Water Cement Ratio

Water Cement Ratio

Uploaded by

Prashant PradhanCopyright:

Available Formats

Water Cement Ratio

Water Cement Ratio

Uploaded by

Prashant PradhanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Water Cement Ratio

Water Cement Ratio

Uploaded by

Prashant PradhanCopyright:

Available Formats

WATER CEMENT RATIO

INTRODUCTION

Water-cement ratio is the ratio of weight of water to the weight of

cement used in a concrete mix.

It has an important influence on the quality of concrete produced.

A lower water-cement ratio leads to higher strength and durability,

but may make the mix more difficult to place.

Placement difficulties can be resolved by using plasticizer.

The water-cement ratio is independent of the total cement content

(and the total water content) of a concrete mix.

2 WATERCEMENT RATIO

Often, the water to cement ratio is characterized as the water to

cement plus pozzolan ratio, w/(c+p). The pozzolan is typically a fly ash, or

blast furnace slag. It can include a number of other materials, such as silica

fume, rice hull ash or natural pozzolans. The addition of pozzolans will

influence the strength gain of the concrete.

The concept of water-cement ratio was developed by Duff A. Abrams and first

published in 1918.

Concrete hardens as a result of the chemical reaction between cement and

water (known as hydration). For every 4 lbs of cement, 1 lb of water is needed

to fully complete the reaction. This results in a water-cement ratio of 1:4 or

20% (1/1+4).

3 WATERCEMENT RATIO

In reality, a mix formed with 20% water is too dry and does not flow well

enough to be placed, and some of the water is taken up by the sand and

stone and is not available to participate in the hydration reaction.

So more water is used than is technically necessary to react with the

cement. More typical Water-Cement ratios of 35% to 40% are used, along

with a plasticizer.

Too much water will result in settling and segregation of the sand/stone

components (more sand in the top layers because the stone will settle at the

bottom).

Also, any water that is not consumed by the hydration reaction will

eventually leave the concrete as it hardens, resulting in microscopic pores

or holes that will reduce the final strength of the concrete .

CONCRETE MIX DESIGN 4

For flatwork (driveways, steps, sidewalks, etc) an air-entrainment agent is added

to create small bubbles in the concrete. This helps the finished, hardened concrete

resist fracturing caused by freeze-thaw temperature cycling. Finished, hardened

concrete can be as much as 6% air (by volume) because of this .

And finally, a mix with too much water will experience more shrinkage as the

excess water leaves, resulting in internal cracks and visible fractures (particularly

around inside corners) which again will reduce the final strength.

Anyone who has set wooden fence posts in concrete piers will probably notice

cracks radiating from the corners of the post. This can be reduced by keeping the

water to an absolute minimum.

5 WATERCEMENT RATIO

6 WATERCEMENT RATIO

You might also like

- Project Report On Self Compacting ConcreteDocument89 pagesProject Report On Self Compacting ConcretePirpasha Ujede0% (1)

- Chemsheets As 015 (Forces Between Molecules)Document2 pagesChemsheets As 015 (Forces Between Molecules)burhan0% (2)

- Mix Design c40Document13 pagesMix Design c40Jaime Manalili LandinginNo ratings yet

- Factors Affecting Strength of ConcreteDocument4 pagesFactors Affecting Strength of Concreteعباس حمزة الحسين100% (1)

- Lecture 7 Properties of Hardened ConcreteDocument40 pagesLecture 7 Properties of Hardened ConcreteGirum MenassieNo ratings yet

- Concrete Technology Unit 4Document30 pagesConcrete Technology Unit 4sainathNo ratings yet

- Mix DesignDocument27 pagesMix DesignSoni Mishra TiwariNo ratings yet

- Glass Poweder PPT - 2Document38 pagesGlass Poweder PPT - 2siddham shroff100% (2)

- CONCRETE TECHNOLOGY NOTES NustDocument59 pagesCONCRETE TECHNOLOGY NOTES NustgladNo ratings yet

