An investigation on the inspection of grey & finished knit fabric in wet processinge

- 1. PROJECT ON An investigation on the inspection of grey & finished knit fabric in wet processing

- 2. SOUTHEAST UNIVERSITY SOUTHEAST UNIVERSITY WELCOME TO OUR PRESENTATION

- 3. Company profile Name of the Company: Aman Tex Ltd Year of Establishment: 2009 Manufacturing products: Export oriented knit fabrics dyeing and readymade garments Owner and directors of the factory: MD. RAFIQUL ISLAM Factory Address: Boiragirchala ,Sreepur Gazipur, Bangladesh Total Employees: 5900 Number of units: 4 (Four) units Part-A: Knitting unit Part-B: Dyeing unit Part-C: Garments unit – 3 floors Part-D: Printing unit Total area: 271,000 square feet.

- 4. INDRODUCTION After fabric is received, inspection should be done to determine its acceptability from a quality view point; otherwise extra cost in garment manufacturing may be returns and dissatisfaction due to poor fabric quality. Either way fabric inspection after the fabric production process will release the burden responsibility at the marking, spreading and cutting section. As a result a spreader will be concentrating more in spreading rather to worry about fabric inspection and detecting faults.

- 5. Aim of the project 1. Research. 2. Analysis various inspection Fault in different process of wet processing and find out the remedial measure. 3. Product testing. 4. Product Quality improvement. 5. Reduce wastage. 6. To maximize the production. 7. To minimize the production cost.

- 6. Inspection Machine Fabric inspection is usually done on fabric inspection machines such as those shown in the Figure. These machines are designed so that fabric rolls can be mounted behind the inspection table under adequate light and rerolled as they leave the table. This inspection m/c is either power driven or the inspector pulls the fabric over the inspection table. The defects are tracked, marked and recorded on an inspection sheets

- 7. Fabric Inspection When, why, where Producer likes to know the quality of his products (says quality for 500,000 yds fabric) Buyer wants to assure the product quality he ordered. 10% check will give buyer some ideas of his product quality 25% check maybe necessary for new supplier 3% check maybe enough for a proven record supplier Fabric inspection must be selected randomly The fabric sample must be selected from different place, different lot and different time Inspector must use a packing list and select different bales on different place The samples should be selected from early, middle and late production.

- 8. Inspection Standards 1. Ten Point System Oldest and most used in woven finished fabric 2. Four point System Widely adopted and used in knitted fabric 3. The Graniteville’78 System major and minor types, used in garment pieces AMAN TEX LTD (KNIT COMPOSITE) - All inspection 4 point system

- 9. Grey Fabric Inspection Grey fabric inspection is the process of identifying knitting faults in the knitted fabric just after the grey fabric production in the knitting machine

- 10. Four Point System Four Point System is adopted by American Apparel Manufacturers Association (AAMA) for piece goods knitted fabric. Fabric defects is penaltized by maximum of 4 points. In this system fabric faults are identified with defect points in the scale of 4. I.e. maximum defect point is 4.

- 11. Four Point System Calculation: Such as point =12 WTX1000X39.37 23.82X1000X39.37 MTR = = =52M F/G X F/D 380X47 POINTX100X39.37 16X100X39.37 TOTAL POINT = = =25 (B) F/DXMTR 47X52

- 12. Grey Fabric Inspection Repot of Aman Tex Ltd

- 13. Grey Fabric Inspection Faults 1. Needle Mark 2. Needle Broken 3. Hole Mark 4. Pin Hole 6. Drop Stitches 7. Bariness 8. Loop 9. Lycra Out 5. Star Mark 10. Seat Up

- 14. Grey Fabric Inspection Faults 1. Needle Mark Causes: 1. When a needle breaks down. 2. If a needle or needle hook is slightly bends . 3. If needle does not catch yarn . Remedies: Needle should be straight as well as from broken latch.

