Steam Trapping and Steam Tracing Equipment

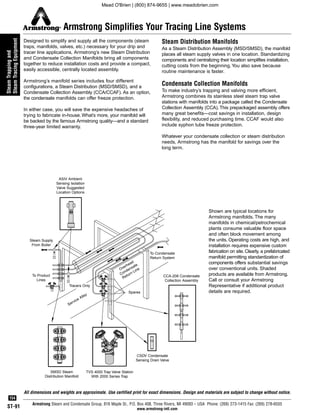

- 1. Steam Trapping and Steam Tracing Equipment 838_Traps1.qxd 11/4/03 4:07 PM Page 3 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 2. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Pay less money for energy— and more attention to the environment. It’s pretty obvious, really. An efficient steam trap wastes less energy, which means you burn less fuel and reduce emissions. The results are energy savings and a cleaner, healthier environment. By helping companies manage energy, Armstrong steam traps are also helping protect the world we all share. As a steam trap wears, it loses efficiency and begins to waste energy. But Armstrong inverted bucket traps last years longer than other traps. They operate more efficiently longer because the inverted bucket is the most reliable steam trap operating principle known. Clearly, the longer an efficient trap lasts, the more it reduces energy wasted, fuel burned and pollutants released into the air. It’s an all-around positive situation that lets the environment win, too. Bringing energy down to earth in your facility could begin with a renewed focus on your steam system, especially your steam traps. Said another way: Zeroing in your steam traps is an easy way to pay less money for energy—and more attention to the environment. Companies around the world are beginning to realize that rather than being separate challenges, energy and the environment are and have always been a single mission. And that quality management in one area will surely impact the other. ST-1 SteamTrappingand SteamTracingEquipment Steam Traps 64 838_Traps1.qxd 11/4/03 4:07 PM Page ST-1 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

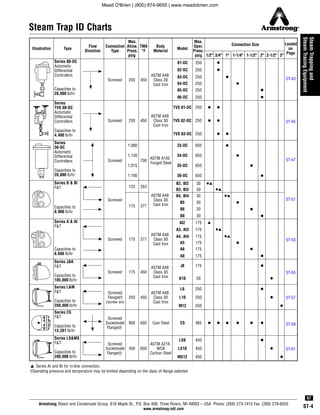

- 3. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com ST-2 Armstrong Steam Trap ID Charts SteamTrappingand SteamTracingEquipment 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 211 250 212 250 213 250 214 250 215 250 216 250 800 150 811 250 812 250 813 250 814 250 815 250 816 250 880 150 881 250 882 250 883 250 981 600 983 600 770 310 400 600 312 600 1,080 700 313 650 1,130 314 650 965 315 650 1,050 316 650 Series 411G Inverted Bucket Capacities to 1,300 lb/hr Screwed Socketweld Flanged† 1,000 700 ASTM A105 Forged Steel 411G 1,000 Series 421 Inverted Bucket Capacities to 1,300 lb/hr Screwed Socketweld Flanged† 1,000 700 Body ASTM A105 Forged Steel Cap ASTM A216 WCB 421 1,000 1,050 413 1,000 1,080 850 415 1,000 1,350 416 1,000 See tables on pages ST-21, ST-24 and ST-26 for complete temperature/pressure rating information. †Operating pressure and temperature may be limited depending on the class of flange selected. Located on Page Max. Oper. Press. psig Model ASTM A105 Forged Steel Connection Size ASTM A48 Class 30 Cast Iron ASTM A48 Class 30 Cast Iron ASTM A216 WCB Carbon Steel ASTM A48 Class 30 Cast Iron Body Material 450250Screwed Illustration TMA °F Max. Allow. Press. psig Connection Type Type Flow Direction 250 450 Series 200 Inverted Bucket Capacities to 20,000 lb/hr Series 800 Inverted Bucket Capacities to 20,000 lb/hr 450 Series 880 Inverted Bucket Capacities to 4,400 lb/hr Screwed Screwed 250 Series 300 Inverted Bucket Capacities to 20,000 lb/hr Screwed Socketweld Flanged† ASTM A182 F22 Forged Steel Series 400 Inverted Bucket Capacities to 20,000 lb/hr Screwed Socketweld Flanged† Screwed Socketweld Flanged† 600 Series 980 Inverted Bucket Capacities to 4,400 lb/hr 650 ST-11 ST-15 ST-17 ST-19 ST-21 ST-23 ST-23 ST-25 ST-13 65 838_Traps1.qxd 11/4/03 4:07 PM Page ST-2 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 4. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Steam Trap ID Charts ST-3 3/8" 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" Series 401-SH Inverted Bucket Capacities to 770 lb/hr Screwed Socketweld Flanged† 1,000 800 Carbon Steel ASTM A106 Gr. B 401-SH 1,000 Series 501-SH Inverted Bucket Capacities to 950 lb/hr Screwed Socketweld Flanged† 1,540 850 316L Stainless Steel ASTM A312 501-SH 1,540 1,730 5133G 1,500 2,070 5155G 1,800 Series 6000 Inverted Bucket Capacities to 6,500 lb/hr Socketweld Flanged† 3,090 900 ASTM A182 F22 Forged Steel 6155G 2,700 400 800 1010 150 400 800 1011 400 650 600 1022 650 450 800 1013 450 400 500 U-1010 150 400 500 U-1011 400 450 500 U-1022 450 1810 200 400 800 1811 400 650 600 1822 650 2010 200 400 800 2011 400 650 600 2022 650 21-DC 250 22-DC 250 23-DC 250 24-DC 250 25-DC 250 26-DC 250 See tables on pages ST-30 and ST-32 for complete temperature/pressure rating information. †Operating pressure and temperature may be limited depending on the class of flange selected. 304L Stainless Steel Series 20-DC Automatic Differential Controllers Capacities to 20,000 lb/hr Screwed 250 450 ASTM A48 Class 30 Cast Iron Series 2000 Inverted Bucket Capacities to 1,300 lb/hr Screwed Socketweld 304L Stainless Steel (optional strainer is carbon steel) Series 1800 Inverted Bucket Capacities to 2,380 lb/hr Screwed Socketweld 304L Stainless Steel Series U-1000 Inverted Bucket Capacities to 2,380 lb/hr Screwed Socketweld Socketweld Flanged† 900 ASTM A182 F22 Forged Steel Series 1000 Inverted Bucket Capacities to 4,400 lb/hr Screwed Socketweld 304L Stainless Steel Illustration Series 5000 Inverted Bucket Capacities to 5,150 lb/hr Type Flow Direction Connection Size Located on Page Max. Oper. Press. psig Model Body Material TMA °F Max. Allow. Press. psig Connection Type ST-27 ST-27 ST-29 ST-31 ST-35 ST-35 ST-37 ST-39 ST-41 SteamTrappingand SteamTracingEquipment 66 838_Traps1.qxd 11/4/03 4:07 PM Page ST-3 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

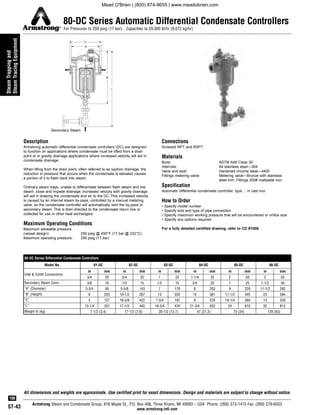

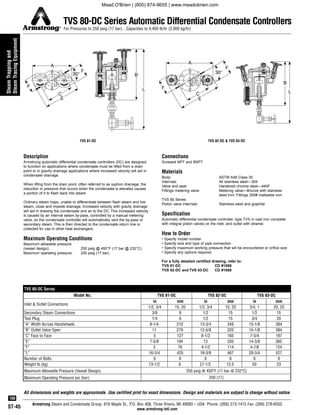

- 5. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Steam Trap ID Charts ST-4 SteamTrappingand SteamTracingEquipment 1/2" 3/4" 1" 1-1/4" 1-1/2" 2" 2-1/2" 3" 81-DC 250 82-DC 250 83-DC 250 84-DC 250 85-DC 250 86-DC 250 TVS 81-DC 250 TVS 82-DC 250 TVS 83-DC 250 1,080 33-DC 650 1,130 34-DC 650 1,015 35-DC 650 1,100 36-DC 650 B2, BI2 30 v B3, BI3 30 v B4, BI4 30 v B5 30 B6 30 B8 30 AI2 175 v A3, AI3 175 v A4, AI4 175 v A5 175 A6 175 A8 175 J8 175 K10 50 L8 250 L10 250 M12 250 Series CS F&T Capacities to 13,281 lb/hr Screwed Socketweld Flanged† 600 650 Cast Steel CS 465 LS8 450 LS10 450 MS12 450 v Series AI and BI for in-line connection. †Operating pressure and temperature may be limited depending on the class of flange selected. Series 30-DC Automatic Differential Controllers Capacities to 20,000 lb/hr Screwed 700 ASTM A105 Forged Steel ASTM A216 WCB Carbon Steel Series LS&MS F&T Capacities to 280,000 lb/hr Screwed Socketweld Flanged† 450 650 ASTM A48 Class 30 Cast Iron ASTM A48 Class 30 Cast Iron 125 175 ASTM A48 Class 30 Cast Iron 175 ASTM A48 Class 30 Cast Iron 353 Series L&M F&T Capacities to 208,000 lb/hr Screwed Flanged† (screw on) 250 450 Series J&K F&T Capacities to 105,000 lb/hr Screwed 175 450 Series A & AI F&T Capacities to 8,600 lb/hr Screwed 377 Located on Page Max. Oper. Press. psig Model Flow Direction Type Series B & BI F&T Capacities to 8,900 lb/hr Screwed Connection Size Illustration Body Material TMA °F Max. Allow. Press. psig Connection Type ASTM A48 Class 30 Cast Iron Series 80-DC Automatic Differential Controllers Capacities to 20,000 lb/hr Screwed 250 450 ASTM A48 Class 30 Cast Iron Series TVS 80-DC Automatic Differential Controllers Capacities to 4,400 lb/hr Screwed 250 450 ST-43 ST-45 ST-47 ST-51 ST-53 ST-55 ST-57 ST-59 ST-61 67 377 838_Traps1.qxd 11/4/03 4:07 PM Page ST-4 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