- Engineering Properties of AggregatesDocument4 pagesEngineering Properties of Aggregatessuryakantame100% (1)

- Structure of Hydrated Cement PasteDocument11 pagesStructure of Hydrated Cement PasteAli Ismael100% (1)

- Damp Proof Course PDFDocument13 pagesDamp Proof Course PDFJohn MathewNo ratings yet

- Unit-2 Chemical and Mineral AdmixturesDocument3 pagesUnit-2 Chemical and Mineral AdmixturesChockalingamNo ratings yet

- Advanced Concrete Technology - 10cv81 - ACE NotesDocument185 pagesAdvanced Concrete Technology - 10cv81 - ACE Notessaqeeb33% (3)

- Entroy and Shaclock Mix Design For HSCDocument9 pagesEntroy and Shaclock Mix Design For HSCvempadareddyNo ratings yet

- Failures in Paver BlockDocument5 pagesFailures in Paver BlockGaneshNo ratings yet

- Concrete Technology Unit 3Document33 pagesConcrete Technology Unit 3sainathNo ratings yet

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignRony BaloyiNo ratings yet

- Soil ReinforcementDocument15 pagesSoil Reinforcementsamea .No ratings yet

- Concrete Technology Unit 5Document27 pagesConcrete Technology Unit 5sainathNo ratings yet

- Bituminous MaterialsDocument53 pagesBituminous MaterialsRoopen FearkyNo ratings yet

- F-Admixture Project ThesisDocument61 pagesF-Admixture Project Thesismuhammad najeebNo ratings yet

- High Performance ConcreteDocument15 pagesHigh Performance ConcreteGaurav Dhembare100% (2)

- Concrete-Classification, Types and TestingDocument33 pagesConcrete-Classification, Types and TestingRishabh Lala100% (1)

- 3.properties of Fresh ConcreteDocument17 pages3.properties of Fresh ConcretedhanarajNo ratings yet

- Testing of Sand Quality at Construction SiteDocument3 pagesTesting of Sand Quality at Construction Sitevikas100% (1)

- AdmixturesDocument3 pagesAdmixturesAbhi0% (1)

- Concrete Mix DesignDocument36 pagesConcrete Mix DesignRafiq MirNo ratings yet

- Anna UniversityDocument131 pagesAnna UniversityDilipKumarAkkaladeviNo ratings yet

- Admixtures in Concrete - NotesDocument55 pagesAdmixtures in Concrete - Notesnital poteNo ratings yet

- Concrete TechnologyDocument100 pagesConcrete TechnologyAnonymous 2UbC4s94M0100% (2)

- Alkali Aggregate Reaction in Concrete - Types, Causes, and EffectsDocument7 pagesAlkali Aggregate Reaction in Concrete - Types, Causes, and EffectsPritha DasNo ratings yet

- Concrete Mix Design C30 - MDocument7 pagesConcrete Mix Design C30 - MMitendra Kumar ChauhanNo ratings yet

- High Strength ConcreteDocument9 pagesHigh Strength Concreteneethu26No ratings yet

- Low Cost RoadsDocument21 pagesLow Cost RoadsIntishar Rahman50% (4)

- Interview QueDocument9 pagesInterview QueDhanashri MusaleNo ratings yet

- Admixtures For ConcreteDocument4 pagesAdmixtures For ConcreteRm1262No ratings yet

- Advance Concrete Technology PDFDocument185 pagesAdvance Concrete Technology PDFrahul landgeNo ratings yet

- Project FINAAL 11Document16 pagesProject FINAAL 11vaibhavmnprNo ratings yet

- Road Note No. 4 Method/DOE MethodDocument11 pagesRoad Note No. 4 Method/DOE MethodashoknrNo ratings yet

- How To Mix MortarDocument3 pagesHow To Mix MortarRi Sovannaphumi100% (2)

- Seminar Presentation On BitumenDocument18 pagesSeminar Presentation On BitumenRohit SinghNo ratings yet

