Dam construction

- 1. E4014 Construction Surveying Dam Construction

- 2. Objectives On completion of the module you should be capable of: • describing the various types of dam construction • describing the provision of spillways and river diversions • planning detail surveys for damsite design • planning dam wall monitoring surveys • reading and understanding the plans and drawings associated with dam construction

- 3. Introduction The material covered in this lecture is specific to dam construction. It is assumed that the concept of control and detail surveys is already known by the student

- 4. Dams Dams are constructed for one or more of the following purposes: • Storage of water for urban supply • storage of water for farm irrigation • flood mitigation

- 5. Dams • A watertight seal placed in a river in order to create a lake or reservoir by impounding the stream flow • Must be stable under all loading conditions • must resist – hydrostatic pressures on its upstream face – destructive influences of water perculation and possible uplift due to it

- 6. Investigation for Dams Factors to be considered include: • Geological conditions – effect the location and construction of the foundations, abutments, dam itself, and spillways • long and short term stream flow • rainfall and storage reservoir characteristics of the proposed dam catchment • access road

- 7. Investigation for Dams Factors to be considered continued: • local availability of earth and rock materials and their suitability for dam construction – or as concrete aggregates • degree of permeability of the rock formation on which the dam is to be placed – may affect hydrostatic uplift pressures and the degree of grouting necessary to control it

- 8. Investigation for Dams Factors to be considered continued: • planning for river diversion to occur while the dam is being constructed – cutting a temporary channel which by-passes the dam itself – installation of large pipes under the dam

- 9. Investigation for Dams Factors to be considered continued: • provision of sites for: – water intake structures and pumping stations for water supply dam – Penstocks ( inlet tower ) – power station in the case of hydro-electric facilities

- 10. Investigation for Dams Factors to be considered continued: • an Environmental Impact Study – short and long term effects of of the proposed reservoir and the construction operations on the region – aesthetics, plant and animal, ecology, fish preservation and public amenity of the reservoir and downstream reaches – noise and dust hazards in construction – effects of the dam on the regional micro-climate

- 11. Types of Dams Dams are classified by the materials of which they are constructed: • earth • earth and rock • rock • concrete

- 12. Types of Dams The first three can be subgrouped as embankment dams whilst there are also several different types of concrete dams: • Embankment – earth - earth and rock – rock • concrete – solid gravity - concrete arch – arch-gravity - hollow gravity – prestressed concrete

- 13. Embankment Dams One constructed of naturally excavated materials • Two sub groups – earthfill – rockfill

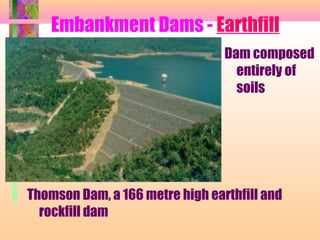

- 14. Embankment Dams - Earthfill Dam composed entirely of soils Thomson Dam, a 166 metre high earthfill and rockfill dam

- 15. Embankment Dams - Earthfill • Fine grained impervious material • only moderate stability, necessitating flat side-slopes • protect slopes from erosion by layers of rock rip-rap

- 16. Embankment Dams - Earthfill • Symmetrical zoned material • somewhat steeper slopes • most common type

- 17. Embankment Dams - Earthfill • Hybrid of types A and B • large upstream impervious section • transition zone • downstream pervious zone • may be used when rapid reservoir draw

- 18. Embankment Dams - Earthfill Process of dam construction: • All vegetable matter and organic material is cleared from the dam site • grout holes for the cut-off curtain are drilled to a depth where the grout curtain will effectively seal off the seepage of water beneath the proposed dam

- 19. Embankment Dams - Earthfill Process of dam construction: • The holes are filled with cement-water at sufficient pressure to force it into rock fissures beneath the dam foundation

- 20. Embankment Dams - Earthfill Process of dam construction: • When placing the embankment layers of soil should be kept horizontal, but graded slightly from the centre to the sides • layers should be approx – 150mm after compaction for impervious core – 225mm for outer pervious zones

- 21. Embankment Dams - Earthfill Process of dam construction: • Protection of the embankment from upstream wave action – stone rip rap commonly used • prevention of erosion on dry downstream side – grass, stone or concrete • No earth dam should be overtopped from the reservoir, spillways are provided to discharge excess water from the reservoir

- 22. Embankment Dams - Earthfill Crotty Dam, an 82 metre high concrete-faced rockfill structure.

