Lightweight Materials Obtained by Utilization of Agricultural Waste

Lightweight Materials Obtained by Utilization of Agricultural Waste

Uploaded by

abdullmalikCopyright:

Available Formats

Lightweight Materials Obtained by Utilization of Agricultural Waste

Lightweight Materials Obtained by Utilization of Agricultural Waste

Uploaded by

abdullmalikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Lightweight Materials Obtained by Utilization of Agricultural Waste

Lightweight Materials Obtained by Utilization of Agricultural Waste

Uploaded by

abdullmalikCopyright:

Available Formats

World Academy of Science, Engineering and Technology 64 2012

Lightweight Materials Obtained by Utilization of Agricultural Waste

Bogdan Bogdanov, Irena Markovska, Yancho Hristov, Dimitar Georgiev

AbstractLightweight ceramic materials in the form of bricks and blocks are widely used in modern construction. They may be obtained by adding of rice husk, rye straw, etc, as porous forming materials. Rice husk is a major by-product of the rice milling industry. Its utilization as a valuable product has always been a problem. Various technologies for utilization of rice husk through biological and thermochemical conversion are being developed. The purpose of this work is to develop lightweight ceramic materials with clay matrix and filler of rice husk and examine their main physicomechanical properties. The results obtained allow to suppose that the materials synthesized on the basis of waste materials can be used as lightweight materials for construction purpose. Keywordslightweight ceramic materials, properties, agro-waste

The aim of this work is to develop lightweight ceramic materials from clay and rice husk, and to investigate the effect of varying rice husk and clay contents on the insulating properties of kaolin clay firebrick. II. EXPERIMENTAL SECTION A. Methods The materials obtained were characterized by X-ray analysis, differential thermal analysis (DTA) and scanning electron microscopy (SEM). The X-ray analyses were carried out by the method of powder diffraction using X-ray apparatus equipped with goniometer URD-6 (Germany) with cobalt anode and K emission. The DTA experiments were performed on an apparatus for complex thermal analysis (STA 449 F3 Jupiter), NETZSCH Germany. The micrographs were taken using scanning electron microscope Tesla BS 340 (Czech Republic). The SiO2 content in the solid residue was determined after treatment with hydrofluoric acid. B. Materials As the main raw materials were used: i. Kaolin clay with impurities of iron and organic compounds, whose composition is given in Table II ii. rice husk - the present study was carried out with rice husk obtained during processing of rice variety Krasnodarski 424 grown in Bulgaria. Before use, the rice husk were thoroughly washed three times with tap water followed by three times with deionised water to remove adhering soil, clay and dust, boiled for an hour to desorbs any impurities and finally, dried at 100 0 overnight. The dried husk were ground in rotary cutting mill and sieved manually with 0.630.12 mm sieves. This starting material was used for all further studies.

TABLE I OXIDE COMPOSITION OF CLAY

I. INTRODUCTION

HE lightweight ceramic materials in the form of clay bricks and blocks are more widely used in modern construction. The way of its obtaining is to add in clay different porous forming agents - including rice husk, straw of rye and barley, etc. [1-3]. The usage of these combustible materials as porous forming agents for production of lightweight insulating bricks has two main advantages - the need for less energy due to the large amount of energy that is released during combustion byproducts. In the same time this is an alternative method for the efficient utilization of large amounts of waste materials [4-6]. The rice husk is a major coproduct of rice manufacturing. Investigations showed that the interest towards rice husk is increasing worldwide. It is connected with the leading role of rice as a grain culture from which waste products cannot be used as food, fertilizer or fuel. In this aspect, the problem with the utilization of the large amounts of this material elimination of certain ecological threat remains to be solved [7-11]. A number of reviews have been dedicated to rice husk and the products obtained from its thermal degradation at different conditions [12-16].

