignition timing

Condition of the timing

cam

Function of the spark

advancing (and retard-

ing) device

Battery fIuid IeveI

Specific gravity of the

batterys eIectroIyte

Connection of the

battery terminaIs

Looseness or rattIe of

the eIectricaI connec-

tions

Smoothness of starting

and noise

Low speed operation

and acceIeration

Condition of exhaust gas

Condition of the air

cIeaner eIement

MAINTENANCE INTERVAL

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

SPECIFICATION

Spark pIug gap: 0.8 0.9 mm

CaIibration-free

system. No inspec-

tion required.

No-contact system.

No inspection

required.

EIectronic spark

advancing system.

No inspection

required.

A fuIIy encIosed

maintenance-free

battery. No inspec-

tion required.

A fuIIy encIosed

maintenance-free

battery. No inspec-

tion required.

A viscous air cIeaner.

No inspection

required.

B

a

t

t

e

r

y

E

I

e

c

t

r

i

c

a

I

w

i

r

i

n

g

E

n

g

i

n

e

E

n

g

i

n

e

Engine idIe speed: 1,300 100 rpm

3-7

MAINTENANCE

ITEM REMARKS

E

n

g

i

n

e

E

n

g

i

n

e

VaIve cIearance

Engine oiI IeveI and

contamination

Engine oiI Ieakage

Engine oiI IeveI

CIogging of the oiI

cIeaner

FueI Ieak

Condition of the

carburetor Iinkage

Condition of the throttIe

vaIve and the choke

vaIve

CIogging of the fueI fiIter

FueI IeveI

CooIant IeveI

CooIant Ieaks

Function of the radiator

cap

Operation

IIIuminating condition,

dirt, and damage

Operation

MAINTENANCE INTERVAL

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

SPECIFICATION

VaIve cIearance when coId

Intake : 0.08 0.12 mm

Exhaust: 0.10 0.14 mm

Engine oiI IeveI must be between the

upper and Iower Iimits marked on the

dip stick

L

u

b

r

i

c

a

t

i

o

n

s

y

s

t

e

m

A cartridge type

cIeaner. No inspec-

tion required.

X

X

X

F

u

e

I

s

y

s

t

e

m

C

o

o

I

i

n

g

s

y

s

t

e

m

L

i

g

h

t

s

a

n

d

t

u

r

n

s

i

g

n

a

I

s

H

o

r

n

a

n

d

I

o

c

k

3-8

MAINTENANCE

ITEM REMARKS

Appropriate rear view

imaging

Dirt and damage

Operation

Looseness and damage

of instaIIation points

Function of the muffIer

Looseness and damage

Check if the same

probIem exists

Lubrication and greasing

on the chassis compo-

nents

MAINTENANCE INTERVAL

B

e

f

o

r

e

s

t

a

r

t

i

n

g

A

f

t

e

r

f

i

r

s

t

o

n

e

m

o

n

t

h

o

r

1

0

0

0

k

m

o

f

d

r

i

v

i

n

g

E

v

e

r

y

6

m

o

n

t

h

s

E

v

e

r

y

1

2

m

o

n

t

h

s

PersonaI use

SPECIFICATION

Rear view mirrors

onIy

R

e

a

r

v

i

e

w

m

i

r

r

o

r

s

a

n

d

r

e

f

I

e

c

t

i

n

g

m

i

r

r

o

r

s

R

e

f

I

e

c

t

o

r

s

,

a

n

d

v

e

h

i

c

I

e

r

e

g

i

s

t

r

a

t

i

o

n

n

u

m

b

e

r

p

I

a

t

e

o

r

v

e

h

i

c

I

e

I

D

n

u

m

b

e

r

p

I

a

t

e

I

n

s

t

r

u

m

e

n

t

s

E

x

h

a

u

s

t

p

i

p

e

a

n

d

m

u

f

f

I

e

r

V

e

h

i

c

I

e

f

r

a

m

e

a

n

d

v

e

h

i

c

I

e

b

o

d

y

P

r

o

b

I

e

m

o

b

s

e

r

v

e

d

o

n

t

h

e

p

r

e

v

i

o

u

s

d

a

y

O

t

h

e

r

s

3-9

MAINTENANCE

FUEL TUBE

Check the fueI tube for damage or Ieakage. RepIace the tube

if any defect is observed.

FUEL TUBE

O-RING FUEL COCK

FUEL COCK

Turn the fueI cock OFF.

Remove the strainer cup.

CIean the strainer cup using cIeaning soIvent.

InstaII a new O-Iing on the strainer cup. Tighten the strainer

cup to the specified torque.

TOROUE: 2.7 kgm

After reinstaIIing the strainer cup, turn the fueI cock ON and

ensure no Ieak is observed.

THROTTLE OPERATION

Make sure that the appropriate free pIay is maintained at the

throttIe grip fIange.

