Cracks in Buildings

- 2. Contents 1. Introduction 2. Dangers & affects of cracks 3. TYPES OF CRACKS 4. Causes & Preventive measures 5. Techniques to cure cracks 6. conclusion 7. REFERENCES www.CIVILSCHOLAR.com

- 3. 1. Introduction A crack is a complete or incomplete separation of concrete into two or more parts produced by breaking or fracturing. Cracks are one kind of universal problems of concrete construction as it affects the building artistic and it also destroys the wall’s integrity, affects the structure safety and even reduce the durability of structure www.CIVILSCHOLAR.com

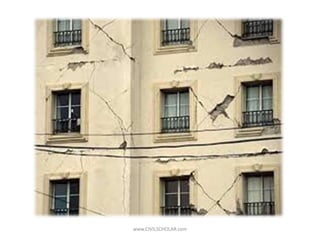

- 5. 2. Dangers & affects of cracks Carbon dioxide penetrates into the concrete through the cracks and speed up carbonation around the cracks, thus shortening the structure usage. The cracks in the concrete wall would cause the leakage of the building; it reduces the stiffness, durability and seismic performance of buildings. Cracks on the wall surface damage to the later rendering, will affect to the appearance. www.CIVILSCHOLAR.com

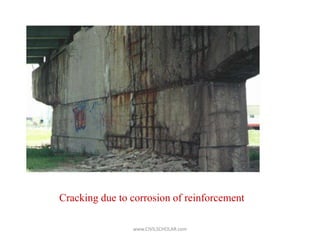

- 6. Cracking due to corrosion of reinforcement www.CIVILSCHOLAR.com

- 7. 3. TYPES OF CRACKS I. Structural Cracks: These cracks occur due to incorrect design, faulty construction or overloading and these may endanger the safety of a building. II. Non-Structural Cracks: They are due to internal forces developed in materials due to moisture variations, temperature variation, crazing, effects of gases, liquids etc. III. Based On Width: a) Thin - less than 1mm in width b) Medium - 1 to 2mm in width c) Wide - more than 2mm in widthwww.CIVILSCHOLAR.com

- 8. cracks around window opening cracks around drilled hole cracks on the columnwww.CIVILSCHOLAR.com

- 9. Horizontal cracks in the middle of wall vertical cracks in the middle of wall www.CIVILSCHOLAR.com

- 10. 4. Causes & Preventive measures A. Elastic Deformation B. Thermal Movement C. Chemical Reaction D. Shrinkage E. Foundation Movement and Settlement of Soil F. Earthquake G. Vegetation H. Poor Construction practices www.CIVILSCHOLAR.com

- 11. Effect of variation in water content of concrete on drying shrinkage www.CIVILSCHOLAR.com

- 12. Relation between mix proportion and drying shrinkage of cement concrete mortar www.CIVILSCHOLAR.com

- 13. Roots of Fast Growing Tree Under the Foundation of Compound Wall www.CIVILSCHOLAR.com

- 14. 5. Techniques to cure cracks i. Epoxy injection: Cracks as narrow as 0.002 in. (0.05 mm) can be bonded by the injection of epoxy. The technique generally consists of establishing entry and venting ports at close intervals along the cracks, sealing the crack on exposed surfaces and injecting the epoxy under pressure. However, unless the cause of the cracking has been corrected, it will probably recur near the original crack.www.CIVILSCHOLAR.com

- 17. ii. Routing and sealing: This method involves enlarging the crack along its exposed face and filling and sealing it with a suitable joint sealant. The procedure is most applicable to approximately flat horizontal surfaces such as floors and pavements. However, routing and sealing can be accomplished on curved surfaces (pipes, piles and pole). www.CIVILSCHOLAR.com

- 18. iii. Stitching: The stitching procedure consists of drilling holes on both sides of the crack, cleaning the holes and anchoring the legs of the staples in the holes, with either a non- shrink grout or an epoxy resin-based bonding system. Stitching may be used when tensile strength must be reestablished across major cracks. www.CIVILSCHOLAR.com

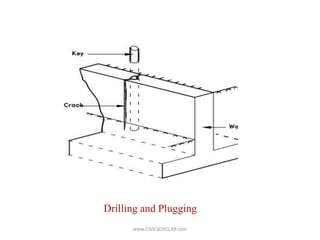

- 20. iv. Drilling and plugging : Drilling and plugging a crack consists of drilling down the length of the crack and grouting it to form a key. This technique is only applicable when cracks run in reasonable straight lines and are accessible at one end. This method is most often used to repair vertical cracks in retaining walls. www.CIVILSCHOLAR.com

- 22. v. Gravity Filling: Low viscosity monomers and resins can be used to seal cracks with surface widths of 0.001 to 0.08 in. (0.03 to 2 mm) by gravity filling. High-molecular- weight methacrylate, urethanes, and some low viscosity epoxies have been used successfully. The lower the viscosity, the finer the cracks that can be filled. Wet surfaces should be permitted to dry several days to obtain the best crack filling.www.CIVILSCHOLAR.com

- 23. 6. conclusion Though it is impossible to guarantee against cracking yet attempts can be made to minimize development of crack. In case of existing cracks, after detail study and analysis of crack parameters, most appropriate method of correction should be adopted for effective and efficient repair of crack. www.CIVILSCHOLAR.com

- 24. 7. REFERENCES https://www.researchgate.net/publication/277715230 _Study_of_Cracks_in_Buildings SP 25:“HANDBOOK ON CAUSES AND PREVENTION OF CRACKS IN BUILDINGS” theconstructor.org › Building Technology basharesearch.com/IJASGE/1040105.pdf www.CIVILSCHOLAR.com