Prof. Bogdan Bogdanov, Depertment of Silicate Tehnology, Prof. Dr. Assen Zlatarov University, Bourgas 8010, Bulgaria Assoc. Prof. Irena Markovska, Depertment of Silicate Tehnology, Prof. Dr. Assen Zlatarov University, Bourgas 8010, Bulgaria, (e-mail: imarkovska@btu.bg) Assoc. Prof. Dimitar Georgiev, Depertment of Materials Science, Prof. Dr. Assen Zlatarov University, Bourgas 8010, Bulgaria Assistant prof. Yancho Hristov, Depertment of Materials Science, Prof. Dr. Assen Zlatarov University, Bourgas 8010, Bulgaria

Oxide SiO2 Al2O3 Fe2O3 TiO2 Na2O K2O CaO MgO LOI

Weight % 54.07 28.11 2.15 1.16 0.90 2.01 1.03 1.56 9.01

725

World Academy of Science, Engineering and Technology 64 2012

III. RESULTS AND DISCUSSION A. Studies on the rice husk 1. Derivatographic studies The development of various technological methods for utilization of rice husk by thermal decomposition can not be accomplished without profound studies on the processes of their thermal destruction by DTA-analysis (fig.1). The present derivatographic studied were carried out under the following conditions: i. in static air, under heating, first the physically adsorbed water was released (5%), followed by the burning of the organic components to obtain solid residue (26% residue containing mainly SiO2 - 91,6%).

Since the raw and the thermally treated rice husk can be used as components in composite materials, it is important to know what structure changes they undergo during heating. The determination of the temperature up to which the powder is amorphous is significant because the crystalline product has lower reactivity than the amorphous one. The diffractogram of sample oxidized at 900C presented in fig. 2 shows a strong peak (d = 4.06 ) corresponding to the high crystalline phase of silica - -cristobalite, and distinguishable peak at d = 2.48 (characteristic also for -cristobalite). Quartz was not detected. The rice husk used in our work, were heated in oxygen medium in the temperature range 400 - 1000 . For the purposes of these experiments have been chosen RH burned at 600 . According to X-ray analysis carried out at temperatures around 600 C, silicon oxide in rice husk is still in active the amorphous form, which combined with the porous structure of the ash makes it very reactive in the process of sintering the samples. B. Studies on the clay The mineralogical composition of clay is determined by the X- ray analysis. The main phases observed were: quartz, kaolinite, feldspar and magnetite. Fig. 3 shows DTA and TG curves of the clays. The DTA of clay carried out shows that wide endo- effect at about 110 0C can be seen due to the release of water-related natural kaolin, which is accompanied by about 1% weight loss. At 340 0C exo-effect appears due to the presence of minerals magnetite, which is accompanied by about 1, 15% loss in weight, it is followed by a wide endoeffect at about 540 0C, due to the collapse of the clay materials and chemical separation related water in the clay, which is associated with about 6% weight loss. At about 950 0C exoeffect reappears which may be associated with the processes of formation of new phases. This process is accompanied by with 1, 20% weight loss.

Fig. 1 DTA and TG curves of RH samples burning in air

It is known [12-14] that the thermal destruction of rice husk has three stages: drying (40-150C), removal of volatile organic components (215 350C) and burning of carbon (350-690C). From thermogravimetric calculations based on the data obtained from DTA, the kinetic characteristics of the destruction processes can be determined, as it has been already reported earlier [15,16]. The DTA analysis of rice husk treated in oxidative medium (Fig.1) showed that the physically adsorbed water was released in the temperature interval 80C 180C which was indicated by the 5% mass loss. The process of thermal destruction began at 220C and ended at 640C with 74% mass loss. The mass loss at 270C was 10% and at 430C 50%. The processes of thermal destruction proceeded with maximum rate at 320C in air and 360C in nitrogen. 2. X- ray analysis

Fig. 3 DTA and TG curves of clay

Fig. 2 X- ray analysis of rice husk, thermally treated in air at 900 0C

Technological properties of clay materials mainly depend on their degree of dispersion [17]. Granulometric composition of clay affects the number of properties such as density, compressibility, porosity, etc. Through the sieve analysis the granulometric composition of clays was investigated. The results show that the largest amount is a fraction with particles size less than 63 m. Distribution of particles in the clay fractions are given in Table II.

