Electron Beam Welding

Electron Beam Welding

Uploaded by

Sahil DhimanCopyright:

Available Formats

Electron Beam Welding

Electron Beam Welding

Uploaded by

Sahil DhimanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Electron Beam Welding

Electron Beam Welding

Uploaded by

Sahil DhimanCopyright:

Available Formats

ELECTRON BEAM WELDING

Sahil Dhiman

Saturday, November 4, 2023 Presenter: Sahil Dhiman 1

CONTENTS

Chapter Topics Slide Number

Electron Beam Welding

1.1 Need of EBW 3

1.2 Working Principle 4-8

1.3 Setup and Equipments 9-10

1

1.4 Process Parameters 11-12

1.5 Microstructural Analysis 13-15

1.6 Advantages, Disadvantages, and Applications 16-17

1.7 Acknowledgement 18

Saturday, November 4, 2023 Presenter: Sahil Dhiman 2

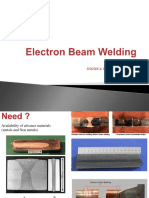

NEED?

• Dr. Karl Heinz (German) – Development of first practical welding machine in 1958.

Figure 1. Comparison of single pass

EB weld profile with multi pass

submerged arc welded joint in 100mm Figure 2. Penetration depth

thickness C-Mn steel. (Image courtesy of EB weld. (Image courtesy

by: https://www.twi-global.com) by https://www.ptreb.com)

Figure 3. Comparison of EBW

over conventional welding.

(Image courtesy by PHM

Industries GmbH)

Figure 4. Comparison of EBW over TIG. (Image

courtesy by https://www.ebpglobal.com)

Saturday, November 4, 2023 Presenter: Sahil Dhiman 3

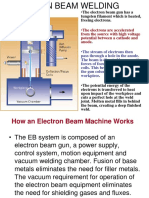

WORKING PRINCIPLE

• Electron beams are composed of electrons that are charged particles having a rest

mass of 9.1x10-31 kg and can be accelerated in electron guns to relativistic velocities,

giving them high kinetic energies.

• At 10 kV (13 hp), electrons travel at approximately 20% of the speed of light, while at

200 kV (270 hp) they travel at approximately 70% the speed of light.

• The higher the potential difference between cathode and anode, the higher would be

the acceleration of the electrons. The electrons get the speed in the range of 50,000 to

200,000 km/s.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 4

WORKING PRINCIPLE

Use kinetic energy of electrons to produce heat.

(a)

High energy electrons

impinged on the surface

generate localized heat

spots

(b)

Figure 6. Electron Beam Welding (Image

This heat is further used to courtesy of: http://www.twitraining.com)

weld two welding plates

Figure 5. (a):The Cathode Ray Oscilloscope (Image courtesy

of: http://www.schoolphysics.co.uk); (b) Electron Gun Cross

Section (Image courtesy of: https://commons.wikimedia.org)

Saturday, November 4, 2023 Presenter: Sahil Dhiman 5

WORKING PRINCIPLE

• ELECTRON GUN

Figure 8. Electron Gun schematic (Image courtesy of:

https://physics.stackexchange.com)

Figure 7. A LaB6 filament.

(Image courtesy by:

http://www.snaggledworks.com)

Notes: LaB6: lanthanum hexaboride

Saturday, November 4, 2023 Presenter: Sahil Dhiman 6

SETUP AND EQUIPMENTS

Electron beam welding is a liquid state welding process. Liquid state welding are those

welding processes in which, the metal to metal joint form in liquid or molten state [1].

Figure 9. EBW Process (Image courtesy of: Figure 10. Molten Pool during EBW [1]

https://www.mech4study.com)

[1] M. Chiumenti, M. Cervera, N. Dialami, B. Wu, L. Jinwei, and C. Agelet de Saracibar, “Numerical modeling of the electron beam welding and its experimental validation,” Finite Elem. Anal. Des., vol. 121, pp. 118–133, 2016.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 7

SETUP AND EQUIPMENTS

POWER SUPPLY

• To supply continuous beam of electrons for welding process.