- Paving Blocks Results Report.Document5 pagesPaving Blocks Results Report.patrick munyaoNo ratings yet

- Concrete Technology 2Document4 pagesConcrete Technology 2Hazem EmamNo ratings yet

- Various Retrofitting Methods For Repair and Rehabilitation For Concrete FailureDocument10 pagesVarious Retrofitting Methods For Repair and Rehabilitation For Concrete FailureUsman ShahidNo ratings yet

- MsandDocument4 pagesMsandKote Bhanu PrakashNo ratings yet

- Hot Weather ConcretingDocument31 pagesHot Weather ConcretingLalitha Krishna MoorthyNo ratings yet

- Workability of ConcreteDocument5 pagesWorkability of ConcretelsatchithananthanNo ratings yet

- Seminar On Shrinkage Compensating ConcreteDocument13 pagesSeminar On Shrinkage Compensating ConcreteShaik Abdul Raheem100% (3)

- Recycling Reuse of Plastic Waste As Construction Material For Sustainable Development A Review (31.08.2023)Document24 pagesRecycling Reuse of Plastic Waste As Construction Material For Sustainable Development A Review (31.08.2023)Velchuri SairamNo ratings yet

- Stabilization of Black Cotton Soil Using Fly AshDocument9 pagesStabilization of Black Cotton Soil Using Fly AshIJRASETPublicationsNo ratings yet

- Seminar Report FinalDocument22 pagesSeminar Report Finalshaaz v s m100% (1)

- Advantages. Disadvantages. Transit Mixed Concrete. Shrink Mixed ConcreteDocument14 pagesAdvantages. Disadvantages. Transit Mixed Concrete. Shrink Mixed ConcretekomalNo ratings yet

- Advantages and Disadvantages of Rigid PavementDocument1 pageAdvantages and Disadvantages of Rigid PavementGelo Dizon100% (1)

- Literature Review ZairadziDocument5 pagesLiterature Review Zairadzisiti elferaNo ratings yet

- EXP - 8..... Concrete Cube CastingDocument5 pagesEXP - 8..... Concrete Cube CastingSandeepNo ratings yet

- Partial Replacement of Cement by Saw Dust Ash in Constructional WorksDocument31 pagesPartial Replacement of Cement by Saw Dust Ash in Constructional WorksHariharasudhanNo ratings yet

- Routing and SealingDocument5 pagesRouting and SealingAlishiyaEliasNo ratings yet

- Discussions Design Mix Concrete (Slump, Compacting, Design Form)Document6 pagesDiscussions Design Mix Concrete (Slump, Compacting, Design Form)Salmah AbasNo ratings yet

- Concrete As Building MaterialDocument92 pagesConcrete As Building MaterialUmed Abd-alsatarNo ratings yet

- Award Staff DutiesDocument6 pagesAward Staff DutiesPrashant PradhanNo ratings yet

- Curing of Concrete: DefinitionDocument5 pagesCuring of Concrete: DefinitionPrashant PradhanNo ratings yet

- $0me Sweet and Sour MemoriesDocument43 pages$0me Sweet and Sour MemoriesPrashant PradhanNo ratings yet

- Managing Food Scraps As Animal FeedDocument4 pagesManaging Food Scraps As Animal FeedPrashant PradhanNo ratings yet

- Deco Heavy Duty Adjustable Anchors Sales SheetsDocument2 pagesDeco Heavy Duty Adjustable Anchors Sales SheetsPete SwiftNo ratings yet

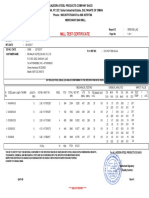

- Mill Test Certificate: END OF REPORTDocument1 pageMill Test Certificate: END OF REPORT220479No ratings yet

- Adil Bhai B-17 Plaza STR Drawings (Revised 18-Oct-2020)Document30 pagesAdil Bhai B-17 Plaza STR Drawings (Revised 18-Oct-2020)MUhammadAHmadNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi Vel100% (1)

