Echnical Information: Oncept and Main Applications

Echnical Information: Oncept and Main Applications

Uploaded by

popokateCopyright:

Available Formats

Echnical Information: Oncept and Main Applications

Echnical Information: Oncept and Main Applications

Uploaded by

popokateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Echnical Information: Oncept and Main Applications

Echnical Information: Oncept and Main Applications

Uploaded by

popokateCopyright:

Available Formats

T

ECHNICAL INFORMATION

6411, 6412, 6413, M611

L L

PRODUCT P 1 /14

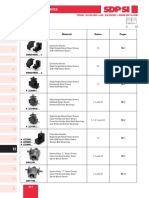

Model No. Description

Drill 10mm (3/8")

H W 6411, 6412 M611 W 6413 H

CONCEPT AND MAIN APPLICATIONS

Models 6411, 6412, 6413 and M611 are cost-competitive 10mm Drills developed as the successor models of 6409, 6410, 6510SB and M610, featuring compact and lightweight design yet with high durability.

Listed below are the specification differences among the four models. Dimensions: mm (") Model No. 6411 Specification Reverse switch No Variable speed control No by trigger Drill chuck type Keyed 6412 Yes Yes Keyed 6413 Yes Yes Keyless M611 Yes Yes Keyed 6411, 6412 6413 M611 228 (9) 234 (9-1/4) Length (L) Width (W) 64 (2-1/2) Height (H) 183 (7-1/4) Model

Specification

Voltage (V) 110 120 220 230 240 Capacities: mm (") Current (A) 4.3 4.0 2.2 2.1 2.0 Steel Wood Cycle (Hz) 50/ 60 50/ 60 50/ 60 50/ 60 50/ 60 10 (3/8) 25 (1) 6411: 3,000 6412, 6413, M611: 0 -3,000 1.5 - 10 (1/16 -3/8) Yes 2.0 (6.6) 1.2 (2.6) Continuous Rating (W) Input Output 450 230 --230 450 230 450 230 450 230 Max. Output (W) 350 350 350 350 350

No load speed: min-1=rpm Chuck capacity: mm (") Double insulation Power supply cord: m (ft) Net weight: kg (lbs)

Standard equipment

Chuck key S10 ............ 1 (for 6411, 6412, M611) Key holder 10 .............. 1 (for 6411, 6412, M611) Note: The standard equipment for the tool shown above may differ by country.

Optional

Drills bits

accessories

P 2/14

Features

and benefits

Ergonomically Designed Grip with Non-Skid Elastomer Covered Surface

Provides more comfort and control while minimizing hand fatigue and pain.

Compact and Lightweight Design Powerful 450W* Motor

Delivers power higher than the predecessor models 6409/6410/6510SB. (*450W= continuous rating input)

3,000 min-1 No Load Speed

All Ball Bearing Construction

Ensures durability higher than the predecessor models 6409/6410/6510SB that use three plane bearings and one ball bearing.

Optimum for light-duty jobs such as small hole drilling in wood

[The image illustrated above is Model 6411.]

Comparison

of products

Performance Comparison

Note: 1) Numbers in the charts below are relative values when the capacities of the competitor B's Model B are indexed at 100. 2) The test results depend to a great extent on the hardness of the material, etc. Test 1: Drilled holes through 60mm thick lauan plywood with 18mm diameter auger bit. slow Makita 6413 Makita 6410 Makita 6510SB Competitor B Model B Competitor H Model H3 Competitor H Model H4

0

[Work speed]

fast

120 90 Beyond capacity 100 115 Beyond capacity

50 100 150

Test 2: Fastened 4.1x38mm wood screws. slow Makita 6413 Makita 6410 Makita 6510SB Competitor B Model B Competitor H Model H3 Competitor H Model H4