• The voltage range of welding is about 5 – 30 kV for low voltage equipment’s or for thin welding and 70 – 150 kV for high voltage equipment’s or for thick

welding.

ELECTRON GUN

• It is a cathode tube (negative pole) which generates electrons, accelerate them and focus it on a spot.

• This gun is mostly made by tungsten or tantalum alloys. The cathode filament heated up to 2500 degree centigrade for continuous emission of electrons.

ANODE

• Anode is a positive pole which is just after the electron gun.

• Its main function is to attract negative charge, (in this case electron) provide them a path and don’t allow them to diverge from its path.

MAGNETIC LENSES

• There are a series of magnetic lenses which allows only convergent electrons to pass.

• They absorb all low energy and divergent electrons, and provide a high intense electron beam.

ELECTROMAGNETIC LENS AND DEFLECTION COIL

• Electromagnetic lens used to focus the electron beam on work piece and deflection coil deflect the beam at required weld area.

• These are last unit of EBW process.

WORK HOLDING DEVICE

• EBW uses CNC table for hold work piece which can move in all three direction.

• The welding plates are clamped on CNC table with the use of suitable fixtures.

VACUUM CHAMBER

• whole this process takes place in a vacuum chamber. Vacuum is created by mechanical or electric driven pump.

• The pressure ranges in vacuum chamber is about 0.1 to 10 Pa.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 8

PROCESS PARAMETERS

PROCESS

PARAMETERS

Accelerating

Beam Current Welding Speed Beam Focusing

Voltage

Saturday, November 4, 2023 Presenter: Sahil Dhiman 9

PROCESS PARAMETERS - VOLTAGE

•A value of electrical potential, usually expressed in kilovolts, being utilized to accelerate

and increase the energy of the electrons being emitted by an electron beam gun.

•Increase in the voltage results into increase in the speed of electrons.

Figure 11. Relationship between electron speed with acceleration voltage. (Image

courtesy by: https://www.didaktik.physik.uni-muenchen.de)

Saturday, November 4, 2023 Presenter: Sahil Dhiman 10

PROCESS PARAMETERS – BEAM CURRENT

• Close relation between electron beam current and depth of penetration.

• Beam current: measure of the quantity of charge (i.e., number of electrons), usually

expressed in units of milli amperes (mA), that flow per unit time in an electron beam.

Figure 12. Variation in DOP with Beam Current [2] Figure 13. Variation in Hardness at Weld and HAZ with

Increase in Beam Current [2]

[2] A. K., “Effect of Beam Current, Weld Speed and Dissolution on Mechnical and Microstructural Properties in Electron Beam Welding,” Int. J. Res. Eng. Technol., vol. 02, no. 06, pp. 1020–1029, 2013.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 11

PROCESS PARAMETERS - SPEED

• Welding speed directly affects on depth of penetration of electron beam into work piece

• Higher speeds results into lower depth of penetration

Figure 14. Variation in DOP with Welding Speed [2] Figure 15. Variation in Hardness at Weld and HAZ with

Increase in Welding Speed [2]

[2] A. K., “Effect of Beam Current, Weld Speed and Dissolution on Mechnical and Microstructural Properties in Electron Beam Welding,” Int. J. Res. Eng. Technol., vol. 02, no. 06, pp. 1020–1029, 2013.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 12

PROCESS PARAMETERS - SPEED

(a)

Figure 16. (a) Optical microstructure of different regions of dissimilar joint at lower welding speed (1000mm/min) condition [3].

(b)

Figure 17. (b) Optical microstructure of different regions of dissimilar joint at higher welding speed (1500mm/min) condition [3].

