Uasb water treatment process

- 2. Tropic of The Presentation Is.. 2sakil.iubat@gmail.com

- 3. Introduction The total volume of water on Earth is about 1.4 billion km3. The volume of freshwater resources is around 35 million km3, Of these freshwater resources, about 24 million km3 or 70 percent is in the form of ice and permanent snow cover in the Antarctic and Arctic regions. 3sakil.iubat@gmail.com

- 4. Domestic households, industrial and agricultural practices produce wastewater that can cause pollution of many lakes and rivers. Industry is a huge source of water pollution, it produces pollutants that are extremely harmful to people and the environment. 4sakil.iubat@gmail.com

- 5. One of the more interesting new processes is the up flow anaerobic sludge blanket process (UASB), which was developed by Lettinga and his co- workers in Holland in the early 1970's Anaerobic granular sludge bed technology refers to a special kind of reactor concept for the "high rate" anaerobic treatment of wastewater. 5sakil.iubat@gmail.com

- 6. • Sewage is greatest source of aquatic pollution & public health concern in urban areas of developing countries. • Domestic sewage is defined as human excreta, urine, and the associated sludge (collectively known as blackwater), as well as, kitchen wastewater and wastewater generated through bathing (collectively known as greywater. Several technology in the field of wastewater treatment: *Conventional aerobic treatment in ponds *Trickling Filters ,RBC ,ASP *Anaerobic treatment *Combination of Anaerobic And Aerobic Treatment Adequate treatment system have to be : •Simple in design •Efficient in removing the pollutants •Energy consumption should be low •Re use of water for use purpose •Use of sophisticated equipment must be kept to a minimum. 6sakil.iubat@gmail.com

- 8. Anaerobic Waste Treatment : An Overview Historical development: Mainly used for reducing mass of high solids wastes, e.g. human waste (night soil), animal manure, agricultural waste and sludge Early applications of anaerobic waste treatment include: Mouras automatic scavenger - cited in French journal cosmos in 1881 Septic tank- developed by Donald Cameron in 1895 (England) Imhoff tank: developed by Karl Imhoff in 1905 (Germany) 8sakil.iubat@gmail.com

- 9. Aerobic treatment process - considerable progress in short span of time. Anaerobic technology: energy crisis in 70 and 80’s- a renewed interest in anaerobic process 0 200 400 600 800 1000 1200 1978 1981 1984 1987 1990 1993 1996 1999 No.ofplants Anaeroic treatment plants for industrial applications (Source: Frankin, 2001) 9sakil.iubat@gmail.com

- 10. Definition: Anaerobic treatment is a biological process carried out in the absence of O2 for the stabilization of organic materials by conversion to CH4 and inorganic end-products such as CO2 and NH3. Organic materials + Nutrients CH4 + CO2 +NH3 + Biomass Anaerobic microorganisms Anaerobic processes Anaerobic fermentation Anaerobic respiration Anaerobic Waste Treatment 10sakil.iubat@gmail.com

- 11. COMPLEX ORGANIC MATTERS Proteins Carbohydrates Lipids Amino Acids, Sugars Fatty Acids, Alcohols hydrolysis Acetate Hydrogen, Carbon dioxide acetogenesis INTERMEDIARY PRODUCTS (C>2; Propionate, Butyrate etc) acidogenesis Methane Carbon dioxide Overview Anaerobic Biodegradation methanogenesis 11sakil.iubat@gmail.com

- 12. Doubling Time Cell Yield Cell Activity ks days g VSS g-1 COD g COD g-1 VSS d-1 mM Active Sludge (sugar) Aerobic Bacteria 0.030 0.40 57.8 0.25 Acidification (sugar) Fermentative Bacteria 0.125 0.14 39.6 ND Acetogenesis (fatty acids) Acetogenic Bacteria 3.5 0.03 6.6 0.4 Methanogenesis Autotrophic (H2) 0.5 0.07 19.6 0.004 Acetoclastic (acetate) Methanosarcina 1.5 0.04 11.6 5.0 Methanosaete 7.0 0.02 5.0 0.3 Kinetic Parameters Anaerobes 12sakil.iubat@gmail.com