- MLP of Coordination Compound PDFDocument23 pagesMLP of Coordination Compound PDFAkash SureshNo ratings yet

- Activity 1Document2 pagesActivity 1DENZ RAYMOND LACUESTANo ratings yet

- 01 SNAME On Advanced Ultimate Limit State Design of Ship StiffenedDocument35 pages01 SNAME On Advanced Ultimate Limit State Design of Ship StiffenedJ T Mendonça SantosNo ratings yet

- Natural Frequencies of BeamsDocument10 pagesNatural Frequencies of BeamsPurwandy HasibuanNo ratings yet

- 1 s2.0 S1359431123005240 MainDocument9 pages1 s2.0 S1359431123005240 MainmohamedNo ratings yet

- 2018 CTI Paper - No Charge - A Novel Non-IonicDocument18 pages2018 CTI Paper - No Charge - A Novel Non-IonicMike StandishNo ratings yet

- Thermal Strap PaperDocument7 pagesThermal Strap PaperSuraj_73No ratings yet

- Catalog 2009 PdfwebDocument420 pagesCatalog 2009 PdfweblynxxNo ratings yet

- Eurotech Catalog - Edition 3Document44 pagesEurotech Catalog - Edition 3mathconsNo ratings yet

- Experimental Study On Sea Sand by Using Partial Replacement of Fine Aggregate Incorporating Steel FibresDocument7 pagesExperimental Study On Sea Sand by Using Partial Replacement of Fine Aggregate Incorporating Steel FibresIJIRSTNo ratings yet

- SAV 244 01 en PDFDocument1 pageSAV 244 01 en PDFAsier GarciaNo ratings yet

- 24x1.5 RM NYY-1.docxx PDFDocument1 page24x1.5 RM NYY-1.docxx PDFRasel AhmedNo ratings yet

- Procedures Guides 4 Import N Distribution BiofuelsDocument26 pagesProcedures Guides 4 Import N Distribution BiofuelsIsioma1No ratings yet

- Two Marks - Questions & AnswersDocument21 pagesTwo Marks - Questions & AnswersCivil PmrNo ratings yet

- 1 Pair 16 AWG Overall Foil Shielded Multi Conductor Cable - 600VDocument2 pages1 Pair 16 AWG Overall Foil Shielded Multi Conductor Cable - 600VARNOLDNo ratings yet

- Activity No. 1 (Dry Lab) Formula and NomenclatureDocument2 pagesActivity No. 1 (Dry Lab) Formula and NomenclatureSumayyaNo ratings yet

- Pre-Qualification Submittal Updated 07242023Document142 pagesPre-Qualification Submittal Updated 07242023azim.rmaxNo ratings yet

- OREAS 620: Volcanic Hosted Massive Sulphide Zn-Pb-Cu-Ag-Au Ore Certified Reference MaterialDocument17 pagesOREAS 620: Volcanic Hosted Massive Sulphide Zn-Pb-Cu-Ag-Au Ore Certified Reference MaterialKEVINNo ratings yet

- 1x2.0x2.0 Culvert DesignDocument36 pages1x2.0x2.0 Culvert DesignVenkata MayurNo ratings yet

- Atomic Structure and Bonding v3cDocument34 pagesAtomic Structure and Bonding v3cBirdii97No ratings yet

- Revised STI-1489 (1) - 08092017Document14 pagesRevised STI-1489 (1) - 08092017vijay k100% (1)

- Zahid Ali: - Refinery LimitedDocument50 pagesZahid Ali: - Refinery Limitedzahid aliNo ratings yet

- Methods, Processes and Equipment Involved in Manufacturing SteelDocument22 pagesMethods, Processes and Equipment Involved in Manufacturing SteelNiño Gerard JabagatNo ratings yet

- ME 342 Final Exam Fall 2021 - StudentsDocument6 pagesME 342 Final Exam Fall 2021 - StudentsSaad RasheedNo ratings yet

- District MalappuramDocument127 pagesDistrict MalappuramnimasatheeshNo ratings yet