Engineering challenges in algae energy

- 1. Engineering Challenges in Algae Energy Presented by Oilgae Team (www.oilgae.com)

- 2. What am I here for? To talk about Alternative energy Algae energy Engineering challenges in algae energy Engineering Challenges in Algae Energy

- 4. Alternative Energy Alternative energy refers to energy sources which are not based on the burning of fossil fuels or the splitting of atoms. The renewed interest in this field of study comes from the undesirable effects of pollution both from burning fossil fuels and from nuclear waste byproducts.

- 5. Alternative energy Various forms of alternative energy ENERGY SOURCE Renewable Energy Non Renewable Energy Wind Solar Hydro Bio Based Geothermal Ocean Hydrogen Energy from Waste Traditional Alternative Oil Gas Coal Synfuel Nuclear Oil shale Tar sands

- 6. Non renewable alternative energy Nuclear Synfuel Oil shale Tar sands

- 7. Nuclear energy Nuclear energy is the energy that is trapped inside each atom. Presently, nuclear energy provides for approximately 16% of the world's electricity.

- 8. Nuclear energy Pros 1. Little Pollution 2. Reliability 3. Safety Cons 1. Meltdowns 2. Radiation 3. Waste Disposal

- 9. Synfuel A gaseous, liquid, or solid fuel that does not occur naturally. Synthetic fuels can be made from coal, oil shale, or tar sands.

- 10. Synfuel Pros- Produce gasoline, diesel or kerosene directly without the need for additional steps No need for new vehicles or convert engines to use a different fuel No need for new distribution network Less damaging to the environment Cons- Very expensive process It contain only the one-third the energy content of solid coal.

- 11. Oil shale A sedimentary rock containing solid, combustible organic matter in a mineral matrix. The organic matter, often called kerogen, is largely insoluble in petroleum solvents, but decomposes to yield oil when heated.

- 12. Pros Potential to produce a superior liquid-fuel product. less complex process low sulfur content and therefore less air pollution Cons Costs of fuel production from oil shale have not yet been fully evaluated. Disposal of the used shale Technology failures Oil shale

- 13. Renewable alternative energy Wind Solar Hydro Geothermal Hydrogen Bio based

- 14. Solar energy EPIA predicts solar will contribute 26% of total global energy needs by 2040.

- 15. Solar energy PROS- Saves money Environmentally friendly Independent/ semi-independent Low/ no maintenance CONS- Potentially large areas required Not many places in the world have enough constant and intense sunshine Initial cost

- 16. Wind energy “ The global wind market to grow by over 155% from its current size to reach 240 GW of total installed capacity by the year 2012” -Global Wind Energy Council The electricity produced by wind energy will reach over 500TWh in 2012 from 200TWh in 2007 accounting for around 3% of global electricity production

- 17. Wind energy PROS- Clean Efficient Renewable CONS- Wind might not blow when we need it Hard to maintain Too much space

- 18. Hydroenergy Pros – No pollution Most efficient energy sources possible Sustainable power Economical Cons – Change the local environment drastically Many acres of land being flooded Relocation of entire species that habitat the area Hydroenergy - energy that is taken from water and converted to electricity

- 19. Geothermal Energy Geothermal Energy provides approximately 0.4% of the world global power generation, with a stable long term growth rate of 5%.

- 20. Geothermal Energy PROS- 1. Safe 2. Clean 3. Economical 4. Efficient 5. One power plant can produce a lot of steam by drilling more than one well CONS- 1. May cause small after-shock earthquakes 2. Minor damage may take 1000 years to recover.

- 21. Hydrogen Pros Hydrogen is an extremely clean fuel, producing few emissions when combusted directly or in combination with hydrocarbon fuels. When used in a fuel cell, the only byproducts are heat and water. Hydrogen has the highest energy per weight rating (good fuel) Cons hydrogen is separated by a reforming process that uses natural gas and other fossil fuels. The technology to produce, store, and transport hydrogen power at a reasonable cost is not yet in place and likely will not be for some time.

