2004_0605TN

- 1. TRIC Training Log: 06-05-04 Client: ARS Rescue Rooter, Memphis, TN Job: Residence, under driveway Pull: 45’ / 4” / SDR17

- 2. For Sale: A grand old home in the historic district of Memphis. Sewer needs work.

- 3. The connection: Under the driveway, joining the cottage adjacent to the garage (behind trees) with the main house.

- 4. Saving the surface: The connection at the house is roughly 8’ deep; all excavation is done in the planted areas.

- 5. Garden view. Note excavator to the right.

- 6. Entry point: PVC irrigation pipe can be cut. Unused steel pipe protruding above surface at edge of hole will also be removed.

- 7. Facing.

- 8. Keep blades moving: Watch for full ribbons of trim from both faces.

- 9. Clean and check: Remove shaved material from fusing area.

- 10. Before heating: Double check mating surfaces, and remove any debris from edges with a clean cloth.

- 11. Heating the pipe: Make firm, even contact with heating iron, then use neutral pressure.

- 12. The melt: This varies according to pipe size and rating; for SDR 17 in smaller sizes (3”, 4”, 6”) look for a melt of 1/8” or slightly less.

- 13. Entry: Breaking out the old pipe. Note minimal excavation.

- 14. Entry: Cutting away unused protruding pipe in “drag path” (left).

- 15. Feeding the cable: In many cases, it is not necessary to use the duct rod to pull cable through the line. Here the pull is downhill, relatively short, and steep.

- 16. Positioning the new pipe: Making the approach as direct as possible.

- 18. Pulling end: Cribbing the wall to provide even support for the resistance plate.

- 19. Ready for tension: Keep pressure gauge visible.

- 20. Feeding the pipe: It’s important to give the bursting head a good start.

- 21. Well underway: After a good entry, pipe often needs little attention.

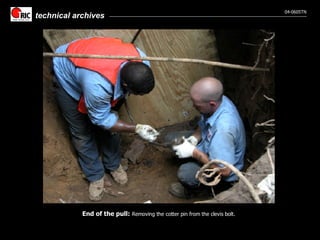

- 22. End of the pull: Removing the cotter pin from the clevis bolt.

- 23. “ Bumping”: Fuse enough pipe to have this option when the pull is done.

- 24. Photo Op: Hands-on Management!

- 25. Ready to connect: When possible, give plenty of cutoff length behind the head. (Note brass water supply line, which was easily avoided with the TRIC system.)