- 13. Methanosaeta Methanosarcina Growth kinetics of Methanosarcina and Methanosaeta 13sakil.iubat@gmail.com

- 15. Essential conditions for efficient anaerobic treatment • Enough nutrients (N & P) and trace metals especially, Fe, Co, Ni, etc. COD:N:P = 350:7:1 (for highly loaded system) 1000:7:1 (lightly loaded system) • Avoid excessive air/O2 exposure • No toxic/inhibitory compounds present in the influent • Maintain pH between 6.8 –7.2 • Sufficient alkalinity present • Temperature around mesophilic range (30-38 oC) 15sakil.iubat@gmail.com

- 16. Environmental factors The successful operation of anaerobic reactor depends on maintaining the environmental factors close to the comfort of the microorganisms involved in the process. Rule of thumb: Rate of a reaction doubles for every 10 degree rise in temperature Psychrophilic (5 - 15oC) Mesophilic (35 – 40 C) Thermophilic (50-55 oC) Temperature 16sakil.iubat@gmail.com

- 17. Relative activity of methanogens to pH 0.0 0.3 0.5 0.8 1.0 1.3 3 4 5 6 7 8 9 10 11 pH Activity pH range for acidogens is 5.5 – 6.5 Methanogensis 7.8 – 8.2. operating pH for combined cultures is 6.8- 7.4 with neutral pH being the optimum pH Since methanogenesis is considered as a rate limiting step, It is necessary to maintain the reactor pH close to neutral. 17sakil.iubat@gmail.com

- 18. All microbial processes including anaerobic process requires macro (N, P and S) and micro (trace metals) nutrients in sufficient concentration to support biomass synthesis. In addition to N and P, anaerobic microorganisms especially methanogens have specific requirements of trace metals such as Ni, Co, Fe, Mo, Se etc. The nutrients and trace metals requirements for anaerobic process are much lower as only 4 - 10% of the COD removed is converted biomass. Nutrients and trace metals COD:N:P = 350:7:1 Inhibition/Toxicity The toxicity is caused by the substance present in the influent waste or byproducts of the metabolic activities. Ammonia, heavy metals, halogenated compounds, cyanide etc. are the examples of the former type whereas ammonia, sulfide, VFAs belong to latter group. 18sakil.iubat@gmail.com

- 19. Anaerobic Aerobic Organic loading rate: High loading rates:10-40 kg COD/m3-day Low loading rates:0.5-1.5 kg COD/m3-day (for high rate reactors, e.g. AF,UASB, E/FBR) (for activated sludge process) Biomass yield: Low biomass yield:0.05-0.15 kg VSS/kg COD High biomass yield:0.37-0.46 kg VSS/kg COD (biomass yield is not constant but depends on types of substrates metabolized) (biomass yield is fairly constant irrespective of types of substrates metabolized) Specific substrate utilization rate: High rate: 0.75-1.5 kg COD/kg VSS-day Low rate: 0.15-0.75 kg COD/kg VSS-day Start-up time: Long start-up: 1-2 months for mesophilic : 2-3 months for thermophilic Short start-up: 1-2 weeks Comparison between anaerobic and aerobic processes 19sakil.iubat@gmail.com

- 20. Anaerobic Aerobic SRT: Longer SRT is essential to retain the slow growing methanogens within the reactor. Microbiology: Anaerobic process is multi-step process and diverse group of microorganisms degrade the organic matter in a sequential order. Aerobic process is mainly a one-species phenomenon. Environmental factors: The process is highly susceptible to changes in environmental conditions. SRT of 4-10 days is enough in case of activated sludge process. The process is less susceptible to changes in environmental conditions. Continue..…. 20sakil.iubat@gmail.com