- 15. Grey Fabric Inspection Faults 2. Needle Broken Causes: •High Yarn Tension •Bad Setting of the Yarn Feeders •Old & Worn out Needle set Remedies: Ensure uniform & the right Yarn tension on all the feeders. Keep the recommended gap, between the Yarn Feeders & the Needles. Periodically change the complete set of needles.

- 16. Grey Fabric Inspection Faults 3. Hole Mark Causes: Yarn breakage or yarn cracks. If the yarn count is not correct on regarding structure, gauge, course and density. Badly knot or splicing. Yarn feeder badly set. If yarn tension too high Remedies: Yarn strength must be sufficient to withstand the stretch as well as uniform. Use proper count of yarn. Correctly set of yarn feeder. Knot should be given properly.

- 17. Grey Fabric Inspection Faults 4. Pin Hole Causes: Improper tension. Same drive for both knit & tuck stitch. Curved needle latch. Remedies: Different drive have to maintained Needle has to change. Needle has no change.

- 18. Grey Fabric Inspection Faults 5. Star Mark Causes: Yarn tension variation during production. Buckling of the needle latch. Low G.S.M fabric production. Remedies: Maintain same Yarn tension during production. Use good conditioned needles.

- 19. Grey Fabric Inspection Faults 6. Drop Stitches Causes: Defective needle. If yarn is not properly fed during loop formation i.e. not properly laid on to the needle hook. Take-down mechanism too loose. Insufficient yarn tension. Badly set yarn feeder. Remedies: Needle should be straight & well. Proper feeding of yarn during loop formation. Correct take up of the fabric & correct fabric tension. Yarn tension should be properly.

- 20. Grey Fabric Inspection Faults 7. Bariness Causes: Use of irregular yarn having higher long term irregularities. Using different count thread. Remedies: Remove irregular yarn. Use proper yarn count. We can use it for white fabric.

- 21. Grey Fabric Inspection Faults 8. Loop Causes: If needle latch is hard or curve. If yarn tension is loose. Remedies: Clean or change the needle. Set proper yarn tension

- 22. Grey Fabric Inspection Faults 9. Lycra Out Causes: Cause by If lycra is missed or Lycra attach with the yarn. Remedies: Check the feeder and attach lycra.

- 23. Grey Fabric Inspection Faults 10. Seat Up Causes: If needle latch is not work properly. Causes by thick yarn. Improper/large knot. Remedies: Make sure all the latches of needle are closed with feeding yarn after a drop stitch.

- 24. Finished Fabric Inspection Finished inspection is done after dyeing and finishing process to find out the dyeing and finishing faults, calculate the number of faults ,grading and taking decision to accept or reject a finished fabric roll. In AMAN Tex, 4 point system is followed for finished fabric inspection.

- 25. Finished Fabric Inspection Repot of Aman Tex Ltd

- 26. Grey Fabric Inspection Faults 1. Uneven Dyeing 3. Soda Spots 4. Fabric hole 5. Compacting hole 6. Crease Mark 7. Dark Colored oil Spots 8. Softener Mark 9. Batch to Batch Shade variation 10. Roll to roll variation 11. GSM Variation 2. Dye spot

- 27. Finished Fabric Inspection Faults 1. Uneven Dyeing Sources & Causes: Uneven pretreatment (uneven scouring & bleaching). Improper color dosing. Using dyes of high fixation property. Uneven heat-setting in case of synthetic fibers. Lack of control on dyeing m/c. Effects: Dyeing process loss. Fabric waste in garments section. More time. Waste of chemical & dyes. More water & steam. Remedy: By ensuring even pretreatment. By ensuring even heat-setting in case of synthetic fibers. Proper dosing of dyes and chemicals. Proper controlling of dyeing m/c.

- 28. Finished Fabric Inspection Faults 2. Dye spot Sources & Causes: Improper Dissolving of dye particle in bath. Improper Dissolving of caustic soda particle in bath. Effects: Body fabric rejected in the garments section. More dye & caustic. More fabric damage. Less production. Cost highly. Remedies: By proper dissolving of dyes & chemicals.