[3] S. K. Dinda, M. Basiruddin Sk, G. G. Roy, and P. Srirangam, “Microstructure and mechanical properties of electron beam welded dissimilar steel to Fe–Al alloy joints,” Mater. Sci. Eng. A, vol. 677, pp. 182–192, 2016.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 13

MICROSTRUCTURAL ANALYSIS

• Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC®

718PLUSTM superalloy

Figure 18. Optical microstructure of the as-received 718 Plus alloy. [4]

[4] K. R. Vishwakarma, N. L. Richards, and M. C. Chaturvedi, “Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC ® 718PLUS TM superalloy,” Mater. Sci. Eng. A, vol. 480, no. 1–2,

pp. 517–528, 2008.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 14

MICROSTRUCTURAL ANALYSIS

• Fusion zone microstructures Fusion zone consisting of cellular dendritic microstructure with an average

secondary dendrite arm spacing of 4m.

(a)

(b)

Figure 19. (a) Typical nail head type of weld profile of 718 Plus welds with porosity at the bottom; (b)

heat affected zone cracking as observed in the shoulder region of the nail head-shaped weld profile of

718 Plus alloy; no cracking was observed in the fusion zone [4].

[4] K. R. Vishwakarma, N. L. Richards, and M. C. Chaturvedi, “Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC ® 718PLUS TM superalloy,” Mater. Sci. Eng. A, vol. 480, no. 1–2,

pp. 517–528, 2008.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 15

MICROSTRUCTURAL ANALYSIS

• HAZ microstructures

Figure 20. SEM micrograph of HAZ showing

partially melted zone and liquation cracking

[4].

[4] K. R. Vishwakarma, N. L. Richards, and M. C. Chaturvedi, “Microstructural analysis of fusion and heat affected zones in electron beam welded ALLVAC ® 718PLUS TM superalloy,” Mater. Sci. Eng. A, vol. 480, no. 1–2,

pp. 517–528, 2008.

Saturday, November 4, 2023 Presenter: Sahil Dhiman 16

ADVANTAGES & DISADVANTAGES

• It can weld both similar and dissimilar metals.

• It provides high metal joining rate.

• Low operating cost because no filler material and flux are used.

ADVANTAGES • It provide high finish welding surface.

• It can used to weld hard materials.

• Less welding defects occur due to whole process carried out in vacuum.

• High capital or set up cost.

• High skilled labour required.

• Frequently maintenance required.

DISADVANTAGES • Work pieces size is limited according to vacuum chamber.

• It cannot do at site due to vacuum.

0.097mm

• 60 kV 4 kW (610 mm3) electron beam welder including CNC controlled work

manipulation systems £220,000.00 i.e. 17609882.40 INR (1 £ = 80.02 INR)

Saturday, November 4, 2023 Presenter: Sahil Dhiman 17

APPLICATIONS

APPLICATIONS:

• It is used in aerospace industries and marine industries for structure work

1

• It is used to join titanium and its alloy.

2

• This type of welding is widely used to join gears, transmission system, turbocharger etc. in automobile

3 industries.

• It is used to weld electronic connectors in electronic industries.

4

0.097mm

• This process is also used in nuclear reactors and in medical industries

5

Saturday, November 4, 2023 Presenter: Sahil Dhiman 18

THANK YOU

0.097mm

Saturday, November 4, 2023 Presenter: Sahil Dhiman 19

You might also like

- Schaum's Outline of Electromagnetics, Fifth EditionFrom EverandSchaum's Outline of Electromagnetics, Fifth EditionRating: 4.5 out of 5 stars4.5/5 (2)

- Thin Film Phenomena: Kasturi L. ChopraDocument11 pagesThin Film Phenomena: Kasturi L. ChopraSubham AdhikariNo ratings yet

- Inspection and Test Plan For Power TransformerDocument10 pagesInspection and Test Plan For Power TransformerpaolocparreraNo ratings yet

- Crate Pa4-Complete SMDocument2 pagesCrate Pa4-Complete SMrobert starNo ratings yet

- Modeling Control ExampleDocument252 pagesModeling Control Examplebudi_umm100% (1)

- Electron Beam Welding: Submitted byDocument13 pagesElectron Beam Welding: Submitted byTanmay WalkeNo ratings yet

- Electron Beam Welding: Author's: A. Leonard Pawan, A. Antony Ajay, K. Manjunath, S .Yuvaraj PandiDocument11 pagesElectron Beam Welding: Author's: A. Leonard Pawan, A. Antony Ajay, K. Manjunath, S .Yuvaraj PandiLeonard PawanNo ratings yet

