Cement

- 2. CEMENT

- 3. CEMENT DEFINITION A cement is a binder, a substance used for construction that sets, hardens, and adheres to other material to bind them together Cement basically constituents of two different types of compound – Argillaceous compound (clay) & Calcareous compound (lime)

- 4. CEMENT Cement Ingredients Formula % Lime 𝐶𝑎𝑂 62-65 Silica 𝑆𝑖𝑂2 17-25 Alumina 𝐴𝑙2 𝑂3 3-8 Gypsum 𝐶𝑎𝑆𝑂4 3-4 Iron Oxide 𝐹𝑒2 𝑂3 3-4 Magnesia 𝑀𝑔𝑂 1-3 Sulphur 𝑆 1-2 Alkali 𝑁𝑎2 𝑂, 𝐾2 𝑂 0.2-1 Raw Materials Of Cement

- 5. CEMENT Functions of Different Ingredients in Cement 1. LIME Lime Imparts strength and soundness (change in volume) to the cement If it is in excess it makes the cement unsound, causes it to expand and disintegrate. If it is in deficiency it reduces the strength of the cement and causes it to set quickly. 2. SILICA Silica also imparts strength to the cement. If it is in excess, it increases the strength of the cement but also increase the setting time of the cement.

- 6. CEMENT Functions of Different Ingredients in Cement 3. Alumina Alumina imparts quick setting properties to the cement. It acts as a flux and help in reducing the clinkering temperature during the burning of the cement. If it is in excess it weakens the cement. 4. Gypsum It helps in increasing the initial setting time of the cement. It prevents flash set.

- 7. CEMENT Functions of Different Ingredients in Cement 5. Iron Oxide It Imparts colour, strength, hardness and toughness to the cement. It imparts reddish brown tint in the cement. 6. Magnesia It also imparts colour and hardness to the cement. It gives yellow tint to the cement. If it is in excess it makes the cement unsound.

- 8. CEMENT Functions of Different Ingredients in Cement 7. Sulphur It is also responsible for inducing the soundness in the cement. 8. Alkali Presence of alkalis in cement leads to the efflorescence and staining of the structure in which the cement is used for construction. Efflorescence – Alkali absorb moisture and reacts with it and leads to the development of white grey spot over the surface of the structure

- 9. CEMENT Manufacturing of Cement 1. Manufacturing of cement is carried out in 3 operations. Mixing of raw ingredients Burning Grinding 2. Generally two methods are available for the manufacturing of cement. Dry process method (Modern method) Wet process method

- 10. CEMENT Manufacturing of Cement 1. Manufacturing of cement is carried out in 3 operations. Mixing of raw ingredients Burning Grinding 2. Generally two methods are available for the manufacturing of cement. Dry process method (Modern method) Wet process method

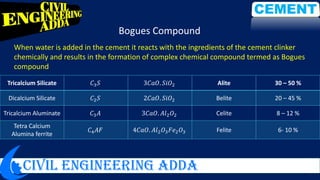

- 12. CEMENT Bogues Compound When water is added in the cement it reacts with the ingredients of the cement clinker chemically and results in the formation of complex chemical compound termed as Bogues compound Tricalcium Silicate 𝐶3 𝑆 3𝐶𝑎𝑂. 𝑆𝑖𝑂2 Alite 30 – 50 % Dicalcium Silicate 𝐶2 𝑆 2𝐶𝑎𝑂. 𝑆𝑖𝑂2 Belite 20 – 45 % Tricalcium Aluminate 𝐶3 𝐴 3𝐶𝑎𝑂. 𝐴𝑙2 𝑂2 Celite 8 – 12 % Tetra Calcium Alumina ferrite 𝐶4 𝐴𝐹 4𝐶𝑎𝑂. 𝐴𝑙2 𝑂3 𝐹𝑒2 𝑂3 Felite 6- 10 %

- 13. CEMENT 1. Tri-Calcium Silicate This compound is formed with in a week on the addition of water in cement. It is responsible for the development of strength of the concrete in its initial age. If in any structure early development of strength is required proportion of tri-calcium silicate is increased. For ex- prefabricate concrete construction, cold weather concrete, where form work is to be removed early in speedy construction. Heat of hydration of tri-calcium silicate is higher in comparison to di-calcium silicate Bogues Compound

- 14. CEMENT Bogues Compound 2. Di-Calcium Silicate It is the last compound that is formed during the hydration process which may take an year or so for its formation. It is responsible for progressive strength of the concrete in its later stage, it means it gives ultimate strength to the structure. Heat of hydration is very less in this case. Di-calcium silicate in high proportion is used in cement in hydraulic structure ( gravity dams, canals etc.), bridges, mass concreting etc. 𝐶3 𝑆 gives faster rate of reaction accompanied by greater heat evolution and gives early strength. On the other hand, 𝐶2 𝑆 hydrate and hardens slowly and provides much of the ultimate strength.

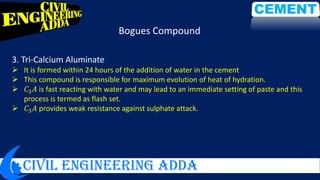

- 15. CEMENT Bogues Compound 3. Tri-Calcium Aluminate It is formed within 24 hours of the addition of water in the cement This compound is responsible for maximum evolution of heat of hydration. 𝐶3 𝐴 is fast reacting with water and may lead to an immediate setting of paste and this process is termed as flash set. 𝐶3 𝐴 provides weak resistance against sulphate attack.

- 16. CEMENT Bogues Compound 4. Tetra-Calcium Aluminate ferrite It is also formed with in 24 hours of the addition of the water. This compound is also responsible for high heat of hydration. 𝐶3 𝐴 and 𝐶3 𝐴𝐹 contributes less in strength ( ‹ 10 %).

- 17. CEMENT Hydration Of Cement The chemical reaction that takes place between cement and water is referred as hydration of cement. The reaction of cement with water is exothermic. During hydration 𝐶3 𝑆 & 𝐶2 𝑆 react with water and calcium silicate hydrate ( C-S-H) gel is formed along with calcium hydroxide 2𝐶3 𝑆 + 6𝐻 𝐶3 𝑆2 𝐻3 + 3𝐶𝑎(𝑂𝐻)2 + 𝐻𝑒𝑎𝑡 2𝐶2 𝑆 + 4𝐻 𝐶3 𝑆2 𝐻3 + 𝐶𝑎(𝑂𝐻)2 + 𝐻𝑒𝑎𝑡 More quantity of calcium hydroxide is formed in hydration of 𝐶3 𝑆 in comparison to 𝐶2 𝑆.

- 18. CEMENT Hydration Of Cement Disadvantages of Calcium Hydroxide Calcium hydroxide is not a desirable product in the concrete mass because it is soluble in water and gets leached out, making the concrete porous, less durable, particularly in hydraulic structure. The calcium hydroxide also reacts with sulphates present in soils and water to form calcium sulphate which further reacts with 𝐶3 𝐴 and cause disintegration of concrete. This is known as Sulphate Attack Advantages of Calcium Hydroxide The only advantage is that it is alkaline in nature and it maintains PH value around 13 in the concrete which resist the corrosion of reinforcement.

- 19. CEMENT Quantity of water required in hydration of cement It has been estimated that on an average 23% of water by weight of cement is required for chemical reaction. This 23% of water chemically combines with cement and therefore it is called bound water. A certain quantity of water is imbided with in the gel course, this water is known as gel water. It has been estimated that about 15% by weight of cement is required to fill up the gel course. Therefore a total of 38% of water by weight of cement is required for the complete chemical reaction and occupy the space with in the gel course.

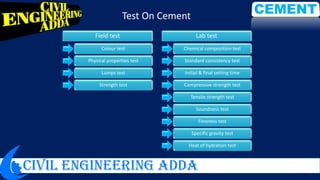

- 20. CEMENTTest On Cement Field test Colour test Physical properties test Lumps test Strength test Lab test Chemical composition test Standard consistency test Initial & final setting time Compressive strength test Tensile strength test Soundness test Fineness test Specific gravity test Heat of hydration test

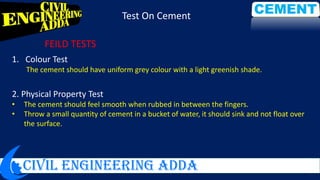

- 21. CEMENTTest On Cement 1. Colour Test The cement should have uniform grey colour with a light greenish shade. 2. Physical Property Test • The cement should feel smooth when rubbed in between the fingers. • Throw a small quantity of cement in a bucket of water, it should sink and not float over the surface. FEILD TESTS

- 22. CEMENTTest On Cement 3. Lumps Test – the sample of the cement should be free from the presence of lumps which are formed due to the absorbtion of moisture from the atmosphere by the cement. 4. Strength Test – Prepare a block of 25mm x 25mm x 200mm from the given sample of the cement and immersed it in water for curing for 7 days, remove the block and placed it over the support that are 150 mm apart. Subject the block to a point load of 340 N. It should show no sign of failure under the application of this load.

- 23. CEMENTTest On Cement 1. Standard Consistency Test The test estimate the quantity of mixing water to form a cement paste of normal consistency. Normal consistency is defined as the % water requirement of the cement paste, the viscosity of paste will be such that the vicat plunger penetrates up to 33 mm to 53 mm from the top (5 mm to 7 mm from bottom) of the vicat mould. LAB. TESTS

- 24. CEMENTTest On Cement 1. Standard Consistency Test PROCEDURE Take 500 gm of cement and mix it with 24% of water by weight in the first trail. Remove all the air voids present in the sample Release the 10 mm dia. Plunger gently to allow it to penetrate into the mould and gind depth of penetration from the top. For Ordinary cement, 33 to 35 mm penetration from the top corresponds to standard consistency of cement The % water corresponding to standard consistency is denoted by ‘P’. Temperature 27⁰C ± 2⁰C and relative humidity 90%. LAB TESTS

- 25. CEMENTTest On Cement 1. Standard Consistency Test Initial and Final setting time a. A cement paste is prepared with 500 gram of cement + 0.85 times the ‘P’ water (0.85P water) to prepare the paste. b. Cement paste is filled in Vicat apparatus c. 1 sqmm needle is lowered gently and penetration is recorded. d. Procedure is repeated until the needle fails to penetrate the mould by about 5 mm to 7 mm measured from the bottom of the mould. e. Time period between the time when water was added to prepare the paste and whe needle fails to penetrate the mould by 5 mm to 7 mm from bottom is taken as initial setting time. LAB. TESTS

- 26. CEMENTTest On Cement 1. Standard Consistency Test Initial and Final setting time e. Now the needle is replaced by a needle with 5 mm diameter annular collar. f. Time interval when the centre needle makes an impression on the sample but annular collar fails to give impression to the same cement paste, is taken as the final setting time. LAB. TESTS For OPC – Initial Setting Time = 30 min Final Setting Time = 10 hours

- 27. CEMENTTest On Cement 1. Soundness Test Purpose of this test is to detect change in volume of cement after setting. Soundness can be measured by following test I. Le-Chatelier’s test II. Auto-clave LAB. TESTS

- 28. CEMENTTest On Cement 1. Soundness Test Le-Chatelier’s Test o Apparatus Apparatus of this test consist a split cylinder of 30 mm diameter and 30 mm height, having a split of size 0.5 mm along the length of cylinder Indicator arms of 160 mm are placed on either side of split to measure the size of the split. LAB. TESTS

- 29. CEMENTTest On Cement 1. Soundness Test Le-Chatelier’s Test o Procedure Cement paste is prepared with 100 gram of cement sample + 0.78P of water. A mould of 30mm diameter and 30mm height is placed on glass plate and it is filled with cement paste. Now mould is covered with another glass plate and small weight is placed on this glass plate. Mould is than submerged in the water at temperature of 27⁰C to 32⁰C for 24 hours. After 24 hours mould is taken out at and the distance saperating the indicator arms is measured. LAB. TESTS

- 30. CEMENTTest On Cement 1. Soundness Test Le-Chatelier’s Test o Procedure Mould is again submerged in water and water is now in boiled condition for 3 hours. Mould is removed from water and the distance between the indicator arms is measured again. Difference between these two measurements represent the soundness of cement. LAB. TESTS For OPC, Rapid hardening cement, PPC, this value is limited to 10 mm whereas for sulphate cement, high alumina cement, this value should not exceed 5 mm

- 31. CEMENTTest On Cement 1. Soundness Test Auto-Clave Test This method calculate soundness due to lime and magnesia. In this test a mould of 25 mm is prepared (cube) and placed in Autoclave. Steam pressure is raised in the autoclave such that gauge pressure of 21 kg/sqcm is attained in 1 hour which is maintained for next 3 hours. Remove the sample and measure the change in dimension. LAB. TESTS For OPC, the change in any dimension should not be greater than 0.8%. i.e. 25 × 0.8 100 = 0.2 𝑚𝑚, therefore, Final dimension ≥ 25.2 mm

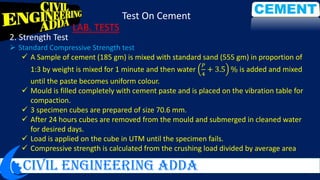

- 32. CEMENTTest On Cement 2. Strength Test Standard Compressive Strength test A Sample of cement (185 gm) is mixed with standard sand (555 gm) in proportion of 1:3 by weight is mixed for 1 minute and then water 𝑃 4 + 3.5 % is added and mixed until the paste becomes uniform colour. Mould is filled completely with cement paste and is placed on the vibration table for compaction. 3 specimen cubes are prepared of size 70.6 mm. After 24 hours cubes are removed from the mould and submerged in cleaned water for desired days. Load is applied on the cube in UTM until the specimen fails. Compressive strength is calculated from the crushing load divided by average area LAB. TESTS

- 33. CEMENTTest On Cement 2. Strength Test Standard Compressive Strength test LAB. TESTS NOTE ≈ 50% of 28 day strength ≈ 2/3 of 28 days strength 3 days ( 𝑁 𝑚𝑚2 ) 7 days ( 𝑁 𝑚𝑚2 ) 28 days ( 𝑁 𝑚𝑚2 ) OPC 33 grade 16 23 33 OPC 43 grade 23 33 43 OPC 53 grade 27 37 53 PPC 16 23 33

- 34. CEMENTTest On Cement 2. Strength Test Tensile Strength test There is no test to measure the tensile strength of the cement directly. o Procedure Briquette method is the indirect method to measure the tensile strength of the cement. Mixture of cement and sand is prepared in 1:3 at % of water is 𝑃 5 + 2.5 % In this test 12 numbers of standard briquette are prepared to measure the tensile strength of cement. LAB. TESTS

- 35. CEMENTTest On Cement 2. Strength Test Tensile Strength test o 𝑇𝑒𝑛𝑠𝑖𝑙𝑒 𝑠𝑡𝑟𝑒𝑛𝑔𝑡ℎ = 𝑇𝑒𝑛𝑠𝑖𝑙𝑒 𝑓𝑜𝑟𝑐𝑒 𝑎𝑡 𝑓𝑎𝑖𝑙𝑢𝑟𝑒 𝐶𝑟𝑜𝑠𝑠 𝑠𝑒𝑐𝑡𝑖𝑜𝑛 𝑎𝑟𝑒𝑎 = 𝑇𝑒𝑛𝑠𝑖𝑙𝑒 𝑓𝑜𝑟𝑐𝑒 𝑎𝑡 𝑓𝑎𝑖𝑙𝑢𝑟𝑒 25.4 ×25.4 𝑚𝑚2 = 𝑇𝑒𝑛𝑠𝑖𝑙𝑒 𝑓𝑜𝑟𝑐𝑒 𝑎𝑡 𝑓𝑎𝑖𝑙𝑢𝑟𝑒 6.45 𝑐𝑚2 LAB. TESTS

- 36. CEMENTTest On Cement 3. Specific Gravity Test Specific gravity of cement is obtained by using “Le-chatelier’s flask. In this method either kerosene or napthene having specific gravity not less than 0.73 is used. LAB. TESTS Specific gravity of cement solid = 3.15

- 37. CEMENTTest On Cement 4. Fineness Test Fineness of the cement is tested in order to check its extent of grinding that directly effect the rate of hydration, rate of gain of strength and rate of evolution of heat. Fineness of the cement can be tested by any of the following method:- a. Sieve test (using 90 µ sieve) b. Air permeability test. (Nurse and Blain test) c. Sedimentation method. LAB. TESTS

- 38. CEMENTTest On Cement 4. Fineness Test a. Sieve test (using 90 µ sieve) 100 g of cement sample is taken & lumps in the sample are broken fingers. Sample is placed on a 90 µ sieve & continuously sieve for 15 min & note the weight of the residue left over the sieve after the test. LAB. TESTS For OPC the % weight residue should not be more than 10%.

- 39. CEMENTTest On Cement 4. Fineness Test b. Air permeability test no. 2250 This method of test covered the procedure for determining the fineness of the cement that is represented as specific surface area. Specific surface area = 𝑇𝑜𝑡𝑎𝑙 𝑠𝑢𝑟𝑓𝑎𝑐𝑒 𝑎𝑟𝑒𝑎 𝑢𝑛𝑖𝑡 𝑤𝑒𝑖𝑔ℎ𝑡 Unit – ( 𝑚2 𝑘𝑔 ) or ( 𝑐𝑚2 𝑔𝑚 ) The principle of this test is based on the relationship between flow of air through the cement bed and the surface area of the cement particles forming the cement bed. LAB. TESTS For OPC, 𝑆𝑆𝐴 ≮ 225 𝑚2 𝑘𝑔

- 40. CEMENTTest On Cement 5. Heat of Hydration Test Heat of hydration of cement is measured by Calorimeter. LAB. TESTS 𝐶3 𝐴 865 𝑗 𝑔𝑚 > 𝐶3 𝑠 500 𝑗 𝑔𝑚 > 𝐶3 𝐴𝐹 420 𝑗 𝑔𝑚 > 𝐶2 𝑆 260 𝑗 𝑔𝑚 Rate of hydration 𝐶3 𝐴𝐹 > 𝐶3 𝐴 > 𝐶3 𝑆 > 𝐶2 𝑆

- 41. CEMENTTest On Cement 6. Chemical Composition Test Ratio of alumina to that of iron oxide should no be less than 0.6 𝐴𝑙2 𝑂3 𝐹𝑒2 𝑂3 ≮ 0.66 Lime saturation ratio 0.66 < 𝐶𝑎𝑂 − 0.7𝑆𝑂3 2.8𝑆𝑖𝑂2 + 1.2𝐴𝑙2 𝑂3 + 0.65𝐹𝑒2 𝑂3 < 1.02 Total sulphur content not be greater than 2.75% Weight of magnesia(MgO) ≯ 5% % of Insoluble residue ≯ 1.5% LAB. TESTS

- 42. CEMENT Types Of Cement • Ordinary Portland Cement • RHC • Extra RHC • Quick Setting Cement • Sulphate resisting cement • Super Sulphate Cement • Portland Slag Cement • PPC • High Alumina Cement • Hydrophobic cement • IRS T-40 Cement

- 43. CEMENTTypes Of Cement 1. Ordinary Portland cement Prepare yourself

- 44. CEMENTTypes Of Cement 2. Rapid Hardening cement This cement achieve high rate of development of strength it should not be confused with quick setting cement which only sets quickly. The early strength of this cement is because of higher % of 𝐶3 𝑆 (approx. 56%) and lower % of 𝐶2 𝑆. This cement attains strength at the age of 3 days, equivalent to the strength of OPC at 7 days. Uses Emergency repair works In rigid pavement construction Where formwork is to be remove early to ensure further construction. In cold weather condition where rate of hydration is slow due to low temperature.

- 45. CEMENTTypes Of Cement 3. Extra Rapid Hardening cement It is manufactured by integrating of RHC clinkers with 2% 𝐶𝑎𝐶𝑙2. This cement achieve 25% more strength than RHC in 1 day and 10 to 20% more strength tha RHC in 7 days Uses This cement is not used these days because it is seen that chlorine creates cracks.

- 46. CEMENTTypes Of Cement 4. Quick Setting Cement This cement is produced by mixing a small quantity of 𝐴𝑙2(𝑆𝑂4)3 in fine grinding cement & increasing the 𝐶3 𝐴 and reducing the cement Initial setting time is 5 minutes and final setting time is 30 minutes. Uses Construction in stagnant and running water.

- 47. CEMENTTypes Of Cement 5. Sulphate Resisting Cement This cement is produced by reducing the proportion of calcium aluminate (𝐶3 𝐴 𝑎𝑛𝑑 𝐶4 𝐴𝐹). This cement has resistance against sulphate attack. Uses – Marine structures Sewage treatment plant Foundation and basement in the soil having higher concentration of sulphate.

- 48. CEMENTTypes Of Cement 6. Super Sulphate Cement This cement is manufactured by integrating of 80 to 85% slag (residue of iron industry), 10 to 15 % gypsum & 5% of cement clinker. This cement is more resisting to the attack of sulphate than sulphate resisting cement. Uses – Marine structures Sewage treatment plant Foundation and basement in the soil having higher concentration of sulphate.

- 49. CEMENTTypes Of Cement 7. Portland Slag Cement It is manufactured by mixing the cement clinker with blast furnace slag & gypsum in pre determined proportion. This cement is low heat cement which has relatively more resistance against sulphate attack. It gains strength with time. It offers less permeability and this cement is also cheap Uses – Marine structures In construction of hydraulic structures. Sewage treatment plant Foundation and basement in the soil having higher concentration of sulphate.

- 50. CEMENTTypes Of Cement 8. Portland Pozzolona Cement In pozzolonic material cilicious or aluminous compounds are present which do not have its own cementing properties but in presence of water it reacts with 𝐶𝑎(𝑂𝐻)2 (release during hydration of cement) and form cementing material (C-S-H gel). 𝐶𝑒𝑚𝑒𝑛𝑡 + 𝑤𝑎𝑡𝑒𝑟 → 𝐶 − 𝑆 − 𝐻 𝑔𝑒𝑙 + 𝐶𝑎 𝑂𝐻 2 + ℎ𝑒𝑎𝑡 𝑃𝑜𝑧𝑧𝑜𝑙𝑜𝑛𝑖𝑐 𝑚𝑎𝑡𝑒𝑟𝑖𝑎𝑙 + 𝐶𝑎(𝑂𝐻)2 + 𝐻2 𝑂 → 𝐶 − 𝑆 − 𝐻 𝑔𝑒𝑙 Examples of pozzolonic material – Fly ash, Rice Husk, Meta Kaoline (type of clay) PPC is manufactured by integrating of OPC clinker with 10% to 30% of pozzolonic material. Properties – It is a low heat cement. This cement is more resisting against sulphate attack. It offers less permeability. This cement is more plastic and workable in compare to OPC.

- 51. CEMENTTypes Of Cement 9. Low Heat Cement This cement is produce by reducing the % of 𝐶3 𝐴 & 𝐶3 𝑆 and corresponding increasing the % of 𝐶2 𝑆 ( Nearly 46 %) The rate of development of strength is low but 28 days strength is same as OPC. Uses Mass Concreting (dams, foundation walls, piles etc.)

- 52. CEMENTTypes Of Cement 10. High Alumina Cement This cement is manufactured by grinding Bauxite ( this contain aluminium > 32%) & the ratio of alumina to lime must be in the range of 0.85 to 1.3 Initial setting time = 3.5 hours Final setting time = 5 hours Hence in this cement we can take more time to place the cement and less time to remove the form work. This cement is more resistant against the attack of sulphate. Uses – it evolve great heat during setting hence not affected by frost action.

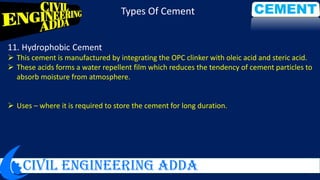

- 53. CEMENTTypes Of Cement 11. Hydrophobic Cement This cement is manufactured by integrating the OPC clinker with oleic acid and steric acid. These acids forms a water repellent film which reduces the tendency of cement particles to absorb moisture from atmosphere. Uses – where it is required to store the cement for long duration.

- 54. CEMENTTypes Of Cement 12. IRS T-40 Cement It is specified type of cement in which higher % of 𝐶3 𝑆 is ensured to develop high early strength. Used in manufacturing the concrete sleepers for Indian Railways.