- 22. Alternative energy Current market potential

- 23. Biofuels

- 24. First generation biofuels Feedstock such as soybeans, palm, canola and rapeseed are considered first generation feedstock for biodiesel production, as they were the first crops to be tried for biodiesel production. Most first generation biodiesel feedstock could be used alternatively to make food for humans as well.

- 25. First generation biofuels Pros: Simple and well-known production methods Familiar feedstocks Scalable to production capacities Easily blended with existing petroleum-derived fuels Experience with commercial production and use in several countries Cons: Feedstocks compete directly with crops grown for food Production by-products need markets Low land-use efficiency Modest net reductions in fossil fuel use and greenhouse gas emissions with current processing methods

- 26. Second generation biofuels Non-food bio-feedstocks are considered as feedstock for second generation biodiesel. Either by using standard transesterification method, or by using technologies such as biomass to liquid (BTL), such feedstock could be converted to biodiesel.

- 27. Pros eliminates competition for food and feed more efficient and more environmentally friendly Less farmland is required mixture of crops can be used useful by-products are produced which can be used in other chemical processes or burned for heat and power. Cons same downfall as the first generation fuels but without as great of an eco imprint. Second generation biofuels

- 28. Third generation biofuels Algae are considered to belong to the third generation of biodiesel feedstock.

- 29. Pros superior yields not directly affecting the human food chain grown in places that are not suitable for agriculture enhanced efficiencies or reduction in cost Cons The problem of course is in developing technologies that will enable this kind of bioo fuel to be more cost effective to make . Third generation biofuels

- 30. Algae energy

- 31. The U.S. Department of energy’s Aquatic Species Programme, for example did over a decade of research (between 1978 and 1996), and found that algae were only economically viable as a biofuel at oil prices of more than $60 a barrel. Since 2002, there have been a number of commercial and research efforts in the algae energy field, and the activities have further accelerated starting 2008. While most of the efforts in the first few years focused on biodiesel as the end-product, recently a number of efforts have recently been initiated to explore the viability of using algae as feedstock for other energy products. History of energy from algae

- 32. Why is the field of algae energy interesting? Micro-algae are the fastest growing photosynthesizing organisms. They can complete an entire growing cycle every few days. Under optimum growing conditions micro-algae are reported to produce up to 15,000 gallons of oil/acre/year.

- 33. Why is the field of algae energy interesting? Grown under conditions which are unsuitable for conventional crop production.

- 34. Why is the field of algae energy interesting? Capable of fixing CO2 in the atmosphere, thus facilitating the reduction of increasing atmospheric CO2 levels, which are now considered a global problem. Algae biofuel is non-toxic, contains no sulfur, and is highly biodegradable.

- 35. Energy products from algae Biodiesel Ethanol Hydrogen Methane Biomass – where algae biomass is directly used for combustion Other hydrocarbon fuel variants, such as JP-8 fuel, gasoline, biobutanol etc.

- 36. Biodiesel from algae Cultivation of Microalgae species Harvesting of Microalgae Extraction of Oil from Microalgae Transesterification Biodiesel

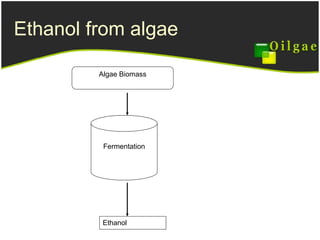

- 37. Ethanol from algae Fermentation Algae Biomass Ethanol

- 38. Hydrogen from algae Biomass Gasification Biogas Fermentation Dark Fermentation Steam Reformation H 2

- 39. Methane from algae Algal Biomass Anaerobic digestion Methane

- 40. Current status of fuel from algae Around 50 companies are working in this industry Around 45 universities are actively exploring the potential of algae Still in research level There is no commercialization yet

- 41. Engineering Challenges in Algae Energy

- 42. Engineering Challenges in Algae Energy Various types of engineering challenges Biological Engineering challenges Chemical Mechanical

- 43. Biological Engineering Challenges in Algae Energy - Strain selection The algal strains to be cultivated would be selected based on productivity, and harvest ability, resistance to contamination, tolerance of high oxygen levels and temperature extremes.