- 21. Advantage of anaerobic process 1. Less energy requirement as no aeration is needed 0.5-0.75 kwh energy is needed for every 1 kg of COD removal by aerobic process 2. Energy generation in the form of methane gas 1.16 kwh energy is produced for every 1 kg of COD removal by anaerobic process 3. Less biomass (sludge) generation Anaerobic process produces only 20% of sludge that of aerobic process Soluble BOD 1 kg Aerobic process CO2 + H2O 0.5 kg New biomass 0.5 kg Biodegradable COD 1 kg Anaerobic process CH4 gas > 0.9 kg New biomass < 0.1 kg 21sakil.iubat@gmail.com

- 22. 4. Less nutrients (N & P) requirement Lower biomass synthesis rate also implies less nutrients requirement : 20% of aerobic 5. Application of higher organic loading rate Organic loading rates of 5-10 times higher than that of aerobic processes are possible 6. Space saving Application of higher loading rate requires smaller reactor volume thereby saving the land requirement 7. Ability to transform several hazardous solvents including chloroform, trichloroethylene and trichloroethane to an easily degradable form 22sakil.iubat@gmail.com

- 23. 1. Long start-up time Because of lower biomass synthesis rate, it requires longer start-up time to attain a biomass concentration. 2. Long recovery time If an anaerobic system subjected to disturbances either due to biomass wash-out, toxic substances or shock loading, it may take longer time for the system to return to normal operating condition. 3. Specific nutrients/trace metal requirements Anaerobic microorganisms especially methanogens have specific nutrients e.g. Fe, Ni, and Co requirement for optimum growth. 4. More susceptible to changes in environmental conditions Anaerobic microorganisms especially methanogens are prone to changes in conditions such as temperature, pH, etc. Limitations of anaerobic processes 23sakil.iubat@gmail.com

- 24. 5. Treatment of sulfate rich wastewater The presence of sulfate not only reduces the methane yield due to substrate competition but also inhibits the methanogens due to sulfide production. 6. Effluent quality of treated wastewater The minimum substrate concentration (Smin) from which microorganisms are able to generate energy for their growth and maintenance is much higher for anaerobic treatment system. Owing to this fact, anaerobic processes may not able to degrade the organic matter to the level meeting the discharge limits for ultimate disposal. 7. Treatment of high protein & nitrogen containing wastewater The anaerobic degradation of proteins produces amines which are no longer be degraded anaerobically. Similarly nitrogen remains unchanged during anaerobic treatment. Recently, a process called ANAMMOX ( ANaerobic AMMonium OXididation) has been developed to anaerobically oxidize NH4 + to N2 in presence of nitrite. NH4 + + NO2 - N2 + 2H2O 24sakil.iubat@gmail.com

- 25. Types of anaerobic reactors Low rate anaerobic reactors High rate anaerobic reactors Anaerobic pond Septic tank Standard rate anaerobic digester Imhoff tank Anaerobic Sequencing Batch Reactor (ASBR) Anaerobic contact process Anaerobic filter (AF) Upflow anaerobic slugde Blanket (UASB) Fluidized bed Reactor Hybrid reactor: UASB/AF Slurry type bioreactor, temperature, mixing, SRT or other environmental conditions are not regulated. Loading of 1-2 kg COD/m3-day. Able to retain very high concentration of active biomass in the reactor. Thus extremely high SRT could be maintained irrespective of HRT. Load 5-20 kg COD/m3-d COD removal efficiency : 80-90% . 25sakil.iubat@gmail.com

- 26. UASB was developed in 1970s by Lettinga in the Netherlands. UASB is essentially a suspended growth system in which proper hydraulic and organic loading rate is maintained in order to facilitate the dense biomass aggregation known as granulation. The size of granules is about 1-3 mm diameter. Since granules are bigger in size and heavier, they will settle down and retain within the reactor. The concentration of biomass in the reactor may become as high as 50 g/L. Thus a very high SRT can be achieved even at very low HRT of 4 hours. The granules consist of hydrolytic bacteria, acidogen/acetogens and methanogens. Carbohydrate degrading granules show layered structure with a surface layer of hydrolytic/fermentative Acidogens. A mid-layer comprising of syntrophic colonies and an interior with acetogenic methanogens. Upflow Anaerobic Sludge Blanket (UASB) 26sakil.iubat@gmail.com

