AVEVA World Conference NA - Tom Singer, Aker Solutions

- 1. © 2018 Aker Solutions Optimized Concepts Through Digital Front End Design Houston, February 2018 Tom Singer, Chief Engineer - Facility Architecture, Front End, Oslo

- 2. © 2018 Aker Solutions February 23, 2018Optimized Concepts Through Digital Front End Design Slide 2 14,000EMPLOYEES 20COUNTRIES 50LOCATIONS Aker Solutions creates solutions to unlock energy safely and sustainably for future generations

- 3. © 2018 Aker Solutions Expertise From subsea to surface and concept to decommissioning, our technical expertise and strong partnerships provide energy companies what they need to succeed February 23, 2018Optimized Concepts Through Digital Front End Design Slide 3 Subsea Production Systems Field Planning, Feasibility and Concept Studies Carbon Capture, Utilization and Storage Subsea Pumps, Compression and Processing Asset Integrity Management Maintenance, Modifications and Operations Fixed and Floating Production Systems Lifecycle Services Decommissioning Hook-Up and Completion

- 4. © 2018 Aker Solutions We Are Ready to Move to the Next Level Engineering a Sustainable Future Johan Castberg World Leading Technology Subsea Compression 2.0 Unlocking Value in Marginal Fields Lean Semi February 23, 2018 Slide 4Optimized Concepts Through Digital Front End Design

- 5. © 2018 Aker Solutions Working Together February 23, 2018Optimized Concepts Through Digital Front End Design Slide 5 1990s PDMS/PEGS and other AVEVA product users since 1992 Control object philosophy with progress and quality measurement KPIs done by PDMS Structural joint development program PDMS Global joint development (1999/2000) 2000s PDMS Global rollout in Workshare projects (2003) Global AKSO standardization in 3D space Joint development on Stairs, Rails and Ladders (2007) 2010s Signed new AVEVA contract (2015) Strategic Joint Development program

- 6. © 2018 Aker Solutions February 23, 2018Optimized Concepts Through Digital Front End Design Slide 6 Transforming our customer value proposition and internal processes by leveraging data and technology digitalization noun | /dɪdʒɪtələˈzeɪʃn/

- 7. © 2018 Aker Solutions Two Decades of Digital Thinking February 23, 2018Optimized Concepts Through Digital Front End Design Slide 7 Computer Assisted Design 1980s Automation & Standardization 2000s 2010s Digitalization, Analytics & Machine Learning Electronic Project Model 1990s

- 8. © 2018 Aker Solutions February 23, 2018Optimized Concepts Through Digital Front End Design Slide 8 Image: Statoil

- 9. © 2018 Aker Solutions KBeDesign™ | Knowledge Based Engineering Optimize. Iterate. Learn. Capture product structure, the design process and tacit knowledge Develop adaptive building blocks Deploy, reuse and adapt to new requirements Automate 3D models and deliverables World Class Engineering Automation February 23, 2018Optimized Concepts Through Digital Front End Design Slide 9

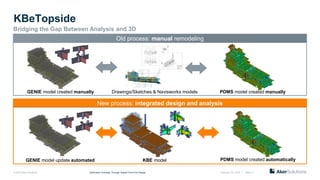

- 10. © 2018 Aker Solutions February 23, 2018 Slide 11 KBeTopside Old process: manual remodeling GENIE model created manually Drawings/Sketches & Navisworks models PDMS model created manually New process: integrated design and analysis PDMS model created automaticallyGENIE model update automated KBE model Bridging the Gap Between Analysis and 3D Optimized Concepts Through Digital Front End Design

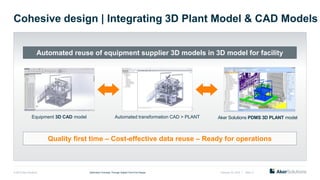

- 11. © 2018 Aker Solutions Cohesive design | Integrating 3D Plant Model & CAD Models Automated reuse of equipment supplier 3D models in 3D model for facility Aker Solutions PDMS 3D PLANT modelEquipment 3D CAD model Automated transformation CAD > PLANT Quality first time – Cost-effective data reuse – Ready for operations February 23, 2018Optimized Concepts Through Digital Front End Design Slide 13

