arijit summer training

- 1. A PRESENTATION OF VOCATIONAL TRAINING ON COMBINED CYCLE POWER PLANT PRESENTED BY:- ARIJIT ROY VIVEKANANDA GLOBAL UNIVERSITY DIPLOMA 5TH SEM, ELECTRICAL DEPTT. ROLL NO:- 14TEC1EE300

- 2. CONTENTS • INTRODUCTION • OVERVIEW OF PLANT • FLOW DIAGRAM OF CCP • BRAYTON CYCLE • RANKINE CYCLE • BASIC CONCEPTS OF ENERGY CONVERSTION • CONVENTIONAL POWER STATION • WAYS TO INCREASE BRAYTON CYCLE EFFICIENCY • WAYS TO INCREASE RANKINE CYCLE EFFICIENCY • CONFIGURATION CCGT POWER PLANT • COMPONENT USED IN POWER PLANT • CONFIGURATION OF STEAM TURBINE • DM WATER PLANT

- 3. INTRODUCTION One of the largest Country-based Gas & Steam exploration and production company Produces around 72% of North Eastern state's Electricity. The OTPC CCGT Power plant is 726.6 MW power plant having 2 units (2×363.3)= 2(232.39+130.91) (GAS+STEAM)

- 4. OTPC TRIPURA ASSET, PALATANA, TRIPURA Tripura is one of the main work centers of ONGC in North- eastern region. On the based of ONGC newly planted OTPC is now larger production of Electricity of 726.6 MW It is based at PALATANA, UDAIPUR with man power of little more than 600.

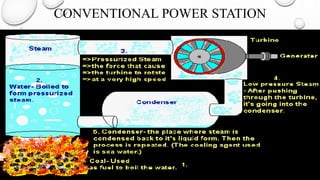

- 6. OVERVIEW: THERMAL POWER PLANT

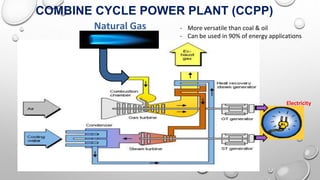

- 7. COMBINE CYCLE POWER PLANT (CCPP) Natural Gas - More versatile than coal & oil - Can be used in 90% of energy applications Electricity

- 8. COMBINED CYCLE GAS TURBINE: • THE COMBINED CYCLE CONSISTS OF THE FOLLOWING TWO CYCLES: BRAYTON CYCLE RANKINE CYCLE

- 9. BASIC CONCEPTS • CHEMICAL ENERGY STORED IN FOSSIL FUELS SUCH AS COAL, FUEL OIL OR NATURAL GAS IS CONVERTED SUCCESSIVELY INTO THERMAL ENERGY MECHANICAL ENERGY ELECTRICAL ENERGY • THE SIMPLE WORD EQUATION FOR THIS CHEMICAL REACTION IS: FUEL + OXYGEN = HEAT + CARBON DI OXIDE + WATER

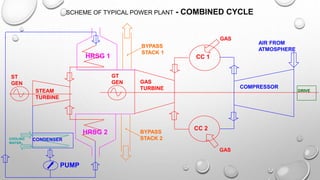

- 11. GAS TURBINE COMPRESSOR CC 1 GAS GAS AIR FROM ATMOSPHERE DRIVE CC 2 BYPASS STACK 2 BYPASS STACK 1 HRSG 1 PUMP STEAM TURBINE HRSG 2 CONDENSERCOOLING WATER GT GEN ST GEN SCHEME OF TYPICAL POWER PLANT - COMBINED CYCLE

- 12. BRAYTON CYCLE • THE IDEAL BRAYTON CYCLE CONSISTS OF FOUR INTERNAL REVERSIBLE PROCESS: 1-2: ISENTROPIC COMPRESSION ( IN COMPRESSOR) 2-3: CONSTANT PRESSURE HEAT ADDITION 3-4: ISENTROPIC EXPANSION ( IN TURBINE) 4-1: CONSTANT PRESSURE HEAT REJECTION

- 13. TO INCREASE THE BRAYTON CYCLE EFFICIENCY • THE BRAYTON CYCLE WITH REGENERATION OR RECUPERATOR. • INTERCOOLING. • RE-HEATING • INTERCOOLING, RE-HEATING & REGENERATION

- 14. RANKINE CYCLE • IDEAL CYCLE FOR VAPOUR PLANTS WITH NO IRREVERSIBILITIES & CONSISTS OF THE FOUR PROCESS: 1-2: ISENTROPIC COMPRESSION IN PUMP. 2-3: CONSTANT PRESSURE HEAT ADDITION IN BOILER. 3-4: ISENTROPIC EXPANSION IN TURBINE. 4-1: CONSTANT PRESSURE HEAT REJECTION IN CONDENSER.