0

[Work speed]

fast

125 90 35 100 110 60

50 100 150

Comparison

Specification Comparison

Makita 6409/ 6410 350 10 (3/8) Keyed 2,100 10 (3/8) 25 (1) No/ Yes No/ Yes No Yes 2.0 (6.6) 248 (9-3/4) 63 (2-1/2) 183 (7-1/4) 1.2 (2.6) 165 (6-1/2) 69 (2-3/4) 64 (2-1/2) 175 (6-7/8) 239 (9-3/8) 228 (9) No Yes N/A 279 (11) N/A 171 (6-3/4) 1.4 (3.1) N/A N/A 1.4 (3.1) N/A 266 (10-1/2) 63 (2-1/2) 190 (7-1/2) No Yes Yes No Yes Yes 15 (9/16) 25 (1) 25 (1) No/ Yes No/ Yes 10 (3/8) 25 (1) No No No Yes 2.5 (8.2) 1.8 (5.9) 230 (9) 59 (2-5/16) 174 (6-7/8) 1.1 (2.4) 0-3,000 0-2,200 2,800/ 0-2,800 Keyed 10 (3/8) 10 (3/8) Keyed 2,500 10 (3/8) 18 (11/16) No/ Yes No/ Yes 2,300/ 0-2,300 230 450 450 420 450 6510SB M610 Model B Model H1/ H2 Model H3 Competitor B Competitor H Model H4/ H5 235

Model No.

Specifications

6411/ 6412 (M611)/ 6413

of products

Continuous rating input: W

450

Max capacity: Drill mm (") chuck Type

10 (3/8)

Keyed/ Keyed/ Keyless

Keyed/ Keyless

No load speed: min-1=rpm

3,000/ 0-3,000/ 0-3,000

2,200/ 0-2,200

Capacities: mm (")

Steel

10 (3/8)

Wood

25 (1)

Reverse switch

No/ Yes/ Yes

Variable speed control by trigger

No/ Yes/ Yes

Soft grip

Yes

Double insulation

Yes

Power supply cord: m (ft)

2.0 (6.6)

228/ 228/ 234 (9/ 9/ 9-1/4)

Length Dimensions: Width mm (") Height

64 (2-1/2)

183 (7-1/4)

Net weight: kg (lbs)

1.2 (2.6)

P 3/14

P 4 /14

Repair

CAUTION: Unplug the machine for safety before repair/ maintenance in accordance with the instruction manual! [1] NECESSARY REPAIRING TOOLS

Code No. 1R004 1R139 1R220 1R222 1R223 A-33750 1R231 1R269 1R273 1R031 Description

Retaining ring pliers ST-2 Drill chuck extractor Ratchet head 9.5 Socket adapter

Torque wrench shaft 20- 90N.m Bit Adaptor 1/4" Hex. shank bit for M8 Bearing extractor Ring spring 26 setting tool B Bearing setting pipe 28-20.2

Use for Removing/Installing Ring spring 13 from Spindle Locking Spindle when removing Drill chuck from Spindle

Assembling Drill chuck to Spindle Note: Preset the fastening torque of 1R223 to 25- 30 N.m (250- 300kgf.cm). Removing Ball bearing 606ZZ Removing/Installing Helical gear 35 Removing/Installing Ball bearing 6902ZZ

[2] LUBRICATION

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect parts and product from unusual abrasion. Item No. 7 Fig. 1 7 Description Housing Portion to lubricate Gear room for Helical Gear 35 (Apply approx. 3g.)

Drill chuck S-10 Helical gear 35 Spindle

P 5 /14

Repair

[3] DISASSEMBLY/ASSEMBLY [3] -1. Drill Chuck

DISASSEMBLING See Fig. 2. 1) Fix 1R139 securely in vise, then lock Spindle by putting it in the U-shaped notch of 1R139. 2) Fix Hex wrench 10 securely in Drill chuck. Attach an appropriate steel pipe to Hex wrench 10 as extension bar. 3) Remove Drill chuck from Spindle by turning Drill chuck counterclockwise using Hex wrench 10 and steel pipe. Fig. 2 1R139 Drill chuck Spindle

steel pipe Hex wrench 10

Vise ASSEMBLING 1) Assemble 1R220, 1R222, 1R223 and A-33750 as illustrated in Fig. 3. Note: Preset the fastening torque of 1R223 to 25- 30N.m (250- 300 kgf.cm). 2) Lock Spindle as you did in step 1) of DISASSEMBLING, then fix 1R231 securely in Drill chuck. (Fig. 4) 3) Assemble Drill chuck to Spindle by turning 1R231 and Drill chuck clockwise using the repairing tools described in step 1) of ASSEMBLING. (Fig. 4) Fig. 3 Fig. 4 1R231

