100%(1)100% found this document useful (1 vote)

380 views3.3 Road Note No. 4-1

3.3 Road Note No. 4-1

Uploaded by

Asad ChoudharyThis document discusses the design of concrete mixes according to Road Note No. 4. It provides an example of designing a concrete mix to meet specific requirements. The mix is designed to have a compressive strength of 20 N/mm2 at 28 days, using ordinary Portland cement, natural sand, and crushed granite coarse aggregate. The aggregate gradations and material properties are provided. Following the methods in Road Note No. 4, the mix proportions by weight and volume are calculated, along with the quantities required for 1 cubic meter of concrete. The density of fresh concrete is also determined. Limitations of the Road Note No. 4 method are noted.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

3.3 Road Note No. 4-1

3.3 Road Note No. 4-1

Uploaded by

Asad Choudhary100%(1)100% found this document useful (1 vote)

380 views40 pagesThis document discusses the design of concrete mixes according to Road Note No. 4. It provides an example of designing a concrete mix to meet specific requirements. The mix is designed to have a compressive strength of 20 N/mm2 at 28 days, using ordinary Portland cement, natural sand, and crushed granite coarse aggregate. The aggregate gradations and material properties are provided. Following the methods in Road Note No. 4, the mix proportions by weight and volume are calculated, along with the quantities required for 1 cubic meter of concrete. The density of fresh concrete is also determined. Limitations of the Road Note No. 4 method are noted.

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document discusses the design of concrete mixes according to Road Note No. 4. It provides an example of designing a concrete mix to meet specific requirements. The mix is designed to have a compressive strength of 20 N/mm2 at 28 days, using ordinary Portland cement, natural sand, and crushed granite coarse aggregate. The aggregate gradations and material properties are provided. Following the methods in Road Note No. 4, the mix proportions by weight and volume are calculated, along with the quantities required for 1 cubic meter of concrete. The density of fresh concrete is also determined. Limitations of the Road Note No. 4 method are noted.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

100%(1)100% found this document useful (1 vote)

380 views40 pages3.3 Road Note No. 4-1

3.3 Road Note No. 4-1

Uploaded by

Asad ChoudharyThis document discusses the design of concrete mixes according to Road Note No. 4. It provides an example of designing a concrete mix to meet specific requirements. The mix is designed to have a compressive strength of 20 N/mm2 at 28 days, using ordinary Portland cement, natural sand, and crushed granite coarse aggregate. The aggregate gradations and material properties are provided. Following the methods in Road Note No. 4, the mix proportions by weight and volume are calculated, along with the quantities required for 1 cubic meter of concrete. The density of fresh concrete is also determined. Limitations of the Road Note No. 4 method are noted.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

Download as pptx, pdf, or txt

You are on page 1of 40

DESIGN OF

LOW AND MEDIUM

STRENGTH CONCRETE

MIXES

ACCORDING TO

ROAD NOTE NO. 4

Road Note No. 4 is mainly based on the

experimental investigations by Glanville,

dealing with the effect of aggregate grading on

the strength and workability of concrete.

By using the same water/ cement ratio,

different strengths are produced by ordinary

Portland, rapid hardening Portland and high

alumina cements.

The Road Note No. 4 presents a set of curves

relative water/cement ratio and compressive

strength at different ages and for different types

of cements.

Extensive laboratory investigations were

conducted at the Road Research Laboratory to

study the relation among the various

parameters, like aggregate/ cement ratio, water/

cement ratio, degree of workability, grading,

and shape and size of aggregates. Based on the

result, design tables are presented in Road Note

No. 4 to select suitable aggregate/cement ratios

for a concrete mix.

Design a Concrete Mix to Suit the Following

Data Using the Method of Road Note No. 4

Specified works cube strength: 20 N/mm 2 at 28 days.

Degree of control: Very good with weigh batching

and constant supervision.

Degree of workability: High, since concrete is

required for casting the junctions of columns and

beams with congested reinforcement.

Type of cement: Ordinary Portland

Type of fine aggregate: Natural sand

Type of coarse aggregate: Crushed granite

(Angular aggregate) of 20 mm maximum size.