- 44. Biological Engineering Challenges in Algae Energy - Maximize Photosynthetic Efficiency

- 45. Biological Engineering Challenges in Algae Energy - Increase the rate at which the algae grow, in order to harvest quickly

- 46. Biological Engineering Challenges in Algae Energy - Increasing lipid production of algae further

- 47. Biological Engineering Challenges in Algae Energy Devising suitable yeast for ethanol fermentation

- 48. Chemical Transesterication Cost of chemical harvesting Removal of toxic chemicals in waste water for algae cultivation - Nutrients for algae Engineering Challenges in Algae Energy

- 49. Transesterication Engineering Challenges in Algae Energy High FFA in algae oil could create transesterification problems .FFA’s create 3 major problems. - More catalyst will need to be used leading to higher cost - Soap (fatty acid salt) is formed, making washing the finished product more difficult. - Water is formed which will retard the main reaction - The FFA’s are not converted into fuel, reducing the yield So It is essential to treat the High FFA oil prior to transesterifiation.

- 50. Challenges in each and every process: Engineering Challenges in Algae Energy Algae cultivation Open/Raceway pond Photobioreactor Algae Harvesting Drying of algae Oil extraction Fermentation Gasification

- 51. Algae Cultivation – Open pond / Raceway pond

- 52. Growing algae in open ponds can lead to mal-odour in the ponds. This problem is mainly a result of lack of oxygen. Open ponds can get contaminated. Control in aeration Efficient and energy intensive mixing Design and engineering of cost effective open pond culture systems Loss of water due to evaporation Too much sunlight can kill algae. So it is essential to control the amount of sunlight falling on the algae cultivation area Light penetration and problem of shading Engineering Challenges in Algae Energy Algae Cultivation – Open pond/Raceway pond

- 53. Algae Cultivation - Photobioreactor

- 54. Engineering Challenges in Algae Energy Algae Cultivation - Photobioreactor With respect to system design, the technical challenges include: reducing capital and operating costs, maintaining temperature and pH control, Removal of oxygen from the growth system assessing water requirements (source, recycle, chemistries and evaporation issues), determining CO2 availability and delivery methods, Algae cultivation systems need to cost-effectively and evenly distribute light within the algae culture.

- 55. Algae Harvesting

- 56. Engineering Challenges in Algae Energy Harvesting Harvesting algae is much more difficult and energy intensive Cost of harvesting (where centrifuges or flocculants are used, the costs could be significant) Ability to determine the right time to extract oil from feedstock is critical. Current methods to determine these are expensive, time consuming and unreliable Scaling up of harvesting systems

- 57. Drying of Algae

- 58. Engineering Challenges in Algae Energy Drying Methods of drying other than Solar are highly expensive Solar drying cannot be applied always Solar drying is a slow process High energy requirement

- 60. Algae organisms are protected by a tough cell wall. That wall must be cracked - an energy-expensive process - to extract the oil. The challenge is to maximize oil yield by cracking as many of the algae cells as possible with the smallest amount of energy. Engineering Challenges in Algae Energy Oil Extraction -Challenges

- 61. Fermentation of Algal Biomass

- 62. Fermentation Engineering Challenges in Algae Energy Low cost Fermenters Devising Closed loop reactors for recirculation of CO2 produced Automation of fermentation followed by distillation process

- 63. Gasification of Algal biomass

- 64. Engineering Challenges in Algae Energy Gasification Very high capital cost EROEI – not clear

- 65. Conclusion “ Algae energy has excellent potential as a source of alternative energy but there are significant engineering challenges to be overcome”

- 66. Thank you