1R223 A-33750 1R222 1R220

P 6 /14

Repair

[3] DISASSEMBLY/ASSEMBLY [3] -2. Gear Section

DISASSEMBLING 1) After disassembling Drill chuck as illustrated in Fig. 2, separate Housing (R) from Housing (L). Remove Gear section from Housing (L). (Fig. 5) 2) Disassemble Gear section as illustrated in Figs. 6, 7, 8. Fig. 5 Fig. 6 Tapping screw 4x18 (7 pcs) 1) Remove Ball bearing 606ZZ with 1R269. Gear section 1R269

Ball bearing 606ZZ

Housing (L)

Housing (R)

Fig. 7 2) Put Gear section on 1R273. 3) By pressing Spindle using arbor press, Spindle can be removed together with Ball bearing 6902ZZ. 4) Remove Ring spring 13 using 1R004. 1R004 Helical gear 35 Spindle Ball bearing 6902ZZ Ring spring 13

Spindle

1R273 Fig. 8 5) Put Spindle on 1R031.

6) By pressing Spindle using arbor press,

Spindle can be removed from Ball bearing 6902ZZ.

Spindle Ball bearing 6902ZZ

Ball bearing 6902ZZ

1R031

Spindle

P 7/14

Repair

[3] DISASSEMBLY/ASSEMBLY [3] -2. Gear Section (cont.)

ASSEMBLING 1) Assemble Gear section as illustrated in Fig. 9 to Fig. 12. 2) Assemble Gear section to Housing (L). (Fig. 5 in page 6) Fig. 9 Fig. 10 1) Assemble Ball bearing to Spindle using 1R031 and arbor press. Spindle Ball bearing 6902ZZ 1R031 2) Fix Ball bearing 6902ZZ by assembling Ring spring 13 to Spindle using 1R004. Note: If Ring spring 13 is deformed or damaged when removed from Spindle, be sure to replace it with new one. Ring spring 13

Fig. 11 3) Assemble Helical gear 35 to Spindle using 1R273 and arbor press. Note: Helical gear 35 is not reversible when assembled to Spindle. The flat side of the gear must face towards Ball bearing 6902ZZ. Ball bearing 6902ZZ flat side Helical gear 35 grooved side

Fig. 12 4) Assemble Ball bearing 606ZZ to Spindle using arbor press.

Ball bearing 606ZZ 1R273 flat side

[3] -3. Motor Section

DISASSEMBLING 1) After separating Housing (R) from Housing (L), disconnect Carbon brushes from Armature commutator by pulling off Brush holders from Housing (L). Disassemble Motor section from Housing (L). (Fig. 13) 2) Pull out Armature from Field. (Fig. 14) Fig. 13 Motor section Brush holder Carbon brush Armature commutator Fig. 14

Leaf spring Carbon brush Housing (L) Brush holder Field Armature

P 8/14

Repair

[3] DISASSEMBLY/ASSEMBLY [3] -3. Motor Section (cont.)

ASSEMBLING Do the reverse of the disassembling steps. Note: Leaf spring is not reversible when assembled to Housing (L). The concave side must face towards Ball bearing 627ZZ on Armature. (Fig. 15) Fig. 15 Housing (L)

Ball bearing 627ZZ

Leaf spring

concave side

P 9/14

Circuit

diagram

Model 6411 (without Variable speed control and Reverse switch) Machines Without Choke Coil and Noise Suppressor Fig. D-1

Color index of lead wires' sheath Black White

Brush holder

Field

Switch

Power supply cord

P 10/14

Wiring

diagram

Model 6411 (without Variable speed control and Reverse switch) Machines Without Choke Coil

Important: Do not put slack portion of any Lead wire in the space surrounded by Field and Brush holders. Otherwise Lead wires will be broken by rotating Armature.

Fig. D-2

Put slack portion of Field lead wire (black) in the space between Brush holder and inside wall of Housing (L).

See "Connecting Lead wire to Brush holder". Brush holder

boss A Field boss B See "Connecting Lead wire to Brush holder". Route the following two Lead wires between the ribs: *Field lead wire (white) *Lead wire (black) from No.2a Terminal of Switch to Brush holder

Switch Route Field lead wire (white) under Brush holder.

