Biomass energy

- 1. UNIT-4 BIOMASS ENERGY BY MR.K.STALIN ASST. PROF/ MECH/AMET UNIVERSITY

- 2. Bioenergy is a form of renewable energy obtained by the conversion of biomass resources such as agricultural and forest residues, organic municipal waste and energy crops to useful energy carriers including heat, electricity and transport fuels Biomass is derived from plant- and algae- based materials that include: What is Bioenergy? Crop wastes Forest residues Purpose-grown grasses Woody energy crops Microalgae Urban wood waste Food waste

- 3. Contents: Biofuels classification – Biomass production for energy forming – Pyrolysis – Gasification and combustion - Aerobic and Anaerobic bio conversion process - Feed stock - Properties of bio-gas composition - Biogas plant design and operation - Alcoholic fermentation.

- 4. The global industrial development in the past century relied heavily on fossil fuels, which not only caused concerns on depletion of this nonrenewable energy source, but also contributed to the global warming issues due to greenhouse gases (GHG) emissions. According to recent studies, the demand for energy will nearly double globally by 2050, while a large portion of current fossil fuel reserves (1/3 of oil, 1/2 of natural gas, and more than 4/5 of coal) should remain unused from 2010 to 2050 in order to meet a target for (GHG) control, i.e. keeping warming below 2 ºC throughout the 21st century. As a result, development of renewable energy, such as bioenergy from biomass, is urgently needed to meet the increasing demand for energy, while reducing GHG emissions. Besides, it is estimated that the use of biofuel for transportation could increase to 27% in 2050. Need for Bio Energy

- 5. Biomass is the largest potential source of renewable energy, providing about 10% of the current world’s primary energy supplies. A variety of bioenergy products, such as bioethanol, biobutanol, and biomethane, can be produced from this abundant and renewable feedstock, and and would reduce our reliance on nonrenewable fossil fuels as our primary energy source. To date, biofuel production at a large scale has been limited due to economic challenges.

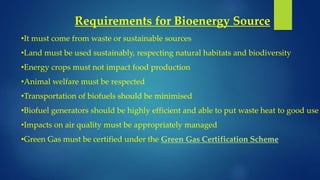

- 6. Requirements for Bioenergy Source •It must come from waste or sustainable sources •Land must be used sustainably, respecting natural habitats and biodiversity •Energy crops must not impact food production •Animal welfare must be respected •Transportation of biofuels should be minimised •Biofuel generators should be highly efficient and able to put waste heat to good use •Impacts on air quality must be appropriately managed •Green Gas must be certified under the Green Gas Certification Scheme

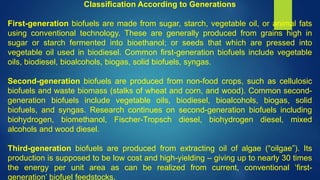

- 8. Classification According to Generations First-generation biofuels are made from sugar, starch, vegetable oil, or animal fats using conventional technology. These are generally produced from grains high in sugar or starch fermented into bioethanol; or seeds that which are pressed into vegetable oil used in biodiesel. Common first-generation biofuels include vegetable oils, biodiesel, bioalcohols, biogas, solid biofuels, syngas. Second-generation biofuels are produced from non-food crops, such as cellulosic biofuels and waste biomass (stalks of wheat and corn, and wood). Common second- generation biofuels include vegetable oils, biodiesel, bioalcohols, biogas, solid biofuels, and syngas. Research continues on second-generation biofuels including biohydrogen, biomethanol, Fischer-Tropsch diesel, biohydrogen diesel, mixed alcohols and wood diesel. Third-generation biofuels are produced from extracting oil of algae (“oilgae”). Its production is supposed to be low cost and high-yielding – giving up to nearly 30 times the energy per unit area as can be realized from current, conventional ‘first- generation’ biofuel feedstocks.

- 9. Biofuel: Ethanol Ethanol (CH3CH2OH) is an alcohol fuel made from the sugars found in grains such as corn sorghum, barley and in plant products such as potato skins, rice, sugar cane, sugar beets , yard clippings , bark and switchgrass. Ethanol can be produced by a process called gasification. Biodiesel Biodiesel is made by combining alcohol (usually methanol) with vegetable oil, animal fat, or recycled cooking grease. It is a nontoxic and biodegradable energy source that produces lower levels of air pollutants. Vegetable Oil It can be directly used as fuel for vehicles or for electricity generation.