- 27. gas cap 3 phase separator weir settler baffles influent effluent gas bubble sludge granule biogas Upward-flow Anaerobic Sludge Blanket sludge bed 27sakil.iubat@gmail.com

- 28. Anaerobic Sludge Granules Physical: dense compact biofilms high settleability high mechanical strength Microbial: balanced microbial community syntrophic partners closely associated high methanogenic activity (0.5 to 2.0 g COD/g VSS.d) protection from toxic shock 28sakil.iubat@gmail.com

- 29. The spaghetti theory of granulation I) disperse methanogens (filamentous Methanosaeta II) floccule formation via entanglement III) pellet formation ("spaghetti balls"); IV) mature granules, with attachment of other anaerobic microorganisms onto the pellet. proposed by Dr. W. Wiegant 29sakil.iubat@gmail.com

- 30. Anaerobic Sludge Granules (close up) 30sakil.iubat@gmail.com

- 31. Acetate as Substrate (Methanosaeta) Sucrose as Substrate (mixed culture) Anaerobic Sludge Granules (SEM) dispersed Anaerobic Sludge Granules (settling) flocculentgranular 31sakil.iubat@gmail.com

- 32. Influent Effluent Recycle Sludge Bed Effluent settler gas cap biogas gas bubble sludge granule Expanded Granular Sludge Bed An expanded granular sludge bed (EGSB) reactor is a variant of the UASB concept (Kato et al. 1994). The distinguishing feature is that a faster rate of upward-flow velocity is designed for the wastewater passing through the sludge bed. The increased flux permits partial expansion (fluidization) of the granular sludge bed, improving wastewater-sludge contact as well as enhancing segregation of small inactive suspended particle from the sludge bed. The increased flow velocity is either accomplished by utilizing tall reactors, or by incorporating an effluent recycle 32sakil.iubat@gmail.com

- 33. Anaerobic contact process (ACP) Anaerobic contact process is essentially an anaerobic activated sludge process. It consists of a completely mixed reactor followed by a settling tank. The settled biomass is recycled back to the reactor. Hence ACP is able to maintain high concentration of biomass in the reactor and thus high SRT irrespective of HRT. Degassifier allows the removal of biogas bubbles (CO2, CH4) attached to sludge which may otherwise float to the surface.. Influent Effluent Waste sludge Recycled sludge Completely mixed reactor Biogas Degassifier Biogas Settling tank 33sakil.iubat@gmail.com

- 34. Anaerobic filter • Anaerobic filter: Young and McCarty in the late 1960s for treat dilute soluble organic wastes. • The filter was filled with rocks similar to the trickling filter. • Wastewater distributed across the bottom and the flow was in the upward direction through the bed of rocks • Whole filter submerged completely . Anaerobic microorganisms accumulate within voids of media (rocks or other plastic media) • The media retain or hold the active biomass within the filter • The non-attached biomass within the interstices forms a bigger flocs of granular shape due to rising gas bubble/liquid • Non-attached biomass contributes significantly to waste treatment • Attached biomass not be a major portion of total biomass. • 64% attached and 36% non-attached 34sakil.iubat@gmail.com

- 35. Upflow Anaerobic Filter Feeding Tank at 4oC Bio gas Effluent Peristaltic Pump Media Perforated Aluminum Plate Sampling Port Heater Constant Temperature Recirculation Line Water Bath Peristaltic Pump Sludge Wastage 35sakil.iubat@gmail.com

- 36. Originally, rocks were employed as packing medium in anaerobic filter. But due to very low void volume (40-50%), serious clogging problem was witnessed. Now, many synthetic packing media made up of plastics, ceramic tiles of different configuration have been used in anaerobic filters. The void volume in these media ranges from 85-95 %. Moreover, these media provide high specific surface area typically 100 m2/m3 or above which enhance biofilm growth. Since anaerobic filter is able to retain high biomass, long SRT could be maintained. Typically HRT varies from 0.5 – 4 days and the loading rates varies from 5 - 15 kg COD/m3-day. Biomass wastage is generally not needed and hydrodynamic conditions play important role in biomass retention within the void space 36sakil.iubat@gmail.com

