Iema ruk aug 2014 v2

- 1. SRM and Remanufacturing IEMA - Waste to Resources August 2014 Andy Whyle Ricoh UK Products Ltd

- 2. Content Ricoh’s Sustainability Strategy Zero waste & Remanufacturing

- 3. Ricoh Global Manufacturing ■ Shanghai Ricoh Digital Equipment Co., Ltd. ■ Ricoh UK Products Ltd. (RPL) ■ Ricoh Industrie France S.A.S. ■ Ricoh Asia Industry (Shenzhen), Ltd. ■ Ricoh Manufacturing (Thailand), Ltd. ■ Ricoh Electronics, Inc California & Georgia U.S.A UK France China Thailand ■ Ricoh Components & Products (Shenzhen) Co., Ltd. ■Ricoh Japan 14 Production Sites.

- 4. Ricoh Environmental Leadership • “As the global environment is in critical condition, business communities are expected to take a leadership role in building a new social paradigm.” (S. Kondo 2008) • “We will continue working together with stakeholders throughout the world, including our customers, suppliers, shareholders and investors, NGOs and NPOs, and the public, to realize a sustainable society.” (S. Kondo 2010) • “ ….. customer expectations of RICOH will evolve into long lasting trust. They will realize that the RICOH Group truly lives up to its "Harmonize with the environment" value. In this way, the RICOH brand will grow in society. “ (M Sakurai 2011) “What makes Ricoh great is not only our superior technology, but it is also our culture of innovation”. Zenji Miura (CEO, Ricoh Company Ltd) The RICOH Way Production System

- 5. Established in 1984 Based in Telford, Shropshire 800 employees £390 million sales Supplying European market place Ricoh Telford - RPL

- 6. Product Range Colour toner Site Entrance RPL 3 RPL 2 RPL 1 + Moulding Cartridge Recycling Remanufactured Copiers Production Printers B&W Toner Production

- 7. Building a Sustainable Society - Balance 1:Reducing the impact of our environmental activities • Energy Saving / Global Warming Prevention • Resource Conservation / Recycling • Pollution Prevention 2: Preserve the eco-system (Biodiversity) • Increase the earth’s regenerative capacity • Maintain and enhance the eco-systems Ricoh Group's global environmental conservation: Keeping environmental impact within the self-recovery capabilities of the Earth 1 2

- 8. Sustainable Environmental Management * Ref - www.ricoh.com/environment/management/picture.html * Ref - www.ricoh.com/environment/management/vision.html Resource Conservation create a resource recirculating society Energy Conservation combat issues associated with climate change Pollution Prevention environmentally safer manufacturing Environmental management system, Environmental information system, Environmental accounting, Environmental education, Produc lifecycle assessment, Communications etc. Biodiversity Conservation improve the Earth’s self-recovery capabilities

- 9. 100% 80% 60% 40% 20% 0% Ricoh’s long-term goals for environmental impact reduction ECO-CENTRIC Encouraging all employees to participate in environmental activities 1/8 TECHNO-CENTRIC Technical innovation effect 2013 Goal 2010 Goal 20% reduction 25% reduction 2030 Goal 30% Reduction 2050 Goal 87.5% Reduction 2000 2010 2013 2020 2030 2040 2050

- 10. Sustainability credentials ISO 9001:2008 Cert no: FS 33325 ISO 14001:2004 BS OHSAS 18001:2007 Cert no: EMS 61761 Cert no: OHS 556746 ISO 27001:2005 Cert no: IS 85241

- 11. Benchmarking Ricoh recognised as one of Top Global sustainable corporations. Ricoh Telford • Energy Efficiency Accreditation Scheme (Top 5 UK) 2004 • BQF UK Gold Medal for Sustained Excellence 2009 • Environment Agency: Best private sector Finalist 2010 • Business Commitment to the Environment Premier Award 2011 • Benchmarking - being confident in sharing validated environmental best practice

- 12. Strategic Summary Concept: Long term strategic approach with staged targets Approach: Eco-centric culture change with Techno-centric development, staged targets (Mid Term Plans) working towards 2050, Result: Not optional activity - Sustainability embedded into management culture with performance targets (organisational and individual).

