12 Ways to Use PLCs & SQL Databases Together

- 2. Moderator Don Pearson Chief Strategy Officer Inductive Automation

- 3. Today’s Agenda • Introduction to Ignition • The Origin of SQL Bridge • SQL Bridge vs. Tag Historian • 12 Use Cases for SQL Bridge • Demo: Recipe Management • Q&A

- 4. About Inductive Automation • Founded in 2003 • HMI, SCADA, IIoT software used in 100+ countries • Supported by 1,400+ integrators • 60% average annual growth rate since 2010 Learn more at: inductiveautomation.com/about

- 5. Used by Major Companies Worldwide

- 6. Web-Based Deployment Unlimited Licensing Security & Stability Real-Time Control & Monitoring Rapid Development & Deployment Easy Expandability 6 Reasons Why Ignition is Unique

- 7. Presenter Travis Cox Co-Director of Sales Engineering Inductive Automation

- 10. The Origin of SQL Bridge We recognized a need: • SQL Bridge Module started out as a product called FactorySQL • While working as a control system integrator, our CEO Steve Hechtman came up with an idea to move data between PLCs and SQL databases using OPC.

- 11. The Origin of SQL Bridge We developed a solution: • Steve & his team developed FactorySQL to move data between PLCs and SQL databases. • Like a “Swiss army knife” for integrators to solve a variety of problems • Eventually started Inductive Automation, offered FactorySQL to other integrators, which is now known as SQL Bridge Module and is an essential part of the Ignition platform.

- 12. SQL Bridge vs. Tag Historian

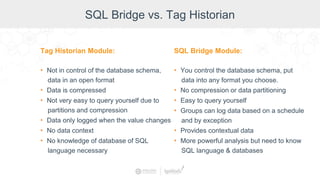

- 13. SQL Bridge vs. Tag Historian Tag Historian Module: • Not in control of the database schema, data in an open format • Data is compressed • Not very easy to query yourself due to partitions and compression • Data only logged when the value changes • No data context • No knowledge of database of SQL language necessary SQL Bridge Module: • You control the database schema, put data into any format you choose. • No compression or data partitioning • Easy to query yourself • Groups can log data based on a schedule and by exception • Provides contextual data • More powerful analysis but need to know SQL language & databases

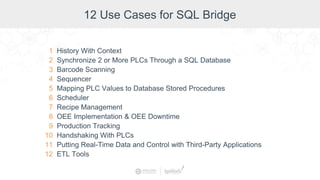

- 14. 12 Use Cases for SQL Bridge 1 History With Context 2 Synchronize 2 or More PLCs Through a SQL Database 3 Barcode Scanning 4 Sequencer 5 Mapping PLC Values to Database Stored Procedures 6 Scheduler 7 Recipe Management 8 OEE Implementation & OEE Downtime 9 Production Tracking 10 Handshaking With PLCs 11 Putting Real-Time Data and Control with Third-Party Applications 12 ETL Tools

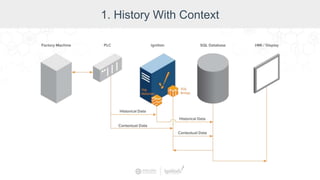

- 15. 1. History With Context • Tag Historian and SQL Bridge work together to connect historical and contextual data • PLC event trigger to log contextual data in a SQL database

- 16. 1. History With Context

- 17. 2. Synchronize 2 or More PLCs Through a SQL Database • Keep 2 PLCs identical at all times • Change in PLC #1 occurs which updates values in PLC #2 and vice versa • Allows communication between different PLC brands and protocols

- 18. 2. Synchronize 2 or More PLCs Through a SQL Database

- 19. 2. Synchronize 2 or More PLCs Through a SQL Database • Another way to synchronize: Use Ignition to synchronize clocks across all PLCs

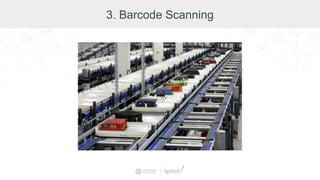

- 20. 3. Barcode Scanning • Action is performed based on a barcode scan • Barcode is scanned, Ignition will check logic in a SQL database • Based on logic, Ignition will send values to a PLC to perform an action

- 22. 4. Sequencer • Uses a procedure kept in a SQL database • Based on value, location, and other criteria, the procedure will send values to the PLC • A sequence of events are performed and are logged into the database once the operation is complete

- 23. 4. Sequencer

- 24. 5. Mapping PLC Values to Database Stored Procedures • Map input/output values • To interface with business systems that have a database that contains a stored procedure • An event happens with a PLC, which is mapped to a stored procedure input. Stored procedure sends down values and writes them to a PLC.

- 25. 5. Mapping PLC Values to Database Stored Procedures

- 26. 6. Scheduler • Similar to sequencer, but based on time values • Control PLCs based on a schedule and outside influences • Map values to a PLC at any time

- 27. 6. Scheduler

- 28. 7. Recipe Management • Recipes should not be stored on a PLC. Store recipes in a database instead. • When a recipe load is triggered, Ignition will take the recipe from the database and load it to the PLC. • SQL database allows for greater flexibility to store more recipes, lets the PLC focus on control.

- 29. 8. OEE Implementation & OEE Downtime • Check the downtime and efficiency of production lines • Simple to perform OEE calculations and have information logged to a database. • Get notifications on downtime and uptimes along with contextual data.

- 30. 8. OEE Implementation & OEE Downtime

- 31. 9. Production Tracking • Know which products have moved through which machines • In addition to OEE downtime, collect data for traceability such as the amount of product being produced, associated work orders, lot numbers. • Create a custom MES system for a very low cost.

- 33. 10. Handshaking with PLCs • Simple handshake with the PLC, so the PLC and SCADA systems are synchronized. • Allows Ignition to notify a PLC if a process has been completed and whether or not it was a success or failure.

- 34. 10. Handshaking with PLCs

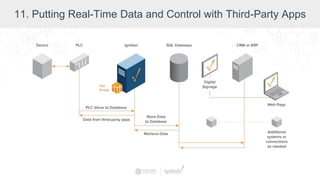

- 35. 11. Putting Real-Time Data and Control with Third-Party Apps • Use open-standard SQL databases to store real-time information • Third-party applications can access data from databases instead of PLCs • Bidirectional functionality of SQL databases allow control values to be sent to PLCs from third-party apps. • Direction of data can be unidirectional or bidirectional

- 36. 11. Putting Real-Time Data and Control with Third-Party Apps

- 37. 11. Putting Real-Time Data and Control with Third-Party Apps

- 38. • Used in data warehousing • Collect data from different systems, parse it, put into database, and potentially load values to PLC • Use a stored procedure to perform this function • Make logic simpler in Ignition, use less scripting 12. ETL (Extract, Transfer, Load) Tool

- 39. 12. ETL (Extract, Transfer, Load) Tool

- 40. Ignition Demo: Recipe Management

- 41. Discover the SQL Bridge Module Incredible power and versatility at a very low price bit.ly/sql-bridge SQL Bridge Module

- 44. Questions & Comments Jim Meisler x227 Vannessa Garcia x231 Ramin Rofagha x251 Vivian Mudge x253 Account Executives Myron Hoertling x224 Shane Miller x218 Melanie Moniz x247 Maria Chinappi x264 Dan Domerofski x273 Lester Ares x214 800-266-7798 x247 Melanie Moniz Director of Sales: Travis Cox (Presenter) Co-Director of Sales Engineering 800-266-7798 x229 travis@inductiveautomation.com