- UNIT_5 Lecture NotesDocument19 pagesUNIT_5 Lecture NotesKothakota harishNo ratings yet

- Electron Beam Welding: Definition, Construction, Working, Applications, Advantages, and Disadvantages (Notes With PDF)Document5 pagesElectron Beam Welding: Definition, Construction, Working, Applications, Advantages, and Disadvantages (Notes With PDF)Tangina TamannaNo ratings yet

- Proc.-6 Advanced Welding ProcessesDocument28 pagesProc.-6 Advanced Welding ProcessesRaghu vamshiNo ratings yet

- Proc.-06 Advanced Welding ProcessesDocument28 pagesProc.-06 Advanced Welding ProcessesK JeevanNo ratings yet

- 3.electron Beam WeldingDocument12 pages3.electron Beam WeldingAnil KumarNo ratings yet

- Advance Welding 11Document6 pagesAdvance Welding 11Isaac BaidooNo ratings yet

- Advanced Manufacturing Process CH-4Document47 pagesAdvanced Manufacturing Process CH-4Seare TekesteNo ratings yet

- Cách Kiểm Tra Lớp Xi MạDocument3 pagesCách Kiểm Tra Lớp Xi Mạzenotv2No ratings yet

- Tungsten Filament Which Is Heated, Freeing Electrons.: - The Electron Beam Gun Has ADocument13 pagesTungsten Filament Which Is Heated, Freeing Electrons.: - The Electron Beam Gun Has APrashant PuriNo ratings yet

- Laporan Praktikum Proses Manufaktur 2 Kelompok S25 Modul PM2-01 Shift Sabtu Siang PDFDocument30 pagesLaporan Praktikum Proses Manufaktur 2 Kelompok S25 Modul PM2-01 Shift Sabtu Siang PDFGilang Tito F.No ratings yet

- 8B-Electron Beam Machining (EBM) Welding (EBW)Document19 pages8B-Electron Beam Machining (EBM) Welding (EBW)HARSHVARDHAN SINGH RATHORE0% (1)

- NTM Mod5Document47 pagesNTM Mod5Vishnu K CNo ratings yet

- CHAPTER 7 - WeldingDocument34 pagesCHAPTER 7 - WeldingMuhamad Haikal OthmanNo ratings yet

- EBWDocument21 pagesEBWbathinsreenivasNo ratings yet

- Electron Beam WeldingDocument25 pagesElectron Beam Weldingகார்த்திகேயன் ராஜன்No ratings yet

- UNIT_4 Lecture NotesDocument16 pagesUNIT_4 Lecture NotesKothakota harishNo ratings yet

- BTM4723 Adv Welding Process Fusion WeldingDocument26 pagesBTM4723 Adv Welding Process Fusion WeldingMas Ayu HassanNo ratings yet

- 40 Non Conventional MachiningDocument20 pages40 Non Conventional MachiningPRASAD326100% (6)

- Advanced Welding Processes PDFDocument9 pagesAdvanced Welding Processes PDFlovaldes62100% (1)

- Band1 Fundamentals NeuDocument102 pagesBand1 Fundamentals Neus_m_taheri100% (1)

- Advanced Welding ProcessesDocument8 pagesAdvanced Welding ProcessesbabbiNo ratings yet

- Ebm and LBMDocument20 pagesEbm and LBMVaibhav KakkarNo ratings yet

- Electromagnetic Forming - Hani Aziz AmeenDocument46 pagesElectromagnetic Forming - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Las Busur KD 4 (32) InggDocument32 pagesLas Busur KD 4 (32) Inggdwisuko12No ratings yet

- Working Principle: Laser Beam WeldingDocument14 pagesWorking Principle: Laser Beam WeldingAkash KumarNo ratings yet

- Electron Microscopes Used For CharacterizationDocument63 pagesElectron Microscopes Used For CharacterizationAishik Roy ChaudhuryNo ratings yet