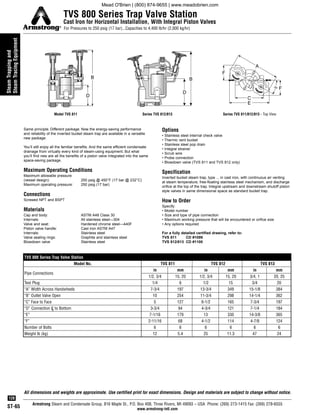

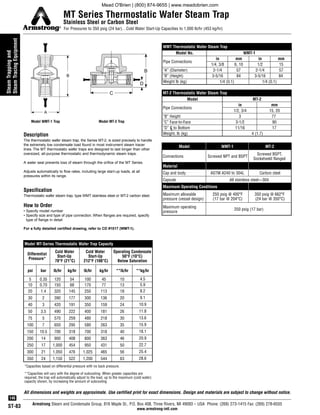

- 6. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Steam Trap ID Charts ST-5 3/8" 1/2" 3/4" 1" TVS 811 250 TVS 812 250 TVS 813 250 TVS 4000 Trap Valve Station Screwed Socketweld 650 600 ASTM A351 Gr. CF8M TVS 4000 650 TVS 2000 Trap Valve Station Screwed Socketweld 600 500 304-L Stainless Steel TVS 2000 600 CD-33 CD-33L CD-33S CD-33SL Series CD-3300 Disc Capacities to 800 lb/hr Screwed Socketweld 720 750 Stainless Steel CD-3300 450 CD-41 600 CD-42 600 CD-43 600 CD-61 600 CD-62 600 CD-63 600 Screwed 400 650 304-L Stainless Steel WT-1 400 600 750 C1018 Carbon Steel WT-3 600 400 650 304-L Stainless Steel WT-2000 400 Screwed 250 400 304-L Stainless Steel WMT-1 250 Screwed Socketweld Flanged † 350 662 Carbon Steel MT-2 250 †Operating pressure and temperature may be limited depending on the class of flange selected. 250 450 Screwed Socketweld Screwed 600 Series WT Thermostatic Wafer Cold Water Start-up Capacities to 1,600 lb/hr 752 Series MT Thermostatic Wafer Cold Water Start-up Capacities to 1,000 lb/hr TVS 800 Trap Valve Station Capacities to 4,400 lb/hr Screwed 500 Series CD-60 Controlled Disc Capacities to 2,850 lb/hr Screwed Socketweld 600 750 Series CD-40 Controlled Disc Capacities to 2,850 lb/hr Illustration Body Material TMA °F Max. Allow. Press. psig Connection Type Flow Direction Type Forged Carbon Steel Located on Page Max. Oper. Press. psig Model Carbon Steel 600 Connection Size ASTM A48 Class 30 Cast Iron ASTM A743 Gr. CA40 Series CD-33 Disc Capacities to 2,428 lb/hr Series CD-33S Disc w/Integral Strainer Capacities to 2,428 lb/hr Screwed 915 1/4" 3/8" ST-63 ST-67 ST-71 ST-75 ST-75 ST-78 ST-79 ST-79 ST-81 ST-83 SteamTrappingand SteamTracingEquipment 68 838_Traps1.qxd 11/4/03 4:07 PM Page ST-5 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

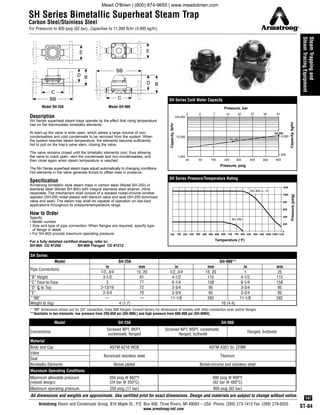

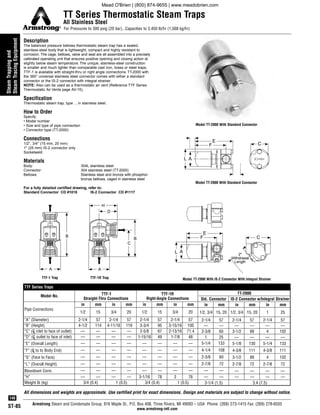

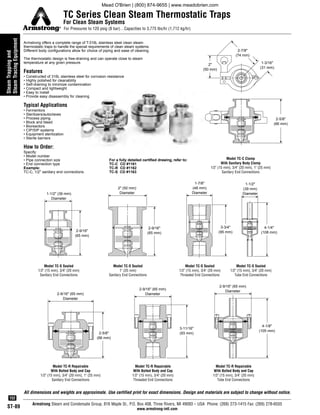

- 7. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Steam Trap ID Charts ST-6 SteamTrappingand SteamTracingEquipment 3/8" 1/2" 3/4" 1" Screwed NPT BSPT Socketweld Flanged† 350 662 Carbon Steel SH-250 250 Screwed NPT BSPT Socketweld Buttweld Buttweld Flanged† TTF-1 TTF-1R Screwed Socketweld TT-2000 50 300 TS-2 50 65 315 TS-3 65 Series TC Thermostatic Clean Steam Clamped Capacities to 3,450 lb/hr Sanitary 120 350 Stainless Steel TC-C 100 Sanitary Threaded Tube End Sanitary Threaded Tube End † Operating pressure and temperature may be limited depending on the class of flange selected. * L = low pressure, H = high pressure. L = 650* H = 900* 900 900 Stainless Steel SH-900 Threaded Model SH Bimetallic Cold Water Start-up Capacities to 11,000 lb/hr Stainless Steel Bronze TC-R 100 Series TC Thermostatic Clean Steam Repairable Capacities to 3,775 lb/hr 120 350 Located on Page Max. Oper. Press. psig Model Connection Size Illustration Body Material TMA °F Max. Allow. Press. psig Connection Type Flow Direction Type 120 Series TS-2/TS-3 Radiator Capacities to 1,600 lb/hr Series TC Thermostatic Clean Steam Sealed Capacities to 3,775 lb/hr 150 366 Stainless Steel TC-S 304-L Stainless Steel 300 Screwed Series TT Thermostatic Bellows Capacities to 3,450 lb/hr 300 450 ST-84 ST-84 ST-85 ST-88 ST-89 Flanged† 69 TAVB Thermostatic Bellows w/Integral Straight-Thru 300 450 304-L Stainless Steel TAVB-2 175Vacuum Breaker Screwed TAVB-3 ST-87 838_Traps1.qxd 11/4/03 4:07 PM Page ST-6 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 8. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.comST-7 The Inverted Bucket Steam Trap Resistance to damage from water hammer Open bucket or float will not collapse as a result of water hammer. Wear and corrosion resistance Free-floating guided lever valve mechanism is “frictionless,” and all wear points are heavily reinforced. All working parts are stainless steel. Valve and seat are stainless steel, individually ground and lapped together in matched sets. Continuous air and CO2 venting Vent in top of bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding. Steam passing through vent is less than that required to compensate for radiation losses from the trap so it’s not wasted. Excellent operation against back pressure Since trap operation is governed by the difference in density of steam and water, back pressure in the return line has no effect on the ability of the trap to open for condensate and close against steam. Virtually no steam loss Steam does not reach the water-sealed discharge valve. Purging action Snap opening of the valve creates a momentary pressure drop and turbulence in the unit drained. This breaks up films of condensate and air and speeds their flow to the trap. Dependable operation Simple, direct operation with nothing to stick, bind or clog. Only two moving parts— the valve lever and the bucket. Freedom from dirt problems Condensate flow under the bottom edge of the bucket keeps sediment and sludge in suspension until it is discharged with the condensate. Valve orifice opens wide and closes tightly. No buildup of dirt or close clearances to be affected by scale. The inverted bucket is the most reliable steam trap operating principle known. The heart of its simple design is a unique leverage system that multiplies the force provided by the bucket to open the valve against pressure. Since the bucket is open at the bottom, it resists damage from water hammer, and wear points are heavily reinforced for long life. The inverted bucket has only two moving parts—the valve lever assembly and the bucket. That means no fixed points, no complicated linkages. Nothing to stick, bind or clog. Energy Efficient Because It’s So Reliable SteamTrappingand SteamTracingEquipment 70 838_Traps1.qxd 11/4/03 4:07 PM Page ST-7 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

