0 ratings0% found this document useful (0 votes)

12 viewsModule 2

Module 2

Uploaded by

ABIGAIL OLAJUMOKE JOSEPHThis document discusses polymer processing techniques, with a focus on extrusion and injection molding. It provides details on:

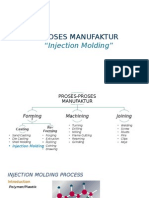

1) Extrusion and injection molding involve heating polymer material, injecting it into a mold under pressure, and cooling it to solidify into the desired shape.

2) Single- and twin-screw extruders are used to melt and convey polymer material through a die to shape it. Injection molding machines inject molten polymer into a closed mold under high pressure.

3) Extrusion and injection molding are widely used to manufacture polymer products for applications in transportation, electronics, construction and more due to their efficiency and ability to form complex shapes.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Module 2

Module 2

Uploaded by

ABIGAIL OLAJUMOKE JOSEPH0 ratings0% found this document useful (0 votes)

12 views21 pagesThis document discusses polymer processing techniques, with a focus on extrusion and injection molding. It provides details on:

1) Extrusion and injection molding involve heating polymer material, injecting it into a mold under pressure, and cooling it to solidify into the desired shape.

2) Single- and twin-screw extruders are used to melt and convey polymer material through a die to shape it. Injection molding machines inject molten polymer into a closed mold under high pressure.

3) Extrusion and injection molding are widely used to manufacture polymer products for applications in transportation, electronics, construction and more due to their efficiency and ability to form complex shapes.

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document discusses polymer processing techniques, with a focus on extrusion and injection molding. It provides details on:

1) Extrusion and injection molding involve heating polymer material, injecting it into a mold under pressure, and cooling it to solidify into the desired shape.

2) Single- and twin-screw extruders are used to melt and convey polymer material through a die to shape it. Injection molding machines inject molten polymer into a closed mold under high pressure.

3) Extrusion and injection molding are widely used to manufacture polymer products for applications in transportation, electronics, construction and more due to their efficiency and ability to form complex shapes.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

0 ratings0% found this document useful (0 votes)

12 views21 pagesModule 2

Module 2

Uploaded by

ABIGAIL OLAJUMOKE JOSEPHThis document discusses polymer processing techniques, with a focus on extrusion and injection molding. It provides details on:

1) Extrusion and injection molding involve heating polymer material, injecting it into a mold under pressure, and cooling it to solidify into the desired shape.

2) Single- and twin-screw extruders are used to melt and convey polymer material through a die to shape it. Injection molding machines inject molten polymer into a closed mold under high pressure.

3) Extrusion and injection molding are widely used to manufacture polymer products for applications in transportation, electronics, construction and more due to their efficiency and ability to form complex shapes.

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

Download as ppt, pdf, or txt

You are on page 1of 21

CHE417

Polymer Process Engineering

Recommended Textbooks

1. Organic Polymers: Advances in Research and Applications. By Tomos Fisher.

Nova Science Publisher

2. Basics of Polymers: Fabrication and Processing Technology. By:

Muralisrinivasan Natamai Subramanian. Published by Momentum Press, 2015

3. Introduction to Polymer Chemistry, 3rd Edition. By: Charles E. Carraher Jr.

Published by CRC Press, Tailor and Francis, 2014

Other methods of making/manufacturing polymer

Polymer Processing

•Because of the properties of polymers, it is possible to mould them and

change their shape using a number of different repetitious manufacturing

processes.

•Polymer processing is influenced by the thermal characteristics of polymer.

They are melt temperature, glass transition temperature, thermal conductivity,

thermal diffusivity, heat capacity, coefficient of linear thermal expansion, and

decomposition temperature.

•Polymer processing techniques are used to meet the requirements or

specification as required by the industries and end-product applications.

•During processing, improved mechanical, thermal, optical, and other

properties are optimized during manufacturing using optimized polymerization

conditions.

• Polymer processing technology helps to convert polymer into long-life

applications for use in areas such as transportation, appliances, electronics,

and construction markets.