726

World Academy of Science, Engineering and Technology 64 2012

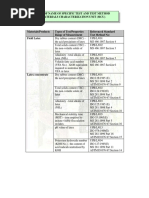

TABLE II GRANULOMETRIC COMPOSITION OF CLAY

TABLE IV PROPERTIES OF SAMPLE BASED ON CLAY AND WRHA

Particle Size, m 500 500 - 125 125 - 63 63

Fraction, %

1 8 10 81

Compo sition 1 2 3 4 5 6 7 8 9 10 11

It is known that the grain composition of the clay plays an important role on the frost resistance [17]. Data from the definitions of grading of clay used are a prerequisite for high frost resistance of bricks made from it. C. Studies on the clay materials with addition of rice husk Based on a clay matrix and thermally treated or raw rice husk 11 kinds of samples were synthesized which composition is given in Table 3. The specimens were formed by semi-dry pressing on hydraulic press Carl Zeiss Yena (Germany). Brick were dried to approximately 5-7 % moisture content. The dried brick were finally fired in a furnace at temperature of 1000 oC. This firing process caused the burning out of the rice husk in the finished bricks.

TABLE III COMPOSITION OF THE SAMPLE, WT.%

Apparent density, x 10 -3 kg/m3 1.72 1.63 1.61 1.56 1.53 1.47 1.69 1.63 1.60 1.56 1.53

Water uptake, % 21.60 22.25 24.90 26.92 27.81 29.71 22.10 24.60 26.10 27.29 27.81

Porosity, %

37.13 37.60 40.44 41.93 43.85 45.11 37.21 39.75 41.22 42.59 42.85

1 2 3 4 5 6 7 8 9 10 11

Clay 100 99 98 97 96 95 99 98 97 96 95

Raw rice husk 2 3 4 5 6 -

WRHA 3 4 5 6 7

The results show that the density of the synthesized material ranges from 1.70 to 1.53 g/cm3, and their water absorption is within 22 to 28%. The density decreases with increasing the addition of rice straw and rice husk ash in the brick, while the apparent density and water absorption increase. This fact may be connected with large losses in ignition, which was in rice straw about 80%, and in ash from rice husk - 16%. In general, the parents synthesized from clay and white ash have better physico-mechanical properties compared to those synthesized from clay and rice straw. The results of the analysis showed that the selected clay can be used for making of hollow insulating bricks. IV. CONCLUSIONS Based on rice husk and clay matrix a number of lightweight ceramic materials were developed. Rice husk - raw and thermally treated contribute to the formation of porous structure in the samples. Synthesized materials are with porosity ranging from 37 to 43%. Using the rice husk, burned at 600 C in air, silicon oxide in rice husk is still in the active amorphous form, so combined with the porous structure of the ash makes it very reactive in the process of sintering the samples.The main phases contained in fired bricks are: quartz, kaolinite, feldspar and magnetite. The samples obtained from clay and ash have higher physical - mechanical properties compared to those synthesized from rice straw and clay. ACKNOWLEDGMENT The authors would like to acknowledge for the financial support provided by Bulgarian Ministry of Education and Science, Fund Scientific Investigation. REFERENCES Emmanuel Ogo Onche, Benjamin Iyenagbe Ugheoke, Sunday Albert Lawal, and Utibe Martin Dickson, Effect of Rice Husk and Diatomite on the Insulating Properties of Kaolin - Clay Firebricks, Leonardo Electronic Journal of Practices and Technologies, vol. 11, pp. 8190, 2007. M. A. Rahman, Properties of clay-sand-rice husk ash mixed bricks,Int. J. Cement Comp. Lightweight Concrete, vol. 9, pp.105 108, 1987. G. Marahleh, Production of Light Weight Ceramics Teils from Local Materials, Am. J. Applied Sci., vol. 2 pp. 778 83, 2005.

Fig. 4 presents electron-scanning microphotograph of the sample 9 with clay matrix reinforced with WRHA.

[1]

Fig. 4 Electron-scanning microphotograph of sample

Data from X- ray analysis showed that the main phases observed are: quartz, kaolinite, feldspar and magnetite. Some of the main physico-mechanical properties of the synthesized samples as density, water absorption and porosity are measured. The results are presented in Table IV.