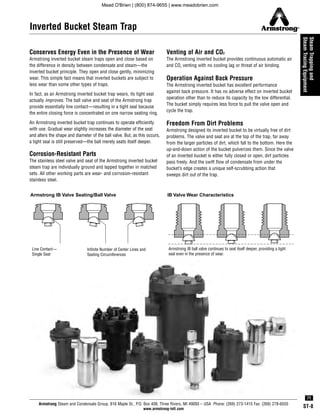

- 9. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com ST-8 Conserves Energy Even in the Presence of Wear Armstrong inverted bucket steam traps open and close based on the difference in density between condensate and steam—the inverted bucket principle. They open and close gently, minimizing wear. This simple fact means that inverted buckets are subject to less wear than some other types of traps. In fact, as an Armstrong inverted bucket trap wears, its tight seal actually improves. The ball valve and seat of the Armstrong trap provide essentially line contact—resulting in a tight seal because the entire closing force is concentrated on one narrow seating ring. An Armstrong inverted bucket trap continues to operate efficiently with use. Gradual wear slightly increases the diameter of the seat and alters the shape and diameter of the ball valve. But, as this occurs, a tight seal is still preserved—the ball merely seats itself deeper. Corrosion-Resistant Parts The stainless steel valve and seat of the Armstrong inverted bucket steam trap are individually ground and lapped together in matched sets. All other working parts are wear- and corrosion-resistant stainless steel. Venting of Air and CO2 The Armstrong inverted bucket provides continuous automatic air and CO2 venting with no cooling lag or threat of air binding. Operation Against Back Pressure The Armstrong inverted bucket has excellent performance against back pressure. It has no adverse effect on inverted bucket operation other than to reduce its capacity by the low differential. The bucket simply requires less force to pull the valve open and cycle the trap. Freedom From Dirt Problems Armstrong designed its inverted bucket to be virtually free of dirt problems. The valve and seat are at the top of the trap, far away from the larger particles of dirt, which fall to the bottom. Here the up-and-down action of the bucket pulverizes them. Since the valve of an inverted bucket is either fully closed or open, dirt particles pass freely. And the swift flow of condensate from under the bucket’s edge creates a unique self-scrubbing action that sweeps dirt out of the trap. Armstrong IB Valve Seating/Ball Valve IB Valve Wear Characteristics Line Contact— Single Seat Infinite Number of Center Lines and Seating Circumferences Armstrong IB ball valve continues to seat itself deeper, providing a tight seal even in the presence of wear. Inverted Bucket Steam Trap SteamTrappingand SteamTracingEquipment 71 838_Traps1.qxd 11/4/03 4:07 PM Page ST-8 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 10. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com How to Use the IB Trap Summary Capacity Chart ST-9 This catalog should be utilized as a guide for the installation and operation of steam trapping equipment by experienced personnel. Selection or installation should always be accompanied by competent technical assistance or advice. Armstrong and its local representatives are available for consultation and technical assistance. We encourage you to contact your Armstrong Representative for complete details. The summary capacity chart plots actual trap capacity vs. inlet pressure on a log-log grid. The trap capacities become straight lines on this grid. The small numbers along the pressure axis identify the subdivisions; for example, between the large 10 and 100, the numbers 2, 3, 5, and 7 represent 20, 30, 50 and 70 psi. The summary chart combines many trap families into one chart by presenting only a portion of the capacity line for each orifice size. For charts that give capacity over a wide range of pressures, see the specific trap model pages. Individual capacity charts for various traps are given throughout this catalog. Those charts show capacity lines for each orifice, with pressures usually from 1 psi up to the maximum rated pressure of that orifice. To select an inverted bucket steam trap using the summary capacity chart, you must know the condensate load, safety factor, inlet pressure and outlet pressure. Remember, the object is to select a trap that can 1) operate at the maximum inlet pressure, and 2) handle the capacity at the minimum differential pressure. Consider the following typical problems. Example 1. Constant pressure, condensing rate. Given: Maximum inlet pressure . . . . . . . . . . . . . . . . . . . . . . . . .70 psi Normal operating differential pressure . . . . . . . . . . . . . . .60 psi Required capacity = 300 lb/hr condensate load times 3:1 safety factor, or . . . . . . . . . . . . . . . . . . . . . .900 lb/hr Enter the chart at the 60 psi line and go up to 900 lb/hr capacity. This is directly on the 5/32'' orifice line for models 211, 811 and 881 (and other traps). Now follow this line to the right, to the vertical drop at 70 psi. This means the orifice will work, in these traps, up to a maximum differential of 70 psi. Assuming a cast iron trap is suitable, the 5/32'' orifice in a Model 211, 811 or 881 trap will meet all the operating requirements. Example 2. Constant condensing rate but with possible reduced inlet pressure. Given: Maximum inlet pressure . . . . . . . . . . . . . . . . . . . . . . . .100 psi Minimum inlet pressure . . . . . . . . . . . . . . . . . . . . . . . . .40 psi Required capacity = 400 lb/hr condensate load times 3:1 safety factor, or . . . . . . . . . . . . . . . . . . . .1,200 lb/hr Consider the maximum operating pressure first. Enter the chart at the 100 psi line and find the first capacity line above 1,200 lb/hr. This is the 5/32'' orifice in a Model 212, 812 or 882, and it has a capacity of 1,800 lb/hr at 100 psi. Now extend this straight line to the left until it intersects the 40 psi pressure line. At 40 psi, read a capacity of 1,300 lb/hr. (You could also refer to the individual capacity charts for Models 212, 812 or 882.) Assuming cast iron is suitable, this is the desired trap selection to meet the requirements of opening at the maximum pressure, and also having the needed capacity at the minimum pressure. This example points out how the capacity is influenced by the trap size. Example 1 also used the same orifice size, but in a physically smaller trap. In the larger trap the same diameter orifice not only has a higher capacity, it will work at higher pressures. Example 3. Constant condensing rate but high back pressure. Given: Inlet pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 psi Normal outlet (back) pressure . . . . . . . . . . . . . . . . . . . . .50 psi Required capacity = 1,800 lb/hr condensate load times 3:1 safety factor, or . . . . . . . . . . . . . . . . . . . .5,400 lb/hr Traditional method: Since the differential pressure is only 50 psi, enter the chart at 50 psi and go up to a capacity of 5,400 lb/hr. This is just under the capacity lines for Models 214 and 814. However, the 5/16'' orifice is the largest orifice that will operate at 100 psi inlet pressure. (Remember that the back pressure may not always be there!) Extend the capacity line for the 5/16'' orifice to the left, and read a capacity of 4,800 lb/hr at 50 psi. Since this is too low, go up to the 215/815 capacity lines and repeat the process. The selection will end up being a Model 215 or 815 with a 3/8'' orifice*. About this chart ... The Armstrong capacity chart shows continuous discharge capacities of Armstrong traps under actual operating conditions, as determined by many hundreds of tests made over the years. In these tests, hot condensate was used, at or near the steam temperature corresponding to the test pressure. The choking effect of flash steam in the orifice and the back pressure created by this flash steam were therefore automatically taken into account. The test setups were similar to an actual installation hookup, so that pipe friction in both inlet and discharge lines was reflected in the results. * This method is conservative. While it will always select a workable trap, it may select a larger trap than necessary. Consult Armstrong Application Engineering for further information about the effects of back pressure. SteamTrappingand SteamTracingEquipment 72 838_Traps1.qxd 11/4/03 4:07 PM Page ST-9 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 11. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com ST-10 IB Trap Summary Capacity Chart SteamTrappingand SteamTracingEquipment 73 838_Traps1.qxd 11/4/03 4:07 PM Page ST-10 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

