Description of design process

- 1. Description of Design Process CONCEPTS IN ENGINEERING DESIGN Chapter 3-41

- 3. Concept Development Embodiment design Detail Design PRODUCT 3

- 4. THE PRODUCT DEVELOPMENT PROCESS. Sequence of steps or activities which an enterprise employs to conceive, design, manufacture & commercialize a product. 4

- 6. 6

- 7. 7

- 8. 8

- 9. PRODUCT PLANNING It is an activity that considers the portfolio of projects that an organization might pursue, and What subset of these projects the organization would pursue rigorously over a defined period of time. 9

- 10. Why Product Planning? It helps determine.. . What product development projects to be undertaken? What mix of fundamentally new products, platforms and derivative products to be pursed? How do various products relates to each other as portfolio? What will be the timing & sequence of the projects? Product development team must know its mission before starting the exercise of development Product planning leads to a mission statement for the team. 10

- 11. Mission Statement What market segments should be considered in designing the product and developing the features? What new technologies (if any) should be incorporated into the new product? What are the manufacturing and service goals and constraints? What are the financial targets for the projects? What are the budget and time frame for the project? 11

- 12. MISSIONSTATEMENT Product Description Key Business Goals Primary Market Secondary Markets Assumptions Stakeholders 12

- 14. Product Planning Helps in Maximizing the effectiveness of its product development efforts by Identifying set of potential projects Deciding which projects are most desirable Launching each project with a focused mission. 14

- 15. Product Plan Is dynamic Competitive environment Changes in technology Information management of success stories Involves senior management Exercised once a year or a few times each year 15

- 16. Bad Product Plan leads to Not proper coverage of target markets with competitive products. Poor timing of introducing products into the market. Mismatches between aggregate development capacity and the number of projects pursued. Poor distribution of resources, with some projects overstaffed and others understaffed. Frequent cancellations of poorly planned projects. Frequent changes in the goals and destinations of the projects. 16

- 17. Who Designs & Develops Products? Marketing Design Manufacturing 17

- 18. Challenges of Product Development Trade-off Performance v/s Cost, Efficiency v/s Technology Dynamics Technology , Customer’s change in Preferences, Competitions’ Challenge. Details Cost of 1 g of material can convert into cost of crores of investment. Time Pressure Fast evolving world, small time to decide and without complete information. Economics Designing, producing & selling takes huge investment & reasonable ROI (return on investment). 18

- 19. Factors for Success Four key factors that determine the success of a product in the marketplace. The quality, performance, and price of the product. The cost to manufacture the product over its life cycle. The cost of product development. The time needed to bring the product to the market. 19

- 20. The team that brings the product first to market enjoys an initial price advantage and subsequent cost advantages from manufacturing efficiencies. 20

- 22. Simplified technology development cycle. Transferring from one technology growth curve (A) to another developing technology (B). 22

- 23. Conceptual design Conceptual design is the process by which the design is initiated, carried to the point of creating a number of possible solutions, and narrowed down to a single best concept. It is sometimes called the feasibility study. Conceptual design is the phase that requires the greatest creativity, involves the most uncertainty, and requires coordination among many functions in the business organization. 23

- 24. The following are the discrete activities that we consider under conceptual design. Identification of customer needs: The goal of this activity is to completely understand the customers’ needs and to communicate them to the design team. Problem definition: The goal of this activity is to create a statement that describes what has to be accomplished to satisfy the needs of the customer. This involves analysis of competitive products, the establishment of target specifications, and the listing of constraints and trade-offs. Gathering information: Engineering design presents special requirements over engineering research in the need to acquire a broad spectrum of information. Conceptualization: Concept generation involves creating a broad set of concepts that potentially satisfy the problem statement. Team-based creativity methods, combined with efficient information gathering, are the key activities. 24

- 25. Concept selection: Evaluation of the design concepts, modifying and evolving into a single preferred concept, are the activities in this step. The process usually requires several iterations. Design review: Before committing funds to move to the next design phase, a design review will be held. The design review will assure that the design is physically realizable and that it is economically worthwhile. It will also look at a detailed product development schedule. This is needed to devise a strategy to minimize product cycle time and to identify the resources in people, equipment, and money needed to complete the project. 25