• Polymer processing operations are extrusion and injection molding, blow

molding, rotational moulding, thermoforming, calendering, vacuum forming,

and compression moulding.

Injection/Extrusion Molding

• Injection molding is labor intensive and extrusion is material intensive. Both

these processes involve the following sequence of steps: (a) heating and

melting the polymer, (b) pumping the polymer to the shaping unit, (c)

forming the melt into the required shape and dimensions, and (d) cooling and

solidification.

Extrusion Molding

• Extrusion is one of the most important polymer processing methods used to

enhance the uniaxial strength and stiffness of polymer materials. It makes

up the material much higher strength along the polymer chain than that

exhibited by the material properties before processing.

• It involves solid conveying, melting, mixing, venting, and homogenizing

and affects the quality of polymer products considerably.

• Single-screw extruder (Figure 7.1) and counter-rotating twin-screw extruder

(Figure 7.2) are used during extrusion of polymeric materials.

• Figure 7.1 Schematic representation of single-screw extruder

Single-screw extruder

• The screw extrusion process consists of three distinct zones, namely feed,

compression, and metering zone.

• The polymer is either conveyed in the solid state or melted under the action of

conducted heat and shear, and the resulting melt is mixed and pumped.

• The three sections of the screw, feed zone having the constant channel depth in

the section, tapering compression or transition section, and the constant depth

metering section, are normally associated with these three functions although

there is often considerable overlap.

• Melting starts in the feed section of the screw and continues into the metering

section.

• Figure 7.2 Schematic representation of twin-screw extruder

Twin-screw extruder

• Twin-screw extruder has been extensively used in the polymer industry,

particularly counter-rotating involves in various applications, including

melting, pressurization, and mixing, which leads to different end products

such as pipe, profile, sheet, and flat film.

• Twin-screw extruders are usually operated at a specific throughput; therefore,

portions of the extruder are completely filled, whereas other locations are

partially filled. Filled regions are formed behind restrictive and reverse

pumping elements in extrusion screws.

Extruder

•Extruder represents a very complex machine to process various types of

polymeric materials and viscosities under high temperature and pressure with

very strong shear forces and short residence time in the barrel.

•During extrusion, the extruder treats the material with mixing, kneading,

heating, shearing, and finally through a die appropriately designed to form the

product under expansion and rapid fall in pressure.

•Extruder is used to extrudate polymeric materials with a series of

subprocesses, including motor-drive control systems and barrel heating/cooling

system. Operation and process reflect the input and output of the extrusion

process.

•During extrusion process, each material undergoes a different temporal,

thermal, and/or mechanical history. As a result, its final properties may be

different from those of the materials subjected to extrusion process.

• Single- and twin-screw extruders differ in conveying mechanism. In single-

screw extruder, the process is highly dependent on the frictional and viscous

properties of the material. In this extruder, the frictional and viscous forces

help in the melt conveying.

• Twin-screw extruders are designed to have positive conveying

characteristics. These extruders can be classified according to their

geometrical configuration. The polymeric material may be more or less

trapped in compartments formed by the two screws and barrel due to their

full intermeshing nature of the twin screw.

• Better the intermesh between the screws, the more positive conveying

occurs. In twin-screw extruder, the frictional and viscous forces have a

minimal effect on the conveying behavior.

Extrusion

• Extrusion is a process that can be compared to squeezing toothpaste out of a

tube. Thermoplastic granules are forced through a heated barrel and the fused

polymer is then squeezed through a die that is the profile of the extruded

component.

• The extrusion is cooled by water or air as it leaves the die and is finally cut to

the required length. The shape of the die can be varied from a simple hole

with a centrally supported core to produce tubes such as pipes, to very

complex sections for curtain tracks or hollow window frames.

• Hence, extrusion consists of processing polymeric materials through an

extruder that heats, softens, and forces the molten plastic through a die to give

the desired shape.

Extrusion dies

• Extrusion dies are metal channels that impart a specific cross-sectional shape

to a polymer stream.

• The swell of the extrudate as it leaves the extrusion die is an important

phenomenon in polymer melt extrusion.