- 13. Resource Conservation Zero Waste & Remanufacturing Reducing Operational Impact Ricoh Group's global environmental conservation: Keeping environmental impact within the self-recovery capabilities of the Earth 1 2

- 14. Ricoh Group Standard: Zero Waste to Landfill All Ricoh Group Manufacturing sites since March 2002

- 15. Zero Waste Launch 2000: Challenges and Problems Adaptation of Corporate model Management Commitment Cultural issues Employee involvement Resources Developing working methods Maintenance and compliance

- 16. Zero Waste Project Steering Group Segregation Group Commercial Parts Engineering 01/12/2014 16

- 17. Zero Waste Launch Project launch included all employees Presentations were given by senior managers/Director to demonstrate support for project Team working activities followed presentations in respective work areas 3R’s: Reduce-Reuse-Recycle

- 18. Manufacturing Environments Segregation in, or adjacent to work areas

- 19. RPL Office Environment No personal bins Central segregation areas

- 20. Ricoh Telford waste streams

- 21. Zero Waste 2001: Waste-2-Product Waste-2-Product Wood pallets Plastic pallets Steel Ferrous metals Aluminium Paper Cardboard Plastics Glass Electronic equipment General Waste Haz waste …. then prepared for the contractor (customer) Recycling Centre

- 22. Reuse: Packaging Re-use • Martini Product Corner post packaging re-use • Returnable post extension designed, enabling waste posts to be used on finished products • Waste reduced by 83 tonnes per year • Reduction of waste for end user • Horizontal deployment opportunities • Returnable packaging opportunity

- 23. Zero Waste to Landfill: 2001 Approach: Recognising “waste” as a resource (Waste-2-Product) Management commitment, targets Ownership through people involvement and use of knowledge “Segregate at Source” approach included in employees induction Compliance with environmental legislation, Result: waste recognised as a resource for sale and cost saving, whilst reducing environmental impacts.

- 24. Zero Waste : Cyclical Business model Improve waste segregation to create new “Product” Supply product Reduce cost – Receive revenue Market saturation Drives innovation & process change (resource required) Decrease in operational Recycling Contractor rejects low quality product performance Zero Waste is an ongoing continuous development

- 25. Resource Security - “Peakonomics” Heed the warnings ……. Chris Martenson (Crash Course) Jae Mather (Carbon Free Group)

- 26. Copper Ore Vein: 0.2% • Earth movers capacity = 255 tonnes • 0.2% = 0.5 tonnes of copper per load

- 27. IEMA – From Waste to Resources Resources are the life blood of manufacturing. Without a clear view of supply risks and an active and ambitious strategy to manage those risks, businesses will be increasingly vulnerable to price volatility, supply chain disruption and business continuity risks. Susanne Baker, AIEMA, EEF and Chair of Materials Security Working Group Read more about Susanne’s work at www.iema.net/rm111 01/12/2014 27

- 28. The Circular Economy COLLECTION Extradition of biochemical feedstock2 Anaerobic digestion /composting Restoration Biogas Biological nutrients Mining/materials manufacturing Technical nutrients Farming collection1 Biochemical feedstock COLLECTION 1. Hunting and fishing 2. Can take both post harvest & post consumer waste as an input Source: Ellen MacArthur Foundation economy team

- 29. IEMA – From Waste to Resources report 01/12/2014 29

- 30. Ricoh Comet Circle 01/12/2014 30

- 31. 100% 80% 60% 40% 20% 0% Ricoh’s 2050 Plan Impact reduction Virgin Fossil and Mineral materials Reuse of products and parts 2000 2050 50% of incoming materials from Recycled or Reused

- 32. Input Output Land use (factory construction/ landscaping). Collection / Recycling Crude Oil (fuel) Natural Gas Coal Zinc Ore Nickel Ore Coppe r Ore Molybdenu m Platinu m Chromium Ore Manganese Ore Silver Ore Bauxite Lead Ore Tin Ore Crude Oil (raw Material) Silver Ore Gold Ore Water Timber Titanium C O (carbon Monoxide) NOx (Nitrogen Oxide) SOx (Sulphur Oxide) CO2 (Carbon Dioxide) N20 (Nitrous Oxide) CxHy (hydro Carbons) CH4 (Methane) Dust NMVOC (Non-methane Hydrocarbons) Slag Unspecifie d Solid Waste Sludge BOD (Biological Oxygen Demand) COD (Chemical Oxygen Demand) SS (suspende d Solids) Logistics/ Marketing Procurement of raw materials Use/ Maintenance Design/ Manufacturing Continuous INPUT of resources to create products and OUTPUT of chemical substances, a linear relationship between these two are to be the basis of increasing the negative environmental impact on the Earth. In the future, if natural resources are to be depleted the we won’t be able to continue our normal business activities. We wonder if there is a way to avoid running out of resources as opposed to such linear activities. Extracted Resources for the business activities such as •Energy resource •Mineral resource •Renewable Resources Substances that discharge in the process of business activities. Resource Security