- 37. Multi-fed Up Flow Anaerobic Filter (MUAF) Waste is fed through several points along the depth of filter. Such feeding strategy has unique benefits:: Wastewater Inletpoints Effluent 1. Homogeneity in biomass distribution 2. Maintenance of completely mixed regime thus preventing short - circuiting and accumulation of VFA. 3. Uniform substrate concentration within the reactor and prevent heavy biomass growth at bottom thus avoids clogging 4. Effective utilization of whole filter bed 37sakil.iubat@gmail.com

- 38. UASB EGSB Hybrid Anaer Filt Fluid. Bed Contact Undefined UASBEGSB contact ? hybrid anaer. filt. fluid. bed EGSB+UASB = 72% Market-Share Granular Sludge Reactors 38sakil.iubat@gmail.com

- 39. OPTIONS FOR POST-TREATMENT OF ANAEROBIC REACTOR EFFLUENTS Beginning with a typical municipal raw wastewater, this level of treatment will generally result in an “enhanced primary” effluent quality, intermediate between primary and secondary (between 30-70 mg/l for BOD5). Post-treatment should be designed to improve the effluent quality in the following parameters. *pathogen contamination (measured by the index of E. coli); *residual organic material (COD/BOD5); *oxygen demand from the reduced forms of N and S; *residual suspended solids (TSS) *inorganic N and P (nutrients) Pond systems Constructed wetlands duckweed Mechanical aerated post treatment basic types of post treatment processes are: 39sakil.iubat@gmail.com

- 40. The government of India has made a major commitment to anaerobic treatment technology in its national river basin improvement program. As of 1996, thirteen new anaerobic treatment plants, with an aggregate treatment capacity of over 306 MLD are under construction in India. The treatment plants described below have been in operation long enough to be able to evaluate their treatment effectiveness and their financial and economic costs and benefits: Indian Scenario A 5 MLD plant in Kanpur, in the state of Uttar Pradesh, built in the late 1989, A 14 MLD plant in Mirzapur, Uttar Pradesh, based on the Kanpur pilot plant design, was commissioned in 1991, A 36 MLD plant in Kanpur reached full performance in 1994, treating a mixture of up to 75 percent municipal wastewater and 25 percent tannery effluent. 40sakil.iubat@gmail.com

- 41. The UASB-process represents one important option for sewage purification in countries with warm climates as it meets the above mentioned basic necessities for a sustainable operation of wastewater treatment plants in developing countries like • Low investment costs, • Low maintenance demand, • Good performance, • Low sludge production • Net energy production. Concluding remarks 41sakil.iubat@gmail.com

- 42. References Journal papers Machdar, Y.Sekiguchi,H.Sumino,A.Ohashi,and H.Harada(1997).combination of a UASB reactor and a curtain type DHS reactor as a cost-effective sewage treatment system for developing countries.Wat.Sci.Tech vol 42 Nos 3-4 pp83-88 IWA publishing 2000. R.A.Barbosa and G.L.Sant’Anna Jr(1989).Treatment Of Domestic Sewage In An UASB Reactor.Wat . Res. Vol.23 , No. 12 pp 1483-1490,1989. G.Lettinga, R.Roersma, and P.Grin, (1983)Anaerobic Treatment of Raw Domestic Sewage At Ambient Temperature Using Agranular Bed UASB reactor.Biotechnology and Bioengineering , vol XXV,pp1701-1723,1983. S.M.M.Vieira and A.D. Garcia Jr.(1992) Sewage Treatment By UASB Reactor ,operation results and recommendation for design and utilization ,Wat.Sci..Tech. Vol.25 No.7 pp.143-157,1992. Sonia M.M. Vieira (1988)Anaerobic Treatment of Domestic Sewage in Brazil – Reaserch Results And Full – scale Experience ,Anaerobic Digestion vol.14 1988. Lalit k . Agarwal , * Hideki Harda and Hiroyuki Okui (1997) Treatment of dilute wastewater in a UASB reactor at a Moderate Temperature : Performance Aspects,Journal of Fermentation and Bioengineering vol.83 ,No. 2 , 179-184.1997. Lalit k . Agarwal , * Hideki Harda and Hiroyuki Okui, Cheng Tseng (1997) Treatment of Wastewater in a UASB Reactor at a Moderate temperature : Microbiological aspects.,Journal of Fermentation and Bioengneering Vol83, No,2 185-190 .1997 Hideki Harda , Shigeki Uemura and Kiyoshi Momonoi(1994) Interaction between sulphate reducing bacteria and methane producing bacteria in UASB reactors fed with low strength wastes containing different levels of sulphate, Wat. Res. Vol.28 No.2 pp 355-367,1994. A.Schellinkhout * and J.Collazos** (1992) Full – Scale Application of the UASB technology For Sewage Treatment, Wat. Res. Vol. 25 No. 7 .PP 159-166.1992 . A.R.M van der Last and G. Lettinga (1992) Anaerobic Treatment of domestic sewage under moderate climatic (dutch) conditions using upflow reactor at increased superficial velocities ,Wat.Sci .Tech. Vol 25 No. 7 pp 167-178 .1992 42sakil.iubat@gmail.com

