Digital Thread & Digital Twin

- 2. 425,000 employees globally 6000+ employees in Central and Eastern Europe 350+ employees at 2 locations in Hungary with a plan to duplicate it within two years Fully connected and leveraging our international network $2.5 billion worth of acquisitions globally to enhance our capabilities 2014 The firm expands its digital capabilities within industrial solutions. Accenture IndustrialAutomation Center of Excellence in Hungary • Innovation and digital product engineering • Manufacturing and digital operations • Connected Business (IIoT, Security) Our top clients have been clients for at least 10 years Earned the Business Superbrand title in Hungary, 2014 25 YEARS in Hungary 2016 The AccentureTechnology DeliveryCenter in Budapest opened Part of the Accenture Global Delivery Network with 50+ centers around the world 40+ industries served custom systems leading technology platforms emerging technologies Innovative solutions based on digital technologies including social, mobile, analytics and cloud Local specialties: SAP, Java, Testing, SalesForce, .NET, Data Visualization + providing all technologies from other Accenture Global Delivery Network Delivering full portfolio of Accenture capabilities in management consulting, technology and outsourcing services ACCENTURE IN HUNGARY

- 3. Two main effects: 1. Evolution of products – the needs of end users change 2. Digital transformation – (I4.0, IIoT, IoT, Connected systems, Smart factory, etc.) EFFECTS IN THE INDUSTRY

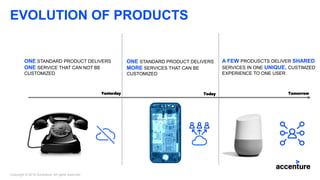

- 4. ONE STANDARD PRODUCT DELIVERS MORE SERVICES THAT CAN BE CUSTOMIZED ONE STANDARD PRODUCT DELIVERS ONE SERVICE THAT CAN NOT BE CUSTOMIZED Copyright © 2018 Accenture. All rights reserved. Yesterday TomorrowToday A FEW PRODUSCTS DELIVER SHARED SERVICES IN ONE UNIQUE, CUSTIMZED EXPERIENCE TO ONE USER EVOLUTION OF PRODUCTS

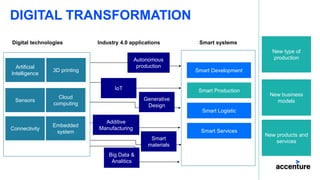

- 5. Digital technologies Artificial Intelligence 3D printing Sensors Cloud computing Connectivity Embedded system Industry 4.0 applications Autonomous production IoT Generative Design Additive Manufacturing Smart materials Big Data & Analitics Smart Development Smart Production Smart Logistic Smart Services New type of production New business models Smart systems New products and services DIGITAL TRANSFORMATION

- 6. DIGITAL TWIN All information about the product on whole product lifecycle DIGITAL TWIN

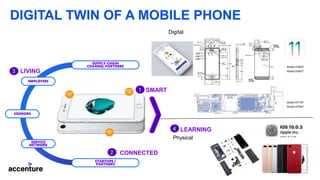

- 7. DIGITAL TWIN OF A MOBILE PHONE Physical Digital SUPPLY-CHAIN CHANNEL PARTNERS EMPLOYEES VENDORS SERVICE NETWORK STARTUPS / PARTNERS CONNECTED SMART LIVING LEARNING 3 1 2 4

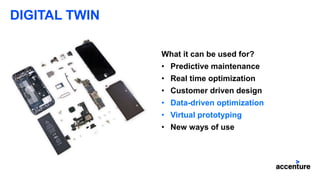

- 8. DIGITAL TWIN What it can be used for? • Predictive maintenance • Real time optimization • Customer driven design • Data-driven optimization • Virtual prototyping • New ways of use

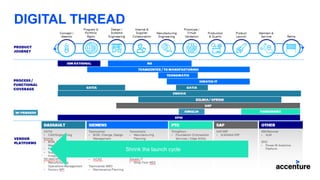

- 9. Shrink the launch cycle DIGITAL THREAD

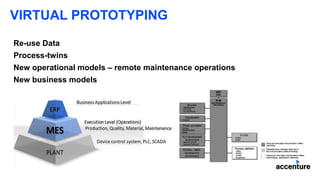

- 10. Re-use Data Process-twins New operational models – remote maintenance operations New business models VIRTUAL PROTOTYPING

- 11. Extend use of digital far beyond engineering: • Manufacturing • Maintenance • Customer service • Create competitive differentiation Program & Portfolio Mgmt Design / NPI Prototype / Virtual Validation Supplier / Channel Collaboration Manufacturing Engineering Production / Realization & Quality Product Launch Maintain & Service Retire Concept / Ideation Copyright © 2018 Accenture. All rights reserved. DIGITAL TWIN & THREAD

- 12. Copyright 2017 Accenture. All rights reserved. 12 THANK YOU FOR YOUR ATTENTION

Editor's Notes

- Az egész életciklus során felmerülő összes információ a twin tárgyával kapcsolatban.

- Vegyünk egy kézenfekvő tárgyat, egy mobiltelefont. Tegyük fel hogy rendelkezésünkre áll róla minden információ amit hasznosítani tudhat egy mérnök. Nem csak adat áll rendelkezésre, hanem van egy modellünk arról digitálisan, hogy milyen összefüggések által épül fel és hogy működik ez a telefon. Milyen szoftverek vannak rajta, ki hol mikor és hogyan gyártotta.

- A digital thread azokat az háttér-rendszereket jelenti, amik kapcsolódnak a digital twinhez. Gyakorlatilag ezeken a rendszereken keresztül tápláljuk a twint. Minél fejlettebb ez a thread, annál éretteb digital twinekkel tudunk dolgozni. Ahhoz, hogy a termék működési elvét tudjuk hasznositani, sok automatikus kapcsolatra képes új interfacet kell kiépiteni ezek között a rendszerek között. Ez azt is jelenti, hogy a digital thread tervezése és méretezése előtt jó ha van arról egy pontos képünk hogy pontosan milyen információkat szeretnénk hasznositani, milyen twint szeretnénk felépiteni a rendszerek összekapcsolása által. Azáltal, hogy ezeket a rendszereket összekapcsoljuk, jelentős további előnyökhöz jutunk, mert lehetővé válik a digital twin kialakitása mellett a rendszerek közti információ-átadaási munkafolyamatok automatizálása. Ami azt jelenti hogy nagyon sok korábban manuálisan végzett munkát teljesen automatikussá lehet tenni relativ nagyon kis befektetéssel.