- 10. The organic material is converted into usable form known as bio-energy. The materials used in the process of energy production are termed as feedstock. Biomass production refers to the increase in the amount of organic matter. It is the addition of organic matter in a given area or population. Biomass is considered renewable energy because it is replenished as plants and animals grow. There are two forms of production − Primary production refers to the generation of energy by plants through photosynthesis. The excess energy generated is stored and adds up to the total biomass in the ecosystem. Primary production could be estimated from the total forest cover in a given year. Secondary production is the absorption of organic matter as body tissues by organisms. It includes ingestion by animals i.e. feeding, whether on other animals or on plants. It also involves decomposition of organic matter by microorganisms. Secondary production could be estimated as the total meat produced per year.

- 11. Direct Combustion for Heat Direct combustion for heat is the oldest method of biomass conversion to energy since the earliest civilizations. Thermochemical conversion (combustion) could be achieved in a number of ways using varied feedstock. Standalone Combustion Biomass based generators use diesel derived from vegetable oils to fuel diesel generators. The generators burn the organic diesel to produce energy to produce electricity. •Combined heat and power plants are known to cogenerate electricity and useful heat energy. Ceramic industries utilize the heat in drying products such as clay tiles. •Some power plants use biomass to heat water and produce steam for electricity generation. The biomass is burnt to produce enough heat to boil water. •Municipal solid waste plants burn solid wastes to generate electricity. This type is prone to criticism since solid wastes mostly contain toxic gases from plastics and synthetic fibers.

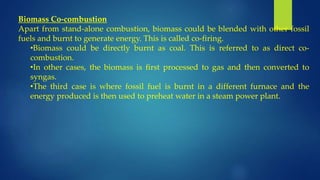

- 12. Biomass Co-combustion Apart from stand-alone combustion, biomass could be blended with other fossil fuels and burnt to generate energy. This is called co-firing. •Biomass could be directly burnt as coal. This is referred to as direct co- combustion. •In other cases, the biomass is first processed to gas and then converted to syngas. •The third case is where fossil fuel is burnt in a different furnace and the energy produced is then used to preheat water in a steam power plant.

- 13. Pyrolysis Pyrolysis is another form of processing bio-fuels by burning under very high temperatures without oxygen, which could cause complete combustion. This causes irreversible physical and chemical changes. The absence of oxidation or halogenations processes results in a very dense bio-fuel that could be used in combustion, co- combustion or converted to gas. •Slow pyrolysis occurs at about 400oC. It is the process of making solid charcoal. •Fast pyrolysis occurs between 450oC to 600oC and results in organic gas, pyrolysis vapor, and charcoal. The vapor is processed by condensation to liquid form as biooil. This must be done within 1 second to prevent further reaction. The resultant liquid is dark brown liquid denser than wood biomass and has equal content in terms of energy. Bio-oil has a number of advantages. It is easier to transport, burn, and store. Many kinds of feedstock can be processed through pyrolysis to produce bio-oil.

- 14. The diagram given below explains the process in converting energy in to a usable form from bio-fuels through Pyrolysis.

- 16. Alcoholic Fermentation Alcoholic fermentation is the process that converts sugars into cellulose. The process results in ethanol and carbon dioxide as the by-products. This process is considered anaerobic since it takes place in the absence of oxygen. Apart from bread baking and manufacturing alcoholic beverages, this process produces alcoholic fuel. Sugarcane is the main feedstock for this process especially in dry environments.

- 17. Application of Products The products have the following applications − •Acetone is a product used for production of food additives, dissolving glue, thinning of paint, grease removers and in cosmetic products. •Hydrogen is used as a cooling agent in power industry. It is also used in hydrogen cells for energy production. •Butanol provides better fuel than ethanol. It is also used as an ingredient in paint, cosmetic products, resins, dyes, polymer extractions and in the manufacture of synthetic fiber. •Ethanol is used as fuel, paint component, and an additive in antiseptics. It is also used in alcoholic beverages.