- 23. Embankment Dams - Embankment Windamere Dam under construction, a 69m high, Earth and Rock Fill Dam Brown clay core in centre of photo with light grey andesite rock fill both upstream (left) and downstream (right) of clay core. Note the narrow zones of dark brown filter material between the clay core and the rock fill both upstream and downstream of the core. In foreground drilling rigs are being used to drill grout holes in the conglomerate, sandstone and shale foundation. Grouting is used to fill open cracks in the foundation rock so water cannot leak out of the dam and is carried out by pumping grout (a mixture of cement and water) under pressure into holes drilled in the foundation rock.

- 24. Embankment Dams - Embankment or Concrete Provided suitable materials are available embankment dams often offer a more economical alternative to concrete structures The inability of the abutment materials to take the thrust from a concrete dam may dictate the construction of an embankment dam however many sites are suited to concrete dams

- 25. Concrete Dams - Types Types of concrete dams include: – solid gravity – concrete arch – arch-gravity – hollow gravity – prestressed concrete

- 26. Concrete Dams - Solid Gravity Straight or curved relying on its weight for stability • Concrete using large aggregate ( 150mm to 225mm maximum size ) • dam is made up of individual vertical blocks with construction joints – later grouted to prevent leakage

- 27. Concrete Dams - Solid Gravity Warragamba Dam, 142 metre high concrete gravity dam

- 28. Concrete Dams - Buttress Sloping concrete slab supported on a number of buttresses • Massive buttress occurs when the buttresses touch

- 29. Concrete Dams - Arch Upstream curvature transmitting the majority of its load onto the abutments • Base thickness < 60% of its height • where base thickness > 60% of its height, the dam is essentially a curved gravity dam • suited to deep, narrow gorges of strong abutment material • constructed in blocks- appropriate shrinkage gaps and construction joints

- 30. Concrete Dams - Arch • Gordon Dam in Tasmania is a 140 metre high concrete arch dam

- 31. Concrete Dams - Arch Gravity Combination of gravity and arch dams curved gravity dams

- 32. Concrete Dams - Hollow Gravity Rely upon their weight for stability for watertightness, an impervious reinforced concrete membrane supported by buttresses securely keyed into sound rock • Include – slab and buttress, with inclined membrane – massive buttress, touching buttresses – conoidal, with a plane upstream face and identical massive buttresses – multiple-arch, membrane is a series of arches as distinct from a slab

- 33. Concrete Dams - Prestressed Downstream curvature dam subjected to compressive forces before filling after filling, tensile stresses resulting in the dam are counteracted by the already existing compressive forces

- 34. River Diversion Before the dam can be constructed, diversion of the river is necessary Satisfactory handling of the stream flow during construction is vital to the success of the work cost of river diversion must be compared with the risk of all or parts of the new dam in peak flood conditions types of diversion tunnel, flume, concrete or steel pipeline and open channel

- 35. River Diversion Building a Cofferdams act diversion as barriers to tunnel the river Construction of the dam Closure of the and power station diversion tunnel

- 36. Spillways • When dams are designed provision needs to be made to cope with large floods. Spillways are built to provide a path for floodwater to flow over or around the dam • Spillways on concrete dams are usually constructed to allow water to flow over the top. • Spillways associated with embankment dams are built to take the water around the side of the dam and away from the downstream face.

- 37. Spillways • Overflow Spillway – overflows a special section of the dam itself • Byewash Spillway – separate open flood channel cut through a nearby saddle and with a small weir at the upstream end • Side-Inlet Spillway – located on the steep side of the gorge – direction of flow is parallel to the crest of the river • Drop-Inlet Spillway – water enters via a horizontal lip, drops through a vertical or sloping shaft and discharges through a horizontal or gently sloping culvert

- 38. Spillways • Overflow Spillways • Glennies Creek Dam spillway

- 39. Spillway Gates • Allow control over the level of fill of the reservoir • Used for three reasons: – to reduce the cost of the dam – to reduce the inundation of land in the reservoir area – to reduce the downstream flood damage • Three types – sliding gates - shutters running grooves – roller gates - employ rollers on the shutters – radial gates - form an arc pivoting on a trunion bearing

- 40. Outlet • Necessary to make provision for the discharge of water as and when it is required for irrigation etc. • Separate outlet required – commonly a pipe passing under or through the dam, with discharge controlled by valves

- 41. Damsite Surveys • Study of existing topographic maps and aerial photographs will indicate possible dam sites. • An estimate of catchment area and storage capacity can also be made • Surveys required – contour survey – watershed traverse – stability of site – cadastral surveys