[2]

[3]

727

World Academy of Science, Engineering and Technology 64 2012

[4]

[5]

[6]

[7]

[8]

[9] [10] [11] [12]

[13]

[14] [15]

[16]

[17]

J.D. Jegatheeswaran, and R. Malathy, Utilization of papermill sludge in manufacturing of bricks - An environmental friendly approach,Pollution Research, vol. 30, pp. 299- 303, 2011. Lyubcho A. L.yubchev and Irena G. Markovska, Waste materials for preparation of porous corundum matrix composites, International symposium Ecology 93, Bourgas, September 9-11, 1993, p.32 37. V. Loryuenyong, T. Panyachai, K. Kaewsimork, and C. Siritai, Fabrication of lightweight clay bricks from recycled glass wastes,Ceramic Transactions, vol. 210, pp. 213-219, 2010. C. Sujivorakul, C. Jaturapitakkul, and A.Taotip, Utilization of flay ash, rice husk ash and Palm Oil Fuel Ash in Glass Fiber-Reinforced Concrete, J. Mater. Civil Eng., vol. 23, pp. 1281-1288, 2011. A. Ashfaq, A., Saadia, Utilization of agriculture waste for removal of heavy metal ions through biosorption, Ecology, Environment and Conservation, vol. 17, pp.353-357, 2011. A. Sharma and T.Rajeswara Rao, Kinetics of pyrolysis of rice husk,Bioresource Technol. vol. 67 pp. 53-59, 1999. D. M. Ibrahim and M. Helmy, Crystallite growth of rice husk ash silica, Thermochim. Acta vol. 45 pp. 79 85, 1981 M. Devan, Proc. Nat. Workshop on rice husk for Energy, Vigian, Bhawan, New Delhi, 1982, p. 35. A. Chakraverty, P. Mishra, and H.D. Banerjee, Investigation of thermal decomposition of rice husk, Thermochim. Acta, vol. 94 pp. 267 275, 1985. H. D. Banerjee, S. Sen, and H. N. Acharya, Investigation on the production of silicon from rice husks by the magnesium method, Mater. Sci. Eng., vol. 5, pp.173-179, 1982 M. A. Hamad, Thermal characteristics of rice hulls, J. Chem. Tech Biotechnol., vol.31, pp. 624 -626, 1981. L. T.Vlaev, I. G. Markovska and L.A. Lyubchev, Non isothermal kinetics of pyrolysis of rice husk, Thermochimica Acta, vol. 406, p. 1 7, 2003. L.T.Vlaev, I.G. Markovska, and L.A. Lyubchev, Kinetics compensation effect at thermal degradation of rice husk, Oxid. commun., vol. 27, pp.444 452, 2004. E. A. Gerasimov, Technology of ceramics products, Technics, Sofia, 2003

728

You might also like

- Alichem P&C Presentation Micronized WaxesDocument13 pagesAlichem P&C Presentation Micronized WaxesChánh Nguyễn TrungNo ratings yet

- Cellgevity Product SheetDocument2 pagesCellgevity Product Sheetapi-350452524No ratings yet

- Production of Activated Carbon From Rice Husk VietDocument7 pagesProduction of Activated Carbon From Rice Husk VietBalakrishna GopinathNo ratings yet

- Utilization of PaperDocument8 pagesUtilization of PaperKatherine RamírezNo ratings yet

- Satwinder Singh Danewalia Gaurav Sharma Samita Thakur K. SinghDocument10 pagesSatwinder Singh Danewalia Gaurav Sharma Samita Thakur K. SinghHarish P PatilNo ratings yet

- Clay With SlagDocument8 pagesClay With SlagJose VargasNo ratings yet

- S4R104Document4 pagesS4R104hriaumNo ratings yet

- The Effect of Natural Retarder On Fly Ash Based Geopolymer ConcreteDocument4 pagesThe Effect of Natural Retarder On Fly Ash Based Geopolymer Concretebolalisi83No ratings yet

- Separation and Purification Technology 118 (2013) 179-187Document9 pagesSeparation and Purification Technology 118 (2013) 179-187Ilyes JedidiNo ratings yet