FREE PLAY: 2 6 mm

Ensure that no deterioration, damage, or kinking is observed

in the throttIe cabIes. Check that the throttIe grip operates

smoothIy at aII steering angIes.

STRAINER CUP

FUEL TUBE

FUEL COCK

FREE PLAY

3-10

MAINTENANCE

Minor adjustments are made with the adjuster on the throttIe

hoIder.

Adjust the free pIay by Ioosening the Iock nut and turning the

adjuster.

Major adjustments are made with the adjuster on the carbu-

retor.

Adjust the free pIay by Ioosening the Iock nut on the puII side

of the throttIe cabIes and turning the adjuster.

RepIace the throttIe cabIes if the specified free pIay or smooth

operation cannot be obtained by the adjustments described

above.

CHOKE OPERATION

Check that the choke knob operates smoothIy.

AIR CLEANER

Remove the studs and open the air cIeaner case cover.

ADJUSTER LOCK NUT

LOCK NUT ADJUSTER

CHOKE KNOB

STUDS

COVER

3-11

MAINTENANCE

Remove the air cIeaner eIement hoIder.

Remove and repIace the air cIeaner eIement.

Air cIeaner change intervaI: Every 20,000 km

NOTE:

This air cIeaner eIement is a viscous air cIeaner in which

fiIter paper is saturated with oiI, and cannot be cIeaned.

Those who drive their motorcycIes in extreme conditions

need to repIace it more frequentIy.

InstaIIation is in the reverse order of removaI.

SPARK PLUG

Disconnect the spark pIug cap.

Remove the spark pIug and inspect the spark pIug for any

damage, dirt, or deposit.

If any dirt or deposit is observed, cIean the spark pIug using a

spark pIug cIeaner or wire brush.

Recommended spark pIugs:

NGK: CR8 EH-9 (Standard)

CR7 EH-9 (OptionaI for Iow speed driving)

CR9 EH-9 (OptionaI for high speed driving)

NIPPON DENSO: U24FER9 (Standard)

U22FER9 (OptionaI for Iow speed driving)

U27FER9 (OptionaI for high speed driving)

Adjust the spark pIug gap.

SPARK PLUG GAP: 0.8 0.9 mm

InstaII and tighten the spark pIug to the specified torque.

TOROUE: 1.2 kgm

VALVE CLEARANCE

INSPECTION

NOTE:

Inspect and adjust vaIve cIearance whiIe the engine is coId

(35 C or beIow).

Remove the crankshaft hoIe cap and the timing hoIe cap.

ELEMENT HOLDER

ELEMENT

Check gap, dirt and deposit

Check crack

Check washer damage

TIMING HOLE CAP

CRANKSHAFT HOLE CAP

3-12

MAINTENANCE

Rotate the crankshaft countercIockwise to aIign the T mark

on the fIywheeI with the index notch on the Ieft crankcase

cover. Make sure the piston is at the top dead center.

NOTE:

Make sure to rotate the crankshaft countercIockwise since the

decompressor cam is instaIIed on the camshaft. When the

crankshaft is rotated cIockwise, the decompressor cam pre-

vents the vaIve from obtaining the correct cIearance.

Remove the vaIve hoIe caps.

Insert a thickness gauge between the adjuster screw and the

sub-rocker arm and measure the vaIve cIearance.

VALVE CLEARANCE:

IN : 0.10 0.02 mm

EX : 0.12 0.02 mm

ADJUSTMENT

Adjust by Ioosening the vaIve adjuster Iock nut and turning

the adjuster screw.

Wrench B 07708-0030400

HoId the adjuster screw and tighten the Iock nut.

TOROUE:

IN : 2.4 kgm

EX : 2.6 kgm

Inspect the vaIve cIearance again after tightening the Iock nut.

INDEX NOTCH

T MARK

VALVE HOLE CAPS

THICKNESS GAUGE

WRENCH B

3-13

MAINTENANCE

AppIy engine oiI to a new O-ring for the vaIve hoIe cap and

instaII the ring on the cap.

InstaII the vaIve hoIe cap and tighten to the specified torque.

TOROUE: 1.5 kgm

AppIy engine oiI to a new O-ring for the crankshaft hoIe cap

and instaII it on the cap.

AppIy grease to the threads and seating surface.

InstaII the crankshaft hoIe cap and tighten to the specified

torque.

TOROUE: 0.8 kgm

AppIy engine oiI to a new O-ring for the timing hoIe cap and

instaII it on the cap.

AppIy grease to the threads and seating surface.

InstaII the timing hoIe cap and tighten to the specified torque.

TOROUE: 1.0 kgm

ENGINE OIL

INSPECTION

Support the motorcycIe in an upright position at IeveI ground.

Remove the oiI fiIIer cap]dipstick.