Design a Concrete Mix to Suit the Following

Data Using the Method of Road Note No. 4

The aggregates available at works site have the

following grading:

Percentage passing

IS Sieve Size

Coarse Aggregate Fine Aggregate

20 mm 100 -

10 mm 31 -

4.75 mm 7 -

2.36 mm - 100

1.18 mm - 92

600 micron - 76

300 micron - 48

150 micron - 3

Design a Concrete Mix to Suit the Following

Data Using the Method of Road Note No. 4

The specific gravity and bulk density of various

ingredients of the mix are as follows:

Dry bulk density

Material Specific gravity

(kg/m3)

Cement 3.15 1472

Coarse Aggregate 2.60 1520

Fine Aggregate 2.60 1680

Design the concrete mix & set out field mix

proportions for weigh batching & volume batching.

Also calculate the quantities of materials required

for 1 cubic meter of concrete.

(a) By weight (b) By volume

DESIGN OF CONCRETE

MIXES

ACCORDING TO

ROAD NOTE NO. 4

Design a Concrete Mix to Suit the Following

Data Using the Method of Road Note No. 4

Specified works cube strength: 20 N/mm 2 at 28 days.

Degree of control: Very good with weigh batching

and constant supervision.

Degree of workability: High, since concrete is

required for casting the junctions of columns and

beams with congested reinforcement.

Grading curve number: 03

Type of cement: Ordinary Portland

Type of fine aggregate: Natural sand

Type of coarse aggregate: Irregular aggregate of 20

mm maximum size.

Design a Concrete Mix to Suit the Following

Data Using the Method of Road Note No. 4

The aggregates available at works site have the

following grading:

Percentage passing

IS Sieve Size

Coarse Aggregate Fine Aggregate

20 mm 100 -

10 mm 31 -

4.75 mm 7 100

2.36 mm - 92

1.18 mm - 76

600 micron - 48

300 micron - 20

150 micron - 3

Design a Concrete Mix to Suit the Following

Data Using the Method of Road Note No. 4

The specific gravity and bulk density of various

ingredients of the mix are as follows:

Dry bulk density

Material Specific gravity

(kg/m3)

Cement 3.15 1472

Coarse Aggregate 2.50 1520

Fine Aggregate 2.60 1680

Design the concrete mix & calculate the quantities

of ingredients required for 1 cubic meter of concrete.

What is the density of fresh concrete? Also refer

following graphs and tables for the mixture design.

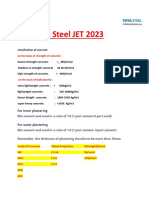

Table 1: Estimated relation between the minimum and mean compressive

strengths of cubes

Figure 1 Curves of four gradings of

20mm aggregate

Figure 2 Relationship between compressive

strength and w/c ratio

Table 2 Agg./cement ratio required to give 4 degrees of workability with different

w/c ratio & gradings

Design of concrete mix

•For

the degree of control used,

minimum strength is 75 percent of the average strength.

= ¿ 2

Mean design strength 27 𝑁 / 𝑚𝑚

Water/ cement ratio = 0.62

For high workability, the required

aggregate/ cement ratio = 5.56

The proportion of fine to total aggregate = 25 percent

Hence the proportion by weight of ingredients are given by

Cement : Fine Aggregate : Coarse Aggregate

1 : :

1 : :

Design of concrete mix

•Quantity

of materials required for 1m3 of concrete

If C = weight of cement required per m3 of concrete

Then by absolute volume method, we have

+ + =1

Therefor, C = Cement = 323 kg

Water = 0.62 x 323 = 200 kg

FA = 1.39 x 323 = 449 kg

CA = 4.17 x 323 = 1347 kg

Density of fresh concrete = 2319

Thank You

Design a Concrete Mix to suite the

Following Data Using the

Method of Road Note No. 4

Specified works cube strength: 30 N/mm 2 at 28 days.

Degree of control: Very good with weigh batching

and constant supervision.

Degree of workability: Vey low since compacting

will be affected by vibration

Type of cement: Ordinary Portland

Type of fine aggregate: Natural sand

Type of coarse aggregate: Irregular aggregate

The aggregates are stockpiled at works site in three

heaps and have the grading shown below:

Cumulative Percentage passing

IS Sieve Size Fine Coarse Aggregate

Aggregate 4.75 to 20 mm 20 to 40 mm

40 mm - 100 100

20 mm - 99 13

10 mm 100 33 8

4.75 mm 99 5 2

2.36 mm 76 0 0

1.18 mm 58 - -

600 micron 40 - -

300 micron 12 - -

150 micron 2 - -

The specific gravity of various ingredients of the

mix are as follows:

Material Specific gravity

Cement 3.15

Coarse Aggregate 2.50

Fine Aggregate 2.60

Design the concrete mix & calculate the quantities

of ingredients required for 1 cubic meter of concrete.