- Damage Behaviour of Geopolymer Composites Exposed To Elevated TemperaturesDocument6 pagesDamage Behaviour of Geopolymer Composites Exposed To Elevated TemperaturesSo Thu DaiNo ratings yet

- Ash From Sunflower Husk As Raw Material For Ceramic ProductsDocument9 pagesAsh From Sunflower Husk As Raw Material For Ceramic Productslara_ramirez_2No ratings yet

- Custom Formulation of Red Ceramics With Clay, Sewage Sludge and Forest WasteDocument7 pagesCustom Formulation of Red Ceramics With Clay, Sewage Sludge and Forest WasteAlejandro Victor Estremadoyro CuevaNo ratings yet

- C. Fernández-Pereira, J.A. de La Casa, A. Gómez-Barea, F. Arroyo, C. Leiva, Y. LunaDocument13 pagesC. Fernández-Pereira, J.A. de La Casa, A. Gómez-Barea, F. Arroyo, C. Leiva, Y. LunahusseinhshNo ratings yet

- 1 s2.0 S0956053X10003168 Main PDFDocument7 pages1 s2.0 S0956053X10003168 Main PDFCarlos AlvarezNo ratings yet

- Hamza Kocserha TheeffectofexpandedperliteonfiredclaybricksDocument9 pagesHamza Kocserha TheeffectofexpandedperliteonfiredclaybricksvaleriacostacivilNo ratings yet

- Operating Conditions For The Pyrolysis of Poly - (Ethylene Terephthalate) in A Conical Spouted-Bed ReactorDocument6 pagesOperating Conditions For The Pyrolysis of Poly - (Ethylene Terephthalate) in A Conical Spouted-Bed ReactorZahid FarooqNo ratings yet

- 0350 820X1803275VDocument15 pages0350 820X1803275VPrinceNo ratings yet

- Production of Refractory Chamotte Particle-Reinforced Geopolymer CompositeDocument6 pagesProduction of Refractory Chamotte Particle-Reinforced Geopolymer CompositeAri RangelNo ratings yet

- 1TANANEJournalPre ProofDocument45 pages1TANANEJournalPre Proofsouka bedNo ratings yet

- Recycling Sugarcane Bagasse Waste Into Fired Clay Brick: A. BackgroundDocument6 pagesRecycling Sugarcane Bagasse Waste Into Fired Clay Brick: A. Backgroundchon1984No ratings yet

- Fly Ash-Cement Based Structural Materials: B. "BaradanDocument4 pagesFly Ash-Cement Based Structural Materials: B. "BaradanChin KamRongNo ratings yet

- Ikhsan MIGS 3Document7 pagesIkhsan MIGS 3Andi Ikhsan MaulanaNo ratings yet

- Utilization of Lignite Bottom Ash As A Raw Material For Ceramic TileDocument5 pagesUtilization of Lignite Bottom Ash As A Raw Material For Ceramic TileRimalianiNo ratings yet

- Characterization of Porcelain Tableware Formulation Containing Bentonite ClayDocument8 pagesCharacterization of Porcelain Tableware Formulation Containing Bentonite ClayLeandro FrisanchoNo ratings yet

- Synthesis of Alkali Activated Cement From Local Clay and Its CharacterizationDocument6 pagesSynthesis of Alkali Activated Cement From Local Clay and Its CharacterizationMeghaNo ratings yet

- The Insulating Effects of Rice Husks Addition On The Mechanical Properties of Clay Samples From Kaduna State NigeriaDocument4 pagesThe Insulating Effects of Rice Husks Addition On The Mechanical Properties of Clay Samples From Kaduna State NigeriaIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Lowered Temperature ResourceDocument18 pagesLowered Temperature ResourceKatherine RamírezNo ratings yet

- Construction and Building Materials: P. Sturm, G.J.G. Gluth, H.J.H. Brouwers, H.-C. KühneDocument6 pagesConstruction and Building Materials: P. Sturm, G.J.G. Gluth, H.J.H. Brouwers, H.-C. KühneChopys As ShidiqiNo ratings yet