- Lab Report WeldingDocument15 pagesLab Report WeldingAhmad ZafranNo ratings yet

- ElectronbeamweldingDocument45 pagesElectronbeamweldingzerogravityNo ratings yet

- Electron Beam MachiningDocument14 pagesElectron Beam MachiningDoopukuntla SmithaNo ratings yet

- Ebw LBWDocument58 pagesEbw LBWAnish AmanNo ratings yet

- Lessons 123Document14 pagesLessons 123PULLONA IAN JOSEPH T.No ratings yet

- Finite-Element Simulation of Electron Beam Machining (EBM) ProcessDocument6 pagesFinite-Element Simulation of Electron Beam Machining (EBM) ProcessBabbu MehraNo ratings yet

- Unesco - Eolss Sample Chapters: High Energy Density Welding ProcessesDocument9 pagesUnesco - Eolss Sample Chapters: High Energy Density Welding ProcessesRuham Pablo ReisNo ratings yet

- Utilization of Electrical Power: Electric WeldingDocument21 pagesUtilization of Electrical Power: Electric WeldingHafsa AlhaddabiNo ratings yet

- Utilization of Electrical Power: Electric WeldingDocument21 pagesUtilization of Electrical Power: Electric WeldingHafsa AlhaddabiNo ratings yet

- Ultrasonic Welding Forge WeldingDocument6 pagesUltrasonic Welding Forge WeldingPradneshNo ratings yet

- Electroslag WeldingDocument10 pagesElectroslag WeldingNazmul Ahsan100% (1)

- Advanced WeldingDocument42 pagesAdvanced WeldingMebrahtom LuelNo ratings yet

- Electron Beam MachiningDocument30 pagesElectron Beam Machiningmehedi hasanNo ratings yet

- IIT Kharagpur: 1.1 Introduction To Electron Beam WeldingDocument16 pagesIIT Kharagpur: 1.1 Introduction To Electron Beam Weldingrajaraji33No ratings yet

- Elecron Beam MachiningDocument9 pagesElecron Beam Machiningpatel ketanNo ratings yet

- Chapter 1 Metal Welding 73Document36 pagesChapter 1 Metal Welding 73srinivasantakapalliNo ratings yet

- Electron Beam MachiningDocument9 pagesElectron Beam MachiningductuanvvNo ratings yet

- Unit - I: Electron Beam WeldingDocument15 pagesUnit - I: Electron Beam Weldingapi-271354682No ratings yet

- Shielded Metal Arc Welding Principles: Chapter ObjectivesDocument8 pagesShielded Metal Arc Welding Principles: Chapter ObjectivesWilly UioNo ratings yet

- Aryan 71Document9 pagesAryan 71Aryan SutarNo ratings yet

- Production Technology: Electron Beam MachiningDocument14 pagesProduction Technology: Electron Beam MachiningFuxNo ratings yet

- 1998台湾 使用不同进给电极对孔进行电抛光和电抛光 Journal of Materials Processing Technology1Document7 pages1998台湾 使用不同进给电极对孔进行电抛光和电抛光 Journal of Materials Processing Technology1bakereskathryn860No ratings yet

- Design and Fabrication 10kva Arc Welding MachineDocument13 pagesDesign and Fabrication 10kva Arc Welding MachineSunday Iweriolor100% (1)

- PB3 1Document5 pagesPB3 1womini1025No ratings yet

- NTM Assigment Topic: Electron Beam Machining: Name: Venu Kabra USN: 1RV07ME115 Branch: Mecanical Sem: 7 "C"Document19 pagesNTM Assigment Topic: Electron Beam Machining: Name: Venu Kabra USN: 1RV07ME115 Branch: Mecanical Sem: 7 "C"Venu KabraNo ratings yet

- An Essential Guide to Electronic Material Surfaces and InterfacesFrom EverandAn Essential Guide to Electronic Material Surfaces and InterfacesNo ratings yet

- Home-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsFrom EverandHome-made Toy Motors: A practical handbook giving detailed instructions for building simple but operative electric motorsNo ratings yet