- 27. MOTIVATION? Identification of a set of customers’ needs Product often benefits when they satisfy needs Information channel between customers and product developers. Use environment. Needs ≈ Wants ≈ Customer Attributes ≈ Customer Requirements ≈ Customer Insights. 27

- 28. Targets Product is focused on customer needs. To identify latent / hidden needs as well as explicit needs. Its fact based to justify the specification & concepts there after. Creation of archival record of the need activity of the development process. No critical product need is missed or non-accounted for. Helps in developing common understanding between team. 28

- 29. Needs versus Specifications Needs independent of product developed. Development does not know how and when needs would be fulfilled. Needs independent of Concept selected while specifications depends on concept selected. Specifications depends on technical and economic feasibility and product range of competitors. Specifications also depends on customer needs. 29

- 30. Stepstoidentifyneeds Gather Raw Data from Customers Interpret Raw Data in terms of Needs Organize the needs into hierarchy, Primary, Secondary and/or Tertiary needs Establish Relative Importance of Needs Results Analysis 30

- 31. Customer Needs Development project starts with specifying • Particular market opportunity • Broad constraints, and • Project objectives Mission Statement or Charter or Design Brief Mission statement output of Product Planning Mission Statement specifies the direction to proceed but does not specify a precise destination or manner to proceed. 31

- 32. 32

- 33. Gather Raw Data from Customers User Research Defining User Journey Map or Product Touch Points Finding Right Customers Interviews Focus Groups Observing Product in Use / Experience it 33

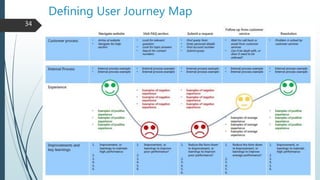

- 34. Defining User Journey Map 34

- 35. Gather Raw Data from Customers Finding Right Customers Identify Users, Buyers, Service Persons & lot more Determine Lead Users - Can articulate their needs - They might have solutions to address these needs - Explicit needs of lead users are mostly the Latent need for the majority market Locating Customer - Recruiting agency - Sales team - Social networking 35

- 36. Lead Users Identifies needs ahead of the market. Needs explicit to them are still latent for the majority. Can articulate their emerging needs. Most often, they invent the solutions to the problems. Helps the designer leapfrog competition. 36

- 37. Gather Raw Data from Customers Interviews Conducted at customer’s environment Duration one to two hours 37

- 38. Gather Raw Data from Customers Focus Groups 8 – 12 customers; approx. duration two hours Moderator governed At times video recorded too Domain – Market Research 38

- 39. Gather Raw Data from Customers Product Observation Elicit data on how a customer uses a product. Mostly a passive exercise but at times, side-by-side working with a customer also exercised. Do-it-yourself tool – product usage simple and natural. Other tools used first on surrogate tasks e.g. surgical tools. 39

- 40. Gather Raw Data from Customers Choosing Customers Interviews 10 – 50 for single market segment. Sequential and terminated as soon as no new data is revealed by the customer. For multiple distinct market segment – 10 or more interviews in each segment. Question to be addressed: Who should be interviewed? The buyer or the user ??? 40

- 41. 41

- 42. 42

- 43. Gather Raw Data from Customers Art of eliciting Customer Needs Be receptive and avoid confrontation or defensive posturing Mostly verbal Prepared interview guide Dipstick Interviews with known users Go with flow Gather all possible information with all possible mean Use visual stimuli & props Try to find stories Go deep under these stories/incidents with follow up questions 43

- 44. Gather Raw Data from Customers Art of eliciting Customer Needs Avoid preconceived notions being formed about product technology. Let the customer demonstrate the product. Watch out for surprises and expressions carrying latent needs. Non-verbal information – comfort, image or style icon. Do observe carefully, facial expression, other movements, especially “Expressions”. Note his/her surrounding in details. 44

- 45. 45

- 46. 46

- 47. 47

- 48. 48

- 49. 49

- 50. 50

- 51. 51

- 52. Gather Raw Data from Customers Documenting Interactions with customers Notes Audio Recording Video Recording Photography Debriefing 52

- 53. Gather Raw Data from Customers Results Raw data in the form of customer statements. Data template implemented in spreadsheet Question, Customers’ statement / observation, Interpreted need. Clues – humorous remarks, less serious suggestions, frustrations, nonverbal information, observations and descriptions of the use environment. Thank you Note 53