• Die entrance angle plays an important role in the die pressure in the extrusion

pressure. Die pressure is affected by flow rate of polymer melt, cross section

of the die, die temperature, and material viscosity.

• As the polymeric material is forwarded along the screw channel, heat is

generated by viscous flow and transferred through both the screw and barrel

surfaces. A die at the end of the channel causes a resistance, resulting in an

adverse pressure gradient in the channel. These factors influence the

temperature distribution between the two surfaces.

Applications:

•Extrusion is a suitable plastic forming method for fabricating a variety

of shapes with constant cross section, not only for flat shapes, but also

for structural shapes, such as I-sections, channels, pipes, and tubes.

Injection Molding

• This process is one of the most common of all plastics manufacturing

processes. The polymer, in granule form, is heated until fused and forced

into a closed mould.

• Because of the viscous (thick, syrupy) nature of the fused polymer, very

high pressures are needed to make it flow, which means that the machine

and mould have to be very strong to withstand the forces involved.

• Injection molding of thermoplastics involves injecting molten resin into a

mold at high pressure and ejecting the cooled part. A better understanding of

the friction conditions during the molding process can lead to improved

injection mold and part designs.

• The polymer material solidifies under homogeneous stress and cooling

conditions in injection molding. The inner structures of the molded article

are inhomogeneous, which influences the product properties.

Therefore, it is necessary to clarify the influences of the structure of polymer

and molding conditions on the inhomogeneous structure of the molded article.

Thus, injection molding is a process with

•high-pressure squeezing of complex and compressible hot melt polymer

fluid,

•hot melt that flows through a very small gate into a cold cavity mold with

high velocity,

•end product having an apparent hierarchical structure, macroscopically as a

skin–core structure,

•higher versatility,

•end product with little or no finishing required

• Injection molding machine (see the Figure) consists of an injection and

plastication unit, mold clamping unit, and hydraulic and control unit. In the

injection unit, the polymer is melted by heating and shearing.

• The polymer is injected under pressure into a mold cavity, which is held by

the mold clamping unit.

• By the application of cooling agent, the polymer melt solidifies into a shape of

the mold cavity.

• Hydraulic unit serves manipulator for the injection unit. Finally, control unit

supervises the process and provides overall control and sequences of the

machine.

• Figure: Injection Mold

Purpose of injection molding

• The purpose of injection molding is to produce polymer end products with

high efficiency and to shape the products with complicated forms. Scientific

molding is an important initial practice to make proper short shot.

• To start up with any mold, short shot is to be made for the safety of the

machine and mold. Therefore, functional areas such as barrel and heating

zones are important for their individual functions.

Applications:

• This technique is economical and efficient to produce a wide range of

polymer parts for industrial, agricultural, electronic, and household articles.

• In polymers, shear and elongational flow are two primary flow mechanisms.

Shear flow describes the response of the polymer to an imposed shearing

force. Elongation flow is the response of the polymer to an imposed

stretching or pulling force. As the shear rate increases, the rate of increase in

shear stress decreases and this is described as shear thinning.

• Polymer processing includes stress relaxation and normal stress differences.

In process such as injection molding and extrusion, the slow stress relaxation

is responsible for frozen-in stresses.

• During processing and extrudate swelling in extrusion, the normal stress

differences are responsible for flow instabilities. Extrudate swelling is the

significant increase in cross-sectional area when a molten material is

extruded out of a die.

You might also like

- Job Offer DraftDocument2 pagesJob Offer DraftWael Ahmed100% (1)

- Collectors Investments: South Africa Coin ListDocument5 pagesCollectors Investments: South Africa Coin ListbelebelNo ratings yet

- Bece English Language Past Questions 2018Document5 pagesBece English Language Past Questions 2018Anonymous lnC6IDg100% (4)

- PlasticsDocument48 pagesPlasticsPavan MehataNo ratings yet

- Plastics PDFDocument18 pagesPlastics PDFV Phanindra BoguNo ratings yet

- Plastics: by Dr. V Phanindra Bogu Dept. of Mech. EnggDocument18 pagesPlastics: by Dr. V Phanindra Bogu Dept. of Mech. EnggV Phanindra BoguNo ratings yet

