How fiber optic work

- 2. Now, we hear about fiber-optic cables whenever we talk about telephone system, the cable TV system or the Internet. Fiber-optic lines are made for optically pure glass as thin as a human hair. Fiber-optic carry digital information over long distance. Fiber-optic is used to in medical imaging and mechanical engineering inspection.

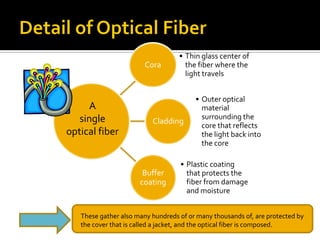

- 3. • Thin glass center of Cora the fiber where the light travels • Outer optical A material single surrounding the Cladding core that reflects optical fiber the light back into the core • Plastic coating Buffer that protects the coating fiber from damage and moisture These gather also many hundreds of or many thousands of, are protected by the cover that is called a jacket, and the optical fiber is composed.

- 4. A fiber-optic cable’s light travels through the core (hallway) by constantly bouncing from the cladding, a principle called total internal reflection. So, the cladding does not absorb any light from the core, the light wave can travel great distances. But some of the light signal degrades within the fiber, mostly due to impurities in the glass. The extent that the signal degrades depends on purity of the glass and the wavelength of the transmitted light.

- 5. Less expensive Non-flammable Thinner Lightweight Higher carrying Flexible capacity Medical imaging Less signal Mechanical imaging degradation Plumbing Light signals Low power Digital signals

- 6. Making a preform glass cylinder Drawing the fibers from the preform Blank Testing the Finished Optic Fiber •Tensile strength •Refractive index profile •Attenuation •Information carrying capacity •Chromatic dispersion •Operating temperature/humidity range •Temperature dependence of attenuation •Ability to conduct light underwater