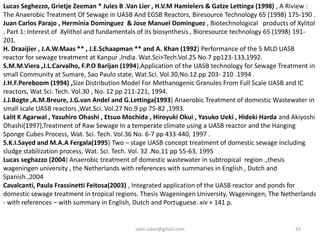

- 43. Lucas Seghezzo, Grietje Zeeman * Jules B .Van Lier , H.V.M Hamlelers & Gatze Lettinga (1998) , A Riview : The Anaerobic Treatment Of Sewage in UASB And EGSB Reactors, Biresource Technology 65 (1998) 175-190 . Juan Carlos Parajo , Herminia Dominguez & Jose Manuel Dominguez , Biotechnological products of Xylitol . Part 1: Interest of Xylithol and fundamentals of its biosynthesis , Bioresource technology 65 (1998) 191- 201. H. Draaijier , J.A.W.Maas ** , J.E.Schaapman ** and A. Khan (1992) Performance of the 5 MLD UASB reactor for sewage treatment at Kanpur ,India. Wat.Sci>Tech.Vol.25 No.7 pp123-133,1992. S.M.M.Viera ,J.L.Carvalho, F.P.O Barijan (1994),Application of the UASB technology for Sewage Treatment in small Community at Sumare, Sao Paulo state, Wat.Sci. Vol.30,No.12.pp 203- 210 .1994 . J.H.F.Pereboom (1994) ,Size Distribution Model For Methanogenic Granules From Full Scale UASB and IC reactors, Wat Sci. Tech. Vol.30 , No. 12 pp 211-221, 1994. J.J.Bogte ,A.M.Breure, J.G.van Andel and G.Lettinga(1993) Anaerobic Treatment of domestic Wastewater in small scale UASB reactors ,Wat.Sci. Vol.27 No.9 pp 75-82 ,1993. Lalit K Agarwal , Yasuhiro Ohashi , Etsuo Mochida , Hiroyuki Okui , Yasuko Ueki , Hideki Harda and Akiyoshi Ohashi(1997),Treatment of Raw Sewage In a temperate climate using a UASB reactor and the Hanging Sponge Cubes Process, Wat. Sci. Tech. Vol.36 No. 6-7 pp 433-440, 1997 . S.K.I.Sayed and M.A.A Fergala(1995) Two – stage UASB concept treatment of domestic sewage including sludge stabilization process, Wat. Sci. Tech. Vol. 32 .No.11 pp 55-63, 1995 Lucas seghazzo (2004) Anaerobic treatment of domestic wastewater in subtropical region .,thesis wageningen university , the Netherlands with references with summaries in English , Dutch and Spanish.,2004 Cavalcanti, Paula Frassinetti Feitosa(2003) , Integrated application of the UASB reactor and ponds for domestic sewage treatment in tropical regions. Thesis Wageningen University, Wageningen, The Netherlands - with references – with summary in English, Dutch and Portuguese. xiv + 141 p. 43sakil.iubat@gmail.com