5 Biggest Risks to Effective Asset Management

- 1. 5 Biggest Risks to Effective Asset Management © Life Cycle Engineering

- 2. There are five common risks that contribute to an organization’s failure to optimally manage their assets. © Life Cycle Engineering

- 3. 1. Not Knowing What You Have © Life Cycle Engineering

- 4. While it might seem intuitively obvious, many organizations either don’t appreciate the need to know with a high level of confidence the assets that they have, or they choose not to take the time to do so. © Life Cycle Engineering

- 5. 2. Over or Under-Maintenance © Life Cycle Engineering

- 6. The typical organization that is accustomed to over-maintaining its assets will most likely be performing intrusive maintenance tasks more frequently, reducing uptime. © Life Cycle Engineering

- 7. The typical organization that is accustomed to under-maintaining its assets often views maintenance as a business expense open to cutting like any other in order to maximize profits. © Life Cycle Engineering

- 8. With these pressures, maintenance departments are constantly struggling with how to balance cost with the performance requirements for the assets such as reliability and uptime. © Life Cycle Engineering

- 9. 3. Improper Operation © Life Cycle Engineering

- 10. The best guidance we can give with respect to this issue is to: 1) find out how your assets should be run; 2) understand the effects of operating outside of design ranges; and 3) if you can’t operate within the ranges, understand the risks or mitigate the risk. © Life Cycle Engineering

- 11. 4. Improper Risk Management © Life Cycle Engineering

- 12. The basic tenet of best practices for asset management dictates that a plan is implemented that not only manages the operation and maintenance of an organization’s assets but also manages the risks associated with the ownership and use of the assets. © Life Cycle Engineering

- 13. 5. Sub-Optimized Asset Management Systems © Life Cycle Engineering

- 14. This generally stems from shortcuts taken during the EAM implementation. The way to fully address this issue is to either do it right the first time or pay more to do it later. © Life Cycle Engineering

- 15. True excellence in asset management performance lies not only in avoiding the pitfalls but also in turning every opportunity to fail into an opportunity to excel. © Life Cycle Engineering

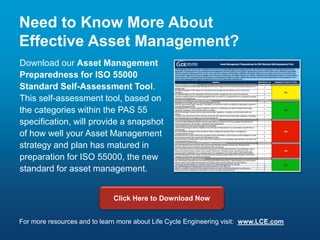

- 16. Need to Know More About Effective Asset Management? Download our Asset Management Preparedness for ISO 55000 Standard Self-Assessment Tool. This self-assessment tool, based on the categories within the PAS 55 specification, will provide a snapshot of how well your Asset Management strategy and plan has matured in preparation for ISO 55000, the new standard for asset management. Click Here to Download Now For more resources and to learn more about Life Cycle Engineering visit: www.LCE.com

- 17. About Life Cycle Engineering Life Cycle Engineering (LCE) provides consulting, engineering, applied technology and education solutions that deliver lasting results for private industry, the Department of Defense and other government organizations. The quality, expertise and dedication of our employees enable Life Cycle Engineering to serve as a trusted resource that helps people and organizations to achieve their full potential. Founded in 1976, LCE is headquartered in Charleston, South Carolina with offices across North America and experience around the globe. Got a specific problem you’re trying to solve? Chances are that we have helped someone solve a similar problem. Email info@LCE.com and we’ll explain how we helped. Or visit our website www.LCE.com. The Life Cycle Institute’s Risk-Based Asset Management course steps you through the fundamental building blocks to create a strategy for implementing a successful asset management program from cradle to grave. Learn more. Life Cycle Engineering's experts have written serveral articles on Asset Management. Learn more. Life Cycle Engineering offers Asset Management Services. Learn more. TRAINING: ARTICLES: SERVICES: