Biogas

- 1. KASHMEERA N.A. IV SEM MSc ZOOLOGY ROLL No: 37 03/13/13

- 2. 03/13/13

- 3. 03/13/13

- 4. Mystery unveiled…. Alessandro volta 03/13/13

- 5. BIOGAS • Mixture of gases. • Produced by anaerobic digestion of organic matter. • Consist of CH4 ,CO2 ,traces of H2 & other gases. 03/13/13

- 7. 03/13/13

- 8. BENEFITS FROM BIOGAS PLANTS • Used mainly for cooking & lighting purposes. • Used in internal combustion engines to power water pumps & electric generators. 03/13/13

- 9. • Used as fuel in fuel type refridgerators. • Sludge - fertilizer. • ↓ envt. pollution 03/13/13

- 10. 03/13/13

- 11. SUBSTRATE • Plant & animal biomass. • Plant biomass – • Animal biomass – cattle dung,manure from poultry,goats & sheep slaughter house & fishery wastes. • Agricultural wastes also used 03/13/13

- 12. 03/13/13

- 13. Parts of biogas plant • Digester • Gas holder • Inlet • Outlet 03/13/13

- 14. Inlet chamber • To supply cow dung to the digester • It is made at the ground level so that the cow dung can be poured easily. • made up of bricks, cement and sand. • The outlet wall of the inlet chamber is made inclined so that the cow dung easily flows to the digester. 03/13/13

- 15. Digester • Most important part of biogas plant • Fermentation takes place - fermentation tank. • Built underground – insulated,airtight • Made up of bricks, sand and cement. 03/13/13

- 16. • Almost at the middle of the height of digester, two openings are provided on the opposite sides for inflow of fresh cow dung and outflow of used cow dung. 03/13/13

- 17. Gas holder • Cylindrical container • Above digester • Collect gas • The gas pipe carries the biogas to the place where it is consumed. 03/13/13

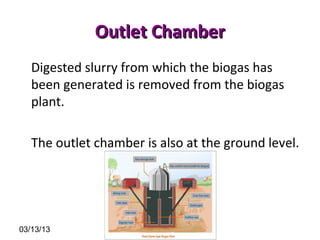

- 18. Outlet Chamber • Digested slurry from which the biogas has been generated is removed from the biogas plant. • The outlet chamber is also at the ground level. 03/13/13

- 19. 03/13/13

- 20. Types • GAS HOLDER • Fixed dome type • Floating drum type FREQUENCY OF FILLING SUBSTRATE Batch type Continuous type 03/13/13

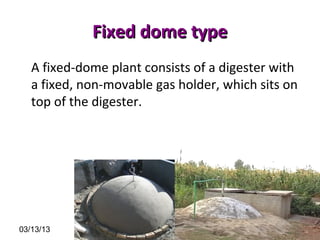

- 21. Fixed dome type • A fixed-dome plant consists of a digester with a fixed, non-movable gas holder, which sits on top of the digester. 03/13/13

- 22. Floating-drum type • Consist of an underground digester and a moving gas-holder. • Gas-holder floats either directly on the fermentation slurry or in a separate water jacket. • The gas is collected in the gas drum, which rises or moves down, according to the amount of gas stored 03/13/13

- 24. • Batch type • Filled once,sealed. • Emptied when raw materials stop producing gas. • Continuous type • Fed with a definite quantity of wastes at regular intervals • Gas production continuous & regular 03/13/13

- 25. 03/13/13

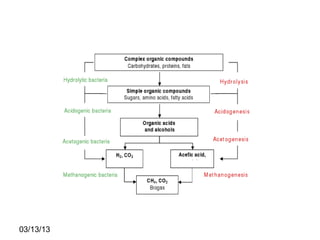

- 26. MICROBIOLOGY OF BIOGAS •4 steps •Hydrolysis •Acidogenesis •Acetogenesis •Methanogenesis 03/13/13

- 27. Hydrolysis • Biomass is made up of large organic polymers • Complex polymers hydrolysed to monomers • complex organic molecules → simple sugars, amino acids, and fatty acids. • Done by hydrolytic fermentative bacteria 03/13/13

- 28. Acidogenesis • Results in further breakdown of the remaining components by acidogenic bacteria. • Ammonia, H2, CO2, H2S, shorter volatile fatty acids, carbonic acids, alcohols, as well as trace amounts of other byproducts produced 03/13/13

- 29. Acetogenesis • Simple molecules created through the acidogenesis phase further digested to acetic acid, carbon dioxide and hydrogen. • Acetogenic bacteria 03/13/13

- 30. Methanogenesis • The terminal stage • Intermediate products of the preceding stages converted to methane, carbon dioxide, and water. • These components make up the majority of the biogas emitted from the system. • Methanogenic bacteria 03/13/13

- 31. MICRO ORGANISMS • Hydrolytic & fermentative bacteria. • Acidogenic bacteria. • Acetogenic bacteria. • Methanogenic bacteria. 03/13/13

- 32. 03/13/13

- 33. Methanogenic bacteria. • Create methane from the final products of acetogenesis as well as from some of the intermediate products from hydrolysis and acidogenesis . • Archaebacteria 03/13/13

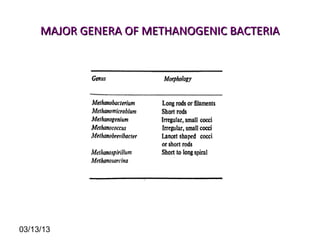

- 34. MAJOR GENERA OF METHANOGENIC BACTERIA 03/13/13

- 35. • Cocci • Spirilli • Bacilli Cocci forming colonies in cubical packets of • sarcina eight or more are called sarcina 03/13/13

- 36. • Methanogens are a diverse group of organisms that can live in a wide range of environments. • They have been found in a range of salinity from freshwater to hypersaline. 03/13/13

- 37. • Biogas plant – Methanosarcina barkeri, Methanobacterium omelianskii 03/13/13

- 38. 03/13/13

- 39. Factors affecting methane formation. • pH • Temperature • Nitrogen concentration • C:N ratio • Creation of anaerobic conditions 03/13/13

- 40. pH • 6-8 • Acidic medium lowers methane formation. • Temperature • Fluctuation ↓ methane formation – inhibit growth of methanogens. • 30-40oC 03/13/13

- 41. Nitrogen concentration • ↑ N2 - ↓ growth of bacteria - ↓ CH4 C:N ratio • Micro organisms in a biogas plant needs both N nitrogen and C carbon. • Research has shown that the methanogenic bacteria work best with a C/N ratio 30:1. 03/13/13

- 42. Creation of anaerobic conditions • CH4 production takeplace in strictly anaerobic condition. • Digesters – airtight, burried under soil. 03/13/13

- 43. 03/13/13