- 54. 54

- 55. 55

- 56. 56

- 57. Interpret Raw Data into Needs 57

- 58. Interpret Raw Data into Needs 58

- 59. Interpret Raw Data into Needs Needs Each observation may be translated into any number of customer needs. Multiple analysts are required to translate customer statements into interpreted needs. Some needs technologically not realizable. At times, customers give conflicting needs (No attempt to resolve) Product Specifications is the output of needs + technical & economic constraints 59

- 60. Express the needs in terms of “WHAT” not “HOW”. Interpret Raw Data into Needs 60

- 61. Interpret Raw Data into Needs Capture the need as specifically as RAW DATA. Needs are evolved and expressed at different levels of detail. Express the need at the same level of detail as raw data, otherwise loss of information. I drop my phone all the time The phone operates normally after dropped repeatedly by accident. The phone is rugged 61

- 62. Interpret Raw Data into Needs 62

- 63. Interpret Raw Data into Needs 63

- 64. 64

- 65. Organize Needs into Hierarchy Primary needs Secondary needs Tertiary needs Or Must have, Can have, May have … 65

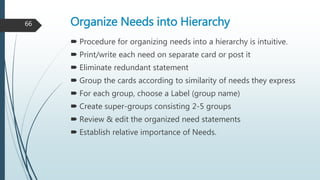

- 66. Organize Needs into Hierarchy Procedure for organizing needs into a hierarchy is intuitive. Print/write each need on separate card or post it Eliminate redundant statement Group the cards according to similarity of needs they express For each group, choose a Label (group name) Create super-groups consisting 2-5 groups Review & edit the organized need statements Establish relative importance of Needs. 66

- 67. 67

- 68. Establish Relative Importance of the Needs Numerical weightages assigned. Two approaches: •Consensus of team members based on their experience with the customers. •Importance assessment on further customer surveys. Trade off – cost and speed v/s accuracy. Survey responses characterized by (a) the means, (b) the standard deviation, or (c) the number of responses in each category. 68

- 69. 69

- 70. 70

- 71. 71

- 72. Result and Process Analysis Identification of customer needs structured. Team must challenge its results to verify that they are consistent with the knowledge and intuition of the team Some points to be taken care are: 1. All important types of customers are interacted 2. The latent needs of the target customers are captured 3. Areas of inquiry to be pursued are identified 4. Identification of customers that may be good participants 5. Any surprise need? 6. All concerned in the organization are associated 7. How the process may be improved in future? 72

- 73. Benchmarking Benchmarking is a process for measuring a company’s operations against the best practices of companies both inside and outside of their industry. It takes its name from the surveyor’s benchmark or reference point from which elevations are measured. Benchmarking can be applied to all aspects of a business. It is a way to learn from other businesses through an exchange of information. Benchmarking operates most effectively on a ‘quid pro quo’ basis as an exchange of information between companies that are not direct competitors but can learn from each other’s business operations. 73

- 75. Types of Design Information 75

- 76. Sources of Information Pertinent to Engineering Design 76

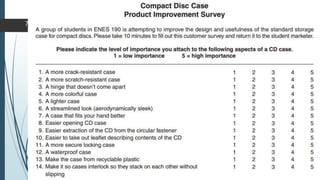

- 79. Creative thinking methods BRAINSTORMING The brainstorming process is structured to overcome many of the mental blocks that curb individual creativity in team members who are left to generate ideas on their own. 79

- 80. Idea Generating Techniques Beyond Brainstorming Six Key Questions Journalism students are taught to ask six simple questions to ensure that they have covered the entire story. These same questions can be used to help you approach the problem from different angles. Who? Who uses it, wants it, will benefit by it? What? What happens if X occurs? What resulted in success? What resulted in failure? When? Can it be speeded up or slowed down? Is sooner better than later? Where? Where will X occur? Where else is possible? Why? Why is this done? Why is that particular rule, action, solution, problem, failure involved? How? How could it be done, should it be done, prevented, improved, changed, made? 80