- Zones of ScrewDocument111 pagesZones of Screwzubi0585100% (2)

- Polymer Procession Term Test-1Document90 pagesPolymer Procession Term Test-1সাইদুর রহমানNo ratings yet

- Extrusion MoldingDocument16 pagesExtrusion Moldingalihyderabro166No ratings yet

- Method 2Document16 pagesMethod 2vaniNo ratings yet

- 1.polymer ProcessingDocument23 pages1.polymer Processingafia rahmanNo ratings yet

- Polymer Processing HandoutDocument68 pagesPolymer Processing HandoutibraheemNo ratings yet

- UnitVI Injection - Compressiona ND Blow MoldingDocument48 pagesUnitVI Injection - Compressiona ND Blow Moldingharrywilson.harish77No ratings yet

- Extrusion of Thermoplastics EXTRUSION Plays A Prominent Part On The Plastics Industry. Extrusion, UnlikeDocument21 pagesExtrusion of Thermoplastics EXTRUSION Plays A Prominent Part On The Plastics Industry. Extrusion, UnlikeParag NambiarNo ratings yet

- Polymers PPT PDFDocument47 pagesPolymers PPT PDFShivani RajeevNo ratings yet

- 202004032240236827nksingh Polymer ProcessingDocument9 pages202004032240236827nksingh Polymer ProcessingMuhammad Umair Akbar GujjarNo ratings yet

- Unit 4 (BCHE-602)Document14 pagesUnit 4 (BCHE-602)Garima TamtaNo ratings yet

- Polymerextrusion 180721114925Document17 pagesPolymerextrusion 180721114925Athlur Sai KiranNo ratings yet

- Plasting ProcessingDocument19 pagesPlasting Processingnethumini GunawardanaNo ratings yet

- Chapter 1-2Document70 pagesChapter 1-2Shivpoojan SinghNo ratings yet

- Injection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarsDocument37 pagesInjection Molding: Manufacturing Plastic Material Pressure Mould Mouldmaker Steel Aluminium CarslakhancipetNo ratings yet

- Olymer Rocessing: The Main Goal of Polymer Processing Is To Produce A Usable ObjectDocument59 pagesOlymer Rocessing: The Main Goal of Polymer Processing Is To Produce A Usable ObjectChaitanya PatelNo ratings yet

- FormingAndShapingPlasticsDocument30 pagesFormingAndShapingPlasticsM PraveenNo ratings yet

- Chapter 13 - Extrusion-Based Processes (Part 1)Document45 pagesChapter 13 - Extrusion-Based Processes (Part 1)hirenpatNo ratings yet

- Extrusion Die DesignDocument67 pagesExtrusion Die DesignShubham Chaudhary100% (2)

- Forming and Shaping Plastics & Composite Materials: Chapter - 18Document35 pagesForming and Shaping Plastics & Composite Materials: Chapter - 18Muddu AlaparthiNo ratings yet

- Manufacturing Processes: International Islamic University IslamabadDocument44 pagesManufacturing Processes: International Islamic University IslamabadMuhammad Qasim SajidNo ratings yet

- Manufacturing Technology-I: Plastic FormationDocument11 pagesManufacturing Technology-I: Plastic FormationPratheep AddrinNo ratings yet

- ICH404-Lecture Note 6 - 7Document5 pagesICH404-Lecture Note 6 - 7Lukman Bola Abdulra'ufNo ratings yet

- Polymer Extrusion Experimental Report: April 2018Document9 pagesPolymer Extrusion Experimental Report: April 2018Mehmet Sarı100% (1)

- New ThermoformingDocument20 pagesNew ThermoformingVijay S PNo ratings yet

- Manufacturing Processes: International Islamic University IslamabadDocument44 pagesManufacturing Processes: International Islamic University IslamabadHassan AliNo ratings yet