- 15. TO INCREASE THE RANKINE CYCLE EFFICIENCY • LOWERING THE CONDENSER PRESSURE. • SUPER-HEATING THE STEAM TO HIGH TEMPERATURE. • INCREASING THE BOILER PRESSURE.

- 16. CONFIGURATION OF CCGT PLANT THE COMBINED-CYCLE SYSTEM INCLUDES SINGLE-SHAFT & MULTI-SHAFT CONFIGURATIONS. THE SINGLE SHAFT SYSTEM CONSIST OF ONE GAS TURBINE , ONE STEAM TURBINE, ONE GENERATOR & ONE HEAT RECOVERY STEAM GENERATOR (HRSG). KEY ADVANTAGES OF SINGLE-SHAFT ARRANGEMENTS: OPERATING SIMPLICITY, SMALLER FOOTPRINT, LOWER START-UP COST. MULTI –SHAFT SYSTEM HAVE ONE OR MORE GAS TURBINE-GENERATORS & HRSG’S THAT SUPPLY STEAM THROUGH A COMMON HEADER TO A SEPARATE SINGLE STEAM TURBINE- GENETRATOR. IN TERMS OF OVERALL INVESTMENT A MULTI-SHAFT SYSTEM IS ABOUT 5% HIGHER IN COST.

- 17. COMPONENTS USED IN POWER PLANT (GAS TURBINE) • SCRUBBERS: FUEL PASSES THROUGH SCRUBBERS THROUGH 10 INCH HEADER TO REMOVE & TO CONTROL MAJOR DUST & DIRTY PARTICLES ALONG WITH LIQUID GASES. • FLAME ARRESTER: IT IS USED TO AVOID ANY KINGD OF ACCIDENTAL FIRE & ANY ENVIRONMENTAL HAZARD CAUSES DUE TO GAS. • GAS BOOSTING COMPRESSOR: INITIAL GAS IS PASSES THROUGH GBC FOR COMPRESSION TO THE REQUIRED INCREASE IN PRESSURE AND TEMPERATURE. • COOLING TOWER: WATER IS USED A COOLING MEDIUM AT VARIOUS STAGES IN GAS BOOSTING CHAMBER SUCH AS LUBRICATION UNIT & BYPASS CHAMBER. THERE WERE 3 COOLING TOWERS FOR THE PURPOSE WITH 4 FANS.

- 18. CONFIGURATION FOR STEAM TURBINE • THE TURBINE IS A SINGLE SHAFT MACHINE WITH SEPARATE HP-IP (COMBINED) AND LP PARTS. • THE INDIVIDUAL TURBINE ROTORS AND GENERATOR ROTOR ARE CONNECTED BY RIGID COUPLING. • THE HP-IP CYLINDER HAS A THROTTLE CONTROL GOVERNING.

- 19. D.M. WATER PLANT • D.M STANDS FOR DE-MINERALIZATION OF WATER. 1. TURBIDITY OF WATER IS REMOVED. 2. REMOVES BACTERIA & OTHER MICROBES. 3. NEUTRALIZES THE BASES & CONVERTS IT INTO CORRESPONDING ACIDS. 4. REMOVES THE ACIDIC IONS PRESENT IN THE WATER. 5. THE FINAL STAGE, BALANCED REMOVAL OF IONS TAKES PLACE USING A MIXED BED.

Editor's Notes

- - Fuel is burned in the gas turbine - The resulting energy in the gas turbine turns the generator drive shaft - Exhaust heat from the gas turbine is sent to a heat recovery steam generator (HRSG) - The HRSG turns the gas turbine exhaust heat into steam and feeds it to the steam turbine - The steam turbine delivers additional energy to the generator drive shaft - The generator converts the energy into electricity