What is the density of fresh concrete?

LIMITATIONS OF ROAD NOTE NO. 4 METHOD

The design tables of aggregate / cement ratios

recommended in Road Note No. 4 cover only

three shapes of aggregates and four types of

grading.

But in practice many aggregates having

different shapes, sizes, and properties have to be

used for the mixes.

The Road Note No. 4 data can not be directly

used for design of air- entrained concrete.

Thank You

You might also like

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar Chauhan50% (2)

- Bs Mix Design Doe MethodDocument22 pagesBs Mix Design Doe Methodsanthu25693% (27)

- Concrete Mix DesignDocument21 pagesConcrete Mix DesignPratyush Kumar DoraNo ratings yet

- Concrete Mix Design DOE PDFDocument15 pagesConcrete Mix Design DOE PDFkarthiksamp100% (2)

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignRony BaloyiNo ratings yet

- Tests For Workability of ConcreteDocument5 pagesTests For Workability of Concretelsatchithananthan100% (1)

- Compressive Strength Test On Concrete CoreDocument4 pagesCompressive Strength Test On Concrete CoreSyed Mohd MehdiNo ratings yet

- High Slump Concrete Mix Design 2Document68 pagesHigh Slump Concrete Mix Design 21man1bookNo ratings yet

- Reference Notes - Tests For ConcreteDocument21 pagesReference Notes - Tests For ConcreteMitali KhedkarNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix DesignChathura ChamikaraNo ratings yet

- Concrete Mix Design and Casting of Sample For Different TestDocument4 pagesConcrete Mix Design and Casting of Sample For Different TestAqeel AliNo ratings yet

- BS 812-109-1990 Testing Aggregates. Methods For Determination of Moisture ContentDocument13 pagesBS 812-109-1990 Testing Aggregates. Methods For Determination of Moisture ContentHaris KyriazisNo ratings yet

- Design of M100 Grade ACI MethodDocument3 pagesDesign of M100 Grade ACI MethodGaurav PatilNo ratings yet

- 8 Mix Design Calculations PDFDocument60 pages8 Mix Design Calculations PDFfahad raza100% (4)

- Mix DesignDocument18 pagesMix Designawotina67% (3)

- IS Code Method of Mix Design Using SuperplasticizerDocument29 pagesIS Code Method of Mix Design Using SuperplasticizerJameel KhanNo ratings yet

- 1 Variability of Concrete MixDocument56 pages1 Variability of Concrete MixHarpreet SinghNo ratings yet

- Evaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteDocument62 pagesEvaluation of Mechanical and Durability Propierties of Concrete Paving Block Containing Granite Slurry WasteRomeo R Chinguel DelgadoNo ratings yet

- Concrete Mix Design (Notes) PDFDocument11 pagesConcrete Mix Design (Notes) PDFMohamad Khaled Nordin100% (2)

- Mix Design Method For Asphalt Concrete PavementDocument16 pagesMix Design Method For Asphalt Concrete PavementElumalai Srinivasan100% (1)

- BS 1881 - Part 108 - 1983Document5 pagesBS 1881 - Part 108 - 1983RACCH1977No ratings yet

- Group 2 - Quality ControlDocument94 pagesGroup 2 - Quality ControlZairah Ann Borja100% (1)

- 2a-Concrete Mix DesignDocument21 pages2a-Concrete Mix Designpankaj_paul6451No ratings yet

- Acceptance Criteria of ConcreteDocument26 pagesAcceptance Criteria of ConcretevempadareddyNo ratings yet

- Mix DesignDocument29 pagesMix Designshahhassa9No ratings yet

- What Is Lean ConcreteDocument2 pagesWhat Is Lean Concreteadam dam jhegsNo ratings yet

- Compaction Factor Test&Slump Test ReportDocument1 pageCompaction Factor Test&Slump Test ReportMUN SIM SOHNo ratings yet

- Entroy and Shaclock Mix Design For HSCDocument9 pagesEntroy and Shaclock Mix Design For HSCvempadareddyNo ratings yet

