Retrofitting

- 1. RETROFITTINGBy Roshni K G Assistant professor Thejus engineering college vellarakkad Thrissur, Kerala

- 2. What is a retrofitting? • Retrofitting is the seismic strengthening of existing damaged or undamaged structures. • It is an improvement over the original strength when the evaluation of the building indicates that the strength available before the damage walls insufficient and restoration alone will not be adequate in future quakes.

- 3. Why retrofitting is required ? • Damage to structural members. • Excessive loading. • Errors in design or construction. • Modification of structural system. • Seismic damage. • Structural cracks. • Corrosion due to penetration- honey combs.

- 4. Objectives of retrofitting • Increasing the lateral strength in one or both directions, by reinforcement or by increasing wall areas or the number of walls and columns. • Giving unity to the structure by providing a proper connection between its resisting elements.

- 5. CLASSIFICATION OF RETROFIT TECHNIQUES :To provide increased lateral stiffness and strength to the building as a whole. And, to ensure that a total collapse of the building does not occur. : To avoid failure of the components, and also thereby enhance the overall performance of the structure • More than one combination of local and global retrofit strategies is possible.

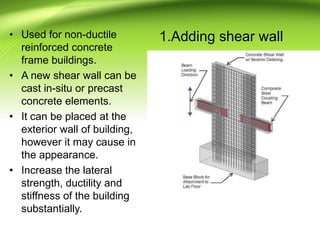

- 7. 1.Adding shear wall• Used for non-ductile reinforced concrete frame buildings. • A new shear wall can be cast in-situ or precast concrete elements. • It can be placed at the exterior wall of building, however it may cause in the appearance. • Increase the lateral strength, ductility and stiffness of the building substantially.

- 8. 2.Adding infill wall • This is the brick masonry infill wall. • Installed tight to surrounding concrete elements. • The lateral stiffness of a storey increases with infill wall. • Due to ‘strut action’ of the infill walls, the flexural and shear forces and ductility demand on the ground storey columns are substantially reduced. • Do not increase the ductility of structure.

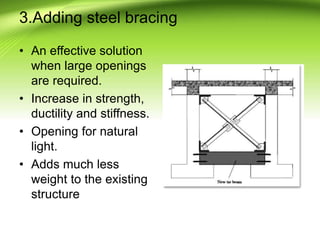

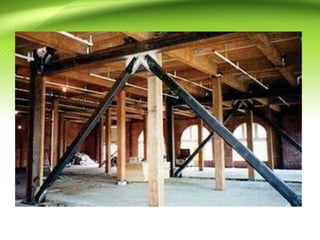

- 10. 3.Adding steel bracing • An effective solution when large openings are required. • Increase in strength, ductility and stiffness. • Opening for natural light. • Adds much less weight to the existing structure

- 12. 4.Wall thickening techniques • Increase the thickness by adding bricks, concrete and steel reinforcement. • It can bear more vertical and horizontal loads. • Does not cause sudden failure of the wall. Wall thickening by reinforce Concrete

- 13. 5.Adding wing wall or buttress • To increase lateral strength, ductility and stiffness of structure. • The wing wall are placed on the exterior side of an existing frame.

- 14. 6.Mass reduction• In this process removing one or more storey of building as shown in figure. • Decrease the load at foundation. • Increase the life and strength.

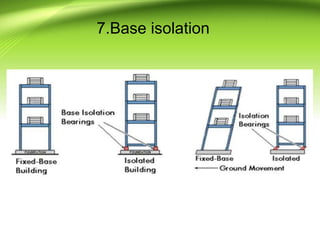

- 15. 7.Base isolation • Isolation of superstructure from the foundation is known as base isolation. • It is the most powerful tool for passive structural vibration control techniques. • Isolates building from ground motion lesser seismic loads, hence lesser damage to the structure, minimal repair of superstructure. • Building can remain serviceable throughout construction. • Does not involve major intrusion upon existing superstructure.

