Burj khalifa , its engineering as well as architectural features and facts.

- 1. 1 Presentation On: Tallest Skyscraper in the world. BURJ KHALIFA (828m) In Dubai. Presented By: Rohit Arora (BE Final yr BCE) M.B.M Engineering College Jodhpur

- 2. Contents 2 Introduction Site Plan Records Challenges Excavation Foundation Casting of Structure Concrete Used Casting of RCC walls. Structural System Shape Buttressed core The Spire Mechanical Rooms Elevators Cladding Test for Cladding Glass Panels Evacuation and Fire Safety Environment friendly

- 3. Introduction 3 The Burj Khalifa is the ever built tallest man made structure. Location: Dubai, United Arab Emirates Project Completion: 2010 Site Area: 104,210 m2 Project Area: 454,249 m2 Number of Stories: 162 Building Height: 828 m Use: Commercial + Office, Hospitality, Mixed Use, Residential Architect : Adrian Smith Structural Engineer: Bill Baker The tower was constructed by a UAE based construction company EMAAR.

- 4. SITEPLAN 4

- 5. Records 5 Tallest existing structure : 829.8 m ( 2,722 ft ) Tallest structure ever built : 829.8 m ( 2,722 ft) Building with the most floors : 163 Highest vertical concrete pumping( for a building) : 606 m building with world’s highest occupied floor World’s highest elevator installation World’s longest travel distance elevators : 504 m World’s tallest structure that includes residential space World’s highest installation of an aluminum and glass facade : 512 m World’s highest night club : 144th floor World’s highest restaurant (At.mosphere) : 122nd floor at 442 m World’s second highest swimming pool: 76th floor

- 6. Challenges Faced 6 High Temperature of Dubai resulted in shorter setting time. Devastating sandstorms in the area. Wind Velocity at such a height. Loose and weak soil in the region. Formation of vortex. Heat resistance of structure. Speed of construction.

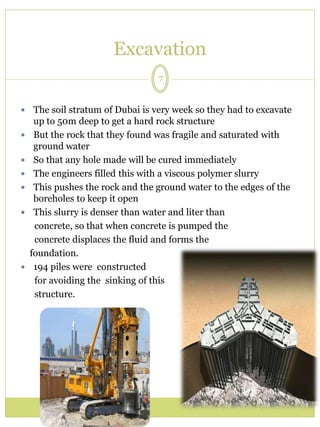

- 7. Excavation 7 The soil stratum of Dubai is very week so they had to excavate up to 50m deep to get a hard rock structure But the rock that they found was fragile and saturated with ground water So that any hole made will be cured immediately The engineers filled this with a viscous polymer slurry This pushes the rock and the ground water to the edges of the boreholes to keep it open This slurry is denser than water and liter than concrete, so that when concrete is pumped the concrete displaces the fluid and forms the foundation. 194 piles were constructed for avoiding the sinking of this structure.

- 8. Foundation 8 The superstructure is supported by a large reinforced concrete mat, which is in turn supported by bored reinforced concrete piles. The design was based on extensive geotechnical and seismic studies. The 1.5 meter diameter x 43 meter long piles represent the largest and longest piles conventionally available in the region. A high density, low permeability concrete was used in the foundations. Cathodic protection system under the mat, to minimize any detrimental effects form corrosive chemicals in local ground water.

- 9. Casting of the structure 9 The casting of the whole structure is mainly done by two materials 1. Concrete 2. Steel Over 30,000 tons of steel were used About 250,000 m3 concrete was also used The reinforced concrete acts as the backbone of the whole structure. The pump needs 630HP to pump about 25000 tons of concrete It had took about 14mints for reaching the concrete to the 150th floor They completed every new floor in 3 day .

- 10. Concrete used 10 High performance concrete(HPC) Low permeability High durability C80-C60 cube strength concrete was used It includes fly ash, Portland cement Two largest concrete pumping machines in the world were used for this purpose For reducing cracks due to high temperature concreting was done only at night

- 11. Casting of RCC walls 11 For simplicity and speed the engineers made no. of steel cages These cages were inserted to the formworks that can be moved easily After installation of cages concrete was filled in these formworks Only took 12hrs for the setting of concrete. After setting the concrete the formworks would move to the next level with in 2hrs.