- Concrete Mix Design: by K.ShahDocument48 pagesConcrete Mix Design: by K.ShahBùi Quang MinhNo ratings yet

- Concrete Mix Design CalculationDocument10 pagesConcrete Mix Design CalculationHari RNo ratings yet

- High Strength Concrete Mix DesignDocument2 pagesHigh Strength Concrete Mix DesignKimo KenoNo ratings yet

- Volume Batching of ConcreteDocument4 pagesVolume Batching of ConcreteHashem EL-MaRimey67% (3)

- Road Note Method No 4Document22 pagesRoad Note Method No 4ramya_an2411100% (1)

- Mix Design For Roller Compacted Concrete RCCDocument3 pagesMix Design For Roller Compacted Concrete RCCpgciprianNo ratings yet

- Concrete Mix Design C30 - MDocument7 pagesConcrete Mix Design C30 - MMitendra Kumar ChauhanNo ratings yet

- M30 For Concrete PavementDocument1 pageM30 For Concrete PavementR ARUNPANDIANNo ratings yet

- Pavement DistressDocument65 pagesPavement DistressPadma ShahiNo ratings yet

- Draft TMH 9 Part B 05052013Document57 pagesDraft TMH 9 Part B 05052013Tshepiso Nthite100% (1)

- Concrete Mix DesignDocument36 pagesConcrete Mix Designamitbd80% (5)

- Supervising Highway Engineer: Passbooks Study GuideFrom EverandSupervising Highway Engineer: Passbooks Study GuideNo ratings yet

- Concrete Workability: An Investigation on Temperature Effects Using Artificial Neural NetworksFrom EverandConcrete Workability: An Investigation on Temperature Effects Using Artificial Neural NetworksRating: 5 out of 5 stars5/5 (1)

- Unit-3 High Strength Concrete PDFDocument17 pagesUnit-3 High Strength Concrete PDFmeena y rNo ratings yet

- Unit-3 High Strength Concrete PDFDocument17 pagesUnit-3 High Strength Concrete PDFmeena y rNo ratings yet

- Exploratory Project 2Document43 pagesExploratory Project 2AMAN GUPTANo ratings yet

- Concrete Mix Design C30 - ACI METHODDocument4 pagesConcrete Mix Design C30 - ACI METHODMitendra Kumar Chauhan100% (1)

- Unit-4 Special ConcreteDocument32 pagesUnit-4 Special Concretemeena y rNo ratings yet

- 3 Concrete Mix DesignDocument28 pages3 Concrete Mix DesignPraveen BhandariNo ratings yet

- L5A-Concrete Mix Design-British Method-Print1Document4 pagesL5A-Concrete Mix Design-British Method-Print1Suhaib SulaimanNo ratings yet

- Concrete Mix DesignDocument27 pagesConcrete Mix DesignMahadi HasanNo ratings yet

- Hoy-Kaab Construction CompanyDocument39 pagesHoy-Kaab Construction Companyabdicasis rashidNo ratings yet

- Concrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25Document15 pagesConcrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25patel2732sNo ratings yet

- Concrete Mix Design Calculation For M20Document25 pagesConcrete Mix Design Calculation For M20Kosygin Leishangthem100% (5)

- CC Mix Design by KLPDocument59 pagesCC Mix Design by KLPstruban8337100% (1)

- Lab Report U1 Workability PDFDocument11 pagesLab Report U1 Workability PDFEn Long BglongNo ratings yet

- Concrete Mix DesignDocument13 pagesConcrete Mix Designpatel2732sNo ratings yet

- Road Note MethodDocument10 pagesRoad Note Methodramya_an2411100% (1)

- Concrete Mixed Design Method (BS Method)Document11 pagesConcrete Mixed Design Method (BS Method)CocoNo ratings yet

- Illustration of Mix Design of Concrete by ISI MethodDocument10 pagesIllustration of Mix Design of Concrete by ISI Methodhitesh16No ratings yet

- BMC Concert DocumentDocument3 pagesBMC Concert DocumentAdyasa SahooNo ratings yet

- Cálculo de Diseño de SeparadoresDocument4 pagesCálculo de Diseño de SeparadoresEdwardNo ratings yet