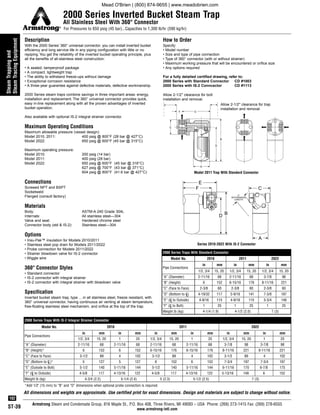

- 12. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com A B 200 Series Inverted Bucket Steam Traps Cast Iron for Vertical Installation For Pressures to 250 psig (17 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) Description The most reliable steam trap known—the inverted bucket—provides efficient condensate drainage of virtually all types of steam-using equipment. Put the inverted bucket to work in a tough cast iron package, and you have the best of both worlds. Because they operate efficiently for longer periods of time, Armstrong cast iron inverted buckets add solid energy savings to lower replacement/labor costs. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating, and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket, which provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, allowing no condensate backup. They are also resistant to water hammer. Maximum Operating Conditions Maximum allowable pressure (vessel design): 250 psig @ 450°F (17 bar @ 232°C) Maximum operating pressure: Model 211-216: 250 psig (17 bar) Connections Screwed NPT and BSPT Materials Body: ASTM A48 Class 30 Internals: All stainless steel—304 Valve and seat: Hardened chrome steel—440F Test plug: Carbon steel Options • Stainless steel internal check valve • Thermic vent bucket • Scrub wire Specification Inverted bucket steam trap, type ... in cast iron, with continuous air venting at steam temperature, free floating stainless steel mechanism, and discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1001. All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-11 Model No. in mm in mm in mm in mm in mm in mm 1/2 15 1/2, 3/4 15, 20 1/2, 3/4, 1 15, 20, 25 1, 1-1/4 25, 32 1, 1-1/4, 1-1/2 25, 32, 40 1-1/2, 2 40, 50 Test Plug 1/8 3 3/8 10 1/2 15 1/2 15 3/4 20 1 25 “A” (Flange Diameter) 4-1/4 108 5-1/4 133 6-3/8 162 7-1/2 190 8-1/2 216 10-3/16 259 “B” (Height) 6-3/8 162 8 203 10-3/4 273 12-1/2 317 14-5/16 364 17 432 Number of Bolts Weight lb (kg) 44-3/4 (20.3) 77-1/2 (35.2)6 (2.7) 11-1/2 (5.2) 20-1/4 (9.2) 33 (15.0) 214 215 216 200 Series, Bottom Inlet, Top Outlet Traps Add suffix “CV” to model number for internal check valve, “T” for thermic vent bucket. 211 212 Pipe Connections 6 8 6 8 12 213 SteamTrappingand SteamTracingEquipment 74 838_Traps1.qxd 11/4/03 4:07 PM Page ST-11 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 13. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 200 Series Inverted Bucket Steam Traps Cast Iron for Vertical Installation For Pressures to 250 psig (17 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) Model 211 Capacity Model 212 Capacity ST-12 Model 213 Capacity Model 214 Capacity Model 215 Capacity Model 216 Capacity SteamTrappingand SteamTracingEquipment 75 838_Traps1.qxd 11/4/03 4:07 PM Page ST-12 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 14. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 800-813 Series Inverted Bucket Steam Trap Cast Iron for Horizontal Installation For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) C A B D Description The most reliable steam trap known—the inverted bucket—provides efficient condensate drainage of virtually all types of steam-using equipment. Put the inverted bucket to work in a tough cast iron package, and you have the best of both worlds. Because they operate efficiently for longer periods of time, Armstrong cast iron inverted buckets add solid energy savings to lower replacement/labor costs. All Armstrong cast iron inverted bucket steam traps are repairable for even bigger maintenance savings. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating, and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket, which provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, allowing no condensate backup. They are also resistant to water hammer. Maximum Operating Conditions Maximum allowable pressure (vessel design): 250 psig @ 450°F (17 bar @ 232°C) Maximum operating pressure: Model 800: 150 psig (10 bar) Model 811-813: 250 psig (17 bar) Connections Screwed NPT and BSPT Materials Body: ASTM A48 Class 30 Internals: All stainless steel—304 Valve and seat: Hardened chrome steel—440F Test plug: Carbon steel Options • Stainless steel internal check valve • Thermic vent bucket • Stainless steel pop drain • Probe connection • Thermo drain • Scrub wire Specification Inverted bucket steam trap, type ... in cast iron, with continuous air venting at steam temperature, free-floating stainless steel mechanism, and discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1000. All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-13 Model No. in mm in mm in mm in mm 1/2, 3/4 15, 20 1/2, 3/4, 1 15, 20, 25 1/2, 3/4 15, 20 3/4, 1 20, 25 Test Plug 1/4 6 1/4 6 1/2 15 3/4 20 “A” (Flange Diameter) 3-3/4 95.2 3-3/4 95.2 5-5/8 143 7 178 “B” (Height) 5-7/16 138 6-7/8 175 9-1/16 230 11-3/4 298 “C” (Face-to-Face) 5 127 5 127 6-1/2 165 7-3/4 197 “D” (Bottom to C Inlet) 2-3/4 70 4-1/4 108 5-3/8 137 7-1/32 179 Number of Bolts Weight lb (kg) 812 813 *Cannot be furnished with both thermic vent bucket and check valve. 800-813 Series Side Inlet, Side Outlet Traps. Add suffix “CV” to model number for internal check valve, “T” for thermic vent bucket. Pipe Connections 6 15 (6.8) 27-1/2 (12.5) 800* 811 5 (2.3) 6 (2.7) L SteamTrappingand SteamTracingEquipment 76 838_Traps1.qxd 11/4/03 4:07 PM Page ST-13 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 15. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 800-813 Series Inverted Bucket Steam Trap Cast Iron for Horizontal Installation For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) ST-14 Model 800 Capacity Model 811 Capacity Model 812 Capacity Model 813 Capacity SteamTrappingand SteamTracingEquipment 77 838_Traps1.qxd 11/4/03 4:08 PM Page ST-14 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 16. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 814-816 Series Inverted Bucket Steam Trap Cast Iron for Horizontal Installation For Pressures to 250 psig (17 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) C A B D Description The most reliable steam trap known—the inverted bucket—provides efficient condensate drainage of virtually all types of steam-using equipment. Put the inverted bucket to work in a tough cast iron package, and you have the best of both worlds. Because they operate efficiently for longer periods of time, Armstrong cast iron inverted buckets add solid energy savings to lower replacement/labor costs. All Armstrong cast iron inverted bucket steam traps are repairable for even bigger maintenance savings. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating, and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket, which provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, allowing no condensate backup. They are also resistant to water hammer. Maximum Operating Conditions Maximum allowable pressure (vessel design): 250 psig @ 450°F (17 bar @ 232°C) Maximum operating pressure: Model 814-816: 250 psig (17 bar) Connections Screwed NPT and BSPT Materials Body: ASTM A48 Class 30 Internals: All stainless steel—304 Valve and seat: Hardened chrome steel—440F Test plug: Carbon steel Options • Stainless steel internal check valve • Thermic vent bucket • Stainless steel pop drain • Probe connection • Thermo drain • Scrub wire Specification Inverted bucket steam trap, type ... in cast iron, with continuous air venting at steam temperature, free-floating stainless steel mechanism, and discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1000. All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-15 Model No. in mm in mm in mm 1, 1-1/4 25, 32 1, 1-1/4, 1-1/2, 2 25, 32, 40, 50 2, 2-1/2 50, 65 Test Plug 1 25 1-1/2 40 2 50 “A” (Flange Diameter) 8 203 9 229 11-1/2 292 “B” (Height) 13-5/8 346 16-1/4 413 21-5/16 541 “C” (Face-to-Face) 9 229 10-1/4 260 13 330 “D” (Bottom to C Inlet) 7-13/16 198 8-1/16 205 11 279 Number of Bolts Weight lb (kg) 44 (20.0) 71 (32.2) 814-816 Series Side Inlet, Side Outlet Traps. Add suffix “CV” to model number for internal check valve, “T” for thermic vent bucket. 814 815 816 Pipe Connections 8 131 (59.4) L SteamTrappingand SteamTracingEquipment 78 838_Traps1.qxd 11/4/03 4:08 PM Page ST-15 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 17. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 814-816 Series Inverted Bucket Steam Trap Cast Iron for Horizontal Installation For Pressures to 250 psig (17 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) Model 814 Capacity Model 815 Capacity Model 816 Capacity ST-16 SteamTrappingand SteamTracingEquipment 79 838_Traps1.qxd 11/4/03 4:08 PM Page ST-16 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 18. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 880 Series Inverted Bucket Steam Traps Cast Iron for Horizontal Installation With Integral Strainer For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) C A B D E Description The most reliable steam trap known—the inverted bucket—provides efficient condensate drainage of virtually all types of steam-using equipment. Put the inverted bucket to work in a tough cast iron package with an integral strainer, and you have the best of both worlds. Because they operate efficiently for longer periods of time, Armstrong cast iron inverted buckets add solid energy savings to lower replacement/labor costs. All Armstrong cast iron inverted bucket steam traps are repairable for even bigger maintenance savings. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating, and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket, which provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, allowing no condensate backup. They are also resistant to water hammer. Maximum Operating Conditions Maximum allowable pressure (vessel design): 250 psig @ 450°F (17 bar @ 232°C) Maximum operating pressure: Model 880: 150 psig (10 bar) Model 881-883: 250 psig (17 bar) Connections Screwed NPT and BSPT Materials Body: ASTM A48 Class 30 Internals: All stainless steel—304 Valve and seat: Hardened chrome steel—440F Test plug: Carbon steel Strainer: Stainless steel—304 Options • Stainless steel internal check valve • Thermic vent bucket • Scrub wire Specification Inverted bucket steam trap, type ... in cast iron with integral strainer, with continuous air venting at steam temperature, with free-floating stainless steel mechanism, and discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1000. All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-17 Model No. in mm in mm in mm in mm 1/2, 3/4 15, 20 1/2, 3/4, 1 15, 20, 25 1/2, 3/4 15, 20 3/4,1, 1-1/4 20, 25, 32 Test Plug 1/4 6 1/4 6 1/2 15 3/4 20 “A” (Flange Diameter) 3-3/4 95.2 3-3/4 95.2 5-5/8 142.9 7 177.8 “B” (Height) 6-1/16 154 7-1/16 179 9-3/8 244 12-3/8 314 5 127 5 127 6-1/2 165 7-7/8 200 “D” (Bottom to C Inlet) 3-7/16 87.3 4-7/16 113 5-3/4 146 7-3/8 187 3/8 9 3/8 9 3/8 9 1/2 15 Number of Bolts Weight lb (kg) 6 (2.7) 15-1/2 (7.0) 880 Series Side Inlet, Side Outlet Traps With Integral Strainers. Add suffix “CV” to model number for internal check valve, “T” for thermic vent bucket. *Cannot be furnished with both thermic vent bucket and check valve. 5-1/2 (2.5) 880* 881 882 883 31 (14.1) Pipe Connections 6 “C” (Face-to-Face) L “E” (Blowdown Connection) SteamTrappingand SteamTracingEquipment 80 838_Traps1.qxd 11/4/03 4:08 PM Page ST-17 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 19. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 880 Series Inverted Bucket Steam Traps Cast Iron for Horizontal Installation With Integral Strainer For Pressures to 250 psig (17 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) Model 880 Capacity Model 881 Capacity Model 882 Capacity ST-18 Model 883 Capacity SteamTrappingand SteamTracingEquipment 81 838_Traps1.qxd 11/4/03 4:08 PM Page ST-18 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