- 81. Five Whys The Five Whys technique is used to get to the root of a problem. It is based on the premise that it is not enough to just ask why one time. For example: Why has the machine stopped? A fuse blew because of fan overload. Why was there an overload? There was inadequate lubrication for the bearings. Why wasn’t there enough lubrication? The lube pump wasn’t working. Why wasn’t the pump working? The pump shaft was vibrating because it had worn due to abrasion. Why was there abrasion? There was no fi lter on the lube pump, allowing debris into the pump. 81

- 82. Fantasy or Wishful Thinking A strong block to creativity is the mind’s tenacious grip on reality. One way to stimulate creativity is to entice the mind to think in a fl ight of fancy, in the hope of bringing out really creative ideas. This can be done by posing questions in an “invitational way” so as to encourage an upbeat, positive climate for idea generation. Typical questions would be: Wouldn’t be nice if . . . . ? What I really want to do is . . . . If I did not have to consider cost, . . . I wish . . . 82

- 83. FUNCTIONAL DECOMPOSITION AND SYNTHESIS A common strategy for solving any complex task or describing any complex system is to decompose it into smaller units that are easier to manage. Decomposing must result in units that meaningfully represent the original entity. 83

- 85. Behavioral Aspects of Decision Making Unconflicted adherence: Decide to continue with current action and ignore information about risk of losses Unconflicted change: Uncritically adopt whichever course of action is most strongly recommended. Defensive avoidance: Evade conflict by procrastinating, shifting responsibility to someone else, and remaining inattentive to corrective information. Hypervigilance: Search frantically for an immediate problem solution. Vigilance: Search painstakingly for relevant information that is assimilated in an unbiased manner and appraised carefully before a decision is made. 85

- 86. EVALUATION METHODS Evaluation is a type of decision making in which alternatives are first compared before making the decision as to which is best. 86

- 87. Pugh Concept Selection Method Concept Screening Method A relative comparison technique Compares each concept relative to a reference or datum concept and rate them as better / poor / same as the reference concept Studies show that an individual is best in creating ideas but a small group is better at selecting ideas. Thus, design team does the concept selection, usually in successive rounds of examination and deliberation 87

- 88. Pugh selection chart for comparing the design alternatives for redesign88

- 89. The steps in concept selection (given by Clausing) are: 1. Choose the criteria by which the concepts will be evaluated. 2. Formulate the design matrix – Criteria as rows and concepts as columns 3. Choose the datum concept: One concept is chosen as a datum for the first round – this is the reference concept with which all other concepts are compared – choose the better concept and mark the relevant column as DATUM 4. Run the matrix: Comparative evaluation with three level scale – better (+), worse (-) or about the same level (S, =, 0) – appropriate symbols are put in the cells of the matrix 5. Evaluate the ratings: Sum of the +, - and = (0) ratings are determined for each concept – All the concepts with net ‘+ve’ score are continued with, all with ‘-ve’ score are rejected and all with same ‘0’ score are combined 89

- 90. 6. Establish a new datum and re-run the matrix: New datum – Usually the concept with the highest rating in the first round – eliminate the lowest rating scores from the 2nd round – purpose is to verify that the selection in Round 1 is valid 7. Plan further work: Look for missing pieces of information, calculations or experiments that need to be made or experts that need to be consulted. 8. Second working session: A major advantage of Pugh Concept Selection method is that it helps the team to develop better insights into the types of features that strongly satisfy the design requirements. 90

- 91. Concept generation and selection, viewed as alternating divergent and convergent processes91

- 92. EMBODIMENT DESIGN Much of the activity at this stage is devoted to 1. Finalizing the product architecture, 2. Determining the form or shape of parts that will satisfy the required functions, 3. Quantifying the important design parameters Embodiment design is also called as analytical design, as it is the design phase where most of the detailed analysis and calculations occurs. Conceptual Design Preliminary (Embodiment) Design Detail Design 92

- 93. Embodiment phase of design Product architecture— determining the arrangement of the physical elements of the design into groupings, called modules. Configuration design —the design of special-purpose parts and the selection of standard components, like pumps or motors. Parametric design— determining the exact values, dimensions, or tolerances of the components or component features that are deemed critical-to-quality. 93

- 94. Embodiment phase of design Product architecture— determining the arrangement of the physical elements of the design into groupings, called modules. Four Steps of Embodiment Design 1. Create a schematic diagram of the product. 2. Cluster the elements of the schematic. 3. Create a rough geometric layout. 4. Identify the interactions between modules. 94