Power supply cord

Connecting Lead wire to Brush holder

1) Brush holders are not reversible when assembled to Housing (L). Terminal insertion hole of each Brush holder must be positioned outside boss A/boss B. 2) Do not route each Lead wire inside boss A/boss B. Field lead wire (black)

boss A boss B

Terminal

Brush holder

Lead wire (black) from No.2a Terminal of Switch

P 11/14

Circuit

diagram

Model 6411 (without Variable speed control and Reverse switch) Machines With Choke Coil Fig. D-3

*Note: Some countries do not use Noise suppressor.

Color index of lead wires' sheath Black White Orange Purple

Choke coil (with purple Lead wires)

Brush holder

Field

Choke coil (with orange Lead wires) Switch *Noise suppressor [if used]

Power supply cord

P 12/14

Wiring

diagram

Model 6411 (without Variable speed control and Reverse switch) Machines With Choke Coil

Important: Do not put slack portion of any Lead wire in the space surrounded by Field and Brush holders. Otherwise Lead wires will be broken by rotating Armature. Note: 1) Some countries do not use Noise suppressor. 2) Put Choke coils and Noise suppressor (if used) in place as illustrated in Fig. D-4.

Fig. D-4

Lead wires Choke coil lead wire (purple) to Brush holder Choke coil lead wire (purple) to No.1a Terminal of Switch Choke coil lead wire (orange) to Brush holder Choke coil lead wire (orange) to Field Field lead wire (black) to No.2a Terminal of Switch

See "Connecting Lead wire to Brush holder". Put slack portion of Lead wire in the space between Brush holder and inside wall of Housing (L). Otherwise the Lead wire will touch rotating Armature. boss A boss B See "Connecting Lead wire to Brush holder". Brush holder

Fix two Lead wires with this Lead wire holder. Choke coil (with purple Lead wires)

Field

Route Lead wires between these ribs.

Switch

Route Lead wires under Brush holder. Choke coil (with orange Lead wires)

Noise suppressor [if used] Power supply cord

Connecting Lead wire to Brush holder

1) Brush holders are not reversible when assembled to Housing (L). Terminal insertion hole of each Brush holder must be positioned outside boss A/boss B. 2) Do not route each Lead wire inside boss A/boss B.

boss A boss B

Terminal

Brush holder

P 13/14

Circuit

Fig. D-5

diagram

Models 6412, 6413, M611 (with Variable speed control and Reverse switch)

Color index of lead wires' sheath Black White Orange Blue Purple

Note: *Choke coil (with blue Lead wire and black Lead wire) is reversible when connected to Switch. **Some countries do not use Noise suppressor or Choke coils. *Choke coil (with purple Lead wires) [if used]

Brush holder

Field

*Choke coil (with orange Lead wires) [if used] *Choke coil (with blue Lead wire and black Lead wire) [if used] **Noise suppressor [if used]

Switch

Power supply cord

P 14/14

Wiring

diagram

Models 6412, 6413, M611 (with Variable speed control and Reverse switch)

Important: Do not put slack portion of any Lead wire in the space surrounded by Field and Brush holders. Otherwise Lead wires will be broken by rotating Armature. Note: 1) Some countries do not use Noise suppressor or Choke coils. 2) Put Choke coils and Noise suppressor (if used) in place as illustrated in Fig. D-6. 3) Choke coil (with blue Lead wire and black Lead wire) is reversible when connected to Switch.

Fig. D-6

Lead wires Choke coil lead wire (purple) to Brush holder Choke coil lead wire (purple) to No.4 Terminal of Switch Choke coil lead wire (orange) to Brush holder Choke coil lead wire (orange) to No.3 Terminal of Switch Field lead wire (black) to No.2a Terminal of Switch Field lead wire (white) to No.5 Terminal of Switch Choke coil lead wire (blue or black) to No.6 Terminal of Switch

See "Connecting Lead wire to Brush holder". Put slack portion of Lead wire in the space between Brush holder and inside wall of Housing (L). Otherwise the Lead wire will touch rotating Armature. Put slack portion of Lead wires in this space. See "Connecting Lead wire to Brush holder". Route Lead wires between these ribs. Brush holder

Fix two Lead wires with this Lead wire holder. Choke coil (with purple Lead wires) [if used]

Field boss A boss B

Switch

Choke coil (with orange Lead wires) [if used]

Route Lead wires under Brush holder.

Choke coil (with blue Lead wire and black Lead wire) [if used]

Noise suppressor [if used] Power supply cord

Connecting Lead wire to Brush holder

1) Brush holders are not reversible when assembled to Housing (L). Terminal insertion hole of each Brush holder must be positioned outside boss A/boss B. 2) Do not route each Lead wire inside boss A/boss B.

boss A boss B

Terminal

Brush holder

You might also like

- Cat 3304 3306 Industrial Marine Service ManualDocument827 pagesCat 3304 3306 Industrial Marine Service Manualruss mathis100% (39)

- Lexus - GS300 - GS430 - Service - Manual 15Document38 pagesLexus - GS300 - GS430 - Service - Manual 15seregap84100% (2)

- PDFDocument9 pagesPDFTimmyJuri100% (1)

- SEBF 8164 гизьзы 3500Document19 pagesSEBF 8164 гизьзы 3500Aminadav100% (1)

- Sap Charm: (Solution Manager 7.2)Document17 pagesSap Charm: (Solution Manager 7.2)Krishna Vamshi50% (2)

- Manual Da Furadeira MakitaDocument10 pagesManual Da Furadeira Makitaani_matrixx4733No ratings yet

- LM Actuator Long-Term Maintenance-Free Type: Equipped With Caged Ball LM Guides and QZ Lubricator For Ball ScrewDocument28 pagesLM Actuator Long-Term Maintenance-Free Type: Equipped With Caged Ball LM Guides and QZ Lubricator For Ball ScrewhrwidiaNo ratings yet

- Starting PDFDocument19 pagesStarting PDFAndrey GladyshevNo ratings yet

- MT955 TeDocument8 pagesMT955 TeMosqq CharriNo ratings yet

- CVP 90spec InformacionDocument7 pagesCVP 90spec InformacionvictorNo ratings yet

- Alignment Coupling Operation Manual Tyre-FlexDocument37 pagesAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatel100% (1)

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Document6 pagesHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianNo ratings yet

- ELINE Ball Screw AssembliesDocument24 pagesELINE Ball Screw AssembliesAnonymous PIqdeNp8No ratings yet

- Bang Catalog Bac Dan NSKDocument0 pagesBang Catalog Bac Dan NSKsariobaoNo ratings yet

- Traction Alternator Type Ta10106cyDocument64 pagesTraction Alternator Type Ta10106cyTirthankar DasNo ratings yet

- VakveDocument5 pagesVakvejondutta189No ratings yet

- Medidas para Mecanizar Alojamiento Anillo Sello EspejoDocument11 pagesMedidas para Mecanizar Alojamiento Anillo Sello EspejoJhonatan Valencia MillanNo ratings yet

- Yoshimura Rs3 Slip On Exhaust Honda Cbr600 f4 I20012006Document4 pagesYoshimura Rs3 Slip On Exhaust Honda Cbr600 f4 I20012006Ahmed WahidNo ratings yet

- 06 639Document15 pages06 639Fernando Sabino100% (1)

- Rolling GearDocument14 pagesRolling GearRamesh SalriaNo ratings yet

- Motor 60Z02152 - 08 (1) CAT 3306 Liner ProjectionDocument2 pagesMotor 60Z02152 - 08 (1) CAT 3306 Liner ProjectionIsmael De Jesus Andrade50% (2)

- sebf8734 гильза с-9Document13 pagessebf8734 гильза с-9Евгений АбрамовNo ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- 100 Series Ordering GuideDocument8 pages100 Series Ordering GuideElectromateNo ratings yet

- Steel MillsDocument60 pagesSteel MillsJulio CarbonettiNo ratings yet

- Caterpillar: Ripper ShanksDocument52 pagesCaterpillar: Ripper ShanksСергей Горовой100% (1)

- Final Pipe Bending MachineDocument27 pagesFinal Pipe Bending MachineVitthal GawhaleNo ratings yet

