Classification of boilers

- 1. ME 6701 POWER PLANT ENGINEERING Faculty A.R.PALANIVELRAJAN Assistant Professor Department of Mechanical Engineering 1

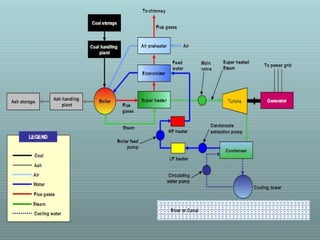

- 2. Layout of Steam Power PLant The Layout consists of four circuits namely Coal and ash circuit. Air and gas circuit. Feed water and steam flow circuit. Cooling water circuit.

- 4. CLASSIFICATION OF BOILERS HORIZONTAL, VERTICAL OR INCLINED BOILER If the axis of the boiler is horizontal, the boiler is called horizontal, if the axis is vertical, it is called vertical boiler and if the axis is inclined it is called as inclined boiler. The parts of horizontal boiler is can be inspected and repaired easily but it occupies more space. The vertical boiler occupies less floor area.

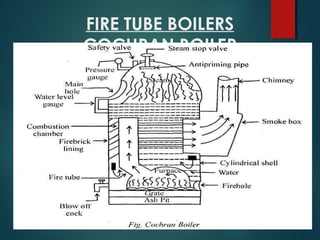

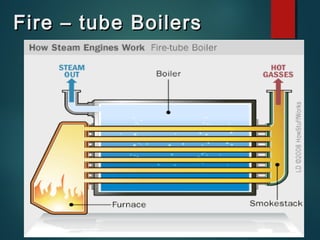

- 5. FIRE TUBE AND WATER TUBE In the fire boilers, the hot gases are inside the tubes and the water surrounds the tubes. Examples: Cochran, Lancashire and Locomotive boilers. In the water tube boilers, the water is inside the tubes and hot gases surround them. Examples: Babcock and Wilcox, Stirling, Yarrow boiler etc.

- 6. EXTERNALLY FIRED AND INTERNALLY FIRED The boiler is known as externally fired if the fire is outside the shell. Examples: Babcock and Wilcox boiler, Stirling boiler etc. In case of internally fired boilers, the furnace is located inside the shell. Examples: Cochran, Lancashire boiler etc.

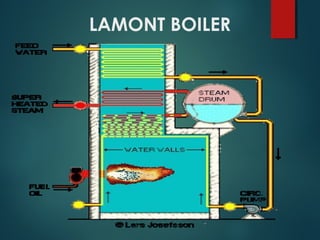

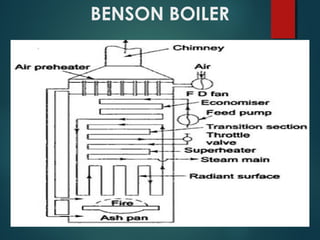

- 7. FORCED CIRCULATION AND NATURAL CIRCULATION In forced circulation type of boilers, the circulation of water is done by a forced pump. Examples: Velox, Lamont, Benson Boiler etc. In natural circulation type of boilers, circulation of water in the boiler takes place due to natural convention currents produced by the application of heat. Examples: Lancashire, Babcock and Wilcox boiler etc.

- 8. HIGHER PRESSURE AND LOW PRESSURE BOILERS The boiler which produce steam at pressures of 80 bar and above are called high pressure boilers. Examples: Babcock and Wilcox, Velox, Lamont, Benson Boiler etc. The boilers which produce steam at pressure below 80 bar are called low pressure boilers. Examples: Cochran, Cornish, Lancashire and Locomotive boiler etc.

- 9. SINGLE TUBE AND MULTI TUBE BOILER The fire tube boilers are classified as single tube and multi- tube boilers, depending upon whether the fire tube is one or more than one. Examples: Cornish ,simple vertical boiler are the single tube boiler and rest of the boilers are multi-tube boiler.

- 10. BOILER MOUNTINGS Boiler mountings are the machine components that are mounted over the body of the boiler itself for the safety of the boiler and for complete control of the process of steam generation.

- 11. Various boiler mountings are as under: 1) Pressure gauge 2) Water Level Indicator 3) Fusible plug 4)Safety Valve 5) Steam stop valve 6) Feed check valve 7) Blow off cock

- 12. PRESSURE GAUGE To record the steam pressure at which the steam is generated in the boiler.

- 13. WATER LEVEL INDICATOR The function of water level indicator is to indicate the level of water in the boiler constantly

- 14. FUSIBLE PLUG To extinguish fire in the event of water level in the boiler shell falling below certain specified limit. It protects fire tubes from burning when the level of the water in the water shell falls abnormally low. It is installed below boiler's water level. When the water level in the shell falls below the top of the plug, the steam cannot keep it cool and the fusible metal melts due to over heating.

- 15. SAFETY VALVE The function of safety valve is to release the excess steam when the pressure of steam inside the boiler exceeds the rated pressure.

- 16. STEAM STOP VALVE A valve is a device that regulates the flow of a fluid (gases, fluidized solids, slurries, or liquids) by opening, closing, or partially obstructing various passageways. Its function is to shut off or regulate the flow of steam from the boiler to the steam pipe or steam from the steam.

