Asme section ii c new

- 1. SECTIONS I Rules for Construction of Power Boilers II Materials Part A Ferrous Material Specification Part B Non-Ferrous Material Specification Part C Specifications for Welding rods, electrodes and Fille Metals Part D Properties (US Customary) Part D Properties (Metrics) III Subsection NCA --- General Requirements for Division 1 & Division 2 III Division 1 Sub Section NB --- Class 1 Components Sub Section NC --- Class 2 Components Sub Section ND --- Class 3 Components Sub Section NE --- Class MC Components Sub Section NF --- Supports Sub Section NG --- Core Support Structures Sub Section NH --- Class 1 Components in Elevated ASME BOILER AND PRESSURE VESSEL CODES

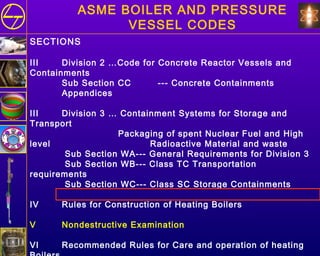

- 2. SECTIONS III Division 2 …Code for Concrete Reactor Vessels and Containments Sub Section CC --- Concrete Containments Appendices III Division 3 … Containment Systems for Storage and Transport Packaging of spent Nuclear Fuel and High level Radioactive Material and waste Sub Section WA--- General Requirements for Division 3 Sub Section WB--- Class TC Transportation requirements Sub Section WC--- Class SC Storage Containments IV Rules for Construction of Heating Boilers V Nondestructive Examination VI Recommended Rules for Care and operation of heating ASME BOILER AND PRESSURE VESSEL CODES

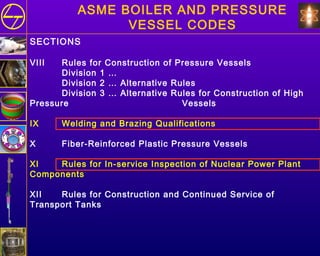

- 3. SECTIONS VIII Rules for Construction of Pressure Vessels Division 1 … Division 2 … Alternative Rules Division 3 … Alternative Rules for Construction of High Pressure Vessels IX Welding and Brazing Qualifications X Fiber-Reinforced Plastic Pressure Vessels XI Rules for In-service Inspection of Nuclear Power Plant Components XII Rules for Construction and Continued Service of Transport Tanks ASME BOILER AND PRESSURE VESSEL CODES

- 4. A Presentation on ASME SECTION II C

- 5. ASME SEC II C Deals with specification for : - Welding Rods - Welding Electrode - Filler metals - Welding Flux

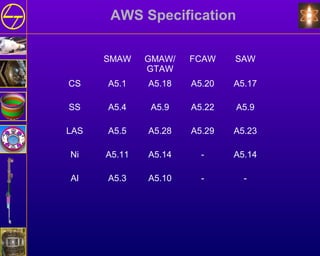

- 6. AWS Specification SMAW GMAW/ GTAW FCAW SAW CS A5.1 A5.18 A5.20 A5.17 SS A5.4 A5.9 A5.22 A5.9 LAS A5.5 A5.28 A5.29 A5.23 Ni A5.11 A5.14 - A5.14 Al A5.3 A5.10 - -

- 7. AWS Specification SFA-5.01 : Filler Metal Procurement Guideline SFA-5.12 : Tungsten & Tungsten-alloy Electrode for Arc Welding & Cutting. SFA-5.13 : Surfacing Electrode for SMAW SFA-5.15 : Welding Electrodes & Rods for Cast Iron SFA-5.21 : Bare Electrodes & Rods for Surfacing. SFA-5.16 : Titanium & Titanium Alloy Welding Electrodes & Rods SFA-5.7 : Copper & Copper Alloy Bare Welding rods & Electrodes.

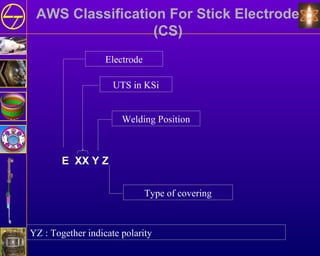

- 8. AWS Classification For Stick Electrode (CS) Electrode UTS in KSi Welding Position Type of covering YZ : Together indicate polarity E XX Y Z

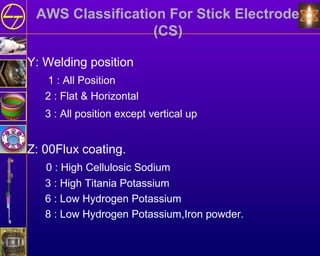

- 9. AWS Classification For Stick Electrode (CS) Y: Welding position 1 : All Position 2 : Flat & Horizontal 3 : All position except vertical up Z: 00Flux coating. 0 : High Cellulosic Sodium 3 : High Titania Potassium 6 : Low Hydrogen Potassium 8 : Low Hydrogen Potassium,Iron powder.