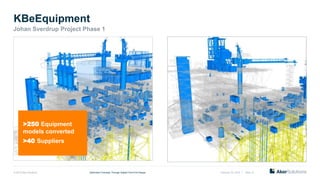

- 12. © 2018 Aker Solutions KBeEquipment February 23, 2018 Slide 14 Johan Sverdrup Project Phase 1 >250 Equipment models converted >40 Suppliers Optimized Concepts Through Digital Front End Design

- 13. © 2018 Aker Solutions Facility Modeler | Front-End Topside Layout February 23, 2018 Slide 16 Layout Principles ■ Global Solution ■ Inherently Safe ■ Facility boundaries limited ■ Consistent deck elevations ■ Main Process modularized or integrated ■ Symmetrical design ■ Piperack matrix ■ Access – comprehensive & simple ■ Functional hull arrangement ■ Simple interfaces Platform Architecture ■ Optimum Layout Configuration ■ Global Thinking ■ Process/Systems/Functionality ■ Constructability/Method ■ Installation ■ Maintenance/Operations ■ HSE ■ Simple Interface/Hook-up ■ Robust ■ Cost Efficient KristinSnorre B Blind FaithNjord P51/P52 Gjoa Midgard Slide 16 “The artist and his philosophies” Interfaces ■ Process/System design ■ Structural ■ Construction Flexibility ■ Marine ■ Subsea Layout ■ Riser ■ Health, Safety, Environment ■ Maintainability/Operability ■ Architectural ■ Weight and C.O.G. Optimized Concepts Through Digital Front End Design

- 14. © 2018 Aker Solutions Topside Facility Value stream February 23, 2018 Slide 17 HYSYS Model MEL Builder MEL Facility Modeler Weight est. Cost est. Function & Capacities System Design Equipment Sizing & Selection MEL Layout Weight Cost Design cycle time reduced from 1 to 2 weeks to 1 to 2 days Design cycle time reduced from 1 to 2 weeks to 1 to 2 days Optimized Concepts Through Digital Front End Design

- 15. © 2018 Aker Solutions February 23, 2018Optimized Concepts Through Digital Front End Design Slide 18 Facility Modeler | Digitalizing Front-End Information Flow Select Template Map EQ to Functional Areas Initial Placement Adjust, validate, iterate Generate outputs MEL Layout Weight Cost Arr. Drawings 3D Model (PDMS / E3D)

- 16. © 2018 Aker Solutions February 23, 2018 Slide 19 Facility Modeler | Digitalizing Front-End Information Flow 4. Import updated MEL 5. Re-use and adjust adaptive equipment 6. Search & re-use equipment 2. Import MEL (list of selected equipment) 3. Assign equipment in functional areas volumes based on rules and reasoning 1. Template Reuse topside and substructure facility with functional areas Optimized Concepts Through Digital Front End Design

- 17. © 2018 Aker Solutions Facility Modeler | The Way Forward ■ Having the right mind-set is vital to developing new solutions ■ What Lies Ahead? ■ Major Focus on Standardisation ■ Minimum Solutions (LEAN) ■ Hybrid Solutions ■ Unmanned Solutions February 23, 2018Optimized Concepts Through Digital Front End Design Slide 21 “If you always do what you’ve always done, you’ll always get what you’ve always got.” Henry Ford

- 18. © 2018 Aker Solutions ■ HSE and OPEX improvements - reduced human exposure ■ CAPEX savings by simplification and elimination ■ Unmanned and LEAN FPSO - ready for next level ■ Digital solutions with remote operations February 23, 2018Optimized Concepts Through Digital Front End Design Slide 22 We Are Ready to Take Unmanned to the Next Level Adopt a new mind-set Reduce total cost of Ownership No compromises on safety or operability Challenge traditional FPSO solutions, philosophies and tools LEAN FPSO Unmanned FPSO

- 19. © 2018 Aker Solutions February 23, 2018 Slide 23 Digital Thinking Enables Standardization and Optimal Solutions UI - Type 1 UI - Type 2 UI - Type 3 UI - Type 4 Optimized Concepts Through Digital Front End Design

- 20. © 2018 Aker Solutions February 23, 2018Optimized Concepts Through Digital Front End Design Slide 24 Be digital. Be curious. Questions?

- 21. © 2018 Aker Solutions