- Study of FiredDocument16 pagesStudy of FiredLeonardo Jesús Chilón PovisNo ratings yet

- Evaluation of Spray-Dried Sludge From Drinking Water Treatment PlantsDocument9 pagesEvaluation of Spray-Dried Sludge From Drinking Water Treatment Plantsgabriel oliveiraNo ratings yet

- Utilisation of Spent Filtration Earth or Spent Bleaching Earth From The Oil Re Finery Industry in Clay ProductsDocument11 pagesUtilisation of Spent Filtration Earth or Spent Bleaching Earth From The Oil Re Finery Industry in Clay ProductsMarkLepetitNo ratings yet

- Develop Activated Carbon From Rice Husk by Using Acid Hydrochloric (HCL)Document5 pagesDevelop Activated Carbon From Rice Husk by Using Acid Hydrochloric (HCL)Chong Khai Lin100% (1)

- Issn 1314-7234, Volume 17, 2023: Ecology & Safety International Scientific PublicationsDocument11 pagesIssn 1314-7234, Volume 17, 2023: Ecology & Safety International Scientific PublicationsM.belhajmedNo ratings yet

- Bioresources: Preparation and Properties of Pulp Black Liquor BriquettesDocument13 pagesBioresources: Preparation and Properties of Pulp Black Liquor BriquettesarjunanpnNo ratings yet

- The Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobDocument7 pagesThe Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobRafaelaMarinhoFonsecaNo ratings yet

- The Effect of Natural Retarder On Fly Ash Based Geopolymer Concrete - LibreDocument4 pagesThe Effect of Natural Retarder On Fly Ash Based Geopolymer Concrete - LibreShahab SadeghpourNo ratings yet

- Artículo Docente. Determinación de La Densidad de Un Líquido Con El Método Del PicnómetroDocument6 pagesArtículo Docente. Determinación de La Densidad de Un Líquido Con El Método Del PicnómetroAlejandro Vargas CalderonNo ratings yet

- Ceramic FoamDocument12 pagesCeramic FoamThao Pham MinhNo ratings yet

- B. Ersoy, T. Kavas, A. Evcin, S. Basßpınar, A. Sarıısßık, G. ÖnceDocument9 pagesB. Ersoy, T. Kavas, A. Evcin, S. Basßpınar, A. Sarıısßık, G. Önceİsmail ApaydınNo ratings yet

- Preparation and Characterization of Bricks Using Bauxite Residue - An Innovative Approach ISSOBA 20111Document8 pagesPreparation and Characterization of Bricks Using Bauxite Residue - An Innovative Approach ISSOBA 20111laurentiu_filipescuNo ratings yet

- Foam Glass Processing Using A Polishing Glass Powder ResidueDocument9 pagesFoam Glass Processing Using A Polishing Glass Powder ResidueAlejandro Vargas CalderonNo ratings yet

- Lin 2012Document9 pagesLin 2012Thauan GomesNo ratings yet

- Energy Saving and Sustainable ConstructionDocument41 pagesEnergy Saving and Sustainable Constructionali_aslam_30No ratings yet

- Poudeu Et Al 2019Document9 pagesPoudeu Et Al 2019joNo ratings yet

- A Case Study of Different Limestone During Quick Lime and Slaked-Lime Production PDFDocument7 pagesA Case Study of Different Limestone During Quick Lime and Slaked-Lime Production PDFGuglielmo CancelliNo ratings yet

- Re-Use of Waste Glass in Improving Properties of Metakaolin-Based Geopolymers: Mechanical and Microstructure ExaminationsDocument13 pagesRe-Use of Waste Glass in Improving Properties of Metakaolin-Based Geopolymers: Mechanical and Microstructure Examinationstaramalik07No ratings yet

- Journal Pre-Proof: Journal of Building EngineeringDocument31 pagesJournal Pre-Proof: Journal of Building Engineeringisaac MbiawaNo ratings yet

- Lama Vermelha en Ceramica VDocument6 pagesLama Vermelha en Ceramica VMiguel Genaro PeraltaNo ratings yet