- 12. Structural System 12 The spiraling “Y” shaped plan was utilized to shape the structural core of Burj Khalifa. This design helps to reduce the wind forces on the tower, as well as to keep the structure simple and foster constructability. The structural system can be described as a “buttressed core”, and consists of high performance concrete wall construction. At mechanical floors, outrigger walls are provided to link the perimeter columns to the interior wall system, allowing the perimeter columns to participate in the lateral load resistance of the structure

- 13. Shape 13 They made a study on the Sears tower at Chicago. Burj Khalifa was designed in triangular shape because it was suitable to deflect the wind to different ways. Triangular shape reduces vortex effect.

- 14. Buttressed core 14 The three wings allow for greater building height by buttressing one another by a central core hence it is called buttressed core structural system This buttressed core is a six sided central piece So that it is called a Hexagonal Hub This hub is surrounded by the three wings These three wings afford the torsional resistance and the twisting of the tower This hub encloses the elevators

- 15. The Spire 15 The crowning touch of Burj Khalifa is its telescopic spire comprised of more than 4,000 tons of structural steel. The spire was constructed from inside the building and jacked to its full height of over 200 metres (700 feet) using a hydraulic pump. Creates a sense of completion for the landmark. Also houses communications equipment.

- 16. Mechanical Floors 16 Seven double-storey height mechanical floors house the equipment that bring Burj Khalifa to life. Distributed around every 30 storeys. house the electrical sub-stations, water tanks and pumps, air-handling units etc, that are essential for the operation of the tower and the comfort of its occupants.

- 17. Elevators and Escalators 17 The Burj can accommodate about 35,000 people at a time Consist of 57 elevators and 8 escalators The biggest elevator carries about 46 people at a time These elevators travel at a speed of 35km/hr The Burj has a service/firemans elevator which have a capacity to hold about 5,500kg And this is the worlds tallest service elevator.

- 18. Cladding of the tower 18 The Burj is claded with high-tech glass which forms as a curtain wall. The exterior cladding is comprised of reflective glazing with aluminum and textured stainless steel spandrel panels and stainless steel vertical tubular fins. If the whole cladding has to be done with high-tech glass which will cost about 100 million dollars.

- 19. Test for the Cladding against Storm 19 The cladding should withstand the heavy sand storms that with in include water and dust Prototypes were selected and with the help of propellers artificially created storm was allowed to hit the glass panels at a greater speed The glass panels withstands the storm up to 75km/hr .

- 20. Glass panel 20 The outer layer of panel is coated with a thin layer of metal so that it reflects the UV radiations The inner layer of panel is coated with thin layer of silver so that it reflects the IR radiations. The exterior cladding is comprised of reflective glazing with aluminum and textured stainless steel spandrel panels and stainless steel vertical tubular fins. Close to 26,000 glass panels, each individually hand-cut, were used in the exterior cladding of Burj Khalifa.

- 21. Speed of construction and Cranes 21 For erecting such a structure in the sky steel and glass panels have to be raised The cranes consist of two plates on the two sides It could jump from one floor to the another So that they were called the kangaroo cranes So as to speed up the construction the RCC walls was done in a simple and clever engineering way

- 22. Evacuation and Fire Safety 22 The Burj is naturally fire resistant as the concrete backbone is already fire resistant More than that the Burj consist of refuge rooms These refuge rooms are made of RCC and fire proof sheets that resist the heat up to 2hrs These refuge rooms has a special supply of air which pumps through fire resistant pipes There are 9 refuge rooms, one in every 30 floors. The Burj fire safety system mainly consist of 3 components i. A smoke detector ii. Water sprinkler iii. High power fans As the water is sprinkled the fire gets extinguished and the high power fans supplies fresh air by pushing the smoke out

- 23. Environment Friendly 23 Water heating The Burj utilizes solar power 378 panels each with an area of 2.7sq.m were installed These panels have the ability to heat 140,000 lit of water when supplied with just 7hrs of day light. This is equal to 32,000KW of energy provided .

- 24. Environment Friendly 24 Condensate recovery system Collects water condensate from the air conditioning system And diverts it to an irrigation tank It provides about 15 million gallons of water per year This water is used for irrigation of landscape around the Burj Reduces water related expenses

- 25. Environment Friendly 25 Air ventilation Air ventilation provided at the top reduces the energy consumption Air at the top of the building is cooler, has low density and relatively humid Its ideal for ventilation Less energy is required to maintain the comfortable condition

- 26. References 26 www.Burjkhalifa.ae www.wikipedia.com www.slideshare.net www.som.com