3D printers

- 2. Technical seminar on 3d Printing Presented by Sudarshan GJ

- 3. CONTENTS → Overview of 3D printing → 3D Printing v/s 2D Printing → General Principles → Methods of 3D Printing →3D Printing Materials → Applications → Conclusion → References

- 5. An Overview of 3D Printing The 3D printing technology made its way into the technological world in the year 1986 but did not gain importance until 1990. 3D printing is also known as desktop manufacturing or additive manufacturing. A real object is created from a 3D design. The printer prints 3D models by adding materials like metals, plastics or polymers layer by layer over each other until the required 3 dimensional shape is formed. Fig. 3D printed shoes

- 6. 3D PRINTING V/S 2D PRINTING 3D printing is a form of additive manufacturing whereas 2D printing involves materials cartridges, flexibility of output, and translation of code into a visible pattern. The things that come out of ink-jet/ home printers are images that have been printed on a flat surface. On the other hand, 3D printer prints shaped layers. 3D printing has more applications compared to 2D printing. Though 2D printers are cheaper (100$) ,3D printer has its own advantage. Developers are constantly creating new 3D printers that are affordable and user-friendly.

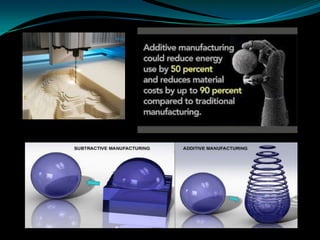

- 8. GENERAL PRINCIPLES 1. MODELING Additive manufacturing takes virtual blueprints from computer aided design (CAD) or animation modeling software and "slices" them into digital cross-sections for the machine to successively use as a guideline for printing. 2. PRINTING To perform a print, the machine reads the design from an .stl file and lays down successive layers of liquid, powder, paper or sheet material to build the model from a series of cross sections 3. FINISHING

- 9. METHODS OF 3D PRINTING The main difference between the different methods of 3D printing is how layers are built to create parts Most widely used technologies are : – SLS (selective laser sintering) – FDM (fused deposition modeling) – SLA (stereolithograhpy) Other methods include PolyJet photopolymer, Syringe Extrusion, Selective laser melting , Electron Beam Melting (EBM)

- 10. ULTRAVIOLET LASERS 1. Lasers are devices that produce intense beams of light which are monochromatic, coherent, and highly collimated. 2. Laser diodes normally based on gallium nitride (GaN), emit in the near-ultraviolet region are used for 3D printing. 3. The short wavelength allows precise focusing and the generation of very fine structures (provided that a light source with high spatial coherence is used). Monomer Polymerization Per polymer Coating Polymer U V U V 4. UV light cures and hardens these polymers with each pass over the object.

- 11. STEREOLITHOGRAPHY Stereolithography (SL or SLA from Stereolithography Apparatus) is an additive manufacturing process using a vat of liquid UV-curable photopolymer "resin" and a UV laser to build parts one layer at a time.

- 13. SELECTIVE LASER SINTERING(SLS) Selective laser sintering (SLS) is an additive manufacturing technique. It uses a high power laser (for example, a carbon dioxide laser) This fuses small particles of plastic, metal (direct metal laser sintering),ceramic or glass powders into a mass that has a desired 3-dimensional shape.

- 14. OTHER METHODS POLY-JET PHOTOPOLYMER • A jetting head slides back and forth along an X-axis, like a line printer, depositing a single-layer of photopolymer onto the build tray. Immediately following each layer built, ultraviolet (UV) light is applied to cure resin material used. • The technology allows for various materials and colors to be incorporated into single prints, and at high resolutions. SYRINGE EXTRUSION • Almost any material that has a creamy viscosity can be used in 3D printers equipped with syringe extruders.

- 16. 3D PRINTING MATERIALS Many different materials can be used for 3D printing, such as ABS plastic, PLA, polyamide (nylon), glass filled polyamide, stereo lithography materials(epoxy resins), silver, titanium, steel, wax, photopolymers and polycarbonate. The other materials used are a. Strong and Flexible plastic b. Alumide c. Steel and sterling steel d. Brass e. Bronze f. Ceramics e. c . b. a .

- 17. APPLICATIONS INDUSTRIAL 3D PRINTING – Stratasys, Ltd. is a manufacturer of 3D printers and 3D production systems for office-based rapid prototyping and direct digital manufacturing solutions. – Assisted NASA engineers while developing Curiosity Mars Rover. CLOTHING AND ACCESSORIES – Companies such as Hip Hop Factory are printing jewellery. – Retailers such as New Balance are printing shoes. – Designers such as Ron Arab are printing sun glasses .

- 18. APPLICATIONS (contd..) MEDICAL – For highly accurate surgical guides and prototypes that mimic the look and feel of the finished medical device, including clear and rubberlike materials. ARCHITECTURE – Poly Jet 3D printers produce astonishingly smooth and detailed architectural models in an array of materials which can be painted readily

- 20. 3D DOODLER 3Doodler The world's first 3D Printing Pen. Developed by Peter Dilworth and Maxwell Bogue of WobbleWorks LLC. It utilizes plastic thread made of either acrylonitrile butadiene styrene (”ABS”) or polylactic acid (”PLA”) that is melted and then cooled through a patented process while moving through the pen, which can then be used to make 3D objects by hand.

- 22. FUTURE OF 3D PRINTING 3D Printed Organs Scientists at Organovo in San Diego have, for the very first time, been able to 3D print tiny replicas of human livers. But if these itty bitty livers are of any indication, then the real deal is on its way. 3D Printed Food Anjan Contractor, a Senior Mechanical Engineer at Systems and Materials Research Corporation(SMRC) in USA hopes to use additive manufacturing to help the continually exponentially increasing population on Earth. NASA has awarded a Small Business Innovation Research (SBIR) to study the feasibility of using 3D printing, for making food in space.

- 23. CONCLUSION 3D Printing technology could revolutionize and re-shape the world. Advances in 3D printing technology can significantly change and improve the way we manufacture products and produce goods worldwide. 3D printing can enable fast, reliable, and repeatable means of producing tailor-made products which can still be made inexpensively due to automation of processes and distribution of manufacturing needs 3D printing may soon start an industry in which everyone has the possibility of being a manufacturer.

- 24. REFERENCES Wikipedia, en.wikipedia.org/wiki/3D_printing Berman, A. “3-D Printing Making the Virtual Real.”EDUCAUSE Evolving TechnologiesCommittee. 2007. Web.1 May 2010. 3D printing: Basic concepts mathematics and technologies Anastasiou, A. Biomed. Eng. Lab., Nat. Tech. Univ. of Athens, Athens, Greece Tsirmpas, C. ; Rompas, A. ; Giokas, K ; Koutsouris, D.(2013) Shapeways, www.shapeways.com 3D Printing Industry, 3dprintingindustry.com Gizmodo, www.gizmodo.com Wired, www.wired.com