- 42. Dam Site Surveys - Contour Survey • Following selection of a possible site an aerial survey should be undertaken to provide a more detailed contour of the storage area • Typical scale, 1 : 10000 with a 2m contour interval • Allows more accurate computation of storage capacity • if the site is feasible, the survey provides a more concise design location of the dam wall • marks placed during the control survey for photo control also provides control for all future surveys

- 43. Dam Site Surveys - Watershed Traverse • Where insufficient information exists to accurately determine the catchment area, it may be necessary to carry out a watershed traverse

- 44. Dam Site Surveys - Stability of Site • Dam must be positioned where it will be stable and where the storage area does not have excessive underground leakage • Soil and rock features must be carefully examined • Large dams require test pits, bore holes and detailed geological survey • small dams may require only test holes to determine sub-surface features • the position of each investigation must be accurately located

- 45. Dam Site Surveys - Cadastral Surveys • Land to be inundated is resumed by the constructing authority • Cadastral surveys required to delineate the land to be resumed • Surveys will also be required to close roads passing through inundated land

- 46. Surveys in Dam Wall Area • General location of dam wall has been decided from earlier surveys • Further surveys are required within this area to aid final design and computation of volumes of excavation and fill - detail surveys - clearing of site - definition of dam wall on plan - pipeline surveys - location of limits of dam on ground - road access - by-wash - pumping stations

- 47. Surveys in Dam Wall Area - Detail Surveys • More intense geological and soil surveys are carried out – ensure absence of geological faults – determine required depth of stripping • Detail and contour survey locating all topographic features, test-bores etc. – total stations or GPS – scale 1 : 1000, contour interval 1m

- 48. Surveys in Dam Wall Area - Definition of Dam Wall on Plan • Following consideration of all factors, it is now possible to to define the centreline of the dam wall on the contour plan – also, working to specified batters, the extent of the earthworks can be plotted on the contour plan

- 49. Surveys in Dam Wall Area - Definition of Dam Wall on Plan • Crest RL 550m • 5m wide pavement on top • batters 2:1

- 50. Surveys in Dam Wall Area - Locate Dam Limits on Ground • Stability of dam is dependent on – foundations, – materials used, and – method of construction • Foundations – remove all unsuitable material or unstable material from within the limits of the dam wall • Requires definition of the limits of the wall marked on the ground – toe of batters require pegging

- 51. Surveys in Dam Wall Area - Grout Curtains • Grout is pumped down drill holes bored along the centreline and on either side of it • Centreline must be marked before actual construction commences

- 52. Surveys in Dam Wall Area - By-Wash • The downstream face of an embankment dam will scour if water flows over the dam crest • an outlet or by-wash channel is necessary to allow excess water to flow around the dam wall to be discharged away from the dam wall – large dams normally have a large concrete channel • The horizontal and vertical position of the by-wash must be defined on the ground

- 53. Surveys in Dam Area - Clearing of Site • Usual to clear the dam storage area of vegitation and tree cover prior to filling of the dam • Requires definition of the limits of the dam storage area marked on the ground – running the contour equal to full storage level

- 54. Surveys in Dam Area - Additional Surveys • Pipeline alignment and sections from dam to consumer • pipeline easement surveys • access roads to dam site, and • surveys for siting and constructing pumping stations

- 55. Surveys in Dam Area - Stability of Dam Wall • Monitoring surveys – to determine if any horizontal or vertical movement occurs after construction and in later years – unusual movement may indicate dam failure • Fix permanent marks along the crest of the dam wall and over the downstream face • regular control surveys required – must be able to identify small movement of say 3mm in horizontal or vertical

- 56. Small Dams • Contour survey of pondage area is undertaken by ground survey rather than aerial survey • only test bore-holes are used to determine sub surface features with respect to site stability investigations • by-wash need only be a grass channel

- 57. Proposed Earth Dam, General Arrangement and Detail (Sheet 1 of 6) • Plan of Works Area – dam centreline – by-wash – Drop Inlet • Longitudinal Section • Embankment - Type Section • Storage Capacity Diagram

- 58. Proposed Earth Dam, General Arrangement and Detail (Sheet 1 of 6) - Plan of Works Area

- 59. Proposed Earth Dam, Plan of Storage Area (Sheet 2 of 6) • Control Traverse • horizontal control – datum, permanent marks • vertical control – datum, bench marks • full storage level • test holes, test Pit Logs

- 60. Proposed Earth Dam, Standard 600 * 100 Drop Inlet (Sheet 5 of 6) • Typical Abutment Plan and elevation • By-Wash Location Plan

- 61. Proposed Earth Dam, Setting Out Survey (Sheet 6 of 6) • Assist with setting out batter points