cheema boiler

- 2. Cheema Boilers Limited is one of India's premier engineering solutions company serving industry's energy requirements. Cheema Boilers Limited builds high capacity boilers for steam-generation power generation & process heating and provides turnkey integrated power plant solutions. Established in 1999

- 3. Bending Machine Rolling Machine Pipe cutter Machine welding Machine

- 4. This machine is used to bend the pipes of the boiler at certain angle. This machine is run by the computer. In the computer I was entered the required angle and required force and specific point where to start the bending. And run that command and the machine was perform the operation according to my requirement

- 5. This machine is used for the boiler plates. This machine is worked manually. In which 3 rollers are placed and the plate is rolled by these 3 rollers and a crane is move upward that rolled plate with the help of the safety joints.

- 6. This machine is performing the cutting operation on the pipes. This machine is run on the computerized technique. In the computer software put the total length of the pipe and the length to cut the pipe and material of the pipe and force required and drives the command to the machine and machine is cut the pipe.

- 7. To join the boiler pipe this is the basic common operation to be performed. In company maximum Arc welding is to be used to join the boiler plates. But for continues welding use submerged arc welding. In this process a wire is used which is run under granular flux.

- 8. A boiler is a closed pressure vessel strongly constructed of steel or iron where water is converted to steam by application of heat. A boiler or steam generator is used wherever a source of steam is required. The form and size depends on the application.

- 9. In Power Sectors In Independent Power Plant (IPP) & Captive Power Plant (CPP). In Process Plants In Oil Refineries, Paper Industry, Sugar Industry, Chemical Industry, Rice mill, Steel Industry etc.

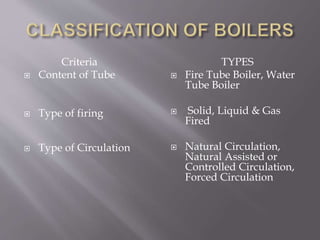

- 10. Criteria Content of Tube Type of firing Type of Circulation TYPES Fire Tube Boiler, Water Tube Boiler Solid, Liquid & Gas Fired Natural Circulation, Natural Assisted or Controlled Circulation, Forced Circulation

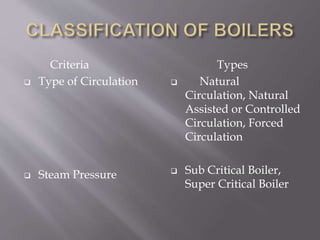

- 11. Criteria Type of Circulation Steam Pressure Types Natural Circulation, Natural Assisted or Controlled Circulation, Forced Circulation Sub Critical Boiler, Super Critical Boiler

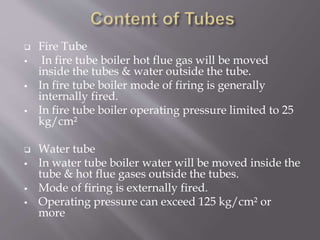

- 12. Fire Tube In fire tube boiler hot flue gas will be moved inside the tubes & water outside the tube. In fire tube boiler mode of firing is generally internally fired. In fire tube boiler operating pressure limited to 25 kg/cm² Water tube In water tube boiler water will be moved inside the tube & hot flue gases outside the tubes. Mode of firing is externally fired. Operating pressure can exceed 125 kg/cm² or more

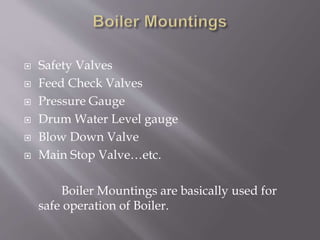

- 13. Safety Valves Feed Check Valves Pressure Gauge Drum Water Level gauge Blow Down Valve Main Stop Valve…etc. Boiler Mountings are basically used for safe operation of Boiler.

- 14. Safety Valve: The Function of a safety valve is to blow off steam when the pressure in the boiler exceeds the working pressure. Feed Check Valve: A feed check valve is used to control the supply of feed water to boiler & also to act as a non- return valve. Pressure Gauge: Pressure gauge indicates the pressure of steam in a boiler. Drum Water Level Gauge: The Function of water gauge glass is to indicate the water level in the Drum. Blow down Valve: Blow down Valves are designed for continuous use to control the concentration of dissolved solids in boiler water. Main Stop Valve: Function of a steam stop valve is to stop or allow the flow of steam from the boiler to Main Stream line.

- 15. Drum Economizer Water Walls Radiant Roof Tubes Steam Cooled Walls LTSH Coil Div Panelist SH Platen SH

- 16. Codes and specification: ASME Sec VII Div 1 BS 5500,IS 2825,IS 803 or as per any other standard Specification: Thickness: up to 125mm Length: 20mtr Weight: upto 60tons Diameter: upto 5mtr Material of construction: Stainless steel 300 & 400 series Carbon steel /Low alloy steel Alloy steel etc.