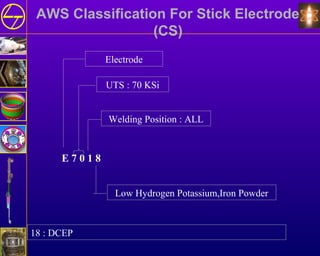

- 10. AWS Classification For Stick Electrode (CS) Electrode UTS : 70 KSi Welding Position : ALL Low Hydrogen Potassium,Iron Powder 18 : DCEP E 7 0 1 8

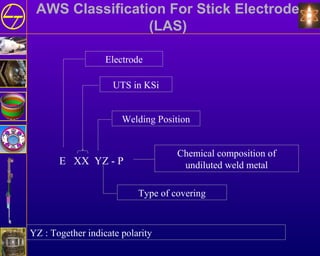

- 11. AWS Classification For Stick Electrode (LAS) Electrode UTS in KSi Welding Position Type of covering YZ : Together indicate polarity Chemical composition of undiluted weld metalE XX YZ - P

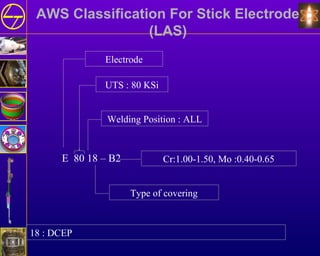

- 12. AWS Classification For Stick Electrode (LAS) Electrode UTS : 80 KSi Welding Position : ALL Type of covering 18 : DCEP Cr:1.00-1.50, Mo :0.40-0.65E 80 18 – B2

- 13. Weld Metal Composition ** Suffix C Mn Si Ni Cr Mo V A1 0.12 0.60 or 1.00* 0.40 or 0.80* -- -- 0.40 – 0.65 -- B1 0.12 0.90 0.60 or 0.80* -- 0.40 – 0.65 0.40 – 0.65 -- B2L 0.05 0.90 0.80 – 1.00 -- 1.00 – 1.50 0.40 – 0.65 -- B2 0.12 0.90 0.60 or 0.80* -- 1.00 – 1.50 0.40 – 0.65 -- B3L 0.05 0.90 0.80 – 1.00 -- 2.00 – 2.50 0.90 – 1.20 -- B3 0.12 0.90 0.60 or 0.80 -- 2.00 – 2.50 0.90 – 1.20 -- B4L 0.05 0.90 1.00 -- 1.75 – 2.25 0.40 – 0.65 -- B5 0.07 0.15 0.40 – 0.60 0.30 – 0.60 -- 0.40 – 0.60 1.00 – 1.25 0.05 C1 0.12 1.20 0.60 or 0.80* 2.00 – 2.75 -- -- -- C2 0.12 1.20 0.60 or 0.80* 3.00 – 3.75 -- -- -- C3 0.12 0.40 – 1.25 0.80 0.80 – 1.10 0.15 0.35 0.05 D1 0.12 1.25 – 1.75 0.60 or 0.80* -- -- 0.25 – 0.45 -- D2 0.15 1.65 – 2.00 0.60 or 0.80* -- -- 0.25 – 0.45 -- G*** -- 1.00 min 0.80 min 0.50 min 0.30 min 0.20 min 0.10 min M+* 0.110 0.60 – 2.25* 0.60 or 0.80* 1.25 – 2.50* 0.15 – 1.50* 0.25 – 0.55* 0.05 * Amount depends on electrode classification. ** Compositions are maximum unless otherwise indicated. *** Electrodes of the “G” classification require only one of the alloying elements listed. +* The “M” suffix is used to cover military electrode classifications. Suffix : Chemical composition of low alloy high tensile steel weld deposit.

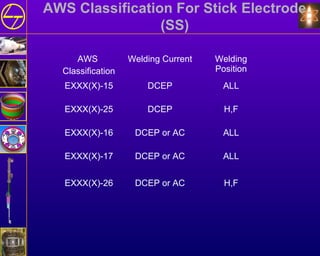

- 14. AWS Classification For Stick Electrode (SS) AWS Classification Welding Current Welding Position EXXX(X)-15 DCEP ALL EXXX(X)-25 DCEP H,F EXXX(X)-16 DCEP or AC ALL EXXX(X)-17 DCEP or AC ALL EXXX(X)-26 DCEP or AC H,F

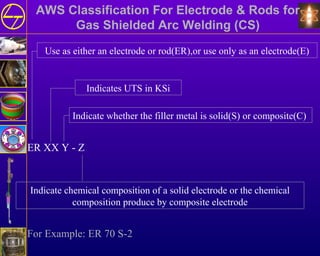

- 15. AWS Classification For Electrode & Rods for Gas Shielded Arc Welding (CS) Use as either an electrode or rod(ER),or use only as an electrode(E) Indicates UTS in KSi Indicate whether the filler metal is solid(S) or composite(C) Indicate chemical composition of a solid electrode or the chemical composition produce by composite electrode For Example: ER 70 S-2 ER XX Y - Z

