Carbonation of concrete

- 1. Seminar on carbonation of Er. Himanshu Jaiswal

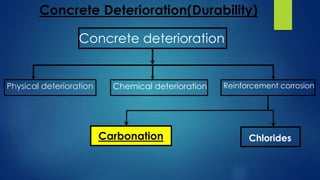

- 3. Overview Concrete Deterioration(Durability) Carbonation. Mechanism of Carbonation. Factors affecting Carbonation . Change in Ph and test of Carbonation(depth). Control and prevention from Carbonation

- 4. Concrete Deterioration(Durability) Concrete deterioration Physical deterioration Chemical deterioration Reinforcement corrosion Carbonation Chlorides

- 5. Carbonation Associated with the corrosion of steel reinforcement and with shrinkage. The dissolution of CO2 in the concrete pore fluid. CO2 reacts with calcium from calcium hydroxide and calcium silicate hydrate to form calcite (CaCO3).

- 6. Reaction involves Ca(OH)2 + CO2 CaCO3 + H2O A Physiochemical Reaction. Reaction between atmospheric carbon dioxide and the calcium hydroxide generated in cement hydration. The precipitation of calcium carbonate reduces the pH level of concrete.

- 7. Mechanism of Carbonation Step 1: H20+C02 HC03 -+ H+ HC03 - H++ C03 2 - Step 2: Ca(0H)2+ 2H++ C03 2 - CaC03 +2H20 This neutralisation reaction penetrates gradually in to the concrete surface. Penetration Rate =k time

- 8. Effect of carbonation on concrete Compressive strength of carbonated concretes slightly Increases in comparison with non-carbonated concretes. Carbonation depth increases with an in- crease of carbonation time and higher CO2 concentration has a higher carbonation depth. The splitting strength of carbonated concretes slightly increases compared to the non-carbonated concretes. Electrical resistivity increases with an increase of carbonation time. Carbonation leads to a significant reduction in the permeability and porosity of concrete.

- 9. Relationship between carbonation depth and compressive strength The depth of carbonation decreases with an increase in compressive strength. Very logical, since both carbonation and compressive strength are significantly controlled by the pore structure of concrete.

- 10. Factors affecting Carbonation Concentration of C0 2 gas in atmosphere Normally 3% but increasing annually Higher in cities, due to motor vehicles and fossil fuel burning. Pore system of Hardened Concrete. Relative humidity (for dissolution of Ca(0H)2 ). Lower humidity , C0 2 can not dissolve. But in higher humidity, C0 2 can easily dissolve.

- 11. Change in Ph value The pH of the fresh cement paste is at least 12.5. The atmospheric carbon dioxide diffuses into the hardened concrete through pores and when carbonation reaction takes place, the alkalinity of the concrete reduces. The pH of a fully carbonated paste is about 7. Means in carbonated zone the Ph range below 9.2.

- 12. Test of Carbonation The measurement of carbonation depth using the phenolphthalein solution. Spraying the indicator on the split surface of the concrete cylinder . The solution became a pink colour in the carbonated concrete. It can be differentiated from the uncarbonated concrete. Carbonation depth upto an accuracy of 5mm can be identified with the naked eye.

- 13. Mechanism- phenolphthalein solution The colourless acid-base indicator (phenolphthalein solution) monitoring the carbonation depth is by capturing the depth at which the pH is about 9.2. It indicates the boundary at which the carbonated front meets with the uncarbonated concrete, where concrete is alkaline . There is a partially carbonated zone where the pH value is not easily detected using phenolphthalein indicator. For find partially carbonated zone we use FT-IR spectrum analysis……

- 14. Compare in phenolphthalein indicator method and FT-IR spectrum analysis FT-IR spectroscopic test can identify a partial carbonation front more readily than a phenolphthalein indicator FT-IR Fourier- transform infrared spectroscopy

- 15. Carbonation Depth Carbonation depth is assessed using a solution of phenolphthalein indicator. Carbonation is slight and eventually comes to a stop, with the depth reached being known as the maximum carbonation depth. 1. Carbonation depth amounts to only a few millimetres and cannot extend as far as the reinforcement. Carbonation protection (CO2-proofing) is not necessary. 2. Carbonation has nearly reached the reinforcement layer. Carbonation protection is necessary in order to stop further progress. 3. The majority of the reinforcement is located in the already carbonated zone of the concrete. In this case, carbonation protection would be too late

- 16. Bi-carbonation Bi-carbonation may occur in concrete with very high water to cement ratio. Due to formation of hydrogen carbonate ions at pH lower than 10. Bi-carbonation results in an increase in porosity making the concrete soft and friable. Bi-carbonation may be recognized by the presence of large "pop-corn" like calcite crystals and the highly porous paste.

- 17. Control of carbonation Using low water cement ratio. Low relative humidity.

- 18. Prevention from Carbonation (Protection) Barrier coatings to protect from the ingress of water and CO2. Keim mineral paints .

- 19. References Department of Building & Construction, City University of Hong Kong, Hong Kong. http://www.elsevier.com/locate/buildenv Journal of Marine Science and Technology, Vol. 10, No. 1, pp. 14-20 (2002). Fattuhi N.J., “Carbonation of Concrete as Affected by Mix Constituents and Initial Water Curing Period,” Materials of Constructions, Vol. 19, No. 110, pp. 131- 136 (1986). http://nptel.iitm.ac.in http://www.sciencedirect.com https://www.google.co.in

- 20. Thank you.