- 29. Finished Fabric Inspection Faults 3. Soda Spots Sources & causes: Soaping start before wash. CaCO3 or MgCO3 in soaping bath. Remedy: Remove hardness water Use sequestering agent

- 30. Finished Fabric Inspection Faults 4. Fabric hole Sources & causes: More acid of knit fabric in the dyeing section. Highly acidity. Temperature highly. Effects: Damage of the knit fabric. Fabric strength, stiffness & comfortable loss. Waste of acid. Loss Time & Temperature. Remedy: Use standard Acid. Proper dosing of Acid. Proper Control of dyeing m/c. Temperature Control. Proper acid addition.

- 31. Finished Fabric Inspection Faults 5. Compacting hole Sources & Causes: More steam pressure. Low roller RPM . Uneven roller. Remedies: Proper steam pressure. Proper roller RPM. Feeding the even roller in compacting m/c.

- 32. Finished Fabric Inspection Faults 6. Crease Mark Sources & Causes: Poor opening of the fabric rope. Shock cooling of synthetic material. If pump pressure & reel speed is not equal. Due to high speed m/c running. Remedy: •Maintaining proper reel sped & pump speed. •Lower rate rising and cooling the temperature. •Reducing the m/c load. •Higher liquor ratio.

- 33. Finished Fabric Inspection Faults 7. Dark Colored oil Spots Sources & Causes: Often encountered when the goods are given silicone finishing agent treatment in soft flow machine using SILICONES which are NOT jet stable. Remedies: Use jet-stable silicones.

- 34. Finished Fabric Inspection Faults 8. Softener Mark Sources & Causes: Improper mixing of the Softener. Improper running time of the fabric during application of softener. Entanglement of the fabric during application of softener. Remedies: Maintaining proper reel sped & pump speed. Proper Mixing of the softener before addition. Prevent the entanglement of the fabric during application of softener.

- 35. Finished Fabric Inspection Faults 9. Batch to Batch Shade variation Sources & Causes: Fluctuation of Temperature. Improper dosing time of dyes & chemicals. Batch to batch weight variation of dyes and chemicals. Dyes lot variation. Improper reel speed, pump speed, liquor ratio. Improper pretreatment. Remedies: Use standard dyes and chemicals. Maintain the same liquor ratio. Follow the standard pretreatment procedure. Maintain the same dyeing cycle. The pH, hardness and sodium carbonate content supply water should check daily.

- 36. Finished Fabric Inspection Faults 9. Roll to roll variation Sources & Causes: Poor migration property of dyes. Improper dyes solubility. Hardness of water. Faulty m/c speed, etc. Remedies: Use standard dyes and chemicals. Proper m/c speed. Use of soft water.

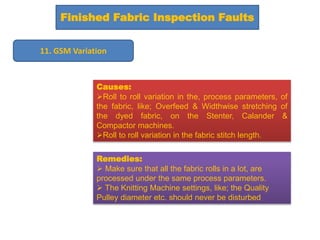

- 37. Finished Fabric Inspection Faults 11. GSM Variation Causes: Roll to roll variation in the, process parameters, of the fabric, like; Overfeed & Widthwise stretching of the dyed fabric, on the Stenter, Calander & Compactor machines. Roll to roll variation in the fabric stitch length. Remedies: Make sure that all the fabric rolls in a lot, are processed under the same process parameters. The Knitting Machine settings, like; the Quality Pulley diameter etc. should never be disturbed

- 38. CONCULATION In Bangladesh most knit dyeing industries are suffering from these above inspection faults. So they faces high production cost & not fulfill the target of production. We observed the grey & finished inspection process at our intern period .We also tried to observe the grey & finished inspection faults , causes of the faults & tried to find out the remedies of the faults. If an industry follows these above remedy measures , it can minimize its production cost and improve quality, productivity and acceptability. We believe that, this project will help us in our future career and we are very hope full that we can utilize this knowledge I our practical job life.

- 39. THANKS TO ALL