- SEBF 8174 коромысла 3500Document13 pagesSEBF 8174 коромысла 3500Евгений АбрамовNo ratings yet

- Connecting Rod - Steel Crankshaft PDFDocument6 pagesConnecting Rod - Steel Crankshaft PDFjoaobargasNo ratings yet

- 12M Montagem Freio de ServiçoDocument10 pages12M Montagem Freio de ServiçoPaulo_GleriaNo ratings yet

- KWGDL KWGDLS AgdlDocument8 pagesKWGDL KWGDLS Agdlalin.butunoi865No ratings yet

- 4rCRB Mounting and Maintenance InstructionsDocument21 pages4rCRB Mounting and Maintenance InstructionsNishant JhaNo ratings yet

- Ball Screw CatalogueDocument12 pagesBall Screw CatalogueCostache AdrianNo ratings yet

- Diagrama Electrico de Una Amoladora-Ingles-OriginalDocument6 pagesDiagrama Electrico de Una Amoladora-Ingles-OriginalErick Contreras QuispeNo ratings yet

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- f2013-013 CASE N SBDocument11 pagesf2013-013 CASE N SBVictor PinedoNo ratings yet

- Echnical Information: Oncept and Main ApplicationsDocument6 pagesEchnical Information: Oncept and Main ApplicationsKakoy Lagusan EcobenNo ratings yet

- J3 Axis R-2000iCDocument14 pagesJ3 Axis R-2000iCCesar PuenteNo ratings yet

- C95 Eu PDFDocument36 pagesC95 Eu PDFMihaela PopNo ratings yet

- WinchDocument4 pagesWinchAntal SrlNo ratings yet

- Alignment PDFDocument12 pagesAlignment PDFVictor Nunez100% (1)

- Actuadores Rotativos DSR DSRLDocument22 pagesActuadores Rotativos DSR DSRLromeoyesNo ratings yet

- KP0800 Te PDFDocument8 pagesKP0800 Te PDFisaac grossiNo ratings yet

- Crusher: With Demolition Specifications Demolition High Reach ofDocument2 pagesCrusher: With Demolition Specifications Demolition High Reach ofkenNo ratings yet

- JDocument32 pagesJlutherblackNo ratings yet

- 12 - Right Angle Drives: Catalog Series Material Pages RatiosDocument16 pages12 - Right Angle Drives: Catalog Series Material Pages RatiosODG_290473No ratings yet

- Inkoma Shaft Hub ConnectionsDocument31 pagesInkoma Shaft Hub ConnectionsnikitaNo ratings yet

- Huong Dan Lap Dat DCL 220kVDocument16 pagesHuong Dan Lap Dat DCL 220kVkenlavie1No ratings yet

- IR Grease Pump Catalouge LM2250E-XX-B3-EnDocument4 pagesIR Grease Pump Catalouge LM2250E-XX-B3-Enankit.jhawarNo ratings yet

- F,') Er R: Maor+Lne DestqnDocument3 pagesF,') Er R: Maor+Lne DestqnMostafaNo ratings yet

- Dobladores de TubingDocument19 pagesDobladores de TubingJuan Chan CanulNo ratings yet

- Plummer Block Housings: FeaturesDocument3 pagesPlummer Block Housings: FeaturesrefeiNo ratings yet

- Sebf 8269 Привод 3408Document16 pagesSebf 8269 Привод 3408mohamed hamedNo ratings yet

- Metric (ISO) Fasteners: Torque SpecificationsDocument5 pagesMetric (ISO) Fasteners: Torque SpecificationsGolbert GolbiNo ratings yet

- NSK Cat E728g 13 (1) LDocument0 pagesNSK Cat E728g 13 (1) LIvana StevanićNo ratings yet

- J-Bolt Edge System For LHD TramsDocument8 pagesJ-Bolt Edge System For LHD TramsfernandojNo ratings yet

- Metric Design Tapered Roller BearingsDocument36 pagesMetric Design Tapered Roller BearingsMohan RajNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- How to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackFrom EverandHow to Power Tune the BMC/BL/Rover 998 A-Series Engine for Road and TrackNo ratings yet

- CV Giulia ValacchiDocument3 pagesCV Giulia Valacchiapi-329008652No ratings yet

- T9-Internet For Teaching and LearningDocument25 pagesT9-Internet For Teaching and LearningJoshua LsqNo ratings yet

- M54 Unit 1-IntroductionDocument17 pagesM54 Unit 1-IntroductionPhilip Yap100% (1)

- Bug AlgorithmsDocument15 pagesBug AlgorithmsAshNo ratings yet

- A Parallel Genetic Algorithm For Performance-Driven VLSI RoutingDocument28 pagesA Parallel Genetic Algorithm For Performance-Driven VLSI RoutingNaveen ChaubeyNo ratings yet

- Daftar Produk CEUDocument1 pageDaftar Produk CEUZulfan STNo ratings yet

- An Anatomy of LonelinessDocument4 pagesAn Anatomy of LonelinessTheodore LiwonganNo ratings yet

- Devotional Poets M 01 Rag HDocument166 pagesDevotional Poets M 01 Rag HYaminikrishna KariNo ratings yet

- Final Notes NCM 100Document4 pagesFinal Notes NCM 100Jasmin CubillasNo ratings yet

- The Descriptor Differential Scale of Pain Intensity: An Evaluation of Item and Scale PropertiesDocument10 pagesThe Descriptor Differential Scale of Pain Intensity: An Evaluation of Item and Scale PropertiesOlavo BrilhanteNo ratings yet

- Pengkajian LukaDocument26 pagesPengkajian LukaPebruariNo ratings yet

- Activity 2 - Moving AveragesDocument4 pagesActivity 2 - Moving AveragesMei MCasNo ratings yet

- Question Bank 3 and 4 UnitDocument8 pagesQuestion Bank 3 and 4 Unitanlacetech133No ratings yet

- IJME-Impact of Single-Multi Rollers Burnishing Tools - IASETDocument14 pagesIJME-Impact of Single-Multi Rollers Burnishing Tools - IASETiaset123No ratings yet

- European Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Document12 pagesEuropean Patent Specification B64C 27/32: Printed by Jouve, 75001 PARIS (FR)Amir BahramiNo ratings yet

- ES FIRST SEM PRETEST Answer KeyDocument10 pagesES FIRST SEM PRETEST Answer KeyCristina Astrero BisqueraNo ratings yet

- What Philosophy Says About The SelfDocument35 pagesWhat Philosophy Says About The SelfKathrina Marie SungaNo ratings yet

- Employee Performance EvaluationDocument6 pagesEmployee Performance Evaluationsoundar rajNo ratings yet

- Lecture 5 Equillibrium of ForcesDocument41 pagesLecture 5 Equillibrium of ForcesAwais Ahmed MirzaNo ratings yet

- History of School CounselingDocument2 pagesHistory of School CounselingJesel Love Patano ValenciaNo ratings yet

- English Test Life 1 Name: Class: : 0. You Cannot Have A Cigarette HereDocument2 pagesEnglish Test Life 1 Name: Class: : 0. You Cannot Have A Cigarette HereMaya TranNo ratings yet

- Static Behavior of Natural GasDocument34 pagesStatic Behavior of Natural GasLemony SnickitNo ratings yet

- EpmaDocument4 pagesEpmaSANKET SINGHNo ratings yet

- Sea of Souls Volume III (Extra Content)Document28 pagesSea of Souls Volume III (Extra Content)Vitor Hugo Sant Ana Vieira (NoName)No ratings yet

- Dokumen - Tips Tube Wells and Their DesignDocument60 pagesDokumen - Tips Tube Wells and Their DesignEng Ahmed abdilahi IsmailNo ratings yet

- Freedom Writers EssayDocument4 pagesFreedom Writers Essayapi-273180236No ratings yet

- PF-Tek For Simple Minds - FungifunDocument25 pagesPF-Tek For Simple Minds - Fungifunb8777144No ratings yet

- CHE3044F, 2013: Reactor Design 1: TUTORIAL 2Document2 pagesCHE3044F, 2013: Reactor Design 1: TUTORIAL 2nmhatityeNo ratings yet

- 1 AC 200 282C ILT 001 Syllabus Introduction AppendicesDocument36 pages1 AC 200 282C ILT 001 Syllabus Introduction AppendicesaaaguilarmNo ratings yet