- Properties and Performances of Concrete Tiles Containing Waste FiredDocument8 pagesProperties and Performances of Concrete Tiles Containing Waste FiredArmigce PintoNo ratings yet

- Kem 757 35Document6 pagesKem 757 35Paul TorachNo ratings yet

- Powder TechnologyDocument6 pagesPowder TechnologySabeur KhemakhemNo ratings yet

- Construction and Building Materials: Noor-ul-AminDocument4 pagesConstruction and Building Materials: Noor-ul-AminArok ANo ratings yet

- Zi0605253260 PDFDocument8 pagesZi0605253260 PDFAJER JOURNALNo ratings yet

- Application of Microwaves For Innovative Hardening of Environment-Friendly Water-Glass Moulding Sands Used in Manufacture of Cast-Steel CastingsDocument11 pagesApplication of Microwaves For Innovative Hardening of Environment-Friendly Water-Glass Moulding Sands Used in Manufacture of Cast-Steel Castingssalar dadashNo ratings yet

- Effect of Temperature On Strength and Microstructure of Lime Stabilized FlyashDocument14 pagesEffect of Temperature On Strength and Microstructure of Lime Stabilized FlyashwuhanbigtreeNo ratings yet

- Recycled Plastic Aggregates in Manufacturing of Insulating MortarsDocument7 pagesRecycled Plastic Aggregates in Manufacturing of Insulating MortarsBasil Baby-PisharathuNo ratings yet

- J.vibspec.2013.02.001 Ftir Batio3Document6 pagesJ.vibspec.2013.02.001 Ftir Batio3Seni Ramadhanti SNo ratings yet

- Mix Design of Polymeric Concrete IncorpoDocument11 pagesMix Design of Polymeric Concrete Incorpo1limonataNo ratings yet

- Faculty of Industrial Technology: Department of Chemical EngineeringDocument6 pagesFaculty of Industrial Technology: Department of Chemical EngineeringangellaNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies VIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies VITatsuki OhjiNo ratings yet

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementFrom EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo ratings yet

- 5SN12017Document1 page5SN12017abdullmalikNo ratings yet

- SPM Fizik Tingkatan 4,5 - Paper2 - DrafDocument13 pagesSPM Fizik Tingkatan 4,5 - Paper2 - DrafabdullmalikNo ratings yet

- Effect of RhaDocument4 pagesEffect of RhaabdullmalikNo ratings yet

- Iinterdependence Among Living Arganism and Living ThingsDocument7 pagesIinterdependence Among Living Arganism and Living ThingsabdullmalikNo ratings yet

- Ceramics Prospect in ConstructionsDocument3 pagesCeramics Prospect in ConstructionsabdullmalikNo ratings yet

- Kita Boleh Mengenalpasti Ciri-Ciri Asid Dan Alkali Dengan Menjalankan Aktiviti-Aktiviti Ujian.Document7 pagesKita Boleh Mengenalpasti Ciri-Ciri Asid Dan Alkali Dengan Menjalankan Aktiviti-Aktiviti Ujian.Abdul Malik AhmadNo ratings yet

- 6.1 Understanding Air Pressure Learning Outcomes: The Students Will Be Able To: Explain The Existence of Air PressureDocument17 pages6.1 Understanding Air Pressure Learning Outcomes: The Students Will Be Able To: Explain The Existence of Air PressureabdullmalikNo ratings yet

- 5 Tips For Writing Interview QuestionsDocument2 pages5 Tips For Writing Interview QuestionsabdullmalikNo ratings yet

- Objective Questions:: Interdependence Among Living Organism and The EnvirontmentDocument6 pagesObjective Questions:: Interdependence Among Living Organism and The EnvirontmentabdullmalikNo ratings yet

- Mal 4Document5 pagesMal 4Heri HidayatNo ratings yet

- MSDS Oxalic AcidDocument5 pagesMSDS Oxalic AcidAmber BurgessNo ratings yet

- Specifications For Oil, Gas, Water, Sewer PipesDocument3 pagesSpecifications For Oil, Gas, Water, Sewer PipesShams TabrezNo ratings yet