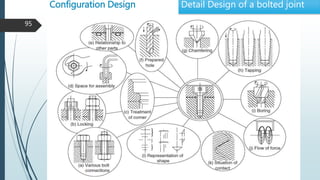

- 95. Configuration Design 95 Detail Design of a bolted joint

- 96. Identify the likely ways the part might fail in service. Identify likely ways that part functionality might be compromised. Materials and manufacturing issues Design knowledge base 96 Configuration Design

- 97. Parametric Design The objective of parametric design is to set values for the design variables that will produce the best possible design considering both performance and cost Robustness means achieving excellent performance under the wide range of conditions that will be found in service. 97

- 98. Interrelationship between function and form and, in turn, their dependence on the material and the method of production 98

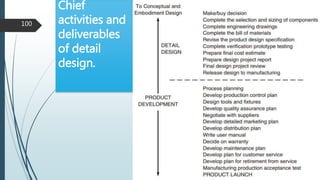

- 99. Detail Design Last stage of design process. It is the phase where all of the details are brought together, all decisions are finalized, and a decision is made to release the design for production. Poor detail design can ruin a brilliant design concept and lead to manufacturing defects, high costs, and poor reliability in service The reverse is not true - A brilliant detail design will not rescue a poor conceptual design Detail design is the lowest level in the design abstraction hierarchy. Many decisions have been made to get to this point. Most of these decisions are very basic to the design and to change them now would be costly in time and effort. Thus, detail design is mainly concerned with filling in the details to ensure that a proven and tested design can be manufactured. 99

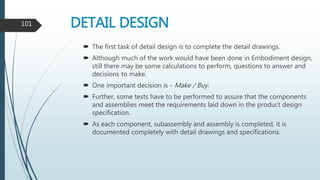

- 101. DETAIL DESIGN The first task of detail design is to complete the detail drawings. Although much of the work would have been done in Embodiment design, still there may be some calculations to perform, questions to answer and decisions to make. One important decision is - Make / Buy. Further, some tests have to be performed to assure that the components and assemblies meet the requirements laid down in the product design specification. As each component, subassembly and assembly is completed, it is documented completely with detail drawings and specifications. 101

- 102. The specifications contain information on: The technical performance of the part Its dimensions Test requirements Material requirements Reliability requirements Design life Packaging requirements, and Marking for shipment The specification should be sufficiently detailed to avoid confusion at any stage. If the product design is complex, then it is necessary to impose a Design Freeze at some point prior to completion. no change permitted without approval Design Record Document 102

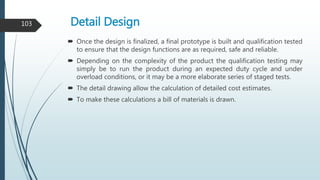

- 103. Detail Design Once the design is finalized, a final prototype is built and qualification tested to ensure that the design functions are as required, safe and reliable. Depending on the complexity of the product the qualification testing may simply be to run the product during an expected duty cycle and under overload conditions, or it may be a more elaborate series of staged tests. The detail drawing allow the calculation of detailed cost estimates. To make these calculations a bill of materials is drawn. 103

- 104. Detail Design Once these steps are successfully completed it is time to review the complete product design in a final design review. This involves: • Top corporate management • The chief design personnel • The responsible manufacturing personnel • The customer (if the product has a defined customer) The successful outcome of the design review is the release of the design to the manufacturing department With release to manufacturing department, detail design phase is over but Product Development process does not end here. Many task are left to launch the product. 104

- 105. Detail Design Drawings must contain the information needed to manufacture the product The drawings should be so complete that they leave no room for misinterpretation The information on a detail drawing includes: Standard views of orthogonal projection – top, front, side Auxiliary views such as sections, enlarged views, isometric views that aid in visualizing the component and clarifying the details Dimensions – presented according to the GD&T standard Tolerances Material specification, and any special processing instructions Manufacturing details, such as parting line location, draft angle, surface finish 105

- 106. Planning for Manufacture Design for Manufacture Material Selection in Design Selection of Manufacturing Processes 106

- 107. Design to Manufacture Role of design in manufacturing – well realized – Simultaneous Engineering or DFM • All aspects of manufacturing should be kept in mind: • Low product cost • Low lead time • Product quality • The designer should capture the strength of the manufacturing company • Designer must have a reasonable knowledge of as well as access to manufacturing 107