- 33. Manufacturing Today The sustainable ideal is a balanced 3Ps approach Most of today’s product tends towards 1st life/ single use (profit centric) Sustainable design is increasing, but not yet the mainstream (Manufacture assembly, disassembly and end of life - MADE BS8887 part2) Ricoh reacts to the market conflict of “1st Life vs. Sustainable Customer Demand” through Developing robust reverse logistics Life cycle (Comet Circle) drive towards retention of assets Ricoh’s role is to learn, and move towards resource conservation. Planet People Profit Profit

- 34. Eco-Line products UK Remanufactured Products

- 35. TELFORD FACTORY Ricoh Remanufcturing Green centre Firmware upgrades PRODUCTION LINE Technical modifications COMPONENTS

- 36. Eco Line - Remanufacturing Process Remanufactured machines (BS-MADE 8887-2) Striped to chassis All mortality parts replaced /All panels sprayed All firmware / software modifications fitted Completely Re-branded and sold as new line Quality Control: inspected and assured the same as new products Extending the life cycle, reducing environmental impact

- 37. Life Cycle Analysis Raw material Manufacture Customer usage Recycle & disposal Remanufacturing = 38% Environmental impact reduction

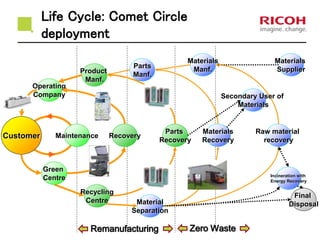

- 38. Life Cycle: Comet Circle deployment Operating Company Customer Product Manf. Parts Manf. Materials Manf. Materials Supplier Maintenance Parts Recovery Materials Recovery Material Separation Raw material recovery Incineration with Energy Recovery Final Disposal Recovery Secondary User of Materials Recycling Centre Green Centre Remanufacturing Zero Waste

- 39. SRM Summary Strategy: to develop our business to maintain materials for productivity Long term approach (2050 Plan) Zero Waste underpins Sustainable Resource Management Increasing Supply Chain awareness of Reverse Logistics Life Cycle - Comet Circle deployment Diversification of operation (remanufacturing) Result: Manufacturers and Customers now beginning to grasp Resource Conservation as a strategic issue. Reduced environmental impact of operation, extended life cycle of materials, resulting in an increased ability to maintain future business continuity (Sustainability).

- 40. The Ricoh Way – Responsible Business Growth RPL’s expertise is used to assist Ricoh Sales and to show customers The Ricoh Way RPL Telford Electricity (MWh) 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 RPL Energy Emissions (CO2) Ricoh Telford’s Energy Reduction exceeds Ricoh’s CO2 targets and also saves £0.5 Million per year. Waste-2-Product The Waste -2-Product program increases the life cycle of materials whilst increasing profitability Remanufacturing Eco Line and Supplies Recycling increase the sustainability of raw materials and our manufacturing process The RICOH Way Production System MWh 19,000 17,000 15,000 13,000 11,000 9,000 7,000 5,000 450 400 350 300 250 200 150 100 50 Waste and CO2 generation is now decoupled from growth (turnover increased by 325% since 2003) in line with Zero Impact Growth philosophy Electricity MWh Corporate Biodiversity actively repairs damage and engages employees and stakeholders. RPL Telford Turnover (£M) 0 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 £ M Turnover (£M) Impact vs £ Turnover

- 41. Greater understanding of your business Knowledge Share Continuous Innovation & Improvements Site Visits Best Practice Technology Assessment Strategy Development Tailored Training Ricoh: sustainable business services Ben Curtis Account Manager Key Commercial ben.curtis@ricoh.co.uk www.ricoh.co.uk