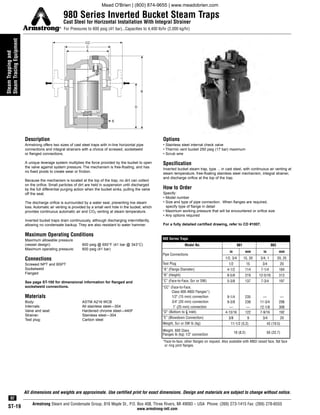

- 20. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 980 Series Inverted Bucket Steam Traps Cast Steel for Horizontal Installation With Integral Strainer For Pressures to 600 psig (41 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) C A B D CC E Description Armstrong offers two sizes of cast steel traps with in-line horizontal pipe connections and integral strainers with a choice of screwed, socketweld or flanged connections. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating, and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket, which provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, allowing no condensate backup. They are also resistant to water hammer. Maximum Operating Conditions Maximum allowable pressure (vessel design): 600 psig @ 650°F (41 bar @ 343°C) Maximum operating pressure: 600 psig (41 bar) Connections Screwed NPT and BSPT Socketweld Flanged See page ST-100 for dimensional information for flanged and socketweld connections. Materials Body: ASTM A216 WCB Internals: All stainless steel—304 Valve and seat: Hardened chrome steel—440F Strainer: Stainless steel—304 Test plug: Carbon steel Options • Stainless steel internal check valve • Thermic vent bucket 250 psig (17 bar) maximum • Scrub wire Specification Inverted bucket steam trap, type ... in cast steel, with continuous air venting at steam temperature, free-floating stainless steel mechanism, integral strainer, and discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1007. All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-19 Model No. in mm in mm 1/2, 3/4 15, 20 3/4, 1 20, 25 Test Plug 1/2 15 3/4 20 “A” (Flange Diameter) 4-1/2 114 7-1/4 184 “B” (Height) 8-5/8 219 12-5/16 313 “C” (Face-to-Face, Scr or SW) 5-3/8 137 7-3/4 197 “CC” (Face-to-Face, Class 600 ANSI Flanges*) 1/2" (15 mm) connection 9-1/4 235 — — 3/4" (20 mm) connection 9-3/8 238 11-3/4 298 1" (25 mm) connection — — 12-1/8 308 “E” (Blowdown Connection) 3/8 9 3/4 20 Weight, Scr or SW lb (kg) Weight, 600 Class Flanges lb (kg) 1/2" connection 18 (8.2) Pipe Connections *Face-to-face, other flanges on request. Also available with ANSI raised face, flat face or ring joint flanges. 43 (19.5) 50 (22.7) 11-1/2 (5.2) 981 983 980 Series Traps L“D” (Bottom to C Inlet) 4-13/16 122 7-9/16 192 SteamTrappingand SteamTracingEquipment 82 838_Traps1.qxd 11/4/03 4:08 PM Page ST-19 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 21. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 980 Series Inverted Bucket Steam Traps Cast Steel for Horizontal Installation With Integral Strainer For Pressures to 600 psig (41 bar)...Capacities to 4,400 lb/hr (2,000 kg/hr) Model 981 Capacity Model 983 Capacity ST-20 SteamTrappingand SteamTracingEquipment 83 838_Traps1.qxd 11/4/03 4:08 PM Page ST-20 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 22. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Description Armstrong offers its 300 Series forged carbon steel traps for vertical installation with a choice of screwed, socketweld or flanged connections. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating, and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket, which provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, allowing no condensate backup. They are also resistant to water hammer. For Superheat Service: 1. Don’t oversize the orifice; a restricted orifice may be advisable. 2. Specify a burnished valve and seat and an extended inlet tube and check valve. 3. Provide a drip leg of adequate diameter and length. 4. Provide a generous length (2'-3') of inlet piping, with the trap below the main. 5. Don’t insulate the trap or the inlet piping. Connections Screwed NPT and BSPT Socketweld Flanged See page ST-100 for dimensional information for flanged and socketweld connections. Materials Body: ASTM A105 Models 312, 313, 316 are also available with cast 316 stainless steel bodies and all stainless steel internals Internals: All stainless steel—304 (larger sizes have cast iron bucket weights) Valve and seat: Hardened chrome steel—440F Options • Stainless steel internal check valve • Thermic vent bucket 250 psig (17 bar) maximum • Scrub wire Specification Inverted bucket steam trap, type ... in forged carbon steel, with continuous air venting at steam temperature, free-floating stainless steel mechanism, and discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1002. 300 Series Inverted Bucket Steam Trap Forged Carbon Steel for Vertical Installation For Pressures to 650 psig (45 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) A B G K All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-21 A BB G K Model No. Screwed or SW Model No. Flanged in mm in mm in mm in mm in mm in mm 1/2, 3/4 15, 20 1/2, 3/4, 1 15, 20, 25 1/2, 3/4, 1 15, 20, 25 1, 1-1/4 25, 32 1, 1-1/4, 1-1/2 25, 32, 40 1-1/2, 2 40, 50 “A” (Diameter) 4-5/8 117 6-3/4 171 8 203 8-5/8 219 9-3/4 248 11-7/8 302 “B” (Height, Screwed or SW) 7-15/16 202 10-3/16 259 11-1/2 292 13-11/16 348 15 381 17-1/8 435 “BB” 12-1/16* 306* 12-5/16 313 13-7/8 352 16-1/16 408 17-9/16 446 19-11/16 500 “G” (Body OD) 3-1/16 78 4-3/4 121 5-1/8 130 5-3/4 146 6-5/8 168 8-3/8 213 “K” (C Outlet to C Inlet) 9/16 14.3 1-1/4 31.7 1-7/16 36.5 1-7/16 36.5 1-3/4 44.4 2-1/8 54.0 Number of Bolts Weight Scr. or SW lb (kg) Weight, Flanged lb (kg) 184 (83.5)103 (46.7)73 (33.1)51 (23.1)32 (14.5) 10 (4.5) 12 (5.4) 300 Series Bottom Inlet, Top Outlet Traps. Add suffix “CV” to trap number for internal check valve. 310 310-FW 312 312-FW 313 313-FW 314 314-FW 315 315-FW 316 316-FW *“BB” dimensions shown are for 3/4" conn., Class 600 flanged No. 310-FW. Consult factory for dimensions of models with other connection sizes and/or flanges. 6 8 9 10 30 (13.6) 50 (22.7) Pipe Connections 70 (31.8) 98 (44.5) 179 (81.2) L Series 300 Trap Series 300-FW Trap Pressure-Temperature Rating for Forged Steel Traps °F °C °F °C °F °C °F °C -20/ -28/ +650 +343 psig bar psig bar psig bar psig bar psig bar 310 400 27.5 770 48 770 48 730 50 600 41 312 600 41 600 41 600 41 560 38.5 500 34.5 313 650 45 1,080 74 1,080 74 970 67 780 54 314 650 45 1,130 78 1,120 77 990 68 810 56 315 650 45 1,015 70 965 66.5 860 59 690 47.5 316 650 45 1,100 76 1,050 72 940 65 760 52 Max. Oper. Pressure, Sat. Steam 700 371 750 399 800 427 Model No. Maximum Allowable Pressure (Vessel Design) of Pressure- Containing Parts at Indicated Temperature L NOTES: Maximum operating pressure to be marked on nameplate will be determined by actual orifice used. Maximum allowable pressures shown in boldface will be marked on nameplate, unless otherwise requested. Traps with flanges may have different pressure- temperature ratings. SteamTrappingand SteamTracingEquipment 84 838_Traps1.qxd 11/4/03 4:08 PM Page ST-21 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 23. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 300 Series Inverted Bucket Steam Trap Forged Carbon Steel for Vertical Installation For Pressures to 650 psig (45 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) ST-22 Model 310 Capacity Model 312 Capacity Model 313 Capacity Model 314 Capacity Model 315 Capacity Model 316 Capacity SteamTrappingand SteamTracingEquipment 85 838_Traps1.qxd 11/4/03 4:08 PM Page ST-22 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 24. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Description Armstrong Model 411G vertical installation and Model 421 horizontal installation offer smaller capacities at higher pressures. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket. Inverted bucket traps drain continuously to prevent condensate backup. They are also resistant to water hammer. Model 421 adds the convenience and savings of in-line repairability and is designed to meet today’s energy-management requirements efficiently and economically over a long, trouble-free service life. Connections Screwed NPT and BSPT Socketweld Flanged See page ST-100 for dimensional information for flanged and socketweld connections. Materials Body: ASTM A105 411G cap: ASTM A105 421 cap: ASTM A216 WCB Internals: All stainless steel—304 Valve and seat: 17-4PH Options Stainless steel internal check valve (411G only) Specifications Inverted bucket steam trap, type ... in forged carbon steel, with continuous air venting at steam temperature, free-floating stainless steel mechanism, with the discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1105. 411G/421 Series Inverted Bucket Steam Traps Forged Carbon Steel for Vertical and Horizontal Installation For Pressures to 1,000 psig (69 bar)...Capacities to 1,300 lb/hr (590 kg/hr) All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-23 B A G K BB G B B A B 411G Bottom Inlet, Top Outlet Traps; 421 Side Inlet, Side Outlet Traps Add suffix “CV” to trap number for internal check valve. Model No. Screwed or SW Model No. Flanged in mm in mm 1/2, 3/4 15, 20 1/2, 3/4 15, 20 “A” (Diameter) 6-5/16 160 8 203 “B” (Height, Screwed or SW) 8-13/16 224 10-9/64 258 “BB” 13-15/16* 354* 11-3/4* 298* “G” (Body OD) 4-1/16 103 3-7/8 98 “K” (C Outlet to C Inlet) 3/4 19.0 – – Number of Bolts Weight Scr. or SW lb (kg) Weight, Flanged lb (kg) *“BB” dimensions shown are for 3/4" conn., Class 900 flanged. Consult factory for dimensions of models with other connection sizes and/or flanges. 411G 411G-FW 421 421-FW Pipe Connections 8 27-1/2 (12.6) 35 (15.9) 36 (16.3) 25 (11.3) 8 L L Model 411G Trap Model 421 Trap SteamTrappingand SteamTracingEquipment 86 838_Traps2.qxd 11/4/03 4:12 PM Page ST-23 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 25. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 411G/421 Series Inverted Bucket Steam Traps Forged Carbon Steel for Vertical and Horizontal Installation For Pressures to 1,000 psig (69 bar)...Capacities to 1,300 lb/hr (590 kg/hr) Model 411G and 421 Capacity ST-24 NOTE: #38 orifice in Model 421 is limited to 560 psi (39 bar). Pressure-Temperature Rating for Forged Steel Traps °F °C °F °C °F °C °F °C -20/+650 -28/+343 700 371 750 399 800 427 psig bar psig bar psig bar psig bar psig bar 411G/421 1,000 69 1,000 69 1,000 69 950 65.5 840 58 Maximum Allowable Pressure (Vessel Design) of Pressure-Containing Parts at Indicated TemperatureMax. Oper. Pressure, Sat. Steam Model No. NOTES: Maximum operating pressure to be marked on nameplate will be determined by actual orifice used. Maximum allowable pressures shown in boldface will be marked on nameplate, unless otherwise requested. Traps with flanges may have different pressure- temperature ratings. SteamTrappingand SteamTracingEquipment 87 838_Traps2.qxd 11/4/03 4:12 PM Page ST-24 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 26. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.comST-25 Description Armstrong offers its 400 Series forged chrome-moly steel traps for vertical installation with a choice of screwed, socketweld or flanged connections. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket. This provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously to prevent condensate backup. They are also resistant to water hammer. Operation on Superheat. A normally operating bucket trap is filled with saturated steam and condensate. Superheated steam can enter only as fast as the steam inside can condense. As a result, the temperature of the trap is at (or slightly below) saturated steam temperature, regardless of the degree of superheat. Trap Selection. The pressure-containing parts of the steam trap should safely withstand the maximum pressure and temperature conditions of the system. For example, a trap is required for a 900 psig (62 bar) main at 900°F (482°C). The normal operating temperature of the trap will be about 532°F (278°C). A Model 415 trap should be selected, even though several smaller traps are capable of handling the working pressure. For Superheat Service: 1. Don’t oversize the orifice; a restricted orifice may be advisable. 2. Specify a burnished valve and seat and an extended inlet tube and check valve. 3. Provide a drip leg of adequate diameter and length. 4. Provide a generous length (2'-3') of inlet piping, with the trap below the main. 5. Don’t insulate the trap or the inlet piping. Connections Screwed NPT and BSPT Socketweld Flanged See page ST-100 for dimensional information for flanged and socketweld connections. Materials Body: ASTM A182 F22 Class 3 Models 413 and 415 are available with cast 316 stainless steel bodies and all stainless steel internals Internals: All stainless steel—304 Valve and seat: 17-4PH or 440F Options Stainless steel internal check valve Specification Inverted bucket steam trap, type ... in forged chrome-moly steel, with continuous air venting at steam temperature, free-floating stainless steel mechanism, with the discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1002. 400 Series Inverted Bucket Steam Trap Forged Chrome-moly Steel for Vertical Installation For Pressures to 1,000 psig (69 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. A B G K A BB G K Series 400 Trap Series 400-FW Trap 400 Series, Bottom Inlet, Top Outlet Traps. Add suffix “CV” to trap number for internal check valve. Model No. Screwed or SW Model No. Flanged in mm in mm in mm 1/2, 3/4, 1 15, 20, 25 1, 1-1/4, 1-1/2 25, 32, 40 1-1/2, 2 40, 50 “A” (Diameter) 8-5/8 219 10-3/4 273 12-1/2 317 “B” (Height, Screwed or SW) 12-3/16 310 14-15/16 379 17-5/8 448 “BB” 14-7/8 378 18-1/16 459 21-1/2 546 “G” (Body OD) 5-3/8 137 6-7/8 175 8-1/2 216 “K” (C Outlet to C Inlet) 1-7/16 36.5 1-3/4 44.4 2-1/8 54.0 Number of Bolts Weight Scr. or SW lb (kg) Weight, Flanged lb (kg) 205 (93.0) 8 Pipe Connections 416 416-FW 70 (31.8) 9 413 413-FW 12 65 (29.5) 126 (57.2) 415 415-FW 132 (59.9) 211 (95.7) L L SteamTrappingand SteamTracingEquipment 88 838_Traps2.qxd 11/4/03 4:12 PM Page ST-25 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 27. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com ST-26 400 Series Inverted Bucket Steam Trap Forged Chrome-moly Steel for Vertical Installation For Pressures to 1,000 psig (69 bar)...Capacities to 20,000 lb/hr (9,072 kg/hr) Model 413 Capacity Model 415 Capacity Model 416 Capacity Pressure-Temperature Rating for Forged Steel Traps °F °C °F °C °F °C °F °C °F °C °F °C -20/+650 -28/+343 700 371 750 399 800 427 850 454 900 482 psig bar psig bar psig bar psig bar psig bar psig bar psig bar 413 1,000 69 1,200 83 1,200 83 1,200 83 1,200 83 1,050 72 780 54 415 1,000 69 1,100 76 1,100 76 1,100 76 1,100 76 1,080 74.5 965 66.5 416 1,000 69 1,700 117 1,700 117 1,700 117 1,660 114 1,350 93 990 68 NOTES: Maximum operating pressure to be marked on nameplate will be determined by actual orifice used. Maximum allowable pressures shown in boldface will be marked on nameplate, unless otherwise requested. Traps with flanges may have different pressure-temperature ratings. Maximum Allowable Pressure (Vessel Design) of Pressure-Containing Parts at Indicated Temperature Max. Oper. Pressure, Sat. Steam Model No. SteamTrappingand SteamTracingEquipment 89 838_Traps2.qxd 11/4/03 4:12 PM Page ST-26 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