- 108. MATERIAL SELECTION IN DESIGN In the beginning the design is fluid and the options are wide – as the design becomes more focused the choice is sharpened. Choice of material depends on Choice of Process Cost The form, texture, feel, colour and decoration of the product Aesthetic aspects Good designs work but excellent design in addition to that gives pleasure 108

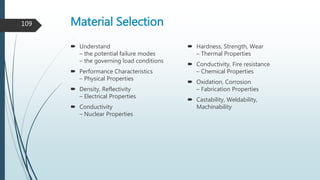

- 109. Material Selection Understand – the potential failure modes – the governing load conditions Performance Characteristics – Physical Properties Density, Reflectivity – Electrical Properties Conductivity – Nuclear Properties Hardness, Strength, Wear – Thermal Properties Conductivity, Fire resistance – Chemical Properties Oxidation, Corrosion – Fabrication Properties Castability, Weldability, Machinability 109

- 110. Selection of Manufacturing Processes Shape generation Changes in internal microstructure Changes in properties of materials As Functional Decomposition of a design can be done in terms of energy, material and information flows Similar is the case with manufacturing Energy flow is required to cause the material flow to give shape Information flow (both shape and material property information) depends on the type of material, the processes used, the tooling used and the pattern of movement of the material relative to the tooling 110

- 111. Selection of Manufacturing Processes Eight categories (Broader): 1. Solidification (Casting) Processes 2. Deformation Processes 3. Material Removal or Cutting (Machining) Processes 4. Polymer Processing 5. Powder Processing 6. Joining Processing 7. Heat Treatment and Surface Treatment 8. Assembly Processes 111

- 112. Selection of Manufacturing Processes The factors that influence the selection of a process to make a part are: 1. Cost of manufacture and life cycle cost 2. Quantity of parts required 3. Complexity – shape, form, size 4. Material 5. Quality of part 6. Availability, lead time and delivery schedule 112

- 113. Planning for Distribution Important technical and business decisions must be made to provide for the effective distribution to the consumer of the products that have been produced. In the strict realm of design, the shipping package may be critical. Concepts such as the shelf life of the product may also be critical and may need to be addressed in the earlier stages of the design process. A system of warehouses for distributing the product may have to be designed if none exists. 113

- 114. 114 Planning for Use The use of the product by the consumer is all-important. The following specific topics can be identified as being important user- oriented concerns in the design process: • Ease of maintenance, • Durability, • Reliability, • Product safety, • Convenience in use (human factors engineering), • Aesthetic appeal, and • Economy of operation. It is becoming increasingly important with the growing concerns for consumer protection and product safety.

- 115. 115 Planning for Retirement The final step in the design process is the disposal of the product when it has reached the end of its useful life. Design for the environment , also called green design, has become an important consideration in design. As a result, the design of a product should include a plan for either its disposal in an environmentally safe way or, better, the recycling of its materials or the remanufacture or reuse of its components.

Editor's Notes

- Rigidly accurate;

- An abstraction belonging to or characteristic of an entity, A construct whereby objects or individuals can be distinguished

- Behavioral psychology provides an understanding of the influence of risk taking in individuals and teams. Making a decision is a stressful situation for most people because there is no way to be certain about the information about the past or the predictions of the future. This psychological stress arises from at least two sources.3 First, decision makers are concerned about the material and social losses that will result from either course of action that is chosen. Second, they recognize that their reputations and self-esteem as competent decision makers are at stake. Frantically: In an uncontrolled manner Painstakingly: In a fastidious and painstaking manner (great effort) Procrastinating: Postpone doing what one should be doing Vigilance: continuous attention

- Design knowledge base ● Are there aspects of the part design where the designer or design team is working without adequate knowledge? Is the team’s knowledge of forces, flows, temperatures, environment, and materials adequate? ● Have you considered every possible unfortunate, unlikely, or unlucky event that could jeopardize the performance of the design? Have you used a formal method like FMEA to check for this?

- In configuration design the emphasis was on starting with the product architecture and then working out the best form for each component. A design variable is an attribute of a part whose value is under the control of the designer. This typically is a dimension or a tolerance, but it may be a material, heat treatment, or surface finish applied to the part. Here main point is to achieve robustness