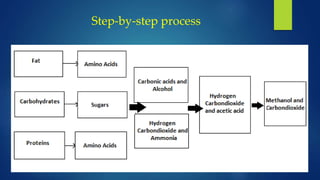

- 18. Anaerobic Digestion of Biogas Anaerobic digestion is the biological process by which organic matter is broken down to produce biogas in the absence of Oxygen. Microorganisms such as Acidogenetic bacteria and acetogens convert the biodegradable matter to biogas. Apart from being a source of energy, it is also a waste deposition method and environmental conservation technique. The step-by-step process is explained below − Step 1 − Breakdown of organic matter to sizable molecules for conversion. This process is known as hydrolysis. Step 2 − Acidogens act on the decomposed matter converting them into volatile fatty acids (VFAs) alongside ammonia, CO2 and hydrogen sulfide. The process is called acidogenesis. Step 3 − The VFAs are further broken down into acetic acid, carbon dioxide and hydrogen. Step 4 − The final stage is the combination of emissions above to produce methanol, carbon dioxide, and water.

- 20. Biogas plant •Biogas or gobar gas is a combustible gas (CH4 + CO2). •It is produced through the anaerobic breakdown of waste biomass. Structure of a biogas (gobar gas) plant: The biogas plant is a dome-like structure made of bricks and cement. It consists of the following five compartments: 1. Mixing tank: Present above the ground level. 2. Inlet chamber/tank: The mixing tank opens underground into a sloping inlet chamber.

- 21. Digester: The inlet chamber opens from below into the digester. The digester is a huge tank with a dome-like ceiling. The ceiling of the digester has an outlet with a valve for the supply of biogas. Outlet chamber/tank: The digester opens from below into an outlet chamber. Overflow tank: The outlet chamber opens from the top into a small overflow tank.

- 23. Working :- In the inlet tank animal waste slurry is prepared containing cow dung and waste in the ratio as 1:1 to 1:1.25 the feeding of animal waste slurry is usually done once in a day. The diameter of the digester of a gas plant rangers from 1.2 to 6m. & its height varies from 3m to 6m.

- 24. Bio Mass Power Plant What is Biomass? Biomass is fuel that is developed from organic materials, a renewable and sustainable source of energy used to create electricity or other forms of power. Some examples of materials that make up biomass fuels are: • scrap lumber; • forest debris; • certain crops; • manure; and • some types of waste residues.

- 25. What is biomass power? Biomass power is carbon neutral electricity generated from renewable organic waste that would otherwise be dumped in landfills, openly burned, or left as fodder for forest fires. When burned, the energy in biomass is released as heat. In biomass power plants, wood waste or other waste is burned to produce steam that runs a turbine to make electricity.

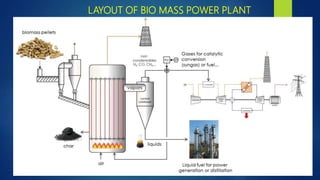

- 26. LAYOUT OF BIO MASS POWER PLANT

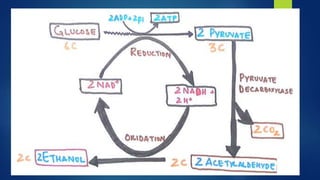

- 27. Fementation Process The two most common types of fermentation are alcoholic and lactic acid fermentation. While alcoholic fermentation may be the most well-known (and is seen in many foods and beverages, such as wine, beer, fermented teas, bread and sausages). Ethanol and biodiesels have been industrially produced from biomass by fermentation and chemical trans-esterification of plant oils, respectively. Biomass can be converted directly into liquid fuels, called "biofuels," to help meet transportation fuel needs. The two most common types of biofuels in use today are ethanol and biodiesel, both of which represent the first generation of biofuel technology. Fermentation is an anaerobic process that allows glycolysis to continue.

- 28. ETHANOL: Ethanol (CH3CH2OH) is a renewable fuel that can be made from various plant materials, collectively known as “biomass.” Ethanol is an alcohol used as a blending agent with gasoline to increase octane and cut down carbon monoxide and other smog-causing emissions. The most common blend of ethanol is E10 (10% ethanol, 90% gasoline).

- 29. BIODIESEL Biodiesel is a liquid fuel produced from renewable sources, such as new and used vegetable oils and animal fats and is a cleaner-burning replacement for petroleum-based diesel fuel. Biodiesel is nontoxic and biodegradable and is produced by combining alcohol with vegetable oil, animal fat, or recycled cooking grease. Biodiesel can be blended with petroleum diesel in any percentage, including B100 (pure biodiesel) and, the most common blend, B20 (a blend containing 20% biodiesel and 80% petroleum diesel).

- 35. NAD - Nicotinamide adenine dinucleotide. This is an organic molecule that contains two nucleotides, one with an adenine base and the other with nicotinamide. ATP stands for adenosine triphosphate. It stores and releases energy for many cellular processes.

- 36. Thank YOU !!!