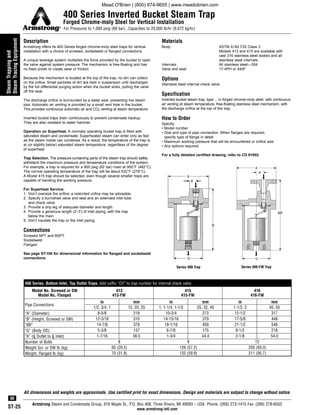

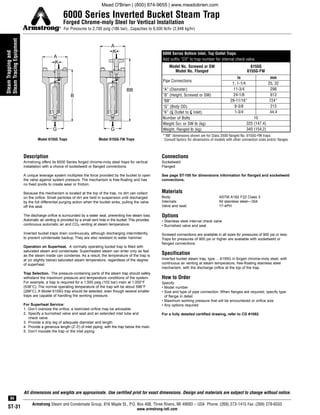

- 28. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Description Armstrong’s 401-SH/501-SH Series inverted bucket steam trap line is made for overcoming the difficult combination of superheat and high pressure/low load service. To survive this most severe steam service, Armstrong created an inverted bucket trap with a unique accumulation chamber. The chamber collects sufficient condensate to ensure full discharge cycles. A cup in the chamber floats up and down on the steam inlet tube, sealing it off as the condensate level rises. At the same time as the chamber collects condensate, steam continues to flow under the bucket, making sure that the discharge valve closes tightly until the condensate rises into the trap body and the bucket falls down. The operation is on/off, no throttling or dribbling. Furthermore, it combines all the advantages of an inverted bucket steam trap: • High resistance to wear, corrosion and water hammer with no gaskets. • A unique leverage system multiplies the force provided by the bucket, to open the valve against system pressure. • The mechanism is located at the top. No dirt can collect on the orifice. Small particles of dirt will be held in suspension until discharged by the full differential purging action. • The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small hole in the bucket. • Inverted bucket traps require no adjustment. They do not allow condensate backup and are resistant to water hammer. Maximum Operating Conditions Maximum allowable pressure (vessel design): Model 401-SH: 1,000 psig @ 800°F (69 bar @ 427°C) Model 501-SH: 1,540 psig @ 850°F (105 bar @ 454°C) Maximum operating pressure: Model 401-SH: 1,000 psig Model 501-SH: 1,540 psig Connections Screwed NPT and BSPT (401-SH only) Socketweld Flanged See page ST-100 for dimensional information for flanged and socketweld connections. Materials Body: Model 401-SH Carbon steel ASTM A106 Gr. B Sch. 80 pipe Model 501-SH Stainless steel 316L ASTM A312 Sch. 80 pipe Internals: Stainless steel—304 Valve and seat: Stellite® Connections: Model 401-SH Stainless steel—304 Model 501-SH Stainless steel—316L Specification Inverted bucket steam trap, type ... in carbon steel (stainless steel), with accumulation chamber, continuous air venting at steam temperature, stainless steel leverage system, with the discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size For a fully detailed certified drawing, refer to: 401-SH CD #1011 501-SH CD #1012 401-SH/501-SH Series Inverted Bucket Superheat Steam Trap Carbon Steel or Stainless Steel for Vertical Installation For Pressures to 1,540 psig (105 bar)...Capacities to 1,300 lb/hr (590 kg/hr) BD C A All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-27 D A C B Model 401-SH Model 501-SH SteamTrappingand SteamTracingEquipment 90 401-SH and 501-SH Series Steam Traps Model in mm in mm in mm 1/2, 3/4 15, 20 1/2 15 3/4 20 “A” Diameter (NPT, BSPT or SW) 4 100 4 100 4 100 “B” Height (NPT, BSPT or SW) 11 275 13-9/16 344 13-9/16 344 “C” Diameter (Flanged)* 4-5/8 117 4-3/4 121 5-1/8 130 “D” Height (Flanged)* 15-1/8 384 18-3/16 462 18-11/16 475 Weight (NPT, BSPT or SW) lb (kg) Weight (Flanged) lb (kg) 15 (6.7) 29 (13) 401-SH 501-SH Pipe Connections 12 (5.5) 15 (7) *401-SH 600 lb RF shown. 501-SH 900/1500 lb RF shown. 838_Traps2.qxd 11/4/03 4:12 PM Page ST-27 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 29. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 401-SH/501-SH Series Inverted Bucket Superheat Steam Trap Carbon Steel or Stainless Steel for Vertical Installation For Pressures to 1,540 psig (105 bar)...Capacities to 950 lb/hr (432 kg/hr) 1,200 700 500 400 300 250 200 150 50 70 150 200 250 300 400 1,540 1,000 501-SH 500 2 7 2 3 5 7 2 3 5 7 1,000 100 100 10010 1,000 100 Capacitykg/hr Pressure, psi Pressure, bar Capacitylb/hr 401-SH Model 401/501 Capacity ST-28 Installation Recommendations What little condensate there is on superheat and high pressure/low load service usually forms in drip legs and in the traps themselves. Therefore proper piping and drip legs of adequate size and diameter are essential for the successful operation of the Armstrong superheat trap. Drip Leg Sizing The properly sized drip leg will capture condensate. Too small a drip leg can actually cause a venturi “piccolo” effect where pressure drop pulls condensate out of the drip leg and trap. D H M Trap Draining Drip Leg on Steam Main Cycling—Discharge Valve Wide Open With the steam feed tube to the trap chamber sealed, condensate flows through the condensate feed tube (from accumulation chamber) into the trap chamber. This sinks the inverted bucket, which opens the discharge valve, cycling the trap. Cycle Ending As the level of condensate in the accu- mulation chamber falls, the cup sealing the steam feed tube moves downward, opening a passage for steam to flow into trap chamber. Trap Closed As steam begins to flow through the accumulation chamber and up the steam feed tube under the inverted bucket in the trap chamber, the discharge valve closes tightly. Cycle About to Repeat As the level of condensate rises in the accumulation chamber, the cup floats up until it again seals the steam feed tube, and the cycle repeats. Incorrectly Sized Recommended Steam Main and Branch Line Drip Leg Tracing in mm in mm in mm in mm 1/2 15 1/2 15 10 250 28 710 3/4 20 3/4 20 10 250 28 710 1 25 1 25 10 250 28 710 2 50 2 50 10 250 28 710 3 75 3 75 10 250 28 710 4 100 4 100 10 250 28 710 6 150 4 100 10 250 28 710 8 200 4 100 12 300 28 710 10 250 6 150 15 380 28 710 12 300 6 150 18 450 28 710 14 350 8 200 21 530 28 710 16 400 8 200 24 600 28 710 18 450 10 250 27 685 28 710 20 500 10 250 30 760 30 760 24 600 12 300 36 910 36 910 H Drip Leg Length Minimum Supervised Warm-Up Automatic Warm-Up M D Steam Main Size Drip Leg Diameter Correctly Sized CondensateSteamAir KEY Cup Accumulation Chamber Condensate Tube Steam Tube Trap Chamber SteamTrappingand SteamTracingEquipment 91 838_Traps2.qxd 11/4/03 4:12 PM Page ST-28 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 30. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com Description Armstrong offers its 5000 Series forged chrome-moly steel traps for vertical installation with a choice of screwed, socketweld or flanged connections. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket.This provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, to prevent condensate backup. They are also resistant to water hammer. Operation on Superheat. A normally operating bucket trap is filled with saturated steam and condensate. Superheated steam can enter only as fast as the steam inside can condense. As a result, the temperature of the trap is at (or slightly below) saturated steam temperature, regardless of the degree of superheat. Trap Selection. The pressure-containing parts of the steam trap should safely withstand the maximum pressure and temperature conditions of the system. For example, a trap is required for a 1,000 psig (68 bar) main at 950°F (510°C). The normal operating temperature of the trap will be about 546°F (286°C). A Model 5133G trap should be selected, even though several smaller traps are capable of handling the working pressure. For Superheat Service: 1. Don’t oversize the orifice; a restricted orifice may be advisable. 2. Specify a burnished valve and seat and an extended inlet tube and check valve. 3. Provide a drip leg of adequate diameter and length. 4. Provide a generous length (2'-3') of inlet piping, with the trap below the main. 5. Don’t insulate the trap or the inlet piping. Connections Screwed NPT and BSPT Socketweld Flanged See page ST-100 for dimensional information for flanged and socketweld connections. Materials Body: ASTM A182 F22 Class 3 Internals: All stainless steel—304 Valve and seat: 17-4PH Options • Stainless steel internal check valve • Burnished valve and seat For a fully detailed certified drawing, refer to: 5133 CD #1069 5155 CD #1096 5000 Series Inverted Bucket Steam Trap Forged Chrome-moly Steel for Vertical Installation For Pressures to 1,800 psig (124 bar)...Capacities to 5,150 lb/hr (2,336 kg/hr) A A K K B BB G G All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-29 5000 Series Bottom Inlet, Top Outlet Traps Add suffix “CV” to trap number for internal check valve. Model No. Screwed or SW in mm in mm 1/2, 3/4, 1 15, 20, 25 3/4, 1, 1-1/4 20, 25, 32 “A” (Diameter) 8-1/2 216 10-3/8 264 “B” (Height, Screwed or SW) 14-1/4 362 16-1/4 413 “BB” 18-7/8* 429* 20-7/8* 506* “G” (Body OD) 5-3/4 146 7-5/8 194 “K” (C Outlet to C Inlet) 1-5/16 33.3 1-3/4 44.4 Number of Bolts Weight Scr. or SW lb (kg) Weight, Flanged lb (kg) 8 10 Pipe Connections 5133G 5133G-FW 5155G 5155G-FW 171 (77.6) *“BB” dimensions shown are for 1" conn. Class 1500 flanged No. 5133G-FW and 1-1/4" conn. Class 1500 flanged No. 5155G-FW. Consult factory for dimensions of models with other connection sizes and/or flanges. 113 (44.5) 120 (47.6) 185 (83.9) L L Model No. Flanged Series 5133G-5155G Traps Series 5133G-FW & 5155G-FW Traps SteamTrappingand SteamTracingEquipment 92 838_Traps2.qxd 11/4/03 4:12 PM Page ST-29 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