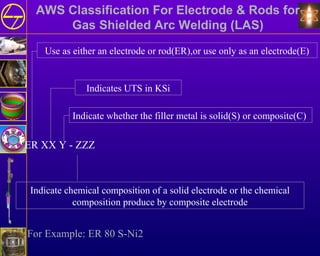

- 16. AWS Classification For Electrode & Rods for Gas Shielded Arc Welding (LAS) Use as either an electrode or rod(ER),or use only as an electrode(E) Indicates UTS in KSi Indicate whether the filler metal is solid(S) or composite(C) Indicate chemical composition of a solid electrode or the chemical composition produce by composite electrode For Example: ER 80 S-Ni2 ER XX Y - ZZZ

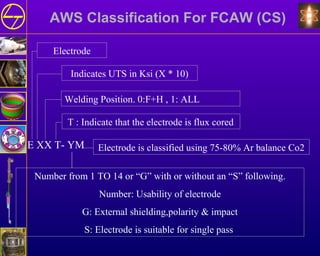

- 17. AWS Classification For FCAW (CS) Electrode Indicates UTS in Ksi (X * 10) T : Indicate that the electrode is flux cored Number from 1 TO 14 or “G” with or without an “S” following. Number: Usability of electrode G: External shielding,polarity & impact S: Electrode is suitable for single pass Welding Position. 0:F+H , 1: ALL Electrode is classified using 75-80% Ar balance Co2E XX T- YM

- 18. AWS Classification For FCAW (CS) Electrode UTS : 70Ksi T : Indicate that the electrode is flux cored Classified using CO2 gas. Designed for single & multi pass welding using DCEP polarity.Electrode characterize by spray transfer,low spatter loss,flat to slightly convex bead contour,& a moderate volume of slag which completely cover the weld bead.Rutile base slag & high deposition rates. Welding Position:ALL E 71 T - 1

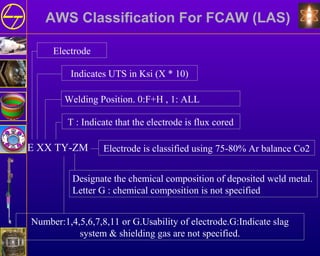

- 19. AWS Classification For FCAW (LAS) Electrode Indicates UTS in Ksi (X * 10) T : Indicate that the electrode is flux cored Number:1,4,5,6,7,8,11 or G.Usability of electrode.G:Indicate slag system & shielding gas are not specified. Welding Position. 0:F+H , 1: ALL Electrode is classified using 75-80% Ar balance Co2 Designate the chemical composition of deposited weld metal. Letter G : chemical composition is not specified E XX TY-ZM

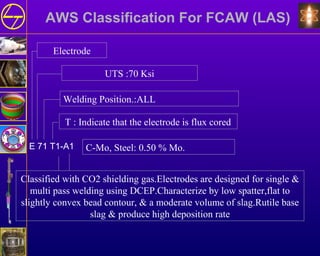

- 20. AWS Classification For FCAW (LAS) Electrode UTS :70 Ksi T : Indicate that the electrode is flux cored Classified with CO2 shielding gas.Electrodes are designed for single & multi pass welding using DCEP.Characterize by low spatter,flat to slightly convex bead contour, & a moderate volume of slag.Rutile base slag & produce high deposition rate Welding Position.:ALL C-Mo, Steel: 0.50 % Mo.E 71 T1-A1

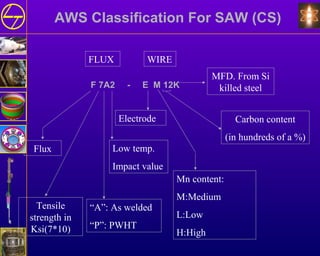

- 21. AWS Classification For SAW (CS) Flux Tensile strength in Ksi(7*10) “A”: As welded “P”: PWHT Low temp. Impact value Electrode Mn content: M:Medium L:Low H:High MFD. From Si killed steel Carbon content (in hundreds of a %) FLUX WIRE F 7A2 - E M 12K

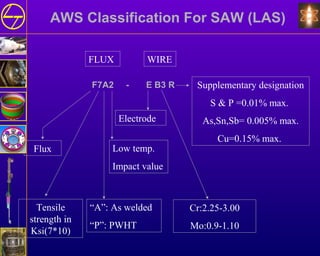

- 22. AWS Classification For SAW (LAS) Flux Tensile strength in Ksi(7*10) “A”: As welded “P”: PWHT Low temp. Impact value Electrode Cr:2.25-3.00 Mo:0.9-1.10 FLUX WIRE Supplementary designation S & P =0.01% max. As,Sn,Sb= 0.005% max. Cu=0.15% max. F7A2 - E B3 R

- 23. Thank You