AIR COOLED HEAT EXCHANGER

- 1. NATIONAL REFINERY LIMITED AIR COOLED HEAT EXCHANGER Process & Maintenance AHSAN SHAKIL (SENIOR MANAGEMENT TRAINEE) 9/22/2015

- 2. Air Cooled Heat Exchanger It belongs to that type of heat exchanger in which air is used as a cooling medium for liquids and vapors, commonly used where there is shortage of water or in other case when entire water supply is being utilized for heat exchange and still further coolant is required. Thus employing air cooled heat exchanger enables to get rid of extensive water treatment techniques and cooling water circuit. On the other hand, they are more expensive than shell and tube heat exchanger and comprised of large foot print. Thus they are usually installed on pipe racks. The minimum temperature to which the process stream can be cooled is 5C above the ambient air temperature. Types Forced Draught (push) Induced Draught (pull) Induced Draught is favored over forced draught when: Hot air recirculation is to be avoided Uniform air distribution is required Less affected by climatic conditions (rain, snow) because of top covered Disadvantages associated with induced draught include: Higher power consumption Fan maintenance more difficult Main Components of Air Cooled Heat Exchanger Axial fan Tube bundle Header Tube supports Fins Nozzles

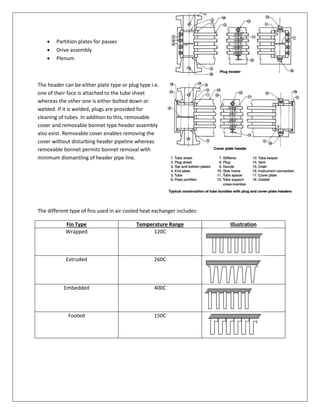

- 3. Partition plates for passes Drive assembly Plenum The header can be either plate type or plug type i.e. one of their face is attached to the tube sheet whereas the other one is either bolted down or welded. If it is welded, plugs are provided for cleaning of tubes. In addition to this, removable cover and removable bonnet type header assembly also exist. Removable cover enables removing the cover without disturbing header pipeline whereas removable bonnet permits bonnet removal with minimum dismantling of header pipe line. The different type of fins used in air cooled heat exchanger includes: Fin Type Temperature Range Illustration Wrapped 120C Extruded 260C Embedded 400C Footed 150C

- 4. Factors Since air is used as a coolant having low thermal conductivity, heat transfer is promoted using extended surfaces called fins, which increases the surface area and ultimately the air side heat transfer coefficient. Fin efficiency depends on thermal conductivity and geometry of fins. Since air moves in perpendicular direction to tube side, considering first row, the air temperature varies in longitudinal direction because heat transferred varies from point to point. Similarly for the second row, temperature differences also vary and temperature changes experienced by the air are different from preceding row. Fowling Fowling refers to uniform accumulation of suspended particles on a surface. It does not involve any sort of reaction and settlement is temporary I.e. it can removed by high velocity stream. External surface of the tubes start to fowl as a result of environmental dust, thus from maintenance point of view, compressed air having pressure up to 600psi is used. Inspection Inspection of following parts/condition is carried out for smooth operation of air cooled heat exchanger: Header/Bolts Gasket Corrosion/Erosion Damaged fin Leakage

- 5. Design For sizing/designing of air cooled heat exchanger, ACHEX proves to be fruitful. References API 661 Heat transfer in Process Engineering (Eduardo Cao)