- 17. FEED CHECK VALVE The function of a feed check valve is to control the supply of water to the boiler and to prevent the escaping of water from the boiler when the pump pressure is less or pump is stopped.

- 18. BLOW OFF COCK To drain out the water from the boiler for internal cleaning, inspection, repair or other purposes.

- 21. FIRE TUBE BOILERS COCHRAN BOILER

- 23. Fire – tube BoilersFire – tube Boilers

- 28. MODERN HIGH PRESSURE BOILERS A boiler which generates steam at pressure greater than 80 bar, a temperature of about 500 degree, producing steam more than 250 tons per hour called high pressure boilers.

- 29. LAMONT BOILER

- 30. BENSON BOILER

- 31. LOEFFLER BOILER

- 32. VELOX BOILER

- 35. FLUIDIZED BED BOILERS • Fluidized bed boilers produce steam from fossil and waste fuels by using a technique called fluidized bed combustion. • These can be divided into two types: 1. Bubbling fluidized bed (BFB) boilers 2. Circulating fluidized bed (CFB) boilers Fluidized bed : defined as the bed of solid particles behaving as a fluid. 35

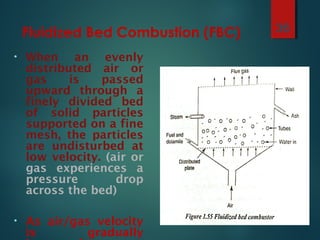

- 36. Fluidized Bed Combustion (FBC) • When an evenly distributed air or gas is passed upward through a finely divided bed of solid particles supported on a fine mesh, the particles are undisturbed at low velocity. (air or gas experiences a pressure drop across the bed) • As air/gas velocity is gradually 36

- 37. Fluidized Bed Combustion (FBC) • With further increase in air/gas velocity, there is bubble formation, vigorous turbulence, rapid mixing and formation of dense defined bed surface. • The bed of solid particles exhibits the properties of a boiling liquid and assumes the 37

- 38. Fluidized Bed Combustion (FBC) • If solid particles in a fluidized state is heated to the ignition temperatures of coal, and coal is injected continuously into the bed, the coal will burn rapidly and bed attains a uniform temperature. • The fluidized bed combustion (FBC) takes place at about 840°C to 950°C. • Since this temperature is much below the ash fusion temperature, melting of ash and associated problems are avoided. 38

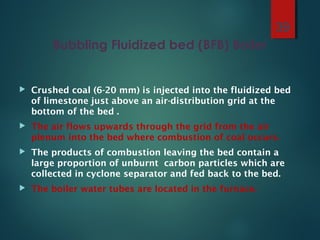

- 39. Bubbling Fluidized bed (BFB) Boiler Crushed coal (6-20 mm) is injected into the fluidized bed of limestone just above an air-distribution grid at the bottom of the bed . The air flows upwards through the grid from the air plenum into the bed where combustion of coal occurs. The products of combustion leaving the bed contain a large proportion of unburnt carbon particles which are collected in cyclone separator and fed back to the bed. The boiler water tubes are located in the furnace. 39

- 40. Schematic of bubbling Fluidized Bed Boiler 40

- 41. Bubbling Fluidized bed (BFB) Boiler As a result of low combustion temperatures (800 – 900°C ), inferior grades of coal can be used without slagging problems and there is less formation of Nox. The volumetric heat release rates are 10 to 15 times higher and the surface heat transfer rates are 2 to 3 times higher than a conventional boiler. This makes the boiler more compact. 41

- 42. Advantages of Fluidized Bed Boilers Fluidized bed combustion (FBC) has emerged as a viable alternative and has significant advantages over conventional firing system and offers multiple benefits – compact boiler design, fuel flexibility, higher combustion efficiency and reduced emission such as SOx and NOx. The fuels burnt in these boilers include coal, rice husk, bagasse & other agricultural wastes. The fluidized bed boilers have a wide capacity range- 0.5 T/hr to over 100 T/hr. 42

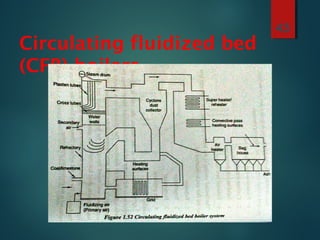

- 43. Circulating fluidized bed (CFB) boilers 43

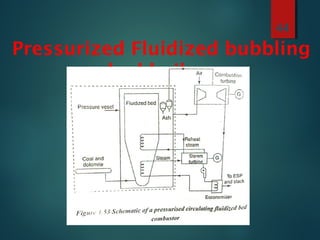

- 44. Pressurized Fluidized bubbling bed boilers 44

- 45. Pressurized Circulating Fluidized bed boilers 45

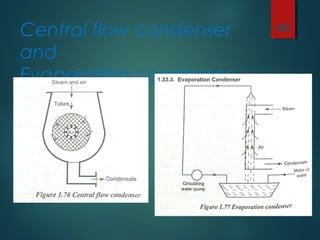

- 46. Condensers It is closed vessel in which steam is condensed by abstracting the heat and where the pressure is maintained below atmospheric pressure by continuously condensing the steam by means of circulating cold water at atmospheric temperature. Types: 1.Down flow condenser 2.Central flow condenser 3.Evaporation condenser 46

- 47. Down flow condenser 47

- 48. Central flow condenser and Evaporation condenser 48