- 16. 7.Base isolation

- 17. 8.Jacketing of structural elements • This is the most popular method for strengthening of concrete building elements like as 1.Beams 2.Columns 3.Beam column Junctions • Due to jacketing, enhancing the shear strength, concrete confinement, flexural strength • Materials to be used –Steel plates –Fiber reinforce polymer (FRP wrap)

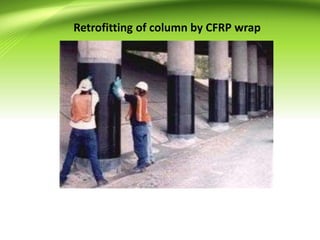

- 18. (i).Carbon fiber reinforce polymer (CFRP) (ii).Glass fiber reinforce polymer (GFRP) (iii)Steel reinforced concrete

- 19. (i).Carbon fiber reinforce polymer (CFRP) • Use of CFRP in structural strengthening – a)CFRP STRIPS – Performance of CRPF strips depend on the strength of adhesive used to bond the strips to the concrete surface. – Strong, ductile and durable structural system can be achieved. – These are four times stronger than structural steel.

- 20. b)CFRP WRAPS • Mainly used for corrosion control and retrofitting of rcc members. • resistance to collapse under earthquake loading • In a circular column an increase in axial capacity is also achieved by wrapping. • the confinement of the CFRP wrap enhances the compressive strength of the concrete and increase in load bearing strength. • Immediate strength gain and open to traffic.

- 21. Advantages • Enhanced strength. • Increased shear capacity of columns. • Technique is easy and it does not need special design criteria.

- 22. Disadvantages • Increase in member cross section- less floor area. • Increase dead weight due to extra steel and concrete. • Prone to high level of corrosion. • Requires more construction time as it involves curing. • Production of dust and debris causes pollution and health hazards. • Needs shuttering, formworks, reinforced steel, concrete, concrete pumps, vibrators, etc..,

- 23. Prone to high level of corrosion. Requires more construction time as it involves curing. Production of dust and debris causes pollution and healthhazards. Needs shuttering, formworks, reinforcedsteel, concrete, concrete pumps, vibrators, etc..,

- 24. Retrofitting at junction by steel plate

- 25. Retrofitting of column by CFRP wrap

- 26. Retrofitting by steel reinforce concrete

- 27. 9.External plate bonding • Steel plates are attached to the surface of damaged members forming a three phase steel composite system • Acts as supplement to existing reinforcement. • Attachment of steel to concrete • Adhesive connecting mechanism (glue). • Bolting connecting mechanism.

- 28. Advantages • Stress reduction due to the external steel plate. • Enhances load bearing capacity. • Decreases chances of cracks and deflection.

- 29. Disadvantages • Increase in dead load. • High installation cost due to heavy weight of steel plate. • If there is any indications of corrosion in the reinforcement this technique cannot be used. • Susceptible to high level of premature de- bonding. • Chances of corrosion is high. • Bonding between concrete and steel plate. • Reaction between epoxy adhesive and concrete.

- 30. 10.External post tensioning • High strength steel strands or pre- stressing tendons are used. • Tendons are pulled and connected to anchor points on member. • Very much suitable for retrofitting of bridges.

- 32. Advantages • Ability to restress, destress and exchange any external pre-stressing cable. • Crack free members. • Reduce deflection. • High fatigue and impact resistance. • Immediate enhancing of load bearing capacity.

- 33. Disadvantages • Usually requires a greater section depth. • Exposed to environmental influences. • Handling of the tensioning devices may be more difficult. • High cost. • Prone to corrosion. • Skilled person is needed for post tensioning

- 34. 11.Ferro cement covering • Composite material reinforced with wire mesh and cement mortar modified with chemicals or polymers with closely spaced layer. • Process involves surface preparation, orientation of wire mesh and Ferro concrete finishing.

- 36. Advantages • Enhanced resistance to cracking • Capacity to carry heavy loads. • High flexural stiffness compared to ordinary cement. • Resistance to penetration of water. • Provide resistance to fire, corrosion and earthquake.

- 37. Disadvantages • Number of labor will be higher. • Rust can be developed on reinforcement if not covered properly by mortar. • It is hard to do welding, screw, nut etc.., properly. • Binding rod and mesh along can be time consuming. • Proper curing is required. • Increases dead weight.

- 38. 12.Retrofit by grouting • Easiest process which involves placing of cementitious material in to the cracks created from excessive loading in concrete member. • Pressure grouting is generally used. • It is commonly used when honey combs are observed. • Prevents reinforcement from corroding. • Very low or no strength gained. • After grouting proper curing has to be done but often it is neglected. • Not effective as other techniques.