- Mt1 Unit 5 NotesDocument11 pagesMt1 Unit 5 NotesvelavansuNo ratings yet

- Injection MouldingDocument76 pagesInjection MouldingYohannesNo ratings yet

- Lecture 4.4: Transfer Molding and Compression Molding Transfer MoldingDocument5 pagesLecture 4.4: Transfer Molding and Compression Molding Transfer Moldingapi-256504985No ratings yet

- Plastic Proc 28 May 09 FinalDocument59 pagesPlastic Proc 28 May 09 FinalAinun ZulfikarNo ratings yet

- Unit 3: Plastic Processing: 1. State The General Properties of PlasticsDocument13 pagesUnit 3: Plastic Processing: 1. State The General Properties of PlasticsSagar Dhage100% (1)

- MTP 3 NotesDocument8 pagesMTP 3 Notespratham95213No ratings yet

- Week 7 Plastic ProcessingDocument67 pagesWeek 7 Plastic ProcessingHanzzel CharlesNo ratings yet

- Forming Techniques of PlasticsDocument10 pagesForming Techniques of Plasticsstephennyaosi32No ratings yet

- Principles of Single Screw ExtrusionDocument44 pagesPrinciples of Single Screw ExtrusionHugo Wizenberg75% (8)

- ExtrusionDocument27 pagesExtrusionShreyas ParbatNo ratings yet

- Forming of PlasticDocument25 pagesForming of PlasticAzhar AliNo ratings yet

- Plastic Processing: Extrusion Compression MouldingDocument88 pagesPlastic Processing: Extrusion Compression MouldingBhushan Shankar Kamble100% (2)

- Gear Type Injection MouldingDocument47 pagesGear Type Injection MouldingJohn Ajish50% (2)

- Plastic Manufacturing ProcessesDocument6 pagesPlastic Manufacturing ProcessesHimanshu TiwariNo ratings yet

- BMP2Document121 pagesBMP2sid sNo ratings yet

- Ceramic Injection MouldingDocument8 pagesCeramic Injection Mouldingsaritha339No ratings yet

- 2 1 ExtrusionDocument69 pages2 1 ExtrusionSingh Anuj0% (1)

- Injection MoldingDocument23 pagesInjection MoldingAditya DhikaNo ratings yet

- Ch13 1 PolymerMelt&ExtrusionDocument32 pagesCh13 1 PolymerMelt&ExtrusionPrabhu MechNo ratings yet

- Textile Composites III-composite MFGDocument10 pagesTextile Composites III-composite MFGYared FikreNo ratings yet

- Roll FormingDocument11 pagesRoll FormingthirumalaikumaranNo ratings yet

- 02 Multilayercompositefilms 110322072335 Phpapp02Document48 pages02 Multilayercompositefilms 110322072335 Phpapp02naveenjeswaniNo ratings yet

- Unit-6 Plastic MouldingDocument12 pagesUnit-6 Plastic MouldingManav Patel100% (1)

- Comp 2Document7 pagesComp 2fan36078No ratings yet

- Gear Type Injection Moulding MachineDocument4 pagesGear Type Injection Moulding MachineJeya KumarNo ratings yet

- Injection Molding SchematicDocument15 pagesInjection Molding SchematicSourav DipNo ratings yet

- Fundamental of Manufacturing by Groover Cahpter 13Document125 pagesFundamental of Manufacturing by Groover Cahpter 13ali kingNo ratings yet

- Chapter 9 PolymersDocument18 pagesChapter 9 Polymersgediontassew007No ratings yet

- FilmsDocument2 pagesFilmsElisya DiantyNo ratings yet

- Interacademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.From EverandInteracademic Collaboration Involving Higher Education Institutions in Tlaxcala and Puebla, Mexico. Presented in Collaboration with Université Clermont Auvergne (France): Case Studies of Collaborative, Multidisciplinary Applications.No ratings yet

- (TMC 321) Personal Value System - Dr. Abraham Owoseni - 11zonDocument58 pages(TMC 321) Personal Value System - Dr. Abraham Owoseni - 11zonABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- ECOBANK Funding Entrepreneurial IdeaDocument12 pagesECOBANK Funding Entrepreneurial IdeaABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- Module 4Document8 pagesModule 4ABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- Module 1Document19 pagesModule 1ABIGAIL OLAJUMOKE JOSEPHNo ratings yet