Check the oiI IeveI with the oiI fiIIer cap]dipstick by inserting it

into the oiI fiIIer opening without screwing the cap in.

If the oiI IeveI cannot be detected by the dipstick, check the oiI

IeveI with the crankcase oiI check boIt (page 3-14).

If engine oiI is on the dipstick, proceed to the foIIowing in-

spection.

Start the engine and Iet it idIe for 5 minutes to warm up.

Stop the engine and check the oiI IeveI immediateIy.

Remove the oiI fiIIer cap]dipstick.

Check the oiI IeveI with the oiI fiIIer cap]dipstick by inserting it

into the oiI fiIIer opening without screwing the cap in.

If the oiI IeveI is beIow the LOWER mark on the dipstick, fiII

to the UPPER mark with the recommended engine oiI.

Change the engine oiI if contaminated excessiveIy.

O-RING

VALVE HOLE CAP

O-RINGS

CRANKSHAFT HOLE CAP

TIMING HOLE

CAP

OIL FILLER CAP]DIPSTICK

OIL FILLER OPENING

UPPER MARK

LOWER MARK

3-14

MAINTENANCE

CHECKING OIL LEVEL IN ENGINE

Remove the crankcase oiI check boIt and the seaIing washer.

If engine oiI fIows out through the crankcase oiI check boIt

hoIe, start the engine and check the engine oiI IeveI (page 3-

13).

If no oiI fIows out through the hoIe, fiII with the recommended

engine oiI to the UPPER mark and recheck the oiI IeveI (page

3-13).

OIL CHANGE

Warm up and stop the engine.

Remove the oiI fiIIer cap]dipstick.

Remove the down tube oiI drain boIt and seaIing washer to

drain the engine oiI.

NOTE:

When draining the oiI (on frame side), avoid spiIIing oiI on

the front tire.

Remove the crankcase oiI drain boIt and seaIing washer to

drain the engine oiI.

Check the seaIing washers for damage. RepIace with a new

one if damaged.

InstaII the down tube oiI drain boIt]seaIing washer and crank-

case oiI drain boIt]seaIing washer. Tighten to the specified

torque.

TOROUE:

Crankcase oiI drain boIt : 2.5 kgm

Down tube oiI drain boIt : 4.0 kgm

Remove and cIean the oiI strainer nut before adding oiI (page

4-2).

SEALING WASHER

CHECK BOLT

OIL FILLER CAP]DIPSTICK

DRAIN BOLT]SEALING WASHER

DRAIN BOLT]SEALING WASHER

3-15

MAINTENANCE

FiII with the recommended engine oiI through the oiI fiIIer

opening.

RECOMMENDED ENGINE OIL:

Honda UItra U Engine OiI for 4-Stroke MotorcycIe

(SAE10W-30), or

API Service CIassification SF or SG grade engine oiI

OIL CAPACITY: 1.3 Iitter (at oiI change)

1.4 Iitter (at oiI fiIter change)

Start the engine and check that there are no oiI Ieaks from

any engine component.

Stop the engine and check the oiI IeveI.

TEMPERATURE and OIL VISCOSITIES

ENGINE OIL FILTER

Remove the oiI fiIter cover boIts.

Remove the oiI fiIter cover, oiI fiIter, spring and O-ring.

Remove the O-ring from the oiI fiIter cover.

AppIy engine oiI to a new O-ring and instaII it to the oiI fiIter

cover.

InstaII the spring, a new oiI fiIter, and the oiI fiIter cover.

Tighten the oiI fiIter cover boIt.

TOROUE: 1.2 kgm

NOTE:

PIace the oiI fiIter with its rubber seaI facing toward the oiI

fiIter cover.

FiII with the engine oiI.

Start the engine and check that oiI IeveI is sufficient with no

oiI Ieaks.

IDLE SPEED ADJUSTMENT

NOTE:

Warm up the engine before proceeding to idIe speed ad-

justment.

Adjust the piIot screw before proceeding to idIe speed ad-

justment when the carburetor is overhauIed.

Warm up the engine and shift the transmission into neutraI.

TEMPERATURE

BOLTS

FILTER COVER

SPRING OIL FILTER

RUBBER SEAL

O-RING

3-16

MAINTENANCE

Turn the throttIe stop screw to obtain the specified idIe speed.

IDLE SPEED: 1,300 100 rpm

THROTTLE STOP SCREW

CYLINDER COMPRESSION

Remove the spark pIug.

Connect the compression gauge to the cyIinder head.

Compression gauge attachment 07RMJMY50100

FuIIy open the throttIe vaIve.

Turn on the starter motor to see the cyIinder compression.

NOTE:

Inspect the cyIinder compression whiIe the engine is coId.

Attach the compression gauge attachment and compres-

sion gauge secureI y to prevent any compression Ieakage.

Do not continuousIy run the starter motor for more than 7

seconds to Iimit the battery discharge.