- 31. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 5000 Series Inverted Bucket Steam Trap Forged Chrome-moly Steel for Vertical Installation For Pressures to 1,800 psig (124 bar)...Capacities to 5,150 lb/hr (2,336 kg/hr) Model 5133G Capacity Model 5155G Capacity ST-30 Options Internal Check Valves are spring loaded stainless steel and screw into an extended inlet tube having a pipe coupling at the top to save fittings, labor and money. Internal check valves may result in slightly reduced capacities. Screwed Connections are available in all sizes for pressures of 900 psi or less. Traps for pressures of 900 psi or higher are available with socketweld or flanged connections. Specification Inverted bucket steam trap, type ... in forged chrome-moly steel, with continuous air venting at steam temperature, free-floating stainless steel mechanism, with the discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size • Any options required Pressure-Temperature Rating for Forged Steel Traps °F °C °F °C °F °C °F °C °F °C °F °C °F °C °F °C -20/+650 -28/+343 700 371 750 399 800 427 850 454 900 482 950 510 1,000 538 psig bar psig bar psig bar psig bar psig bar psig bar psig bar psig bar psig bar 5133G 1,500 103 2,120 146 2,120 146 2,120 146 2,120 146 1,990 137 1,730 119 1,350 93 930 64 5155G 1,800 124 2,520 174 2,520 174 2,520 174 2,520 174 2,370 163 2,070 143 1,610 111 1,110 76.5 Maximum allowable pressures shown in boldface will be marked on nameplate, unless otherwise requested. Traps with flanges may have different pressure- temperature ratings. Model No. Max. Oper. Pressure, Sat. Steam Maximum Allowable Pressure (Vessel Design) of Pressure-Containing Parts at Indicated Temperature NOTES: Maximum operating pressure to be marked on nameplate will be determined by actual orifice used. SteamTrappingand SteamTracingEquipment 93 838_Traps2.qxd 11/4/03 4:12 PM Page ST-30 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

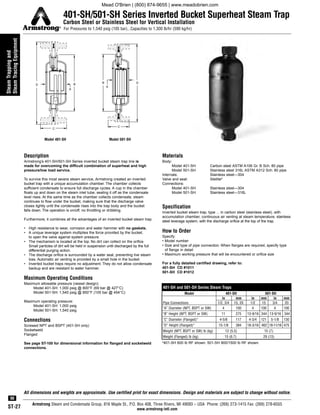

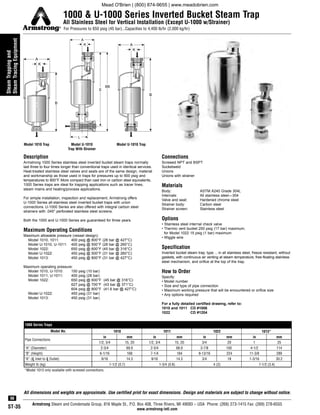

- 32. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 6000 Series Inverted Bucket Steam Trap Forged Chrome-moly Steel for Vertical Installation For Pressures to 2,700 psig (186 bar)...Capacities to 6,500 lb/hr (2,948 kg/hr) A A K K B BB G G Description Armstrong offers its 6000 Series forged chrome-moly steel traps for vertical installation with a choice of socketweld or flanged connections. A unique leverage system multiplies the force provided by the bucket to open the valve against system pressure. The mechanism is free-floating and has no fixed pivots to create wear or friction. Because the mechanism is located at the top of the trap, no dirt can collect on the orifice. Small particles of dirt are held in suspension until discharged by the full differential purging action when the bucket sinks, pulling the valve off the seat. The discharge orifice is surrounded by a water seal, preventing live steam loss. Automatic air venting is provided by a small vent hole in the bucket.This provides continuous automatic air and CO2 venting at steam temperature. Inverted bucket traps drain continuously, although discharging intermittently, to prevent condensate backup. They are also resistant to water hammer. Operation on Superheat. A normally operating bucket trap is filled with saturated steam and condensate. Superheated steam can enter only as fast as the steam inside can condense. As a result, the temperature of the trap is at (or slightly below) saturated steam temperature, regardless of the degree of superheat. Trap Selection. The pressure-containing parts of the steam trap should safely withstand the maximum pressure and temperature conditions of the system. For example, a trap is required for a 1,500 psig (102 bar) main at 1,000°F (538°C). The normal operating temperature of the trap will be about 596°F (299°C). A Model 6155G trap should be selected, even though several smaller traps are capable of handling the working pressure. For Superheat Service: 1. Don’t oversize the orifice; a restricted orifice may be advisable. 2. Specify a burnished valve and seat and an extended inlet tube and check valve. 3. Provide a drip leg of adequate diameter and length. 4. Provide a generous length (2'-3') of inlet piping, with the trap below the main. 5. Don’t insulate the trap or the inlet piping. Connections Socketweld Flanged See page ST-100 for dimensions information for flanged and socketweld connections. Materials Body: ASTM A182 F22 Class 3 Internals: All stainless steel—304 Valve and seat: 17-4PH Options • Stainless steel internal check valve • Burnished valve and seat Screwed connections are available in all sizes for pressures of 900 psi or less. Traps for pressures of 900 psi or higher are available with socketweld or flanged connections. Specification Inverted bucket steam trap, type ... 6155G in forged chrome-moly steel, with continuous air venting at steam temperature, free-floating stainless steel mechanism, with the discharge orifice at the top of the trap. How to Order Specify: • Model number • Size and type of pipe connection. When flanges are required, specify type of flange in detail • Maximum working pressure that will be encountered or orifice size • Any options required For a fully detailed certified drawing, refer to CD #1092. All dimensions and weights are approximate. Use certified print for exact dimensions. Design and materials are subject to change without notice. ST-31 6000 Series Bottom Inlet, Top Outlet Traps Add suffix “CV” to trap number for internal check valve. Model No. Screwed or SW Model No. Flanged in mm 1, 1-1/4 25, 32 “A” (Diameter) 11-3/4 298 “B” (Height, Screwed or SW) 24-1/8 613 “BB” 29-11/16* 724* “G” (Body OD) 8-3/8 213 “K” (C Outlet to C Inlet) 1-3/4 44.4 Number of Bolts Weight Scr. or SW lb (kg) Weight, Flanged lb (kg) 340 (154.2) *“BB” dimensions shown are for Class 2500 flanged No. 6155G-FW traps. Consult factory for dimensions of models with other connection sizes and/or flanges. 325 (147.4) 6155G 6155G-FW Pipe Connections L L Model 6155G Traps Model 6155G-FW Traps 10 SteamTrappingand SteamTracingEquipment 94 838_Traps2.qxd 11/4/03 4:12 PM Page ST-31 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next

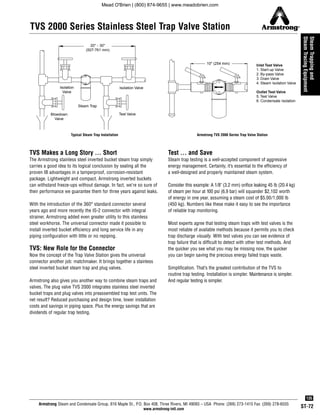

- 33. Armstrong Steam and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555 www.armstrong-intl.com 6000 Series Inverted Bucket Steam Trap Forged Chrome-moly Steel for Vertical Installation For Pressures to 2,700 psig (186 bar)...Capacities to 6,500 lb/hr (2,948 kg/hr) Model 6155G Capacity ST-32 Options Internal Check Valves are spring loaded stainless steel and screw into an extended inlet tube having a pipe coupling at the top to save fittings, labor and money. Internal check valves may result in slightly reduced capacities. Pressure-Temperature Rating for Forged Steel Traps °F °C °F °C °F °C °F °C °F °C °F °C °F °C °F °C -20/+650 -28/+343 700 371 750 399 800 427 850 454 900 482 950 510 1,000 538 psig bar psig bar psig bar psig bar psig bar psig bar psig bar psig bar psig bar 6155G 2,700 186 3,500 241 3,500 241 3,500 241 3,500 241 3,500 241 3,090 213 2,410 166 1,650 114 NOTES:Maximum operating pressure to be marked on nameplate will be determined by actual orifice used. Maximum allowable pressures shown in boldface will be marked on nameplate, unless otherwise requested. Traps with flanges may have different pressure- temperature ratings. Model No. Max. Oper. Pressure, Sat. Steam Maximum Allowable Pressure (Vessel Design) of Pressure-Containing Parts at Indicated Temperature SteamTrappingand SteamTracingEquipment 95 838_Traps2.qxd 11/4/03 4:12 PM Page ST-32 Mead O'Brien | (800) 874-9655 | www.meadobrien.com Next