- Unit-Wise Important QuestionsDocument2 pagesUnit-Wise Important QuestionsThangam MaheshNo ratings yet

- Brochure For CTPT AnalyzerDocument6 pagesBrochure For CTPT AnalyzerBogdan IlieNo ratings yet

- Series Circuits: Prepared By: Alexander T. Montero, Ree, RmeDocument45 pagesSeries Circuits: Prepared By: Alexander T. Montero, Ree, RmeMarc Jairro GajudoNo ratings yet

- Calibration PH MeterDocument17 pagesCalibration PH MeterjeysonmacaraigNo ratings yet

- Ac Axial Fan FP-108-1: FP-108-1 Weight: Bearing System: Impeller: HousingDocument1 pageAc Axial Fan FP-108-1: FP-108-1 Weight: Bearing System: Impeller: HousingazitaggNo ratings yet

- Wireless World 1975 05 PDFDocument148 pagesWireless World 1975 05 PDFAleksandar AndjelkovicNo ratings yet

- RDE10.1 Datasheet enDocument8 pagesRDE10.1 Datasheet enReparatii CncNo ratings yet

- Diagnostics of WeldedDocument9 pagesDiagnostics of WeldedsmeykelNo ratings yet

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDocument4 pagesSilicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDjalma MotaNo ratings yet

- 02-Grounding Systems ENDocument10 pages02-Grounding Systems ENShahzad NazirNo ratings yet

- BR6 Serisi ManuelDocument2 pagesBR6 Serisi ManuelTodi FindraNo ratings yet

- DC Machines Lab Manual PDFDocument54 pagesDC Machines Lab Manual PDFMuralichintakailuNo ratings yet

- Scelleuse de Tube - Sang - Manual - Cr4aa - Cr6aa - Cr6psaa - Eng - 04Document36 pagesScelleuse de Tube - Sang - Manual - Cr4aa - Cr6aa - Cr6psaa - Eng - 04Med KerroumNo ratings yet

- Contents:-1. Transformer 2. Working Principle of Transformer 3. Parts of TransformerDocument31 pagesContents:-1. Transformer 2. Working Principle of Transformer 3. Parts of TransformerNabhaite GurpreetNo ratings yet

- Avani Rev 1.10 2016-2017Document4 pagesAvani Rev 1.10 2016-2017Mayank SharmaNo ratings yet

- Controller Unit and Expansion Module: Installation GuideDocument4 pagesController Unit and Expansion Module: Installation Guideashraf haniaNo ratings yet

- RV4 65B R5 V2 Product SpecificationDocument5 pagesRV4 65B R5 V2 Product SpecificationMario Alvarez GarciaNo ratings yet

- Basic Concepts in Rotating MachinesDocument8 pagesBasic Concepts in Rotating MachinesNeerajNo ratings yet

- Modeling, Simulation and Performance Analysis of Solar PVDocument14 pagesModeling, Simulation and Performance Analysis of Solar PVRicardo AguilarNo ratings yet

- Electrodynamics Revisited (New) ABCD (2019)Document72 pagesElectrodynamics Revisited (New) ABCD (2019)Meena NadeemNo ratings yet

- ATV312HU55N4Document3 pagesATV312HU55N4BianNo ratings yet

- ETE-3 Service ManualDocument19 pagesETE-3 Service Manualalex3712No ratings yet

- IEEE Standard DICTIONARY of Electrical and Electronic TermsDocument9 pagesIEEE Standard DICTIONARY of Electrical and Electronic TermsChamparret SosaNo ratings yet

- Mod5 - MECHATRONICS IN ROBOTICSDocument34 pagesMod5 - MECHATRONICS IN ROBOTICSDeepa Ragav RNo ratings yet

- Acdc - DC Motor - Lecture Notes 5Document30 pagesAcdc - DC Motor - Lecture Notes 5Cllyan Reyes100% (2)

- Data Sheet 6ES7326-2BF40-0AB0: Supply VoltageDocument3 pagesData Sheet 6ES7326-2BF40-0AB0: Supply VoltageAlexandre De Alencar FerreiraNo ratings yet