- 33.2.27A AOAC of Fi Cial Method 2000.18 Fat Con Tent of Raw and Pas Teur Ized Whole MilkDocument2 pages33.2.27A AOAC of Fi Cial Method 2000.18 Fat Con Tent of Raw and Pas Teur Ized Whole MilkJavier muñoz100% (1)

- ENGI 9113 (2016) - Lecture 1 BasicsDocument70 pagesENGI 9113 (2016) - Lecture 1 BasicsShitao GuanNo ratings yet

- Possible Putme Questions and Answers in Physics by Dr. G. O. Okocha-2Document10 pagesPossible Putme Questions and Answers in Physics by Dr. G. O. Okocha-2oniharry12No ratings yet

- Physical Principles of Respiratory Care: Chapter ObjectivesDocument27 pagesPhysical Principles of Respiratory Care: Chapter ObjectivesMatthew SmileyNo ratings yet

- Pengujian Berat JenisDocument70 pagesPengujian Berat JenissangumangNo ratings yet

- Soil Mechanics Lab ManualDocument39 pagesSoil Mechanics Lab ManualDharmaraaj RajalinggamNo ratings yet

- Laboratory Manual: CIV309 (Soil Mechanics Lab)Document75 pagesLaboratory Manual: CIV309 (Soil Mechanics Lab)Assif YousufNo ratings yet

- 11 Physical Properties of MilkDocument25 pages11 Physical Properties of MilkSadia Ashfaq Sadia AshfaqNo ratings yet

- Mechanical MeasurementsDocument13 pagesMechanical MeasurementscaptainhassNo ratings yet

- 1 Fundamental Concepts and PrinciplesDocument82 pages1 Fundamental Concepts and PrinciplesAubrey Alvarez100% (1)

- Seam 2 CombinedDocument41 pagesSeam 2 Combinedjanerniecabe11032002No ratings yet

- Solvent Containing Varnishes Used For Electrical Insulation: Standard Test Methods For TestingDocument9 pagesSolvent Containing Varnishes Used For Electrical Insulation: Standard Test Methods For TestingRossdhan RamosNo ratings yet

- Ss1 PhysicsDocument55 pagesSs1 Physicsonojaella2007No ratings yet

- Fluid Mechanics Final Notes 2Document37 pagesFluid Mechanics Final Notes 2suman rajNo ratings yet

- CMT Manual 2ndSY21 22Document76 pagesCMT Manual 2ndSY21 22estoy estoyNo ratings yet

- Fluids SubjectiveDocument11 pagesFluids SubjectiveSayantan ChatterjeeNo ratings yet

- f1 Phys Et3 Assignment s1Document70 pagesf1 Phys Et3 Assignment s1nwairimu4636No ratings yet

- Hydrometer InformationDocument4 pagesHydrometer InformationArun RaoNo ratings yet

- 1تقرير الوزن النوعي للتربهDocument4 pages1تقرير الوزن النوعي للتربهghaithghaith020No ratings yet

- Is.1448.32.1992 0 PDFDocument26 pagesIs.1448.32.1992 0 PDFNagarajanMuthuramanNo ratings yet

- SR-690 - GTIR - 08 BHs - REV2Document87 pagesSR-690 - GTIR - 08 BHs - REV2AKB CONSULTANTSNo ratings yet

- FMHM NotesDocument205 pagesFMHM NotesSaitama BackupNo ratings yet

- Lecture 1-Fluid Statics 2003Document6 pagesLecture 1-Fluid Statics 2003Leonardo LibresNo ratings yet

- 31-Astm C1077-16Document9 pages31-Astm C1077-16Rolando de GuzmanNo ratings yet

- 004-Astm C 138 2007 Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDocument4 pages004-Astm C 138 2007 Density (Unit Weight), Yield, and Air Content (Gravimetric) of ConcreteDiego Gauna100% (1)

- Chemical Tanker Made Simple v5Document204 pagesChemical Tanker Made Simple v5onur2613No ratings yet

- Physical Properties of SoilDocument3 pagesPhysical Properties of SoilCESHNo ratings yet

- Api-650/653 General Tank Data API-650 11th Edition, June 2007Document3 pagesApi-650/653 General Tank Data API-650 11th Edition, June 2007chompink6900No ratings yet

- 1CH-1 Fundamentals of PhysicsDocument29 pages1CH-1 Fundamentals of PhysicsGauravSaxenaNo ratings yet