Cutter mill.pptx

- 1. TOPIC: Classification of SIZE Reduction& Cutter Mill PHARMACEUTICAL ENGINEERING Prepared by kashish Wilson Assistant Professor, MM College of Pharmacy, MM(DU),Mullana Ambala

- 2. SIZE REDUCTION: INTRODUCTION: Size reduction is a process of reducing large solid unit masses into small unit masses, coarse particles or fine particles. Size reduction process also termed as comminution or diminution or pulverisation. Size reduction may be achieved by TWO methods Precipitation process Mechanical process

- 3. OBJECTIVE OF SIZE REDUCTION : It improves appearance. It increases surface area. It facilitate absorption and bioavailability. It improves the stability. It facilitate extraction. It facilitate mixing. In aerosol and inhalation preparation. Parental suspension. It facilitate drying. Ophthalmic suspension. Increase in viscosity.

- 4. Precipitation process : • Substances is dissolved in an appropriate solvent. Subsequently, it is finely precipitated by the addition of another solvent. • Which is miscible with the first, but in the later substance is insoluble. • This method is suitable for the production of raw materials and bulk drugs. Mechanical process: The substances is subject to mechanical forces using grinding equipment. E.g.: ball mill, roller mill. Dry grinding or milling is used in the production of tablets, capsules. Wet grinding is used in the preparation of suspensions, emulsions and ointments.

- 5. Modes of size reduction: Cutting: The material is cut by means of a sharp blades Eg : cutter mill Compression: In this mode material is crushed between roller by the application of pressure Eg : roller mill Impact: This involve the operation of hammer/bars at high speeds. When a lump of material strikes the rotating hammers, the material splits apart. Eg : fluid energy mill Attrition: breaking down by the rubbing action between two surfaces. Eg : fluid energy mill, ball mill

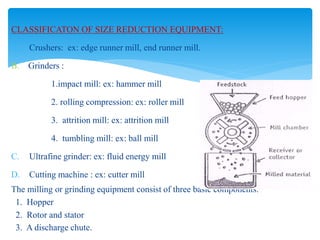

- 6. CLASSIFICATON OF SIZE REDUCTION EQUIPMENT: A. Crushers: ex: edge runner mill, end runner mill. B. Grinders : 1.impact mill: ex: hammer mill 2. rolling compression: ex: roller mill 3. attrition mill: ex: attrition mill 4. tumbling mill: ex: ball mill C. Ultrafine grinder: ex: fluid energy mill D. Cutting machine : ex: cutter mill The milling or grinding equipment consist of three basic components. 1. Hopper 2. Rotor and stator 3. A discharge chute.

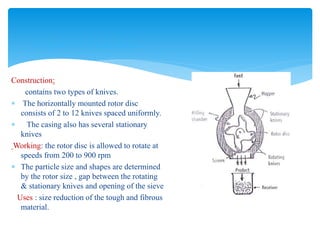

- 7. ROTARY CUTTER MILL : Construction: contains two types of knives. The horizontally mounted rotor disc consists of 2 to 12 knives spaced uniformly. The casing also has several stationary knives Working: the rotor disc is allowed to rotate at speeds from 200 to 900 rpm The particle size and shapes are determined by the rotor size , gap between the rotating & stationary knives and opening of the sieve Uses : size reduction of the tough and fibrous material.

- 8. Thank you