- Jeremy Tan Resume and CVDocument3 pagesJeremy Tan Resume and CVapi-359540985No ratings yet

- Overseas Class 8 Maths 1Document179 pagesOverseas Class 8 Maths 1sana022009No ratings yet

- Yealink SIP-T20P DatasheetDocument2 pagesYealink SIP-T20P DatasheetmartinsNo ratings yet

- Makalah Barir Faqih-Danar Andria SMA Trensains Muhammadiyah Sragen S Nas2021Document5 pagesMakalah Barir Faqih-Danar Andria SMA Trensains Muhammadiyah Sragen S Nas2021Muhammad Barir Faqih HermawanNo ratings yet

- Present Simple WorkshopDocument2 pagesPresent Simple WorkshopnataliaNo ratings yet

- Brochure Simatic Wincc v72 enDocument8 pagesBrochure Simatic Wincc v72 enjeanfmirandaNo ratings yet

- List of MembersDocument8 pagesList of Memberselement EgNo ratings yet

- 1-130 Team1 Project1-Doc Overmyer Gil Ringor Combs BosworthDocument36 pages1-130 Team1 Project1-Doc Overmyer Gil Ringor Combs Bosworthapi-655484178No ratings yet

- Greek Mythology Posters FREEBIEDocument6 pagesGreek Mythology Posters FREEBIEDavidNo ratings yet

- Developing A Global VisionDocument44 pagesDeveloping A Global VisionAndrea DawnNo ratings yet

- Palay Inc Vs ClaveDocument2 pagesPalay Inc Vs ClaveBelzer ResurreccionNo ratings yet

- BUS 1101 Learning Journal Unit 1 2020Document2 pagesBUS 1101 Learning Journal Unit 1 2020joel konse50% (2)

- Hana - Alexis.holubec 2017 (Autosaved) - 1Document1 pageHana - Alexis.holubec 2017 (Autosaved) - 1Anonymous yBbm4g5No ratings yet

- CPE 310 - Method of ResearchDocument17 pagesCPE 310 - Method of ResearchRomano GabrilloNo ratings yet

- SR Eng Added Seen Passgaes With Key (Telangana)Document7 pagesSR Eng Added Seen Passgaes With Key (Telangana)medigachaithu9No ratings yet

- Chapter - 5. Factorization of Algebraic ExpressionsDocument36 pagesChapter - 5. Factorization of Algebraic ExpressionsAnkit LadhaNo ratings yet

- ConstractivismDocument30 pagesConstractivismRaiyan SyedNo ratings yet

- Scriptures For Studying and ExamsDocument3 pagesScriptures For Studying and Examsvimon100% (1)

- Skills For Food Handlers - FinalDocument1 pageSkills For Food Handlers - FinalMMNo ratings yet

- Fundraising and Grant ApplicationsDocument10 pagesFundraising and Grant ApplicationsNelu StoicaNo ratings yet

- InvoiceDocument1 pageInvoiceHighlight Guruji YTNo ratings yet

- POLANYI, M. The Republic of Science.Document20 pagesPOLANYI, M. The Republic of Science.Suzi Da Costa TeixeiraNo ratings yet

- Comparison ASTMDocument8 pagesComparison ASTMSanti CheewabantherngNo ratings yet

- q4 Week 1 Science WorksheetsDocument5 pagesq4 Week 1 Science WorksheetsstephanienicolemanibogNo ratings yet

- 'Take Lessons From Traditional Techniques': COST CONSCIOUS: Architect, Benny KuriakoseDocument3 pages'Take Lessons From Traditional Techniques': COST CONSCIOUS: Architect, Benny KuriakoseTushar SharmaNo ratings yet

- Utica NY Daily Press 1966 - 7474Document1 pageUtica NY Daily Press 1966 - 747411kvnptrckNo ratings yet

- Levi's & Calvin KleinDocument19 pagesLevi's & Calvin Kleinzayana kadeejaNo ratings yet