Assignment on 3 d printing

- 1. BANGLADESH UNIVERSITY OF BUSINESS AND TECHNOLOGY Assignment on 3D Printing Course Code-TXE-317 Submitted by Jotish Chandra roy ID:12132107059 8th Intake(2)

- 2. What is 3D printing? 3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the entire object is created. Each of these layers can be seen as a thinly sliced horizontal cross-sectionof the eventual object. How does 3D printing work? It all starts with making a virtual design of the object you want to create. This virtual design is made in a CAD (Computer Aided Design) file using a 3D modeling program (for the creation of a totally new object) or with the use of a 3D scanner (to copy an existing object). A 3D scanner makes a 3D digital copy of an object.3d scanners use different technologies to generate a 3d model such as time- of-flight, structured / modulated light, volumetric scanning and many more. Recently, many IT companies like Microsoft and Google enabled their hardware to perform 3d scanning, a great example is Microsoft’s Kindest. This is a clear sign that future hand-held devices like smart phones will have integrated 3d scanners. Digitizing real objects into 3d models will become as easy as taking a picture. Prices of 3d scanners range from very expensive professional industrial devices to 30 USD DIY devices anyone can make at home. Below you’ll find a short demonstration of the process of 3D scanning with a professional HDI 3D scanner that uses structured light: To prepare a digital file for printing, the 3D modeling software “slices” the final model into hundreds or thousands of horizontal layers.

- 3. Processes and technologies Not all 3D printers use the same technology. There are several ways to print and all those available are additive, differing mainly in the way layers are build to create the final object. Some methods use melting or softening material to produce the layers. Selective laser sintering (SLS) and fused deposition modeling (FDM) are the most common technologies using this way of printing. Another method of printing is when we talk about curing a photo-reactive resin with a UV laser or another similar power source one layer at a time. The most common technology using this method is called stereo lithography (SLA). To be more precise: since 2010, the American Society for Testing and Materials (ASTM) group “ASTM F42 – Additive Manufacturing”, developed a set of standards that classify the Additive Manufacturing processes into 7 categories according to Standard Terminology for Additive Manufacturing Technologies.Theseseven processesare: 1. Vat Photo polymerization 2. MaterialJetting 3. Binder Jetting 4. MaterialExtrusion 5. Powder BedFusion 6. SheetLamination 7. Directed EnergyDeposition Vat Photo polymerization A 3D printer based on the Vat Photo polymerization method has a container filled with photopolymer resin which is then hardened with UV light source.

- 4. Vat photo polymerization schematics. Image source: lboro.ac.uk The most commonly used technology in these processes is Stereo lithography (SLA). This technology employs a vat of liquid ultraviolet curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and joins it to the layer below. Material Jetting In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by- layer to a build platform making a 3D object and then hardened by UV light.

- 5. Binder Jetting With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the shape of a programmed 3D object. The finished object is “glued together” by binder remains in the container with the powder base material. After the print is finished, the remaining powder is cleaned off and used for 3D printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993 and in 1995 Z Corporation obtained an exclusive license.

- 6. Material Extrusion The most commonly used technology in this process is fused deposition modeling (FDM)

- 7. Fused deposition modeling (FDM), a method of rapid prototyping: 1 – nozzle ejecting molten material (plastic), 2 – deposited material (modeled part), 3 – controlled movable table. Image source: Wikipedia, made by user Uzbeks under CC Attribution-Share Alike 4.0 International license. The FDM technology works using a plastic filament or metal wire which is unwound from a coil and supplying material to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. Powder Bed Fusion The most commonly used technology in these processes is Selective laser sintering (SLS)

- 8. SLS system schematic. Image source: Wikipedia from user Material geezer under Creative Commons Attribution-Share Alike 3.0 Unsorted license This technology uses a high power laser to fuse small particles of plastic, metal, ceramic or glass powders into a mass that has the desired three dimensional shapes. The laser selectively fuses the powdered material by scanning the cross-sections (or layers) generated by the 3D modeling program on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed. All untouched powder remains as it is and becomes a support structure for the object. Therefore there is no need for any support structure which is an advantage over SLS and SLA. All unused powder can be used for the next print. SLS was developed and patented by Dr. Carl Deckard at the University of Texas in the mid- 1980s, under sponsorship ofDARPA.

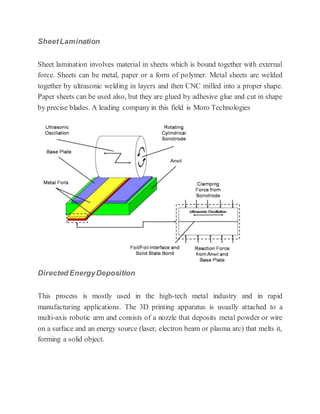

- 9. SheetLamination Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades. A leading company in this field is Moro Technologies Directed EnergyDeposition This process is mostly used in the high-tech metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

- 10. Examples& applicationsof 3D printing Applications include rapid prototyping, architectural scale models & banquettes, healthcare (3d printed prosthetics and printing with human tissue) and entertainment (e.g. film props).Other examples of 3D printing would include reconstructing fossils in paleontology, replicating ancient artifacts in archaeology, reconstructing bones and body parts in forensic pathology and reconstructing heavily damaged evidence acquired from crime scene investigations. 3D printing industry The worldwide 3D printing industry is expected to grow from $3.07B in revenue in 2013 to $12.8B by 2018, and exceed $21B in worldwide revenue by 2020. As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.