- Hidroklortiazid Dan TelmisartanDocument3 pagesHidroklortiazid Dan TelmisartanRetno Rela MahananiNo ratings yet

- In-House Calibration: SOP-QAD-001 Hod-Qa D Hod-Qa MR 23.09.2013Document2 pagesIn-House Calibration: SOP-QAD-001 Hod-Qa D Hod-Qa MR 23.09.2013vishal jaswalNo ratings yet

- Sterilization of Fermenter-1Document11 pagesSterilization of Fermenter-1Shalini M75% (4)

- LabProject StudyofFoamabilityandFoamStabilityDocument17 pagesLabProject StudyofFoamabilityandFoamStabilitySharda RamberanNo ratings yet

- Liquid-Liquid Extraction Tutorial in HYSYSDocument5 pagesLiquid-Liquid Extraction Tutorial in HYSYSkehkashan_pharm1484100% (1)

- KEM Tutorials Chem 17 Module (3rd Exam)Document10 pagesKEM Tutorials Chem 17 Module (3rd Exam)Nyka C.No ratings yet

- White Pepper PDFDocument2 pagesWhite Pepper PDFViji ThulasiramanNo ratings yet

- InsulationDocument24 pagesInsulationermusatNo ratings yet

- Test - 05 - AIATS - JEE (M) - 2024 - FS - GR - 01 & 02 - (Code-A) - 26-03-2023 - Sol.Document13 pagesTest - 05 - AIATS - JEE (M) - 2024 - FS - GR - 01 & 02 - (Code-A) - 26-03-2023 - Sol.rsjjain39No ratings yet

- Analysis of Emulsifier in Food Using Chromatographic TechniquesDocument6 pagesAnalysis of Emulsifier in Food Using Chromatographic TechniquesMaria SiahaanNo ratings yet

- QALCO EPHD Gear Oil 324668100150220320460680 1000Document1 pageQALCO EPHD Gear Oil 324668100150220320460680 1000Vuthpalachaitanya KrishnaNo ratings yet

- Hydrocyclone Model Simulation PDFDocument9 pagesHydrocyclone Model Simulation PDFAnonymous caHv3DvtNo ratings yet

- 2 Tes 209 StructureDocument5 pages2 Tes 209 Structuredgrimjoww 21No ratings yet

- Lecture5 WebDocument43 pagesLecture5 WebAlexandreau del FierroNo ratings yet

- Chemistry ProjectDocument22 pagesChemistry ProjectbheeralingautkurNo ratings yet

- Gradation of AggregatesDocument3 pagesGradation of AggregatesVictoriaNo ratings yet

- Tetrahedron Letters 2020, 61, 151576Document5 pagesTetrahedron Letters 2020, 61, 151576RohanNo ratings yet

- Cable Cleaner Fiber Connector CleanerDocument5 pagesCable Cleaner Fiber Connector CleanerDiogo NovaesNo ratings yet

- Astm D2488-09Document11 pagesAstm D2488-09rokealphaNo ratings yet

- Table of PKa and PI ValuesDocument12 pagesTable of PKa and PI ValuesMariel Defensor ContiNo ratings yet

- Chemistry Investigatory Project (R)Document23 pagesChemistry Investigatory Project (R)BhagyashreeNo ratings yet

- Mass, Volume, and Density: Goals Shape Formula Symbols Table 2.1Document5 pagesMass, Volume, and Density: Goals Shape Formula Symbols Table 2.1SandyNo ratings yet

- Quantum Mechanics II - Homework Assignment 5: Alejandro G Omez Espinosa March 23, 2013Document5 pagesQuantum Mechanics II - Homework Assignment 5: Alejandro G Omez Espinosa March 23, 2013Alejandro EspinosaNo ratings yet

- Strength and Durability Effect of Modified Zeolite Additive On Concrete PropertiesDocument9 pagesStrength and Durability Effect of Modified Zeolite Additive On Concrete PropertiescbilimNo ratings yet

- Mucoadhesive Polymers: Means of Improving Drug Delivery: MucoadhesionDocument4 pagesMucoadhesive Polymers: Means of Improving Drug